A kind of metal lead toughened lead oxide ceramics and preparation method thereof

A lead oxide and metal lead technology is applied in the field of lead oxide ceramics toughened by metal lead and its preparation, which can solve the problems of rapid breakage, high brittleness and fragmentation, and can meet the requirements of scouring operation, strong bending strength and strong impact load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of ingredients:

[0028] PbO and Pb with a purity greater than 99% 3 o 4 Mix with Pb in a mass ratio of 8:1:1, add 5wt% deionized water, mix thoroughly, grind evenly, pre-press for 4 minutes under 30MPa pressure to obtain pre-pressed tablets, and then pre-pressed tablets Crush and grind, then add 4wt% deionized water, and grind evenly, so as to remove the transverse cracking phenomenon in the pressing molding process.

[0029] (2) Making compact:

[0030] Pour the processed powder into the mold, carry out pressure maintenance and pressure relief treatment, and press it into a green compact of the desired shape. The pressure holding and pressure relief treatment process is to increase the pressure to 8MPa at a speed of 0.1MPa / s, hold the pressure for 3.5min, and then release the pressure at a speed of 0.1MPa / s.

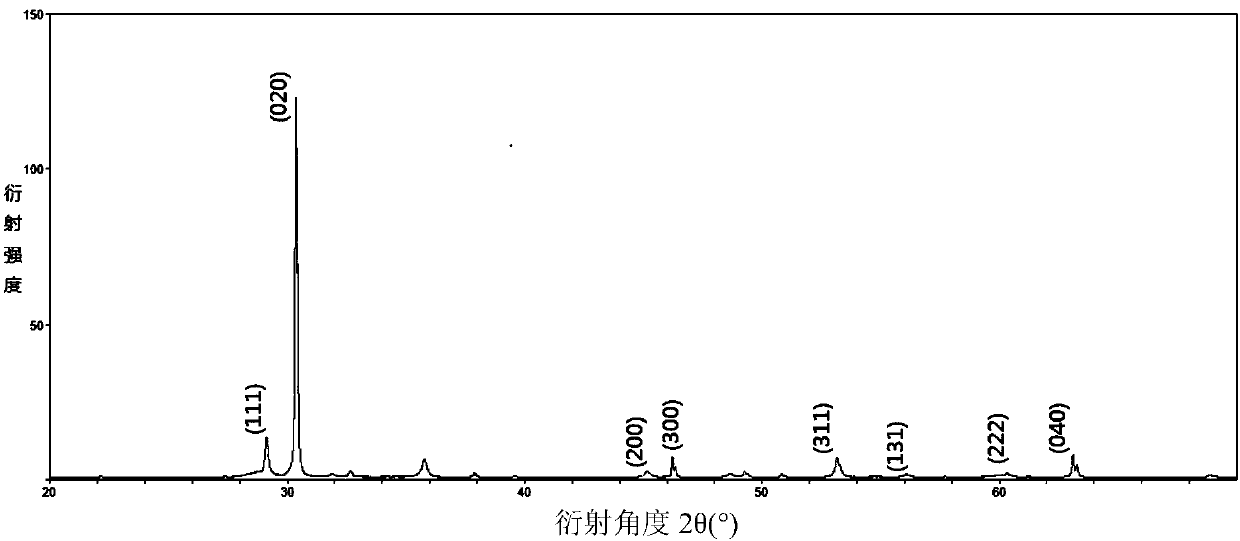

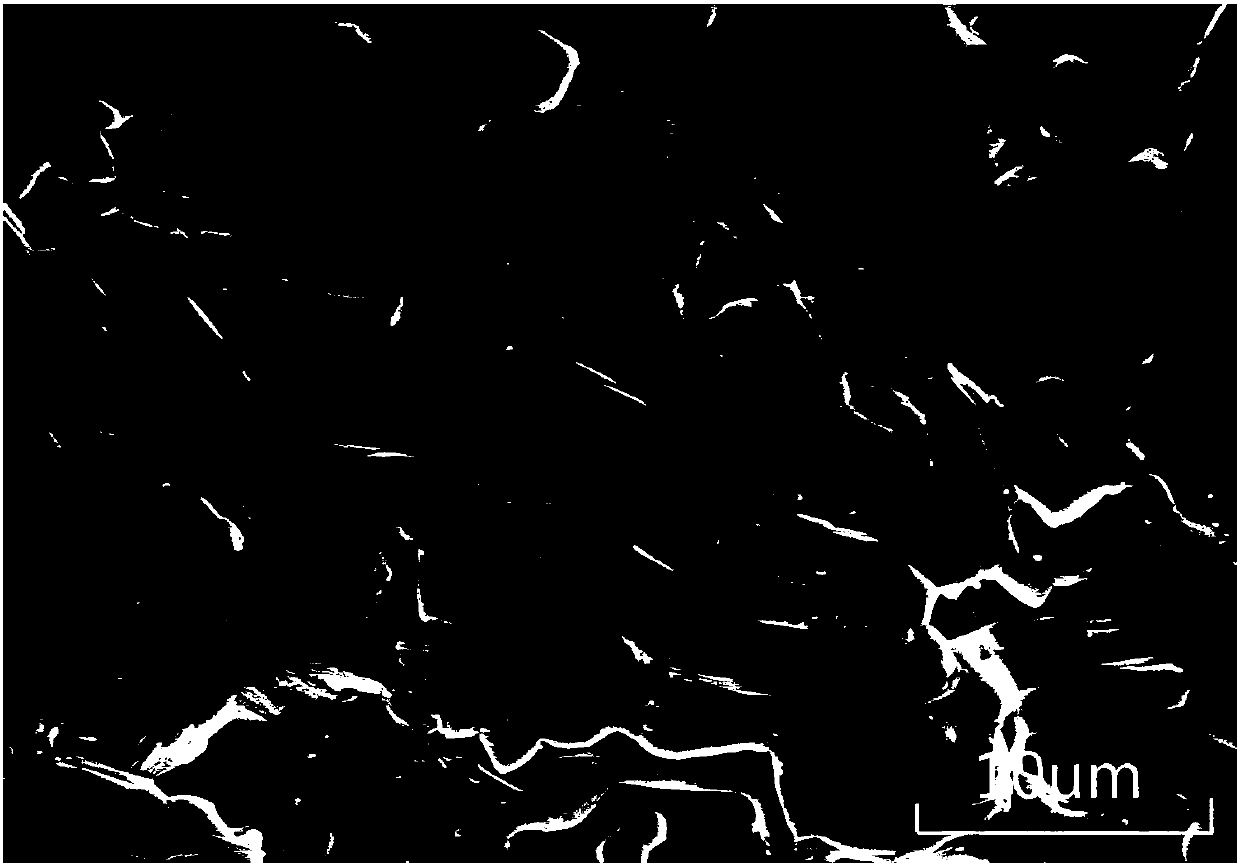

[0031] (3) Microwave sintering treatment:

[0032] The obtained compact is put into a microwave sintering container, and the microwave sint...

Embodiment 2

[0035] (1) Preparation of ingredients:

[0036] Pb and Pb with a purity greater than 99% 3 o 4 Mix according to the mass ratio of 1:1, add 2wt% deionized water, and grind evenly. Pre-compressing under 30MPa pressure for 4min for pre-compression treatment to obtain pre-compression tablets, then crush and grind the pre-compaction tablets, then add 4wt% deionized water, and grind evenly.

[0037] (2) Making compact:

[0038] The powder obtained in the above steps is introduced into the mold, pre-compressed at a pressure of 12MPa for 3 minutes, and then pressure-holding and pressure-releasing are performed, pressurized to a pressure of 8MPa at a speed of less than 0.2MPa / s, and the pressure is maintained for 5min, and then the pressure is less than 0.1MPa / s speed release pressure. Finally, compacts are pressed into the desired shape.

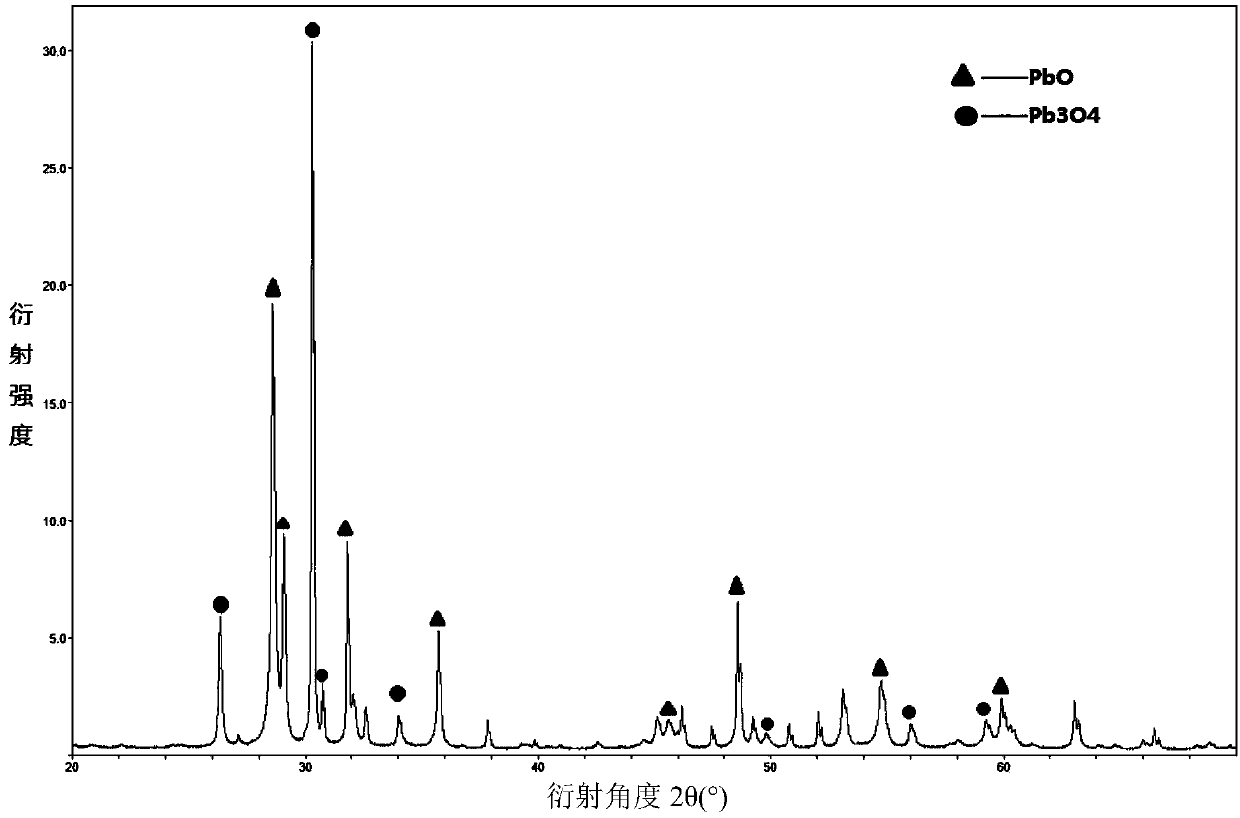

[0039] (3) Conventional sintering treatment:

[0040] The above-mentioned compacts were directly put into a conventional muffle furnace for ...

Embodiment 3

[0043] (1) Preparation of ingredients:

[0044] Mix Pb and PbO with a purity greater than 99% according to the mass ratio of 2:8, add 2wt% deionized water, and grind evenly. Pre-compressing under 30MPa pressure for 4min for pre-compression treatment to obtain pre-compression tablets, then crush and grind the pre-compaction tablets, then add 4wt% deionized water, and grind evenly.

[0045] (2) Making compact:

[0046] The powder obtained in the above steps is introduced into the mold, pre-compressed at a pressure of 15MPa for 5 minutes, and then subjected to pressure-holding and pressure-releasing treatment, pressurized to a pressure of 15MPa at a speed of less than 0.2MPa / s, maintained for 3min, and then pressurized at a speed of less than 0.1MPa / s speed release pressure. Finally, compacts are pressed into the desired shape.

[0047] (3) Conventional sintering treatment:

[0048] The above-mentioned compacts were directly put into a conventional muffle furnace for heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com