Method for manufacturing die for casting

A technology of mold and hot work die steel, applied in vacuum evaporation coating, coating, sputtering coating and other directions, can solve the problem of insufficient bonding force between film and substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

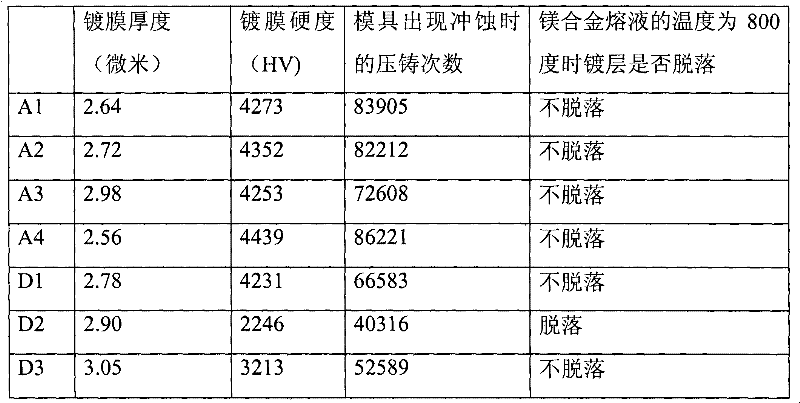

Examples

Embodiment 1

[0031] This embodiment is used to illustrate the mold preparation method provided by the present invention.

[0032] The die-cast die core of the thin-walled parts of the magnesium alloy mobile phone shell was prepared from commercially available hot work die steel model Dievar, and the die core was soaked in a degreasing agent for 3 minutes. The degreasing agent was Ridoline 53S, and the temperature was controlled at 40°C. . Then ultrasonically clean it in pure water for 4 minutes, put it into a vacuum degassing box for degassing and drying, heat to 110°C, vacuumize to 10Pa, and degass for 30 minutes.

[0033] PVD vacuum ion coating equipment is used, and TiB is placed on the top of the vacuum chamber 2 The middle part below the vacuum chamber is a rotatable workbench for placing workpieces. The working gas is argon with a purity of 99.99%, and the reaction gas is nitrogen with a purity of 99.99%. Open the working door of the vacuum chamber of the ion coating machine, plac...

Embodiment 2

[0038]This embodiment is used to illustrate the mold preparation method provided by the present invention.

[0039] The difference from Example 1 is that the degassing drying conditions are 200° C., vacuumed to 5 Pa, and the degassing time is 60 minutes. Obtain mold core A2.

Embodiment 3

[0041] This embodiment is used to illustrate the mold preparation method provided by the present invention.

[0042] The difference from Example 1 is that it does not contain a discharge cleaning step. Obtain mold core A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com