Coking wastewater treatment method

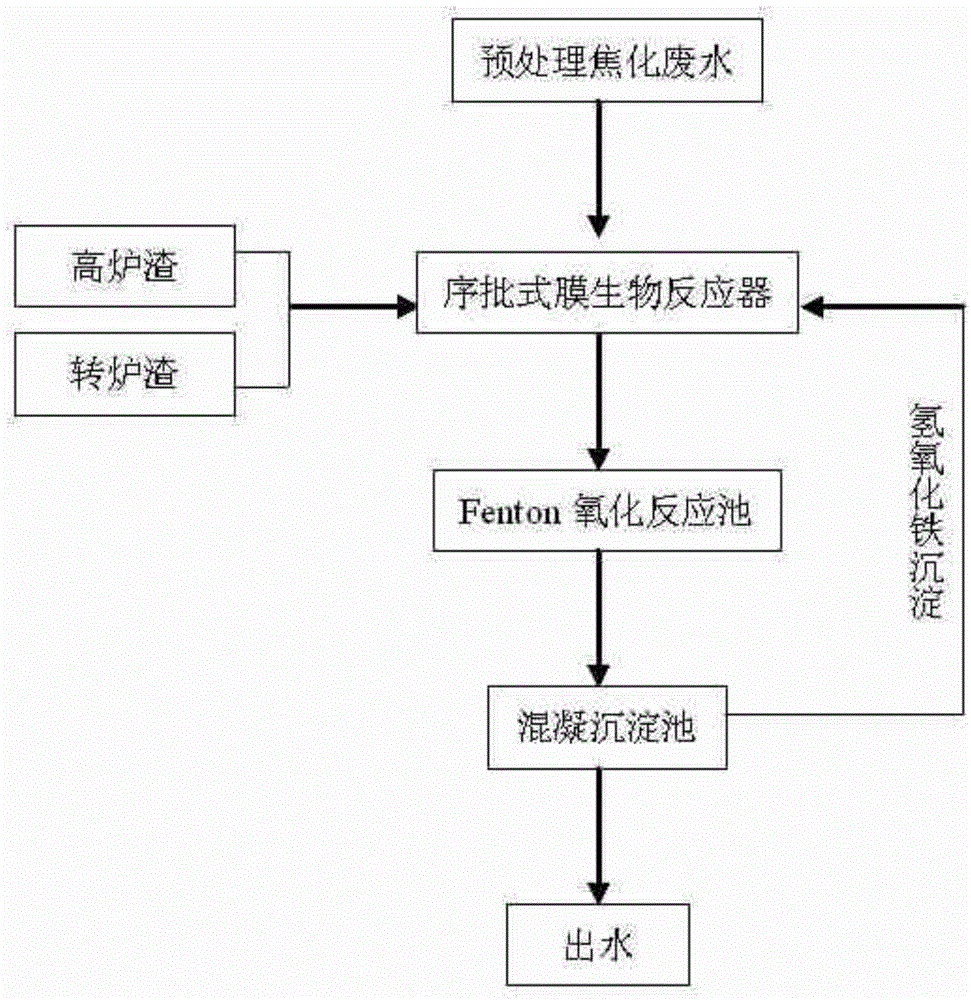

A technology for coking wastewater and treatment methods, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high operating costs, unsatisfactory treatment effects, and complex technological processes , to reduce the cost of wastewater treatment, improve the effect of wastewater treatment, and strengthen the effect of treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add metallurgical slag with a particle size of 1 mm into the reactor, including 60% of blast furnace slag and 40% of converter slag, and the amount added is 1 / 8 of the effective volume of the reactor. Add a certain amount of metallurgical slag to the sequencing batch membrane bioreactor every 10 days, and the added amount is 0.3% of the amount of metallurgical slag in the reactor. According to the sludge concentration in the reactor and the iron ion concentration in the measured sludge, the iron sludge precipitation produced by the Fenton reaction is returned to the sequencing batch membrane bioreactor every 5 days, and the return flow is 6% of the sludge volume in the reactor. . The operation of the sequencing batch membrane bioreactor is anoxic agitation for 7 hours, aerobic aeration for 15 hours, and a residence time of 70 hours per cycle.

Embodiment 2

[0025] Add metallurgical slag with a particle size of 2 mm into the reactor, including 70% of blast furnace slag and 30% of converter slag, and the amount added is 1 / 8 of the effective volume of the reactor. Add a certain amount of metallurgical slag to the sequencing batch membrane bioreactor every 12 days, and the added amount is 0.4% of the amount of metallurgical slag in the reactor. According to the sludge concentration in the reactor and the iron ion concentration in the measured sludge, the iron sludge precipitation produced by the Fenton reaction is returned to the sequencing batch membrane bioreactor every 5 days, and the return flow is 6% of the sludge volume in the reactor. . The operation of the sequence batch membrane bioreactor is anoxic agitation for 7 hours, aerobic aeration for 16 hours and a residence time of 71 hours per cycle.

Embodiment 3

[0027] Add metallurgical slag with a particle size of 4 mm into the reactor, including 75% of blast furnace slag and 25% of converter slag, and the amount added is 1 / 7 of the effective volume of the reactor. Add a certain amount of metallurgical slag to the sequencing batch membrane bioreactor every 15 days, and the added amount is 0.5% of the amount of metallurgical slag in the reactor. According to the sludge concentration in the reactor and the iron ion concentration in the measured sludge, the iron sludge precipitation produced by the Fenton reaction is returned to the sequencing batch membrane bioreactor every 6 days, and the return flow is 7% of the sludge volume in the reactor. . The operation of the sequence batch membrane bioreactor is anoxic stirring for 7.5 hours per cycle, aerobic aeration for 15 hours, and a residence time of 71.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com