Preparation method of graphene oxide hollow fiber and graphene hollow fiber

A technology of graphene and graphene solution, which is applied in the manufacture of hollow filaments, fiber chemical characteristics, wet spinning, etc., can solve the problems of continuous production and post-processing, such as long time for impurity removal, and the inability to realize large batches, etc. And the effect of uniform internal structure, excellent mechanical properties, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Prepare 20mg·mL by the improved Hummers method -1 The graphene oxide solution, concrete steps are as follows:

[0036] Mix 3g of graphite powder, 70ml of concentrated sulfuric acid (98% by mass with water) and 1.5ml of sodium nitrate, and stir evenly in a water bath at 0°C; then add 9g of potassium permanganate, and stir evenly; add after 0.5h 150ml of deionized water, and adjust the temperature of the water bath to 95°C for 15min; then add 500ml of deionized water and 15ml of H 2 o 2 (The mass percentage of water is 30%); the preliminary product is obtained, suction filtered, and the metal ions in the preliminary product are taken out with 250ml hydrochloric acid (36%-38% of the mass percentage of water), and then repeatedly washed with deionized water, Obtain a solid; ultrasonically disperse the solid with deionized water for 1 h to obtain a graphene oxide dispersion 1, then put the dispersion 1 into a centrifuge to remove the coagulated matter to obtain a dispe...

Embodiment 2

[0044] The 25 mg·mL prepared in step (1) of Example 1 -1 The graphene oxide solution was used as the outer layer solution, and the remaining steps were the same as step (2) of Example 1 to obtain a hydrated graphene oxide hollow fiber, which was dried naturally at 25° C. to obtain a graphene oxide hollow fiber.

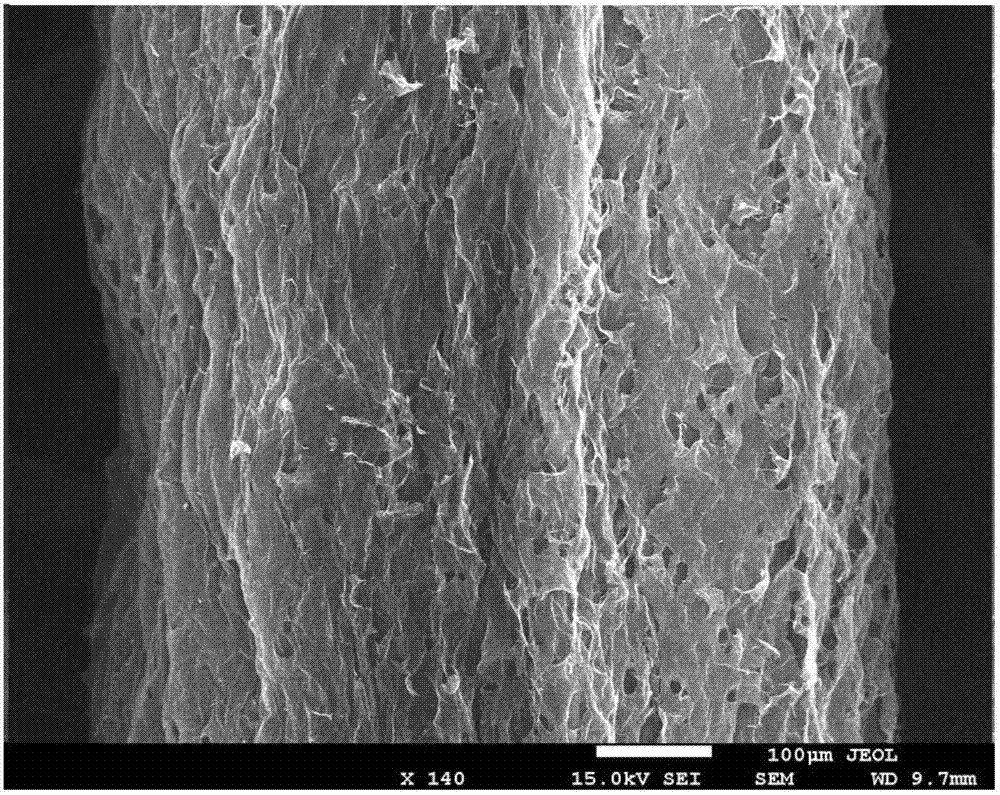

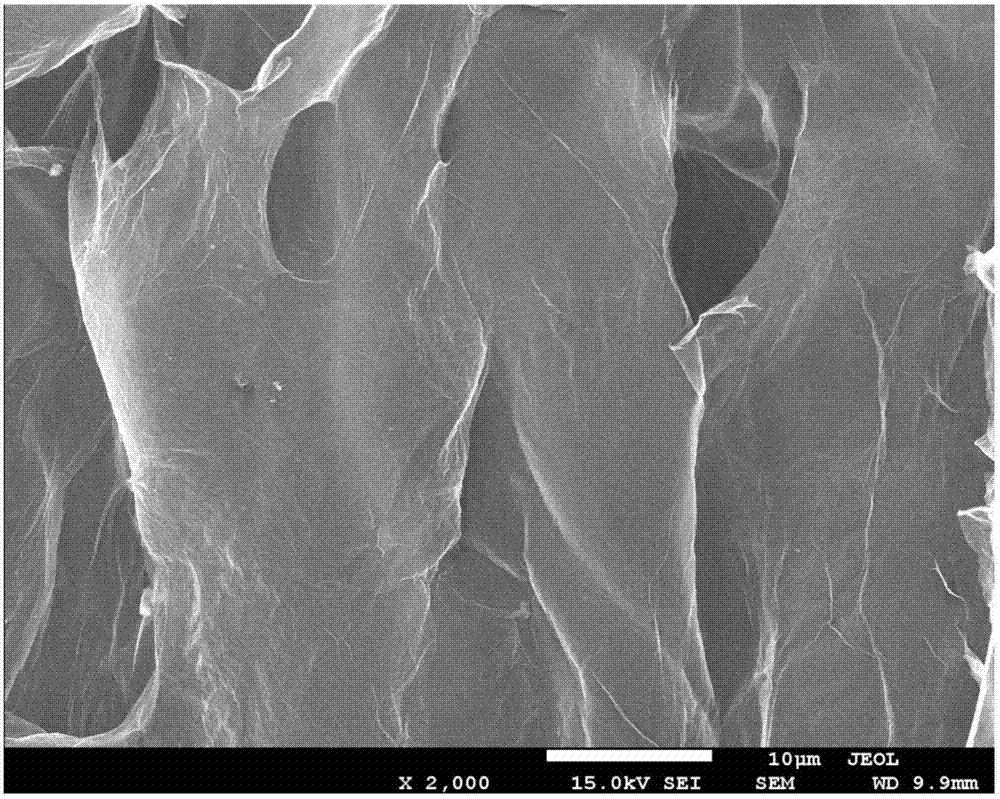

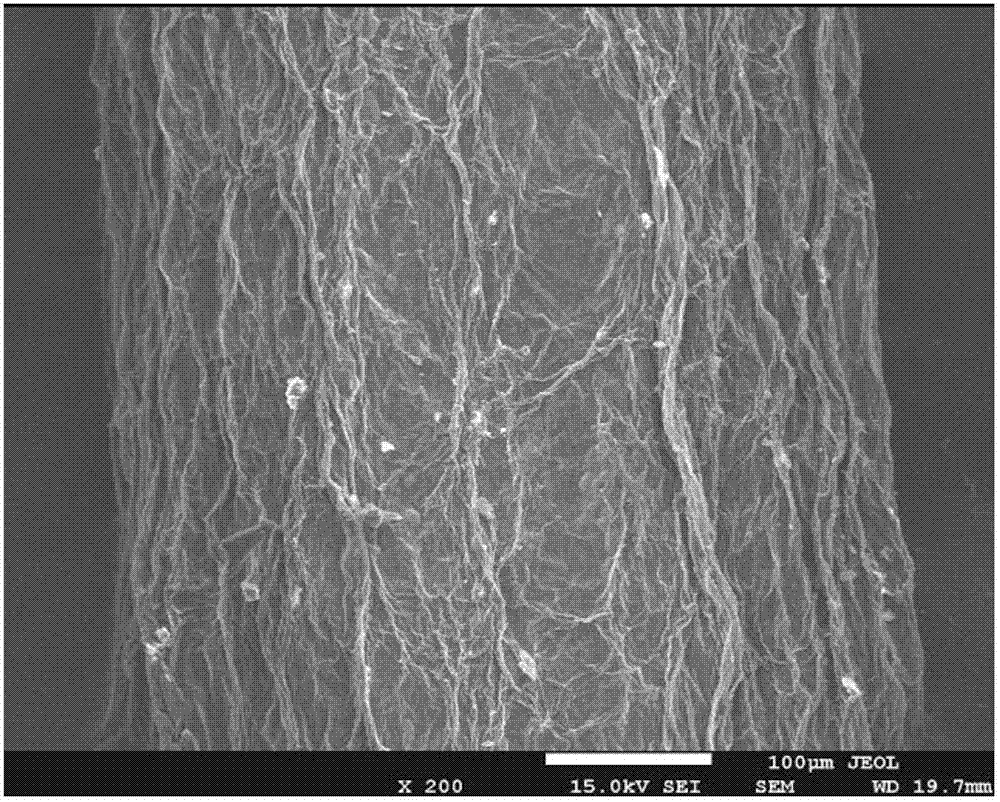

[0045] Observation with a scanning electron microscope shows that the diameter of the hydrated graphene oxide hollow fiber is 700 μm; the hydrated graphene oxide hollow fiber presents a porous structure after freeze-drying; the surface structure of the graphene oxide hollow fiber is flat and the diameter is 470 μm.

[0046] Visual observation shows that the diameter of the graphene oxide hollow fiber shrinks to three-fifths of the diameter of the graphene oxide hollow fiber containing water.

[0047] Graphene oxide hollow fibers have excellent mechanical properties, good flexibility, and can be bent.

[0048] By using shimadzu AGS-X tensile tester to perform tensile ...

Embodiment 3

[0050] The graphene oxide hollow fiber prepared in Example 1 was placed in a tube furnace, and the graphene oxide hollow fiber was heat-treated in air at 400° C. for 1 h to obtain a graphene hollow fiber. The graphene hollow fiber was tensile tested using a shimadzu AGS-X tensile instrument, and its breaking strength was 173 MPa.

[0051] The graphene oxide hollow fiber prepared in Example 1 was put into hydroiodic acid, and kept at 80° C. for 8 hours to obtain a graphene hollow fiber. Using shimadzu AGS-X tensile instrument to carry out tensile test on graphene hollow fiber, it can be known that its breaking strength is 221MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com