Low-pressure and low-humidity gas diffusion layer for fuel cells, fuel cell and preparation method

A gas diffusion layer and fuel cell technology, which is applied in the direction of fuel cells, battery electrodes, electrical components, etc., can solve the problems of low strength, high volume resistance, and easy fracture of the gas diffusion layer, achieve excellent gas diffusion performance, and improve tensile strength. Strength, the effect of increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

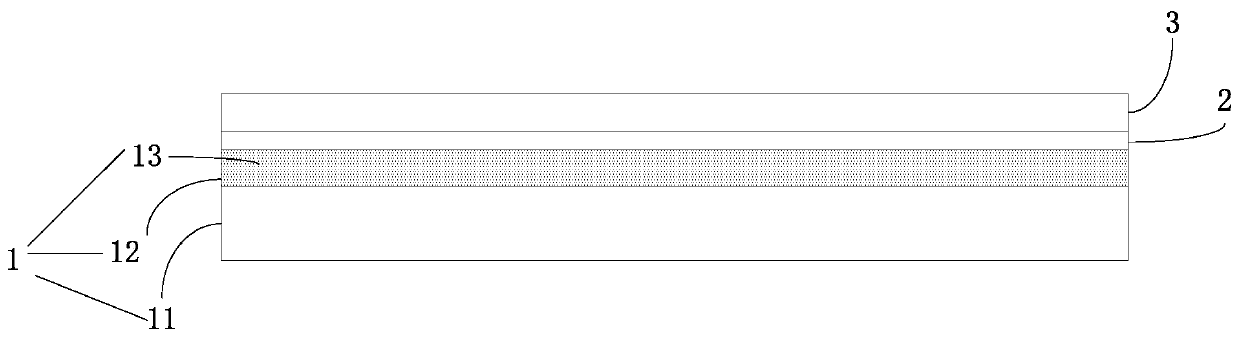

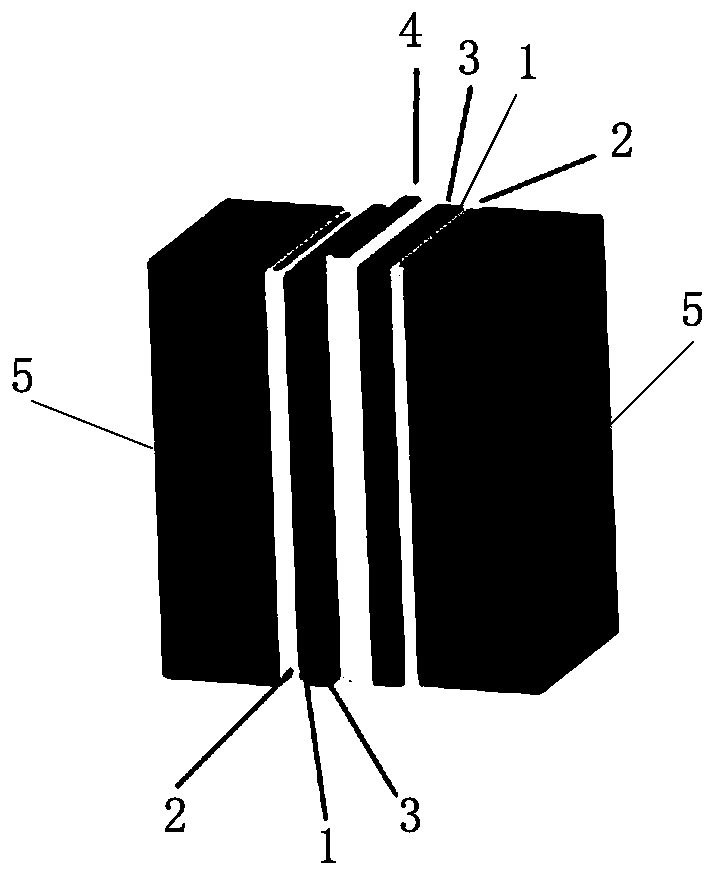

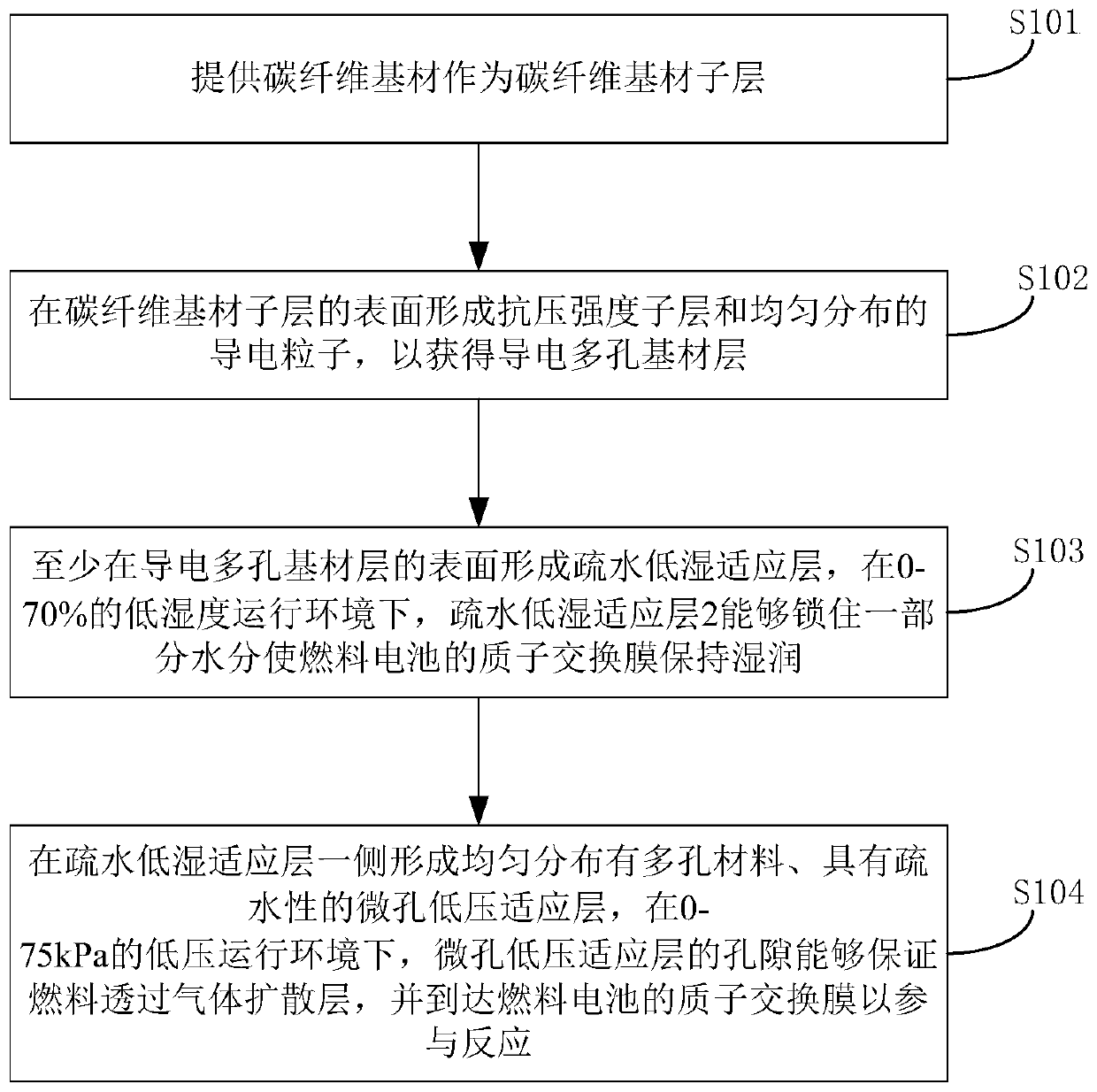

[0061] see in conjunction figure 1 and image 3 , image 3 It is a schematic flow chart of an embodiment of the method for preparing a gas diffusion layer for a low-pressure and low-humidity fuel cell in the present invention. The preparation method of this embodiment can prepare the above-mentioned gas diffusion layer. Let me tell you more. The method includes:

[0062] Step S101 : providing a carbon fiber substrate as a carbon fiber substrate sublayer 11 .

[0063] Step S102 : forming a compressive strength sublayer 12 and uniformly distributed conductive particles 13 on the surface of the carbon fiber substrate sublayer 11 to obtain a conductive porous substrate layer 1 .

[0064] Step S103: forming a hydrophobic low-humidity adaptation layer 2 on at least the surface of the conductive porous substrate layer 1, and in a low-humidity operating environment of 0-70%, the hydrophobic and low-humidity adaptation layer 2 can lock a part of water to keep the proton exchange me...

Embodiment 1

[0082] Example 1: Mix 1.3Kg of carbon powder, 1Kg of acrylic resin and 0.1Kg of methyl cellulose evenly and add them into 12Kg of hot water heated to 80-90°C, stir at a speed of 1300rpm for 1 hour, and then Disperse at a speed of 4000 rpm for 3 hours, and then stir in an ice-water bath at a speed of 300 rpm for 1 hour, thereby obtaining a homogeneously dispersed first mixture slurry. Adjust the coating head of the coating machine to evenly coat the first mixture slurry at 20g / m 2 On the carbon fiber paper, the coating thickness is 100-250μm. After the coating is completed, it is dried in a drying oven at 100°C for 5-10 minutes, sintering in a sintering furnace at 300°C for 2-10 minutes, and under the protection of a nitrogen atmosphere at 1400°C. Carry out carbonization in a carbonization furnace for 10-30 minutes to obtain a conductive porous substrate layer; the conductive porous substrate layer is conveyed by a rewinding and unwinding system through an impregnation tank fil...

Embodiment 2

[0085] Example 2: 1.7Kg of graphite powder, 1.5Kg of phenolic resin and 0.3Kg of hydroxyethyl cellulose were mixed evenly and then added to 15Kg of hot water heated to 80-90°C, stirred at a speed of 1300rpm for 1 hour, and then Disperse at a speed of 4000 rpm for 3 hours, and then stir in an ice-water bath at a speed of 300 rpm for 1 hour, thereby obtaining a uniformly dispersed first mixture slurry. Adjust the coating head of the coating machine to evenly coat the first mixture slurry at 20g / m 2 On the carbon fiber paper, the coating thickness is 100-250μm. After the coating is completed, it is dried in a drying oven at 100°C for 5-10 minutes, sintering in a sintering furnace at 300°C for 2-10 minutes, and under the protection of a nitrogen atmosphere at 1400°C. Carry out carbonization in a carbonization furnace for 10-30 minutes to obtain a conductive porous substrate layer; the conductive porous substrate layer is conveyed by a rewinding and unwinding system through an impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com