Water glass curing agent and preparation method and application thereof

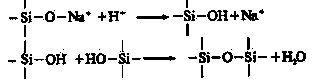

A curing agent, water glass technology, applied in chemical instruments and methods, applications, and other household appliances, etc., can solve the problems of not being able to withstand the impact of hot water and boiling water, limiting the scope of application, poor water resistance, etc., to increase value and improve Water resistance, toughness, and uniform porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation of zinc oxide modified shell powder.

[0038] (1) Weigh 297g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in absolute ethanol;

[0039] (2) Add 38g of PEG-2000 and (2~3)g of glacial acetic acid, mix well, add 594g of shell powder, stir well at 50°C;

[0040] (3) Slowly add 10 mL of a mixed solution of ammonia water and absolute ethanol with a volume ratio of 1:1, keep the reaction for 2 hours, and let stand at room temperature for 12 hours;

[0041] (4) Filtration, washing, drying and calcination.

[0042] Two, prepare water glass curing agent.

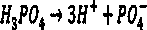

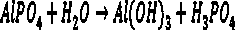

[0043] (1) Phosphoric acid and aluminum hydroxide molar ratio of 1:1 reaction;

[0044] (2) Sintering, crushing and grinding the product;

[0045] (3) Preparation of zinc oxide modified shell powder;

[0046] (4) Mix and sinter all the powders, crush and grind until the particle size reaches the standard;

[0047] 3. Prepare a hydroxyethyl cellulose solution with a mass concentration of 2%.

[0048] Accurately ...

Embodiment 2

[0060] 1. Preparation of water glass curing agent.

[0061] (1) Phosphoric acid and aluminum hydroxide molar ratio of 1:1 reaction;

[0062] (2) Sintering, crushing and grinding the product;

[0063] (3) Preparation of zinc oxide modified shell powder;

[0064] (4) Mix and sinter all the powders, crush and grind until the particle size reaches the standard.

[0065] 2. Preparation of zinc oxide modified shell powder.

[0066] (1) Weigh 300g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in absolute ethanol;

[0067] (2) Add 42g of PEG-2000 and 3g of glacial acetic acid, mix well, add 600g of shell powder, stir well at 55°C;

[0068] (3) Slowly add 15 mL of a mixed solution of ammonia water and absolute ethanol with a volume ratio of 1:1, keep the reaction for 2 hours, and let stand at room temperature for 12 hours;

[0069] (4) Filtration, washing, drying and calcination.

[0070] 3. Preparation of test blocks.

[0071] 1. Accurately weigh sodium silicate (50~100) g, water gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com