Calcium sulfate spherical particle alveolar bone repair material and preparation method and application thereof

A technology of spherical particles and repair materials, applied in medical science, prosthesis, etc., can solve the problems of biological activity and physical and chemical properties decline, coarse particle size of reinforcement, difficult to degrade, etc., achieve complete degradation and degradation cycle, and simple preparation process. , excellent biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation method of calcium sulfate spherical particles alveolar bone repair material, the specific operation is as follows:

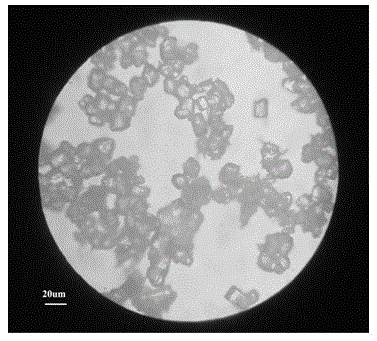

[0035] (1) Preparation of α-type calcium sulfate hemihydrate powder: Weigh 0.45g of ground aluminum sulfate octahydrate powder, put it in a 250ml beaker, weigh 31g calcium sulfate dihydrate powder with weighing paper, and add 0.45 g In the beaker where the aluminum sulfate is located, stir with a glass rod until uniformly mixed. Place the beaker in a closed autoclave with a steam pressure of 0.14 MPa and a temperature of 127°C for 8 hours at a constant temperature and pressure, and then take out the drum placed at 80°C Dry for 12 hours in an air drying oven, grind and encapsulate to obtain α-type calcium sulfate hemihydrate powder, such as figure 1 ;

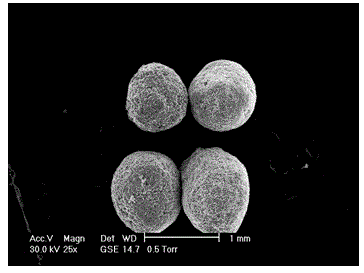

[0036] (2) Prepare spherical calcium sulfate particles with a particle size of 0.5~2.0mm: weigh 2g of α-type calcium sulfate hemihydrate powder, shake it in a vibrating screen, and spray d...

Embodiment 2

[0039] Example 2: Preparation method of calcium sulfate spherical granule alveolar bone repair material, the specific operation is as follows:

[0040] (1) Preparation of α-type calcium sulfate hemihydrate powder: Weigh 0.45g of ground aluminum sulfate octahydrate powder, put it in a 250ml beaker, weigh 31g calcium sulfate dihydrate powder with weighing paper, and add 0.45 g In the beaker where the aluminum sulfate is located, stir with a glass rod until uniformly mixed. Place the above beaker in a closed autoclave with a steam pressure of 0.15 MPa and a temperature of 125°C for 6 hours at a constant temperature and pressure, and then take out the drum placed at 80°C Dry in an air drying oven for 12 hours, grind and encapsulate to obtain α-type calcium sulfate hemihydrate powder;

[0041] (2) Preparation of spherical calcium sulfate particles with a particle size of 0.5~2.0mm: Weigh 2g of α-type calcium sulfate hemihydrate powder, shake it in a vibrating screen, and spray the ball...

Embodiment 3

[0044] Embodiment 3: The preparation method of calcium sulfate spherical particles alveolar bone repair material, the specific operation is as follows:

[0045] (1) Preparation of α-type calcium sulfate hemihydrate powder: weigh 0.08g of ground aluminum sulfate powder, put it in a 250ml beaker, weigh 31g of calcium sulfate dihydrate powder with weighing paper, and put 0.08g of aluminum sulfate in In the beaker, stir with a glass rod until uniformly mixed. Place the beaker in a closed high-pressure reactor with a steam pressure of 0.14MPa and a temperature of 126°C for 4 hours at a constant temperature and pressure, and then take it out and place it in a blast drying oven at 80°C. Dry for 12 hours, grind and encapsulate to obtain α-type calcium sulfate hemihydrate powder;

[0046] (2) Preparation of spherical calcium sulfate particles with a particle size of 0.5~2.0mm: Weigh 2g of α-type calcium sulfate hemihydrate powder, shake it in a vibrating screen, and spray the balls with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com