Patents

Literature

141 results about "Hemihydrate Calcium Sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium Sulfate Hemihydrate is a moderately water and acid soluble Calcium source for uses compatible with sulfates. Sulfate compounds are salts or esters of sulfuric acid formed by replacing one or both of the hydrogen atoms with a metal.

Calcium sulphate-based composition and methods of making same

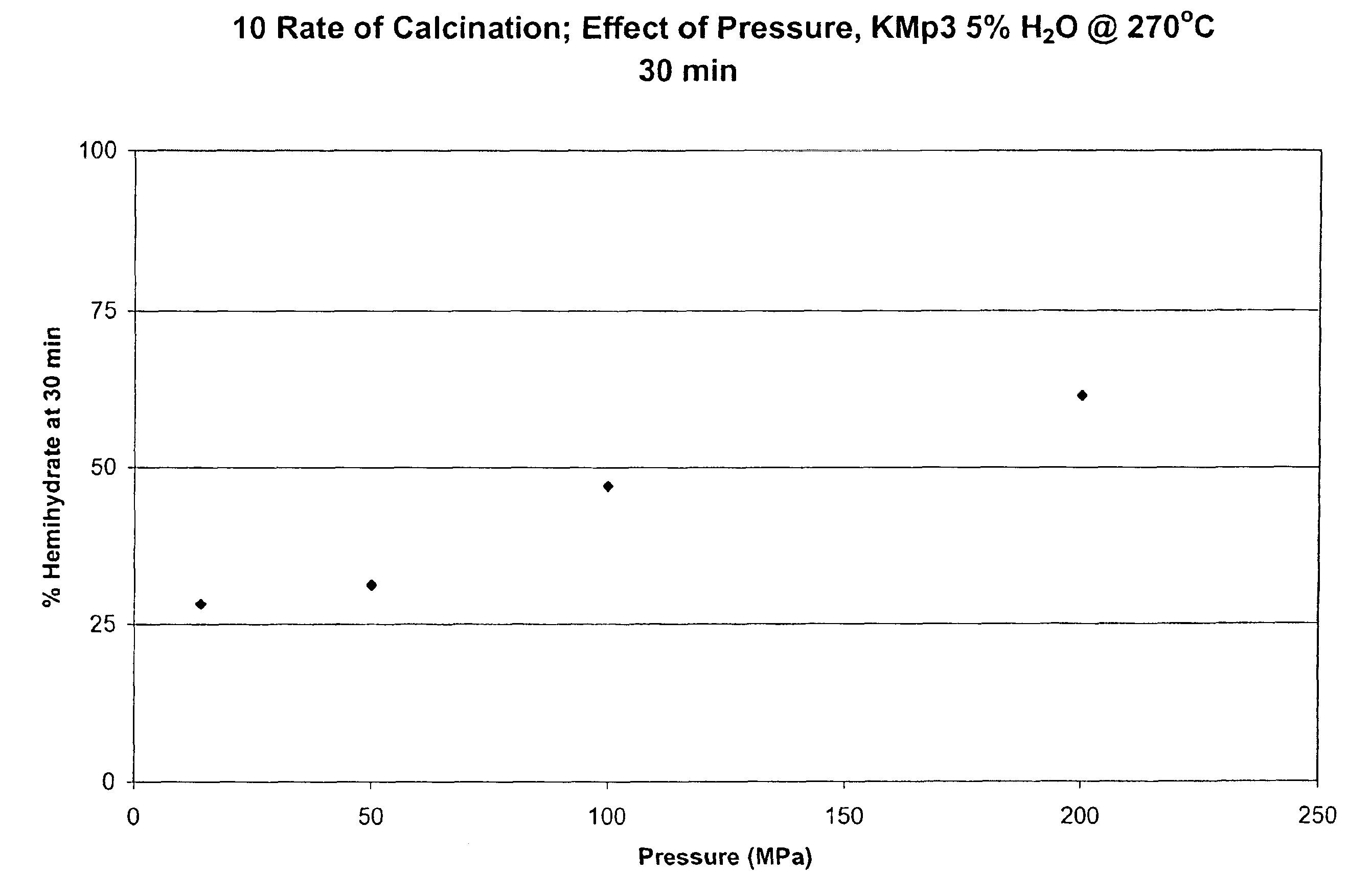

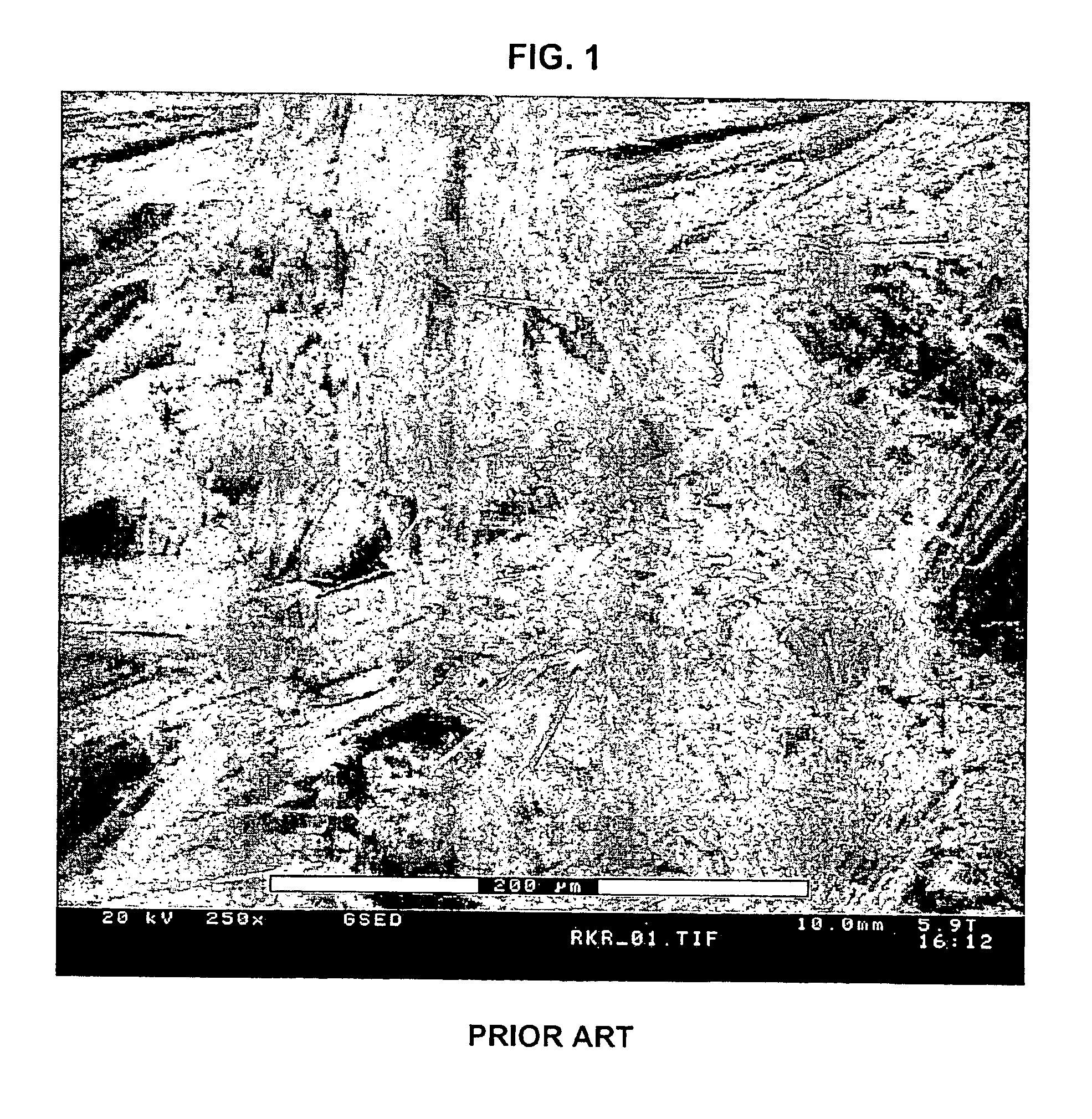

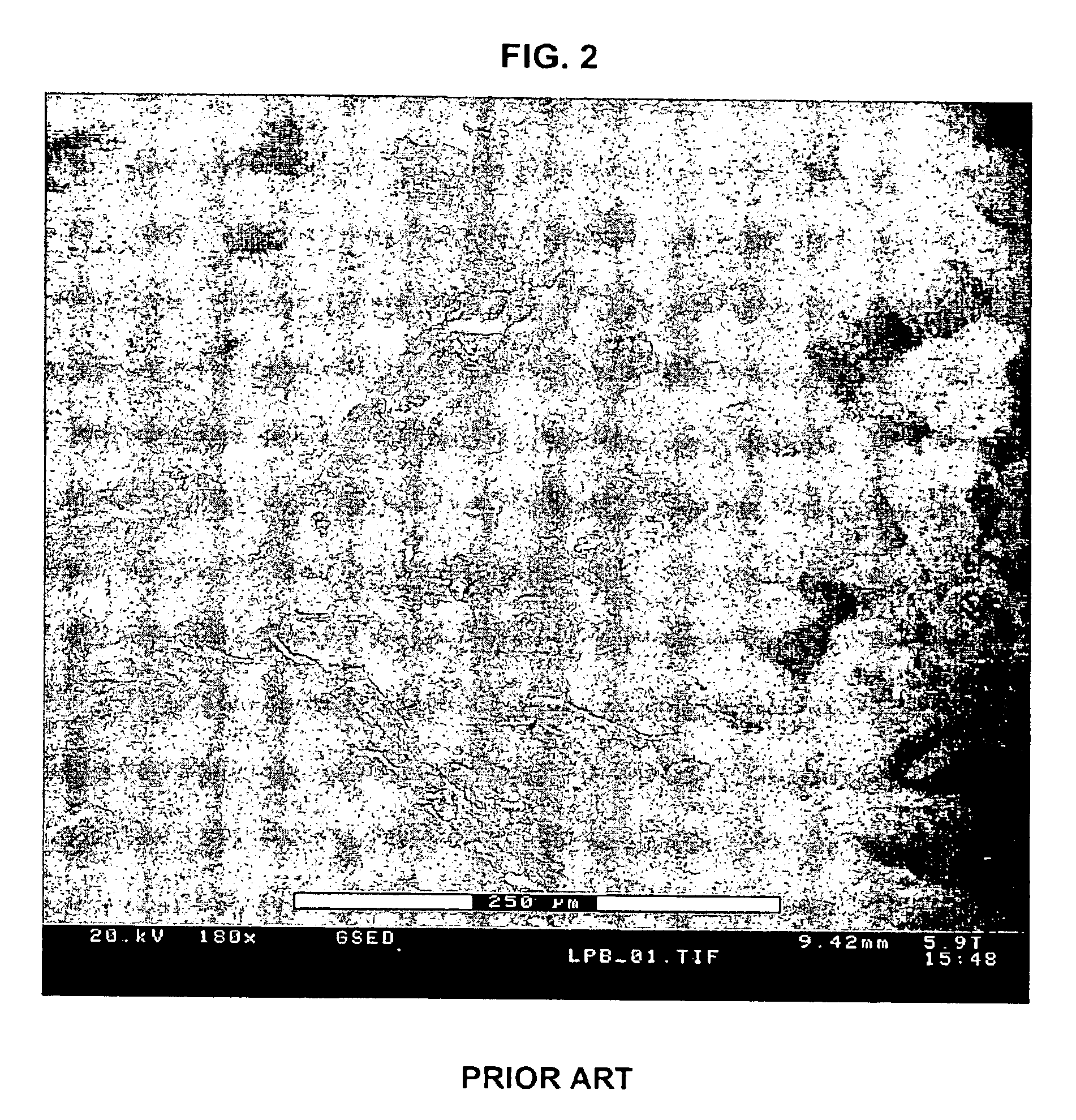

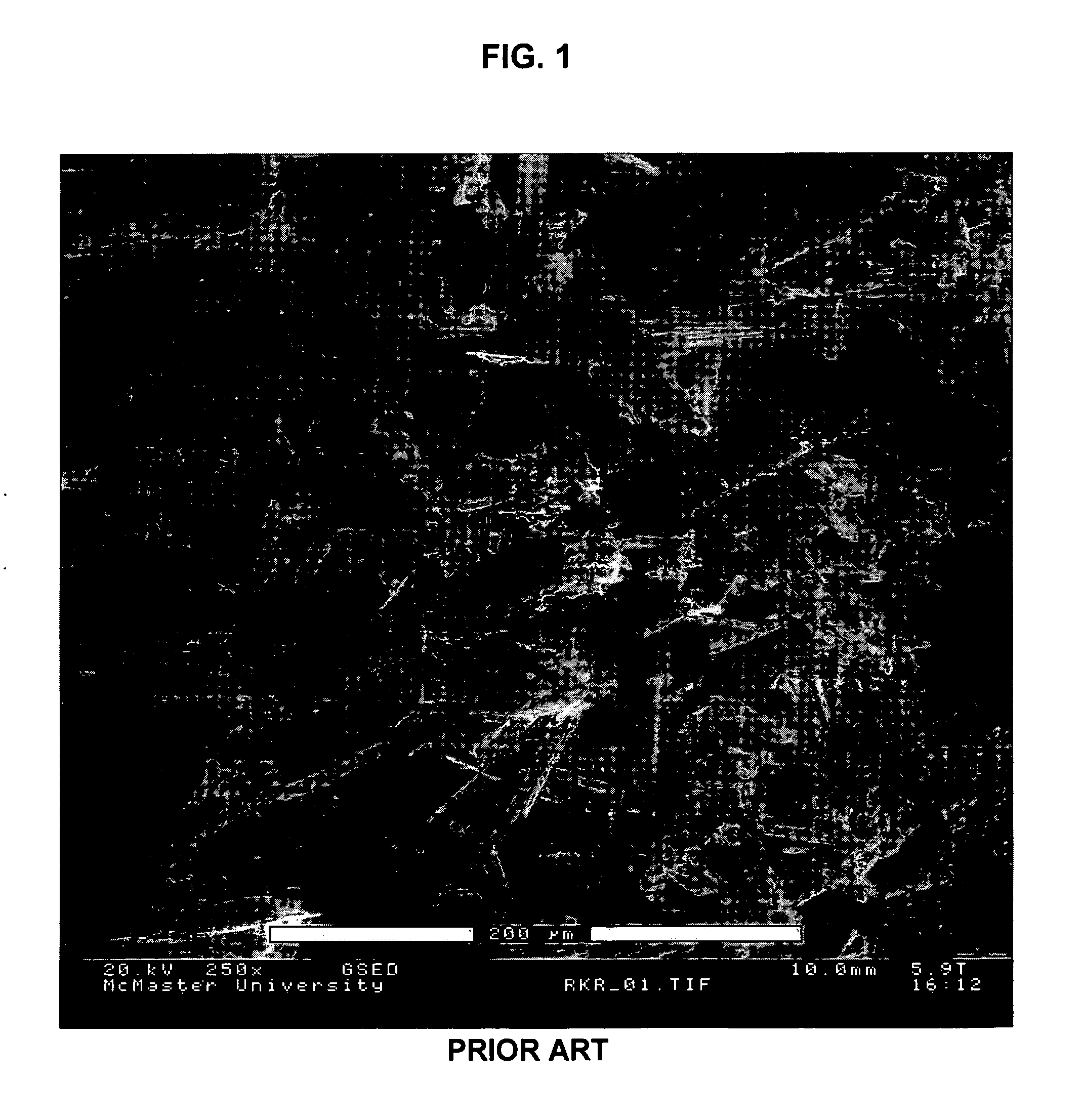

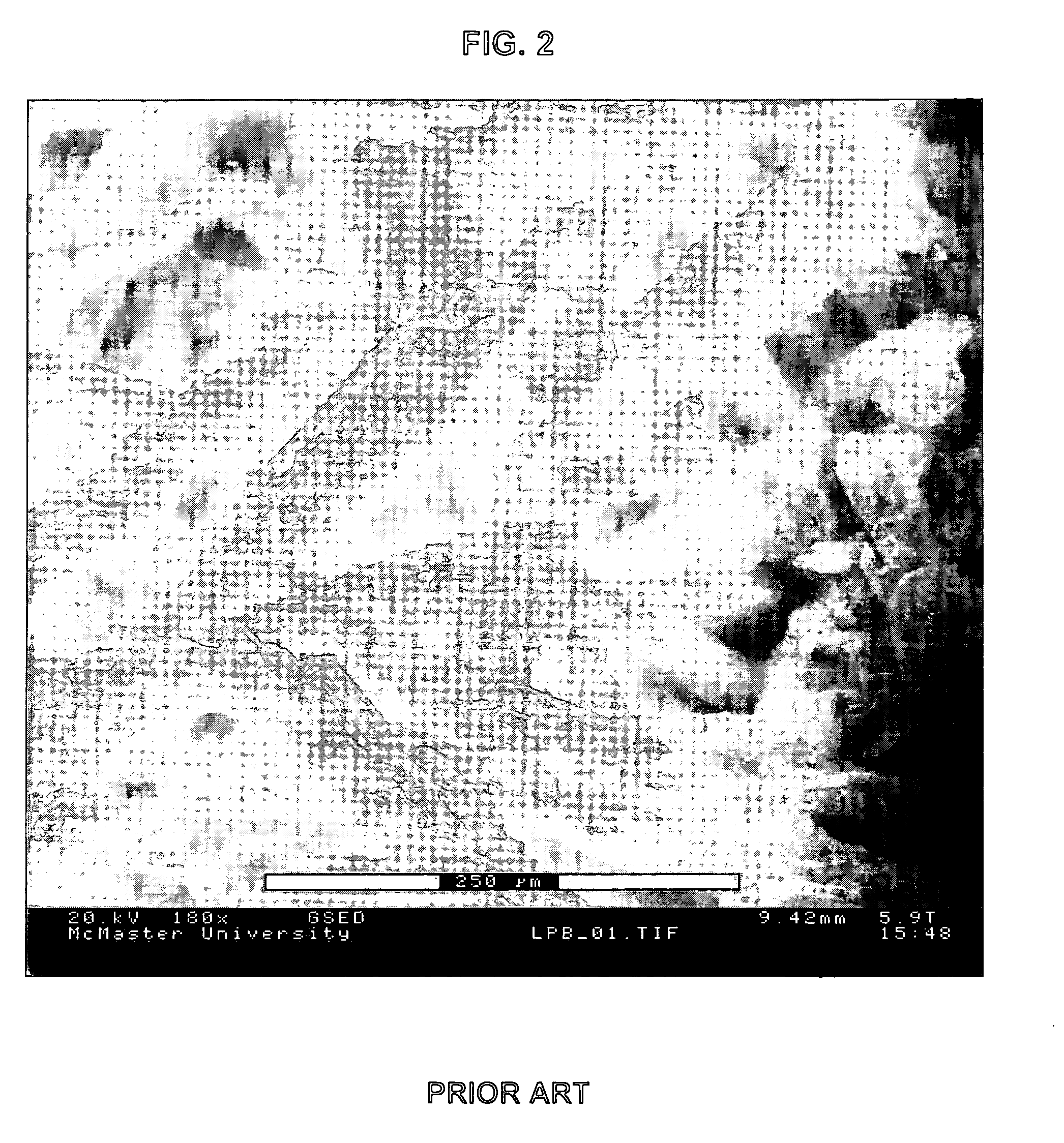

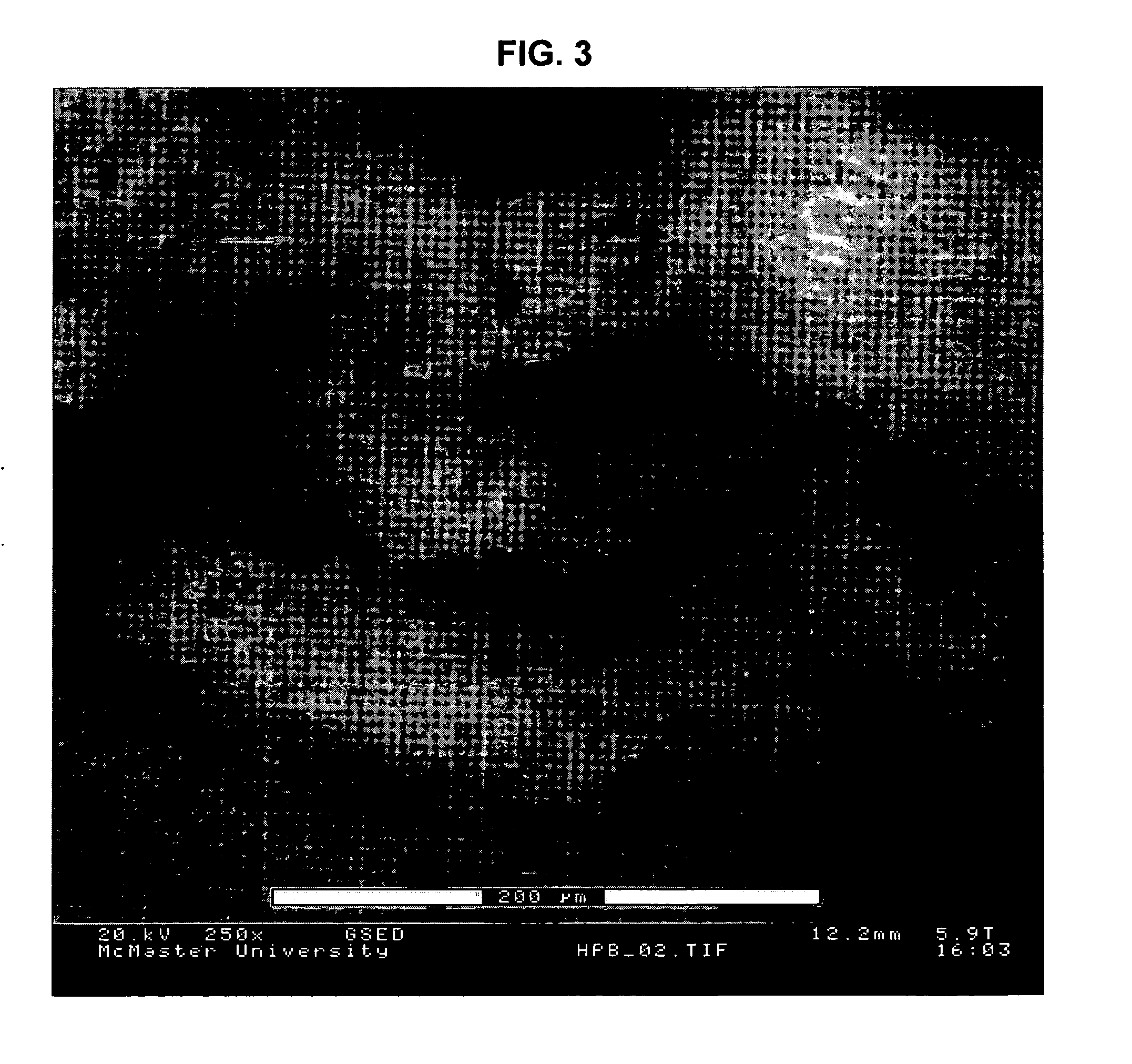

InactiveUS6964704B2Good crystal shapeSolid waste managementCalcium/strontium/barium sulfatesHigh pressureBriquette

Owner:G B TECH LLC

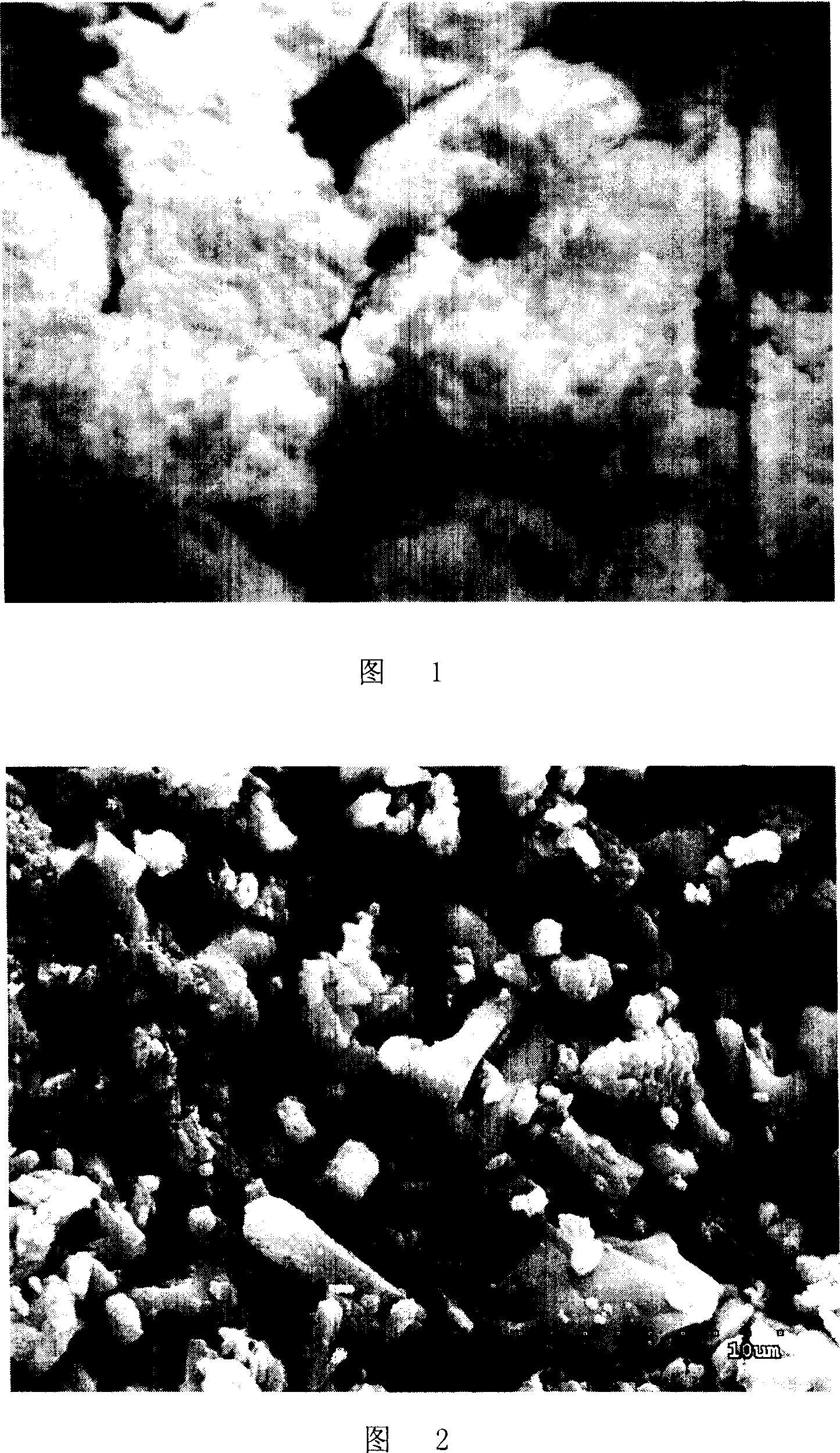

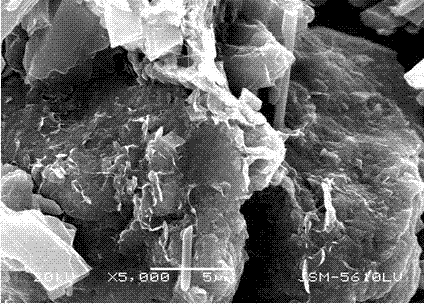

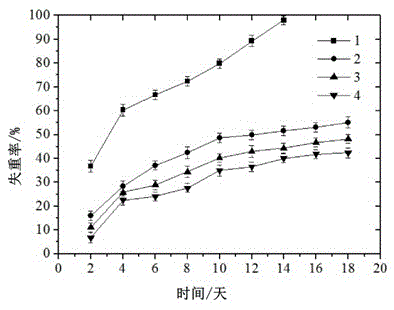

New-type of inorganic bone grafting material and its prepn and use

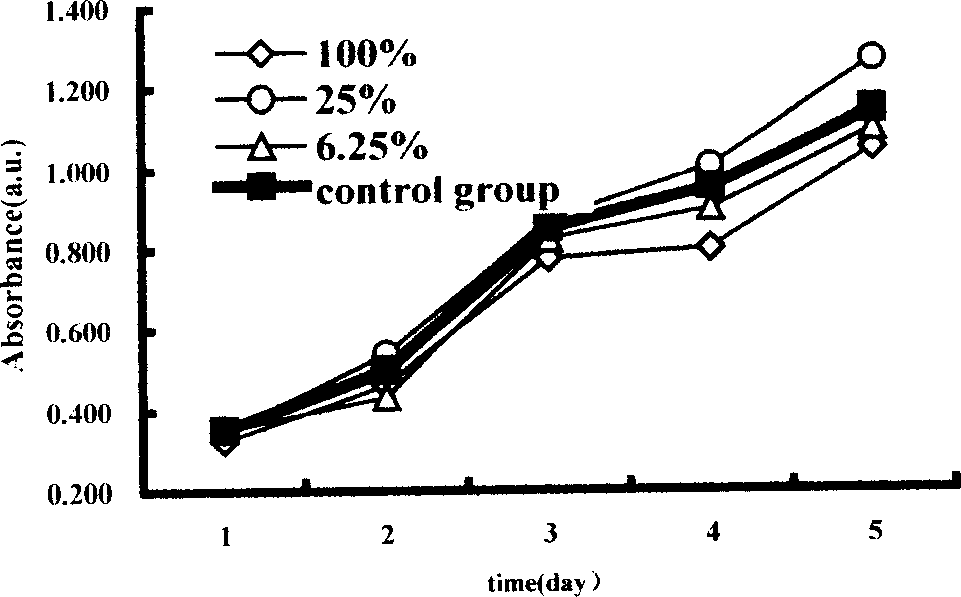

InactiveCN101020085AGood biocompatibilityPromote degradationProsthesisSulfateBiocompatibility Testing

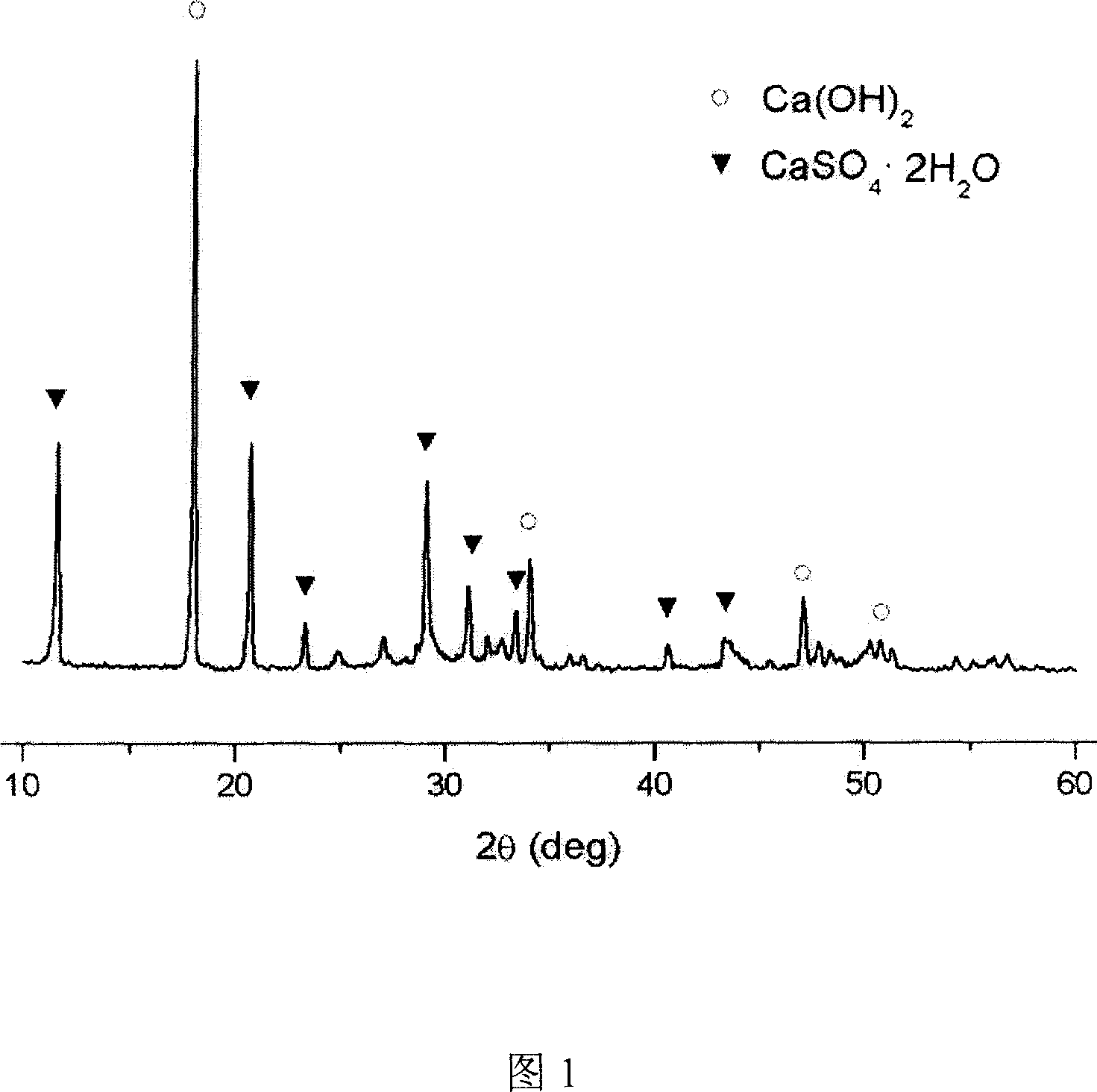

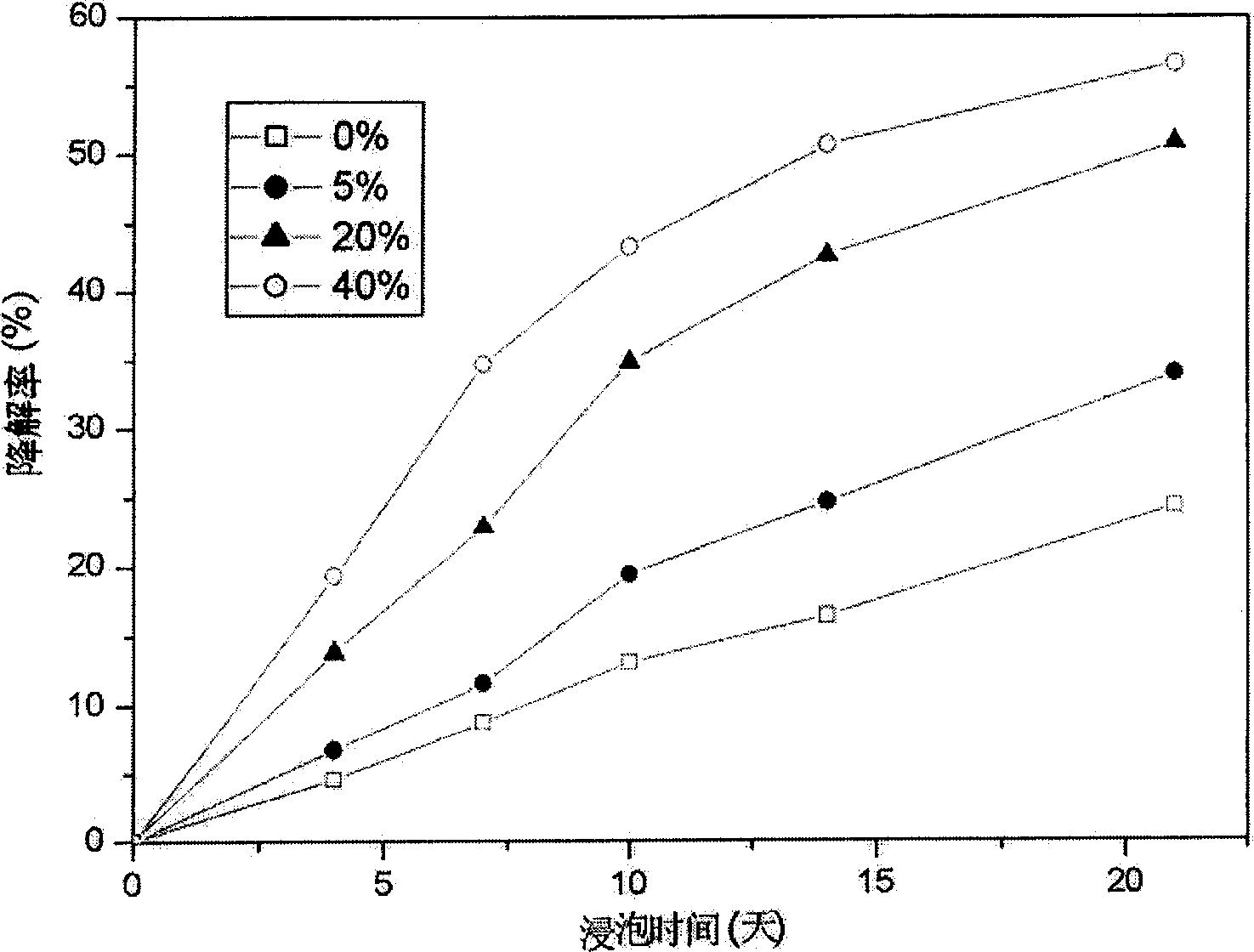

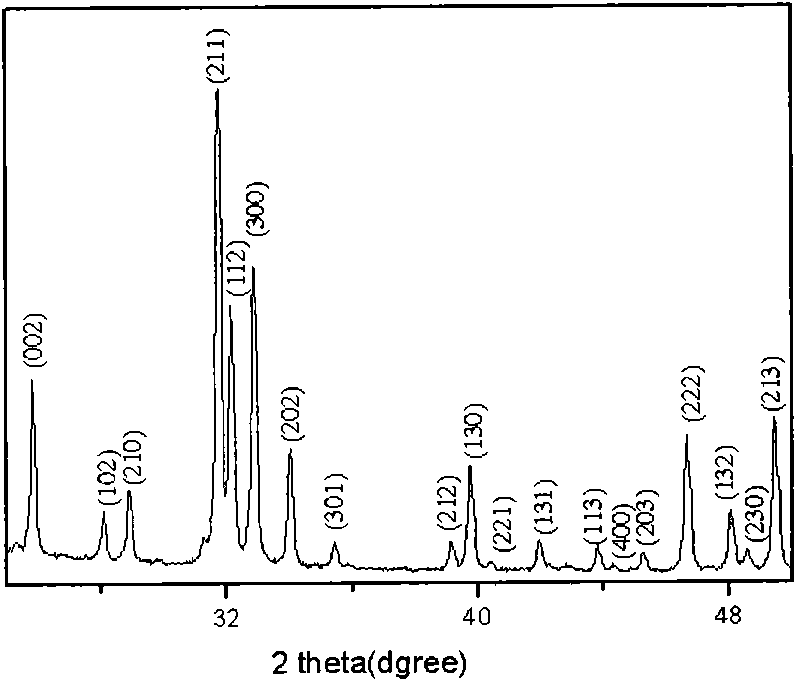

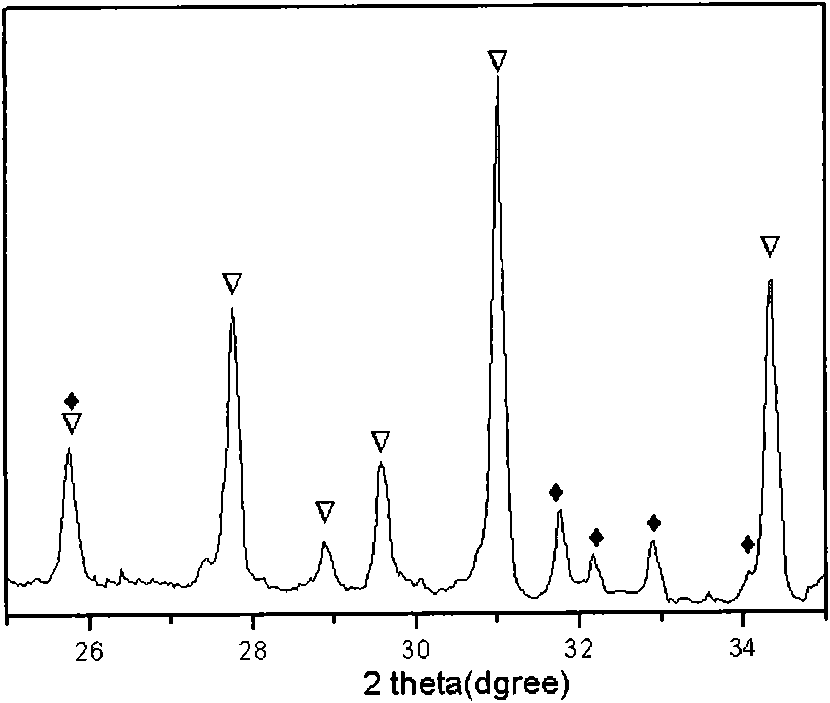

The present invention is one kind of new inorganic bone grafting material and belongs to the field of medical material. The inorganic bone grafting material consists of beta-tricalcium phosphate grain in 20-80 wt% and alpha-calcium sulfate semihydrate powder in 20-80 wt%, and the alpha-calcium sulfate semihydrate powder form layered structure in the surface and / or pores of beta-tricalcium phosphate grain. Both beta-tricalcium phosphate and alpha-calcium sulfate semihydrate have excellent biocompatibility and excellent in vivo degrading performance, and the composite artificial bone grain may be used in repairing bone defect of different shapes. The composite artificial bone grain has wide material source, convenient use, excellent performance, simple preparation process, low cost and other advantages.

Owner:GENERAL HOSPITAL OF PLA

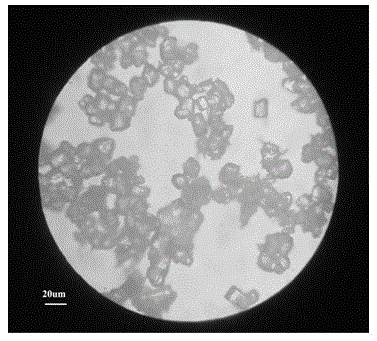

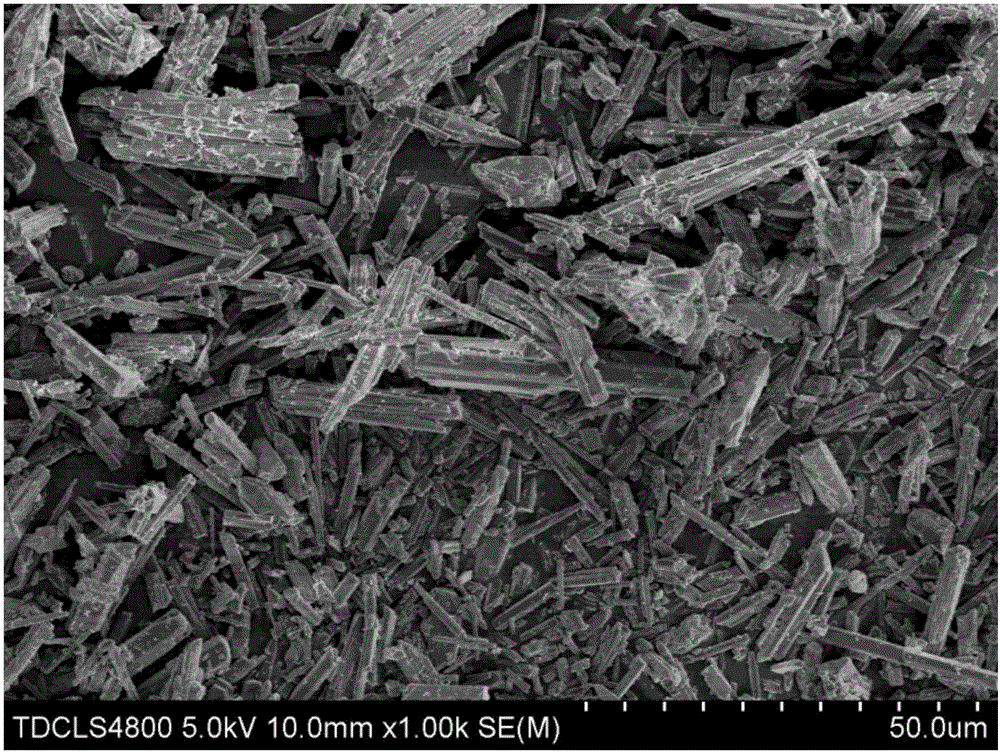

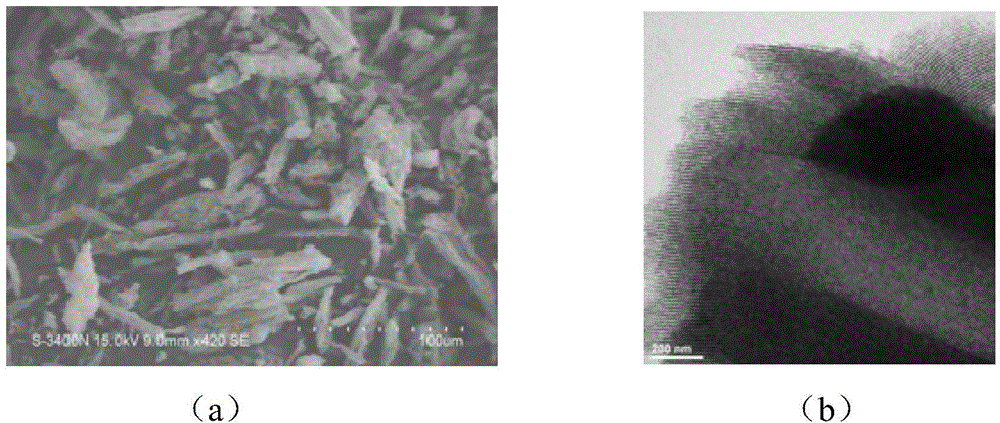

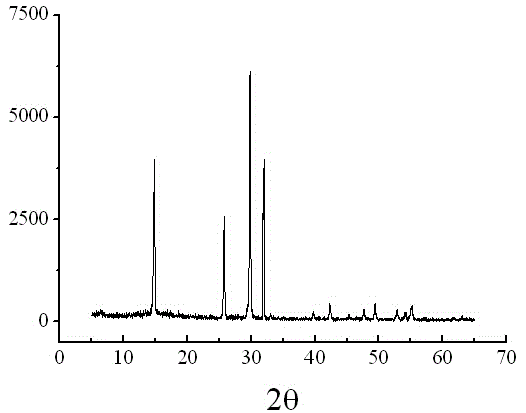

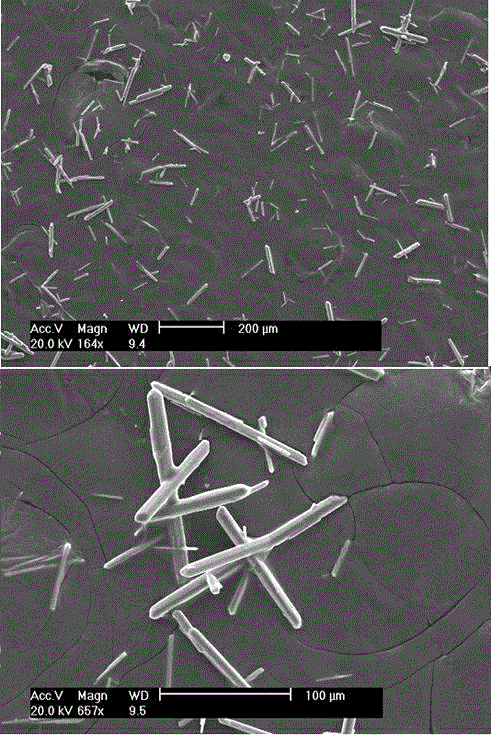

Preparation method of calcium sulfate hemihydrate crystal whiskers high in length diameter ratio

InactiveCN102677177AMorphological rulesUniform particle sizePolycrystalline material growthFrom normal temperature solutionsHemihydrate Calcium SulfatePhysical chemistry

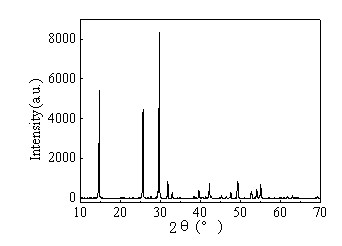

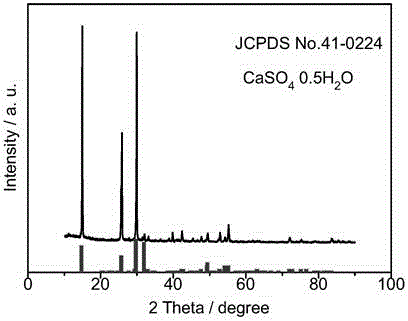

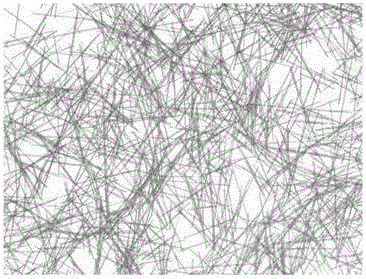

The invention discloses a preparation method of calcium sulfate hemihydrate crystal whiskers high in length diameter ratio. The method includes firstly subjecting soluble inorganic calcium salt and inorganic sulfate to coprecipitation at the temperature of 10-90 DEG C, activating for 1-6 hours at the temperature of 40-150 DEG C to obtain a precursor after filtering and washing, adding the precursor into a hydrothermal medium with crystal form control agent for hydrothermal treatment for 2-10 hours at the temperature of 80-180 DEG C, washing, filtering and drying hydrothermal products, and then obtaining calcium sulfate hemihydrate crystal whiskers in the diameter of 0.1-4 micrometers, the length of 20-3000 micrometers and the length diameter ratio of 50-1000, uniform in shape and identical in size. The preparation method is simple, mild in conditions and low in cost of materials which are easy to obtain, and is easy to industrially popularize. The main content of the calcium sulfate hemihydrate crystal whiskers prepared by the preparation method is larger than 98%, and the calcium sulfate hemihydrate crystal whiskers are uniform in shape and diameter and high in additional value and can be expectedly used as high-performance reinforcing materials for the industries of ceramics, plastics, rubber and paper making and the like.

Owner:KUNMING UNIV OF SCI & TECH

Hydraulic cement compositions and method of forming floor underlayment

InactiveUS20080057206A1Good synergySufficient early strengthLiquid surface applicatorsSolid waste managementSlagPortland cement

The present invention provides a floor underlayment cement composition comprising at least about 95% by weight, based on the weight of the composition, of a hydraulic cementitious mixture and at least about 0.03% by weight, based on the weight of the composition, of a superplasticizer. The hydraulic cementitious mixture includes in the range of from about 35% to about 65% by weight, based on the weight of the mixture, of ground, granulated blast furnace slag, and in the range of from about 35% to about 65% by weight, based on the weight of the mixture, of a gypsum component selected from the group consisting of alpha-calcium sulfate hemihydrate, beta-calcium sulfate hemihydrate and mixtures thereof. It is not necessary to include Portland cement or aluminous cement in the hydraulic cementitious mixture. A floor underlayment slurry and a method of forming a high strength floor underlayment on a floor substrate are also provided.

Owner:HARRISON GYPSUM

Gypsum-rich Portland cement

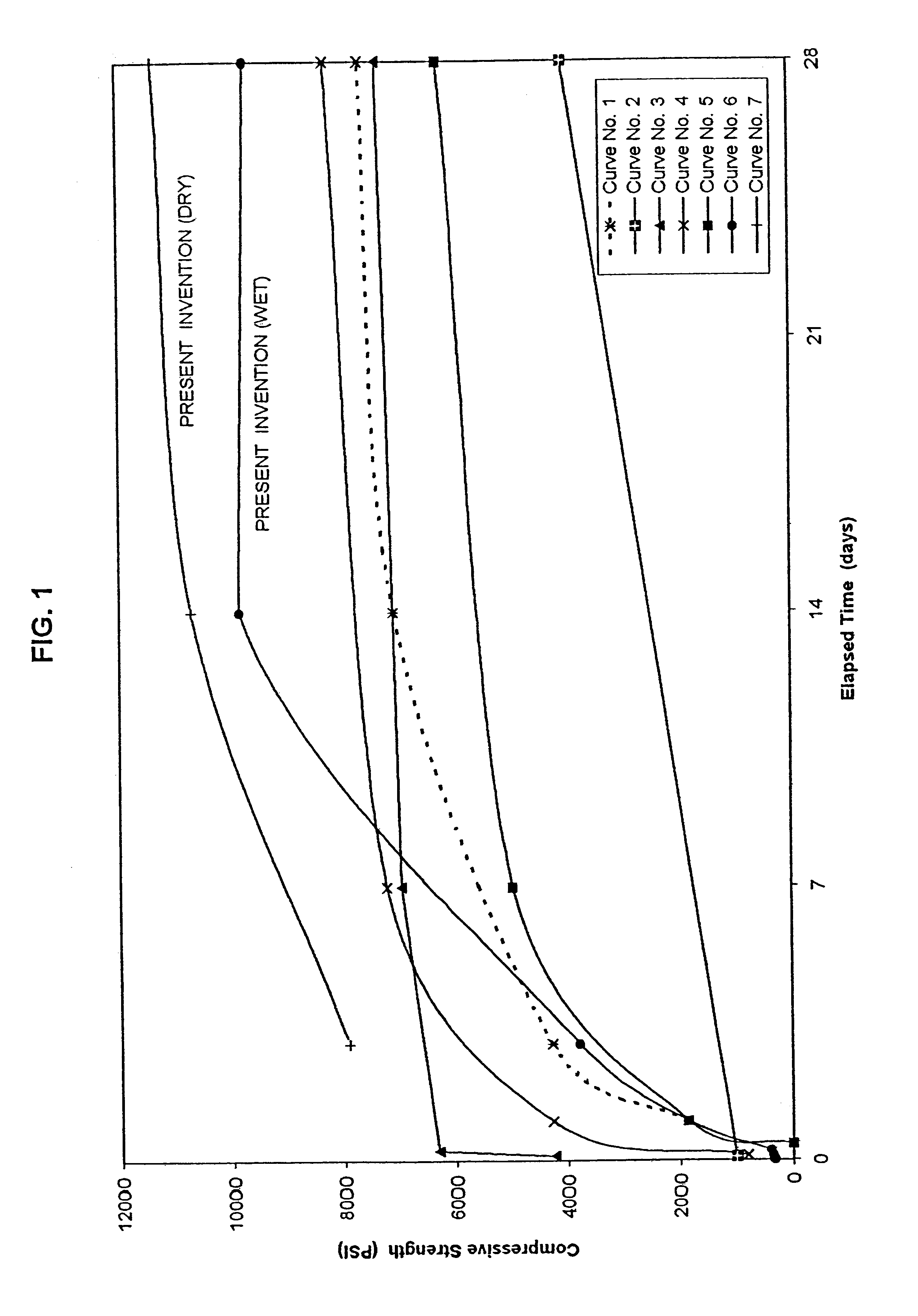

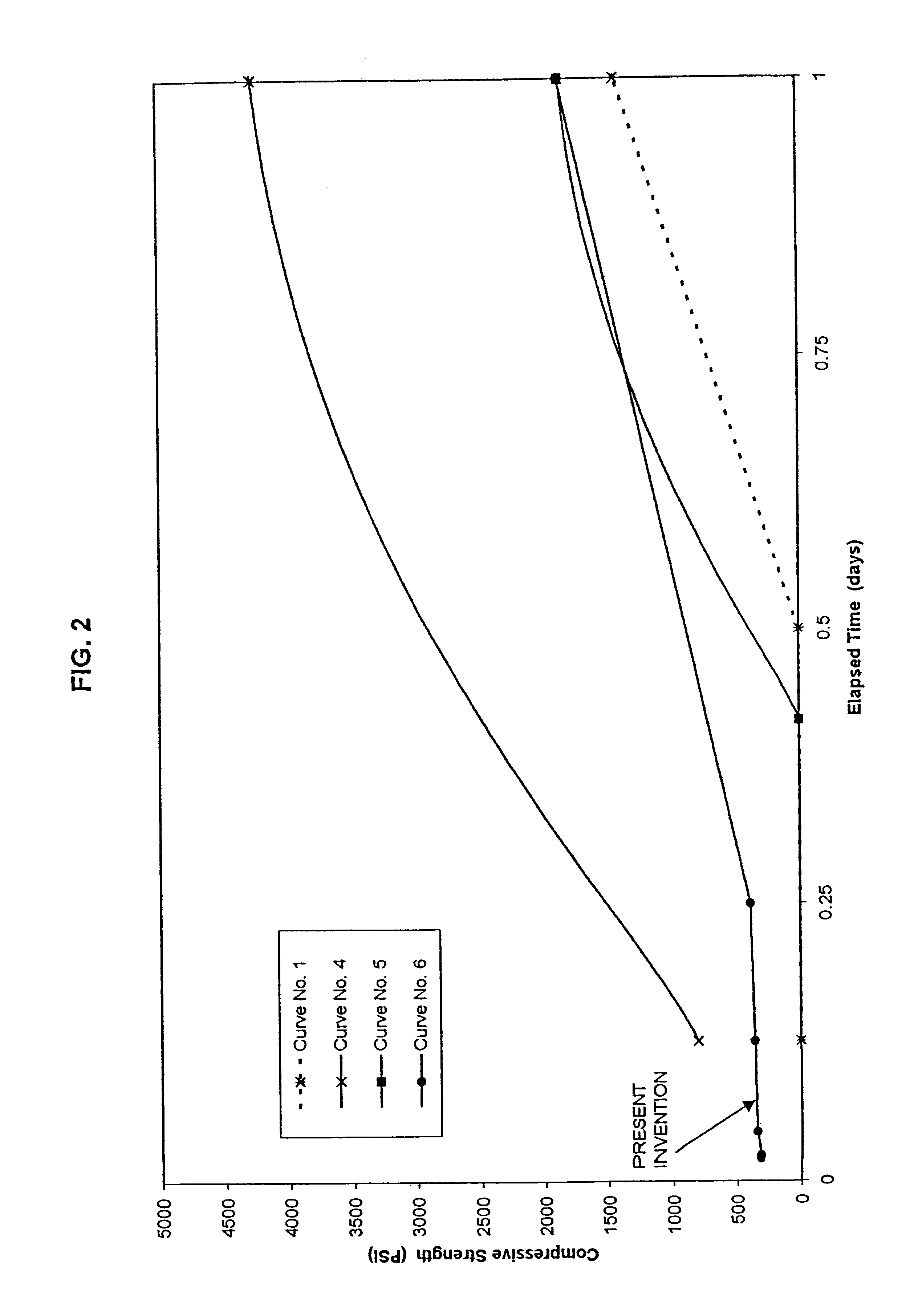

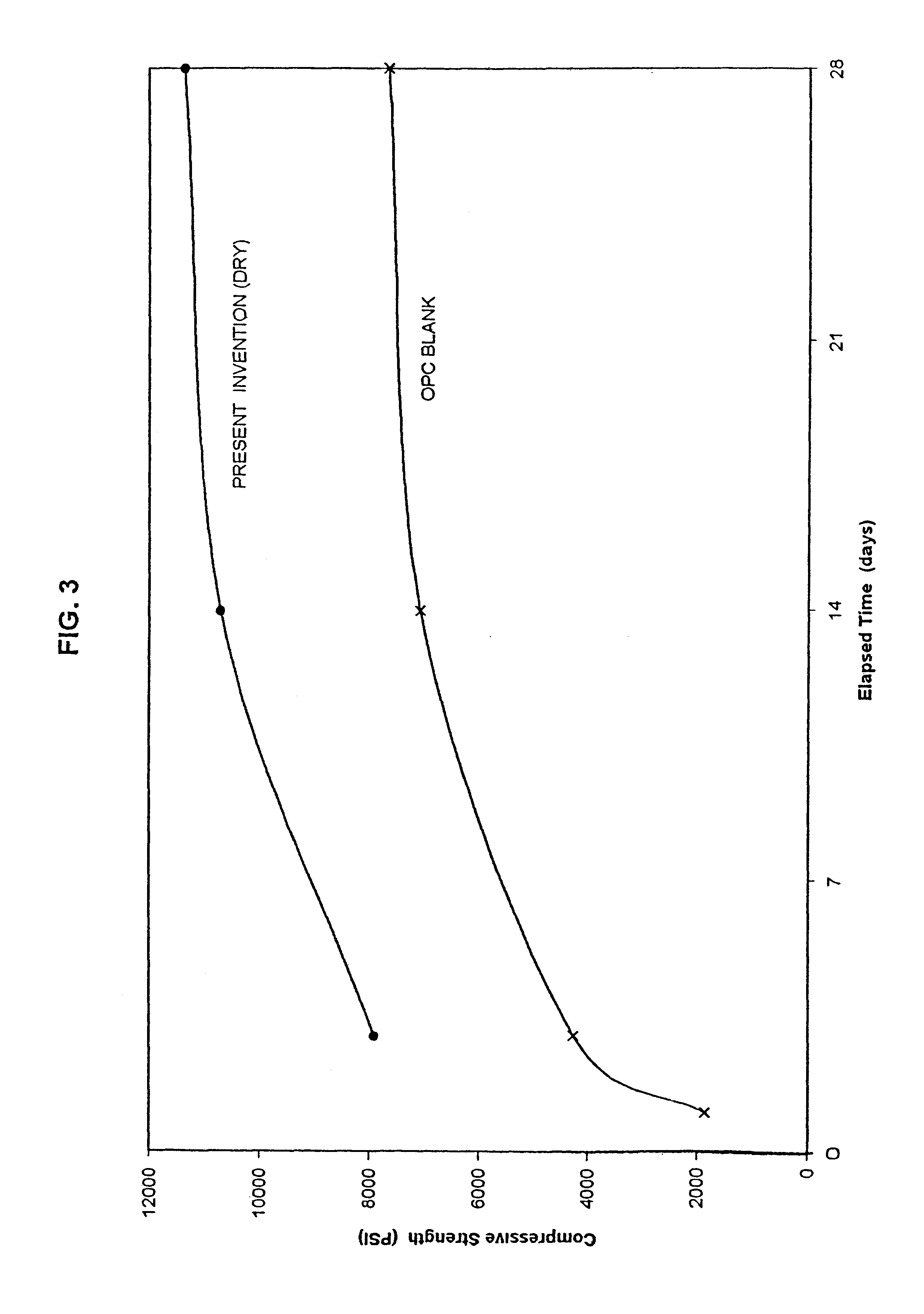

The present invention is of a cementitious composition containing OPC, calcined gypsum, a source of amorphous silica and a source of amorphous alumina. The ratio of calcium sulfate hemihydrate to OPC is 0.7:1.0 to 1.4:1.0, the ratio of amorphous silica and amorphous alumina to OPC is 0.26:1.0 to 0.4:1.0, and the ratio of amorphous alumina to amorphous silica is 0.3:1.0 to 1.5:1.0. The cementitious composition, by itself and mixed with aggregates, is fast-setting and exhibits good early compressive strength and very high compressive strength after hydration. Despite the high content of calcium sulfate relative to prior art OPC formulations, the cementitious composition according to the present invention is essentially waterproof and exhibits excellent strength characteristics, even after 2 years under water. The use of calcined gypsum in place of alumina cement or even OPC is of great economic advantage, and in addition, provides the cementitious composition with quick-setting characteristics.

Owner:M GOLD INVESTMENTS 1999

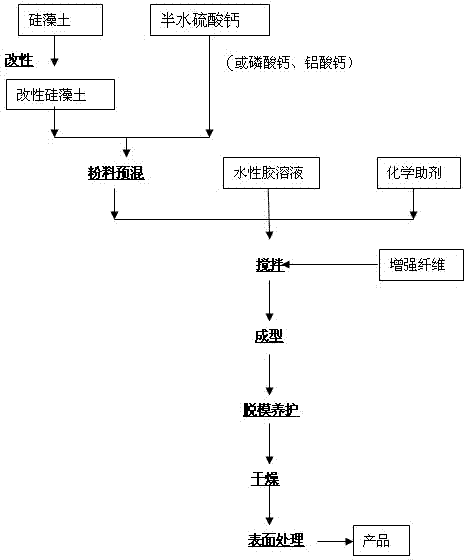

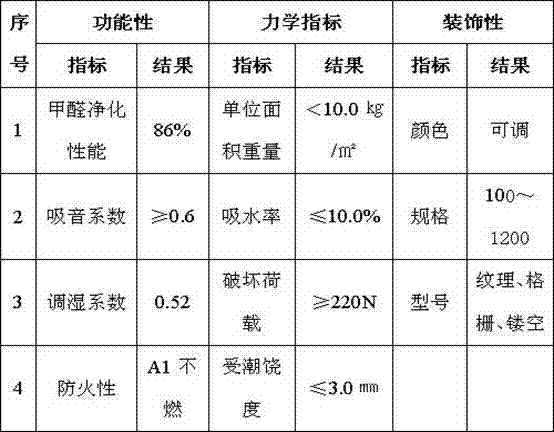

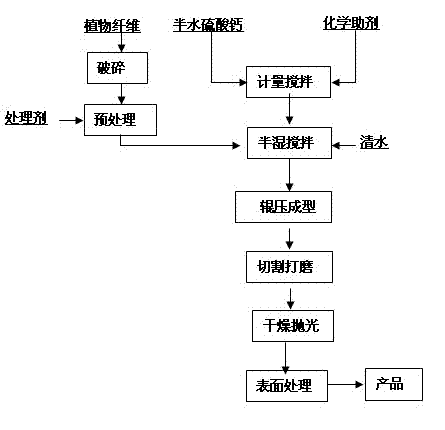

Algae calcium compound material, decorative panel and production method

ActiveCN102515678ASimple processAdsorption functionality is limitedCeramic shaping apparatusFiberWater based

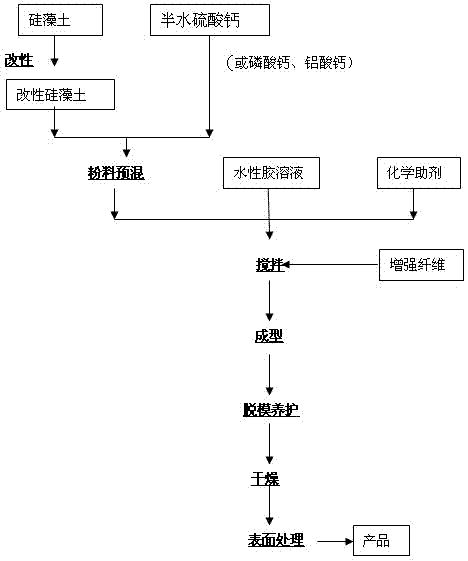

The invention belongs to a building material and particularly relates to an algae calcium compound material, a decorative panel and a production method. Kieselguhr and a calcium-containing inorganic building material substrate are hydrated, gelled and compounded, thereby forming the algae calcium compound material, wherein the calcium-containing inorganic building material substrate is selected from one or more of hemihydrate calcium sulfate, calcium phosphate and calcium aluminate; preferably, the components are mixed at a weight ratio of the calcium-containing inorganic building material substrate to kieselguhr to enhanced fiber chopped strand to water-based gel solution to chemical auxiliaries being 100:(10-50): (1.2-2.0): (50-65): (5-10); and the raw materials are subjected to raw material pretreatment, mixing and stirring, filling and molding, maintaining and drying, and surface treatment, thereby forming a decorative material product. The excellent plasticity and environmental friendliness of the novel compound material are fully excited while the microporosity of the kieselguhr is utilized to endow the material with excellent functions of humidifying and absorbing harmful gas, such as, formaldehyde, and the like, and the environmental protecting functions, such as sterilization, and the like.

Owner:湖北格林森绿色环保材料股份有限公司

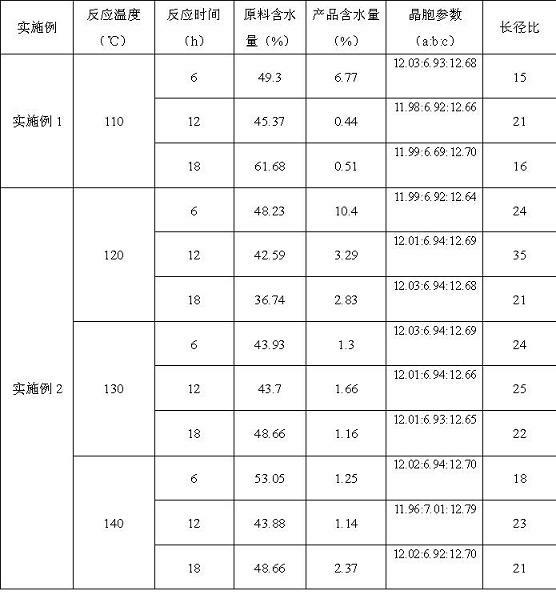

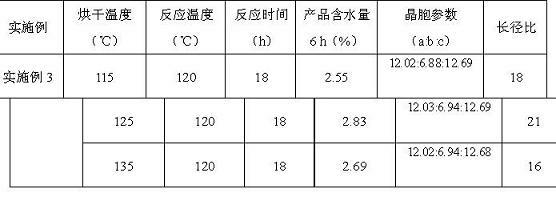

A kind of method that calcium sulfate hemihydrate whisker prepares

InactiveCN102268722AHigh whisker purityHigh aspect ratioPolycrystalline material growthFrom normal temperature solutionsReaction temperatureEngineering

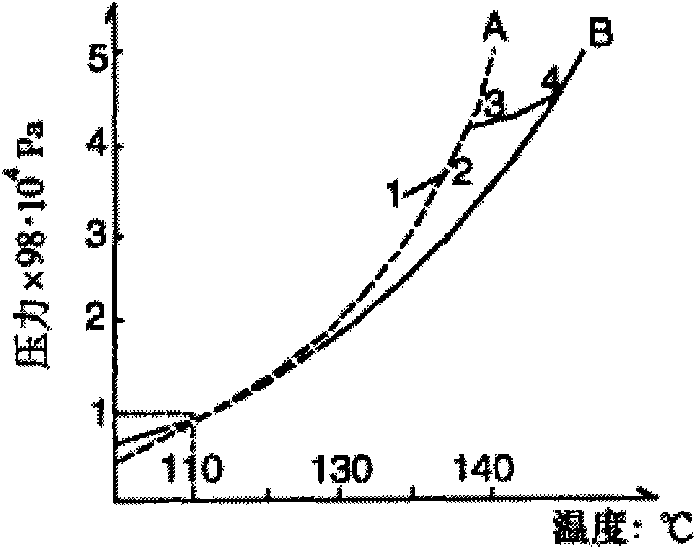

The invention relates to a method for preparing alpha-hemihydrate calcium sulfate crystal whisker. The method comprises the following steps: (1) mixing K2SO4 and Ca(NO3)2.5H2O according to a mole ratio of the K2SO4 to the Ca(NO3)2.5H2O of 1:1, carrying out electric stirring for 30 minutes to prepare amorphous calcium sulfate; (2) dissolving the amorphous calcium sulfate into deionized water, carrying out stirring for 10 minutes, the carrying out ultrasonic dispersion for 20 minutes to prepare calcium sulfate suspension liquid having a mass fraction of 4-6%; transferring the calcium sulfate suspension liquid to a high pressure hydro-thermal reaction kettle, then carrying out a reaction for 6-18 hours under saturated vapor pressure at a reaction temperature of 110-140 DEG C, filtering the resulting precursor when the precursor is hot, followed by carrying out forced air drying for 6-8 hours at the temperature of 110-130 DEG C to prepare the alpha-hemihydrate calcium sulfate crystal whisker. According to the present invention, the amorphous calcium sulfate is adopted as the raw material, the crystal modifier is not required; the prepared alpha-hemihydrate calcium sulfate crystal whisker has characteristics of high purity, uniform long diameter and high length-diameter ratio; the reaction conditions are mild; the production process accords with the requirements of the industrial production.

Owner:中国人民解放军第三五九医院 +1

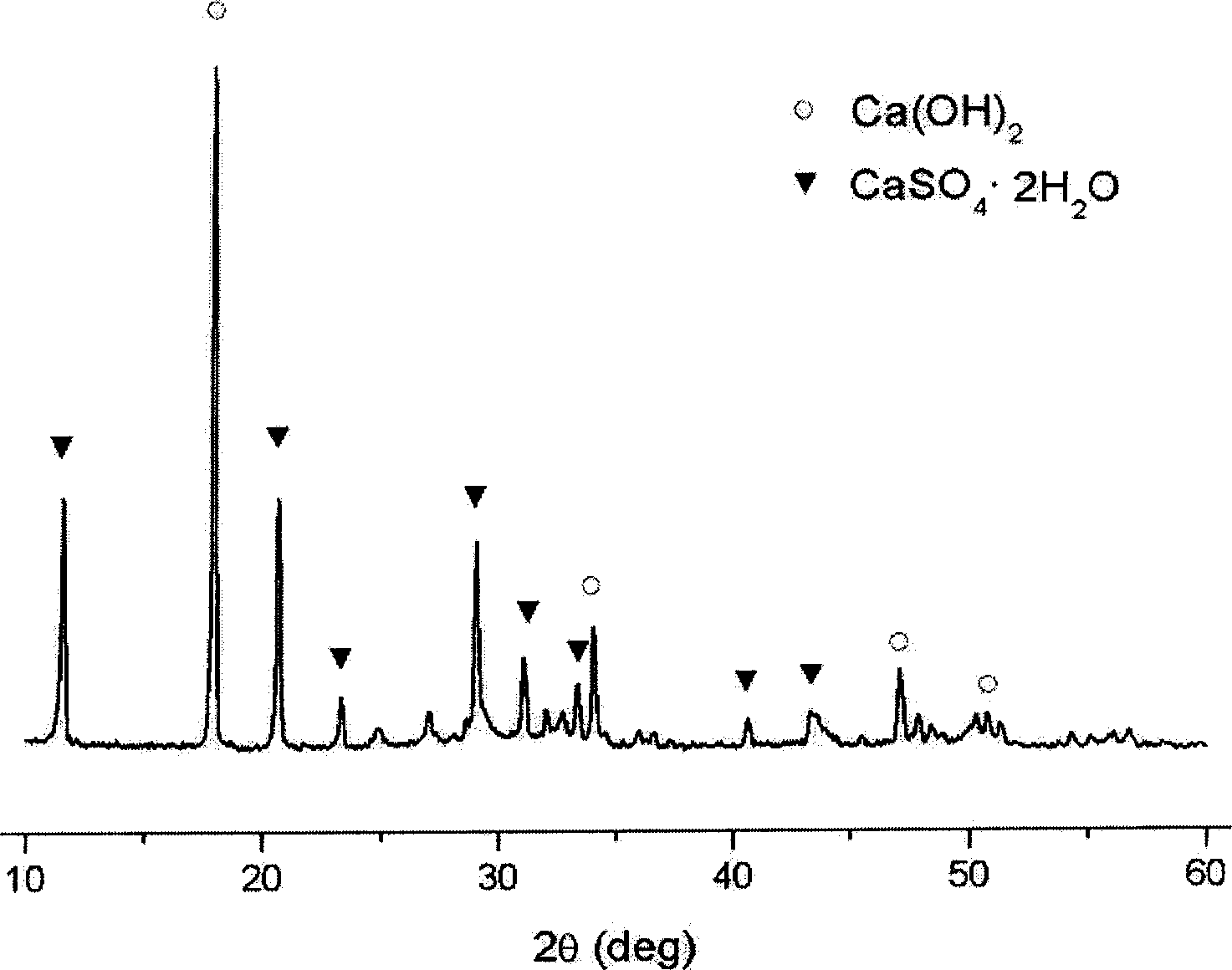

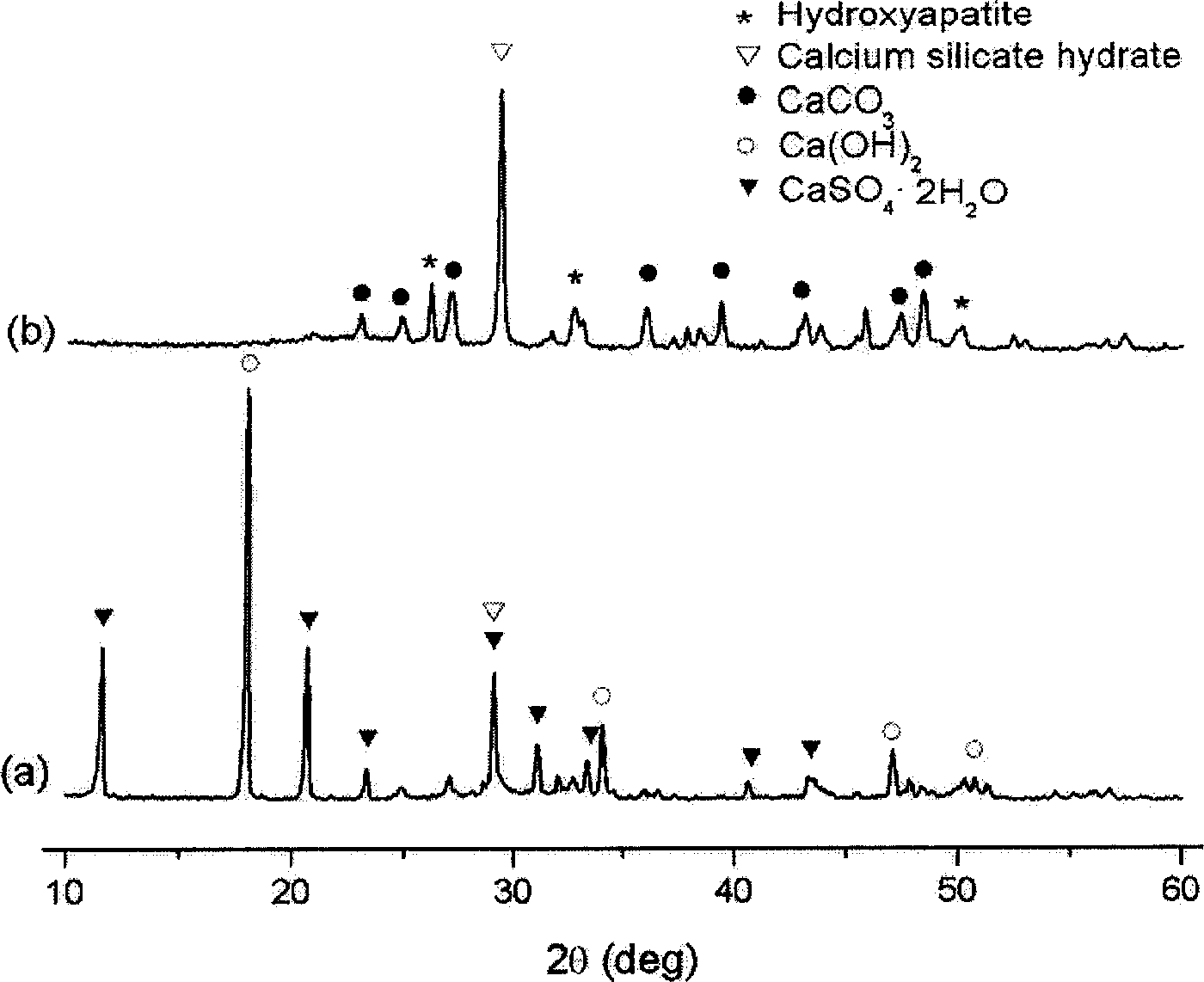

Calcium sulfate semihydrate group combined self-curing bio-active material, preparation and application thereof

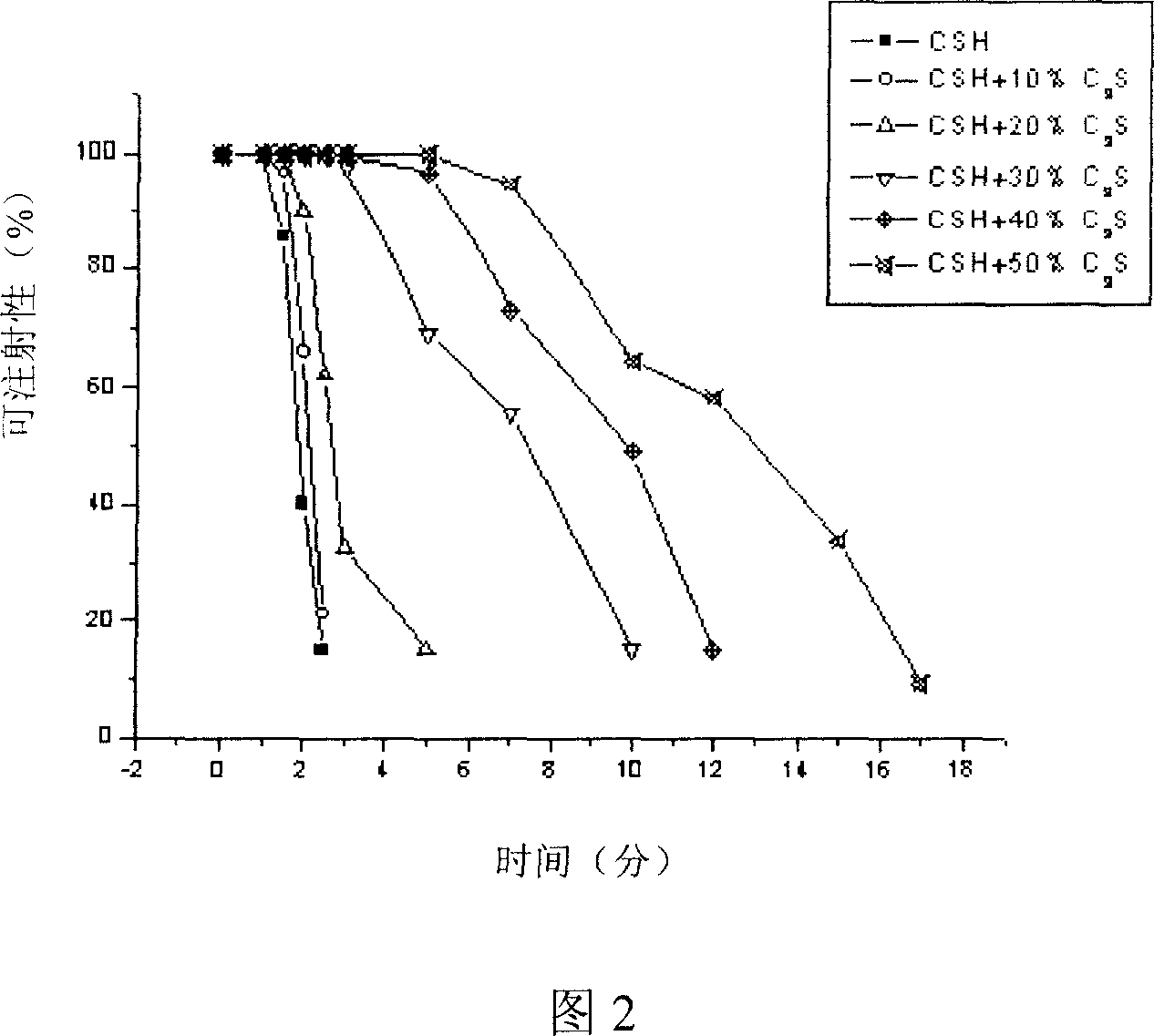

The invention relates to a self-solidification biological active material of hemigydrate calcium sulfate base, relative production and application. Wherein, the invention is characterized in that: said material is paste formed by harmony liquid, hemigydrate calcium sulfate / tricalcium silicate composite powder, while their mass ratio is 0.8-1.2:1; said harmony liquid is one of deionized water, analogue humor, inorganic salt solution or inorganic solution; the content of tricalcium silicate in the hemigydrate calcium sulfate / tricalcium silicate composite is 1-50%. The invention can be shaped freely, without cell toxicity, while it can be degraded stepped with adjustable speed, and it can induce the generation of skeleton agustite, with higher activity then calcium sulfate material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing calcium sulfate hemihydrate whiskers by taking ardealite as main raw material

InactiveCN102925956AIncrease added valueReduce miningPolycrystalline material growthFrom normal temperature solutionsHemihydrate Calcium SulfateSulfate

The invention relates to a method for preparing calcium sulfate hemihydrate whiskers by taking ardealite as a main raw material. The technical scheme of the invention is as follows: firstly, mixing 40-50wt% of ardealite with 3-5wt% of hydrochloric acid, 1-3wt% of sulfuric acid and the balance of water as accessory materials, stirring the obtained mixture for 1-2 h at normal pressure and at a temperature of 80-110 DEG C, and filtering the obtained product so as to obtain a primary filter cake, and washing the primary filter cake; preparing 6-12wt% of habit modifier, 1-5wt% of sulfuric acid, 1-10wt% of primary filter cake subjected to washing and the balance of water into turbid suspension liquid; then, under the condition of normal pressure and 100-120 DEG C, stirring the turbid suspension liquid for 0.5-1 h, adding calcium sulfate whiskers accounting for 0.5-1wt% of ardealite and a whisker modifier accounting for 0.5-1wt% of ardealite while stirring, and then stirring for 4-8 h; carrying out filtering on the obtained product so as to obtain a finished filter cake product, and washing the finished filter cake product; and finally, drying the finished filter cake product for 2-4 hours so as to obtain the calcium sulfate hemihydrate whiskers. The method disclosed by the invention has the characteristics of mild operating condition, low production cost, green and environmental protection, and high product quality.

Owner:WUHAN UNIV OF SCI & TECH

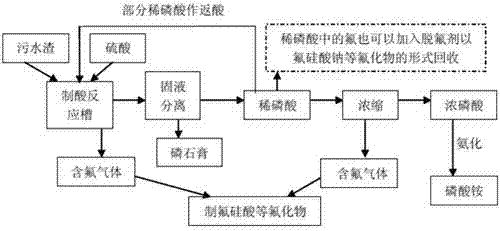

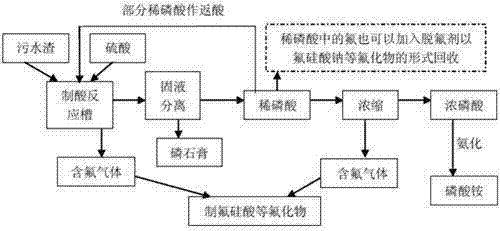

Method for recycling phosphorus and fluoride in sewage residue of phosphorus fertilizer plant

InactiveCN102502552AImprove use valueEffective way to usePhosphatesAlkali orthophosphate fertiliserO-Phosphoric AcidAgricultural engineering

The invention discloses a method for recycling phosphorus and fluoride in the sewage residue of a phosphorus fertilizer plant. According to the method, the sewage residue is decomposed by using sulfuric acid, the phosphorus and the fluoride in the sewage residue are extracted, calcium sulfate dihydrate crystal or calcium sulfate hemihydrate crystal and diluted phosphoric acid solution are generated, diluted phosphoric acid and phosphogypsum which is the by-product are obtained through solid-liquid separation, the diluted phosphoric acid is concentrated into concentrated phosphoric acid, the escaped fluorine containing gas is recycled in the process of concentrating the phosphoric acid and making acid and produced into the fluoride such as the fluosilicic acid and the like, or defluorination agent is added into the diluted phosphoric acid to recycle fluoride resources in the form of the fluoride such as the sodium fluosilicate and the like, and the obtained concentrated phosphoric acid can be used to prepare other phosphate products such as the ammonium phosphate and the like by using the traditional method. The method can be used to effectively recycle the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant so that the waste materials can be changed into the valuable materials and the recycling value of the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant can be improved. The method has good economic benefit and environment protection significance.

Owner:WENGFU (GRP) CO LTD

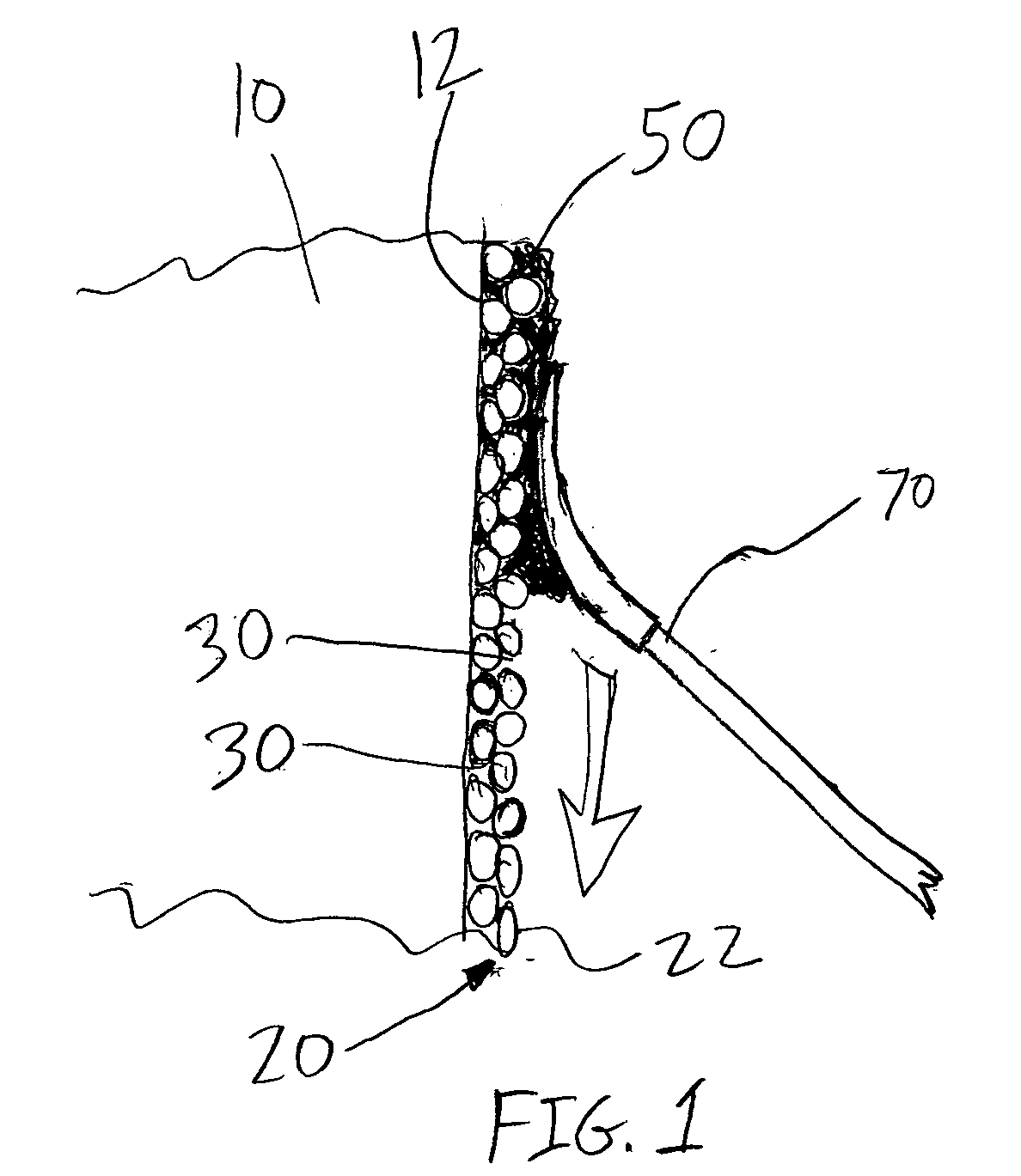

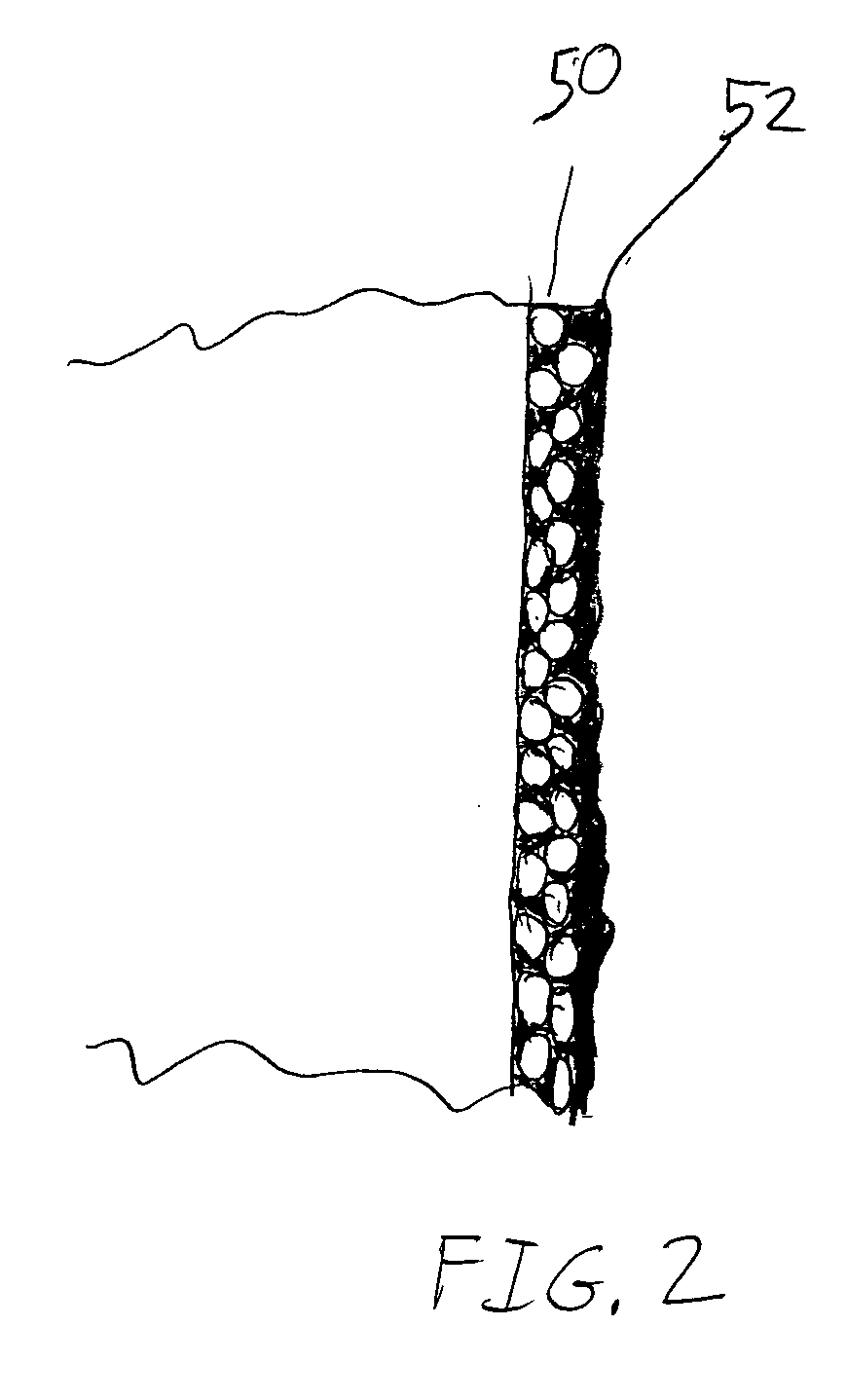

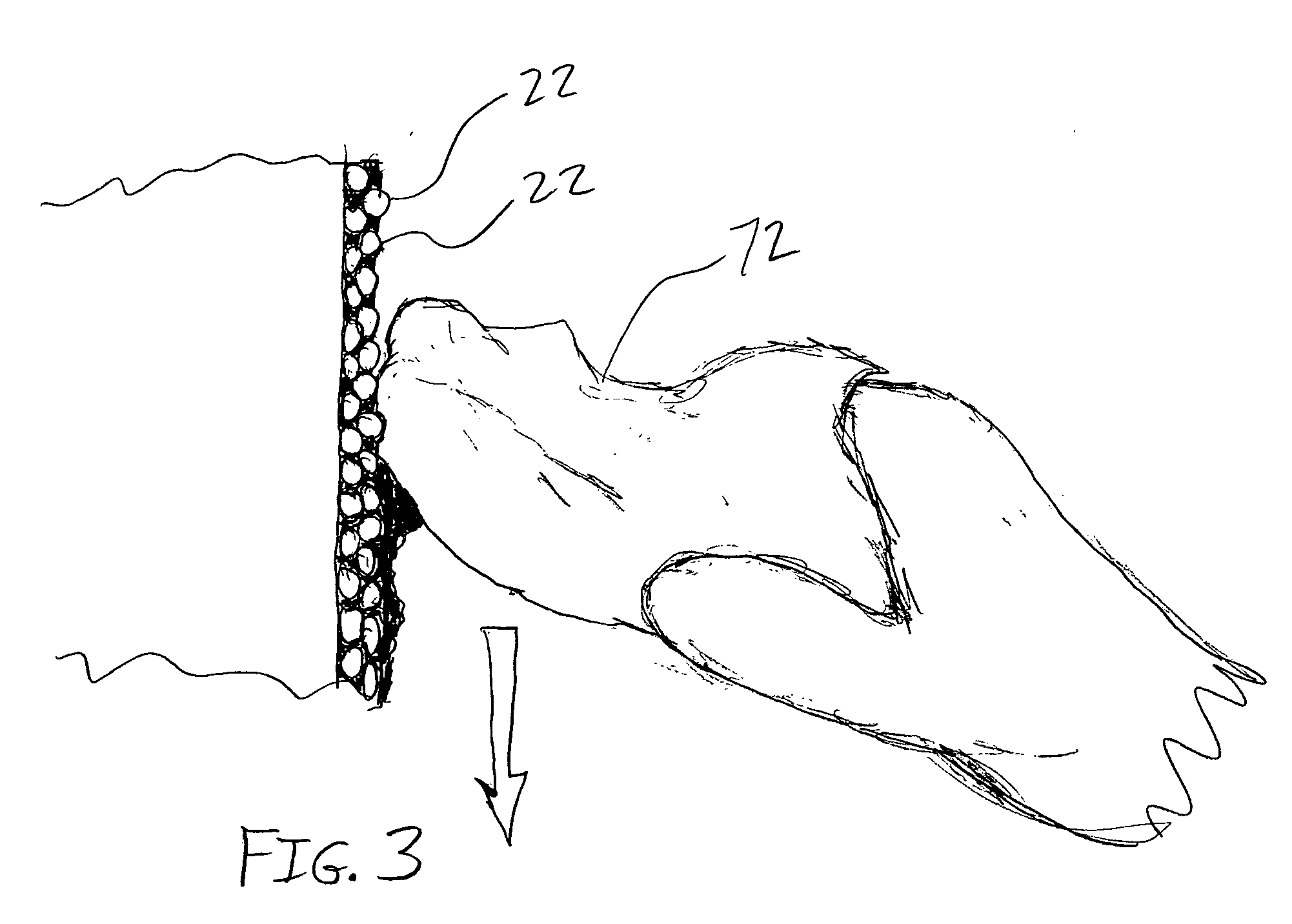

Coating an implant for increased bone in-growth

ActiveUS20060188541A1Promotes increased bone in-growthEconomical and efficient methodImpression capsPretreated surfacesHemihydrate Calcium SulfateSulfate

A method of preparing an implant for bone in-growth comprising: providing a metal implant body, the metal implant body having a metal load bearing layer on an outer surface, the metal load bearing layer having a plurality of pores therein, the pores configured to promote bone in-growth into the load bearing layer; providing calcium sulfate hemi-hydrate; providing a diluent; mixing the calcium sulfate hemi-hydrate and the diluent to form a calcium sulfate paste; applying the calcium sulfate paste to the load bearing layer such that the calcium paste substantially impregnates at least a portion of the pores and forms an excess layer of the calcium sulfate paste on an outer surface of the load bearing layer; and wiping the calcium sulfate paste to remove the excess layer and thereby expose the outer surface of the load bearing layer while leaving the calcium sulfate paste impregnated in the pores.

Owner:WRIGHT MEDICAL TECH

Alpha-type calcium sulfate hemihydrate compositions and methods of making same

InactiveUS20050188898A1Good crystal shapeSolid waste managementCeramic shaping apparatusHemihydrate Calcium SulfateBriquette

Owner:G B TECH LLC

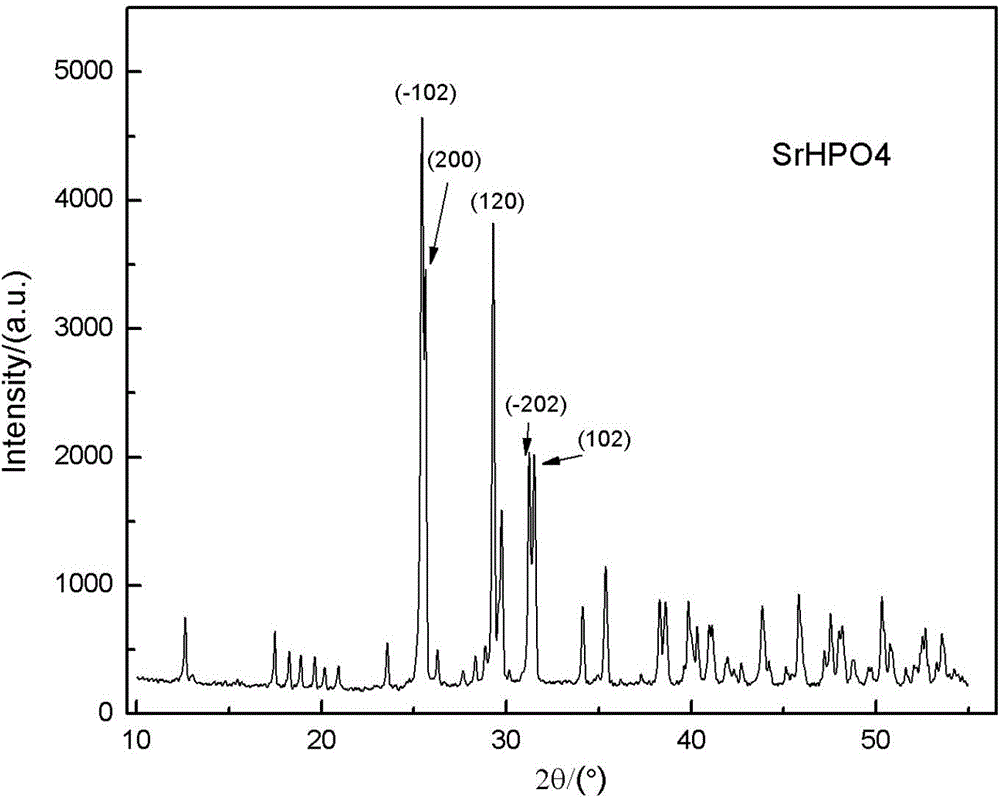

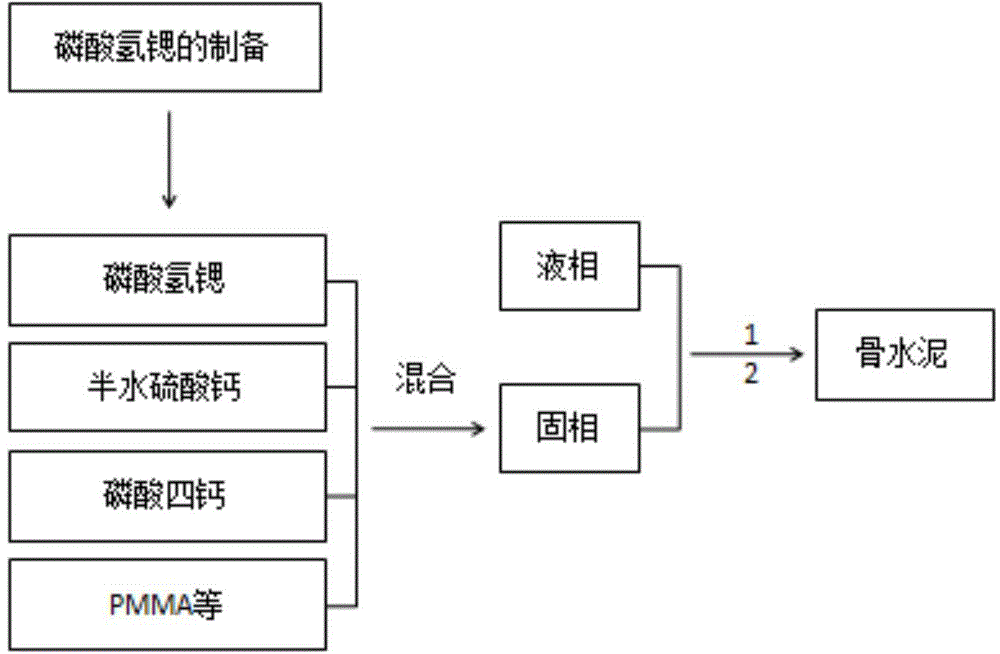

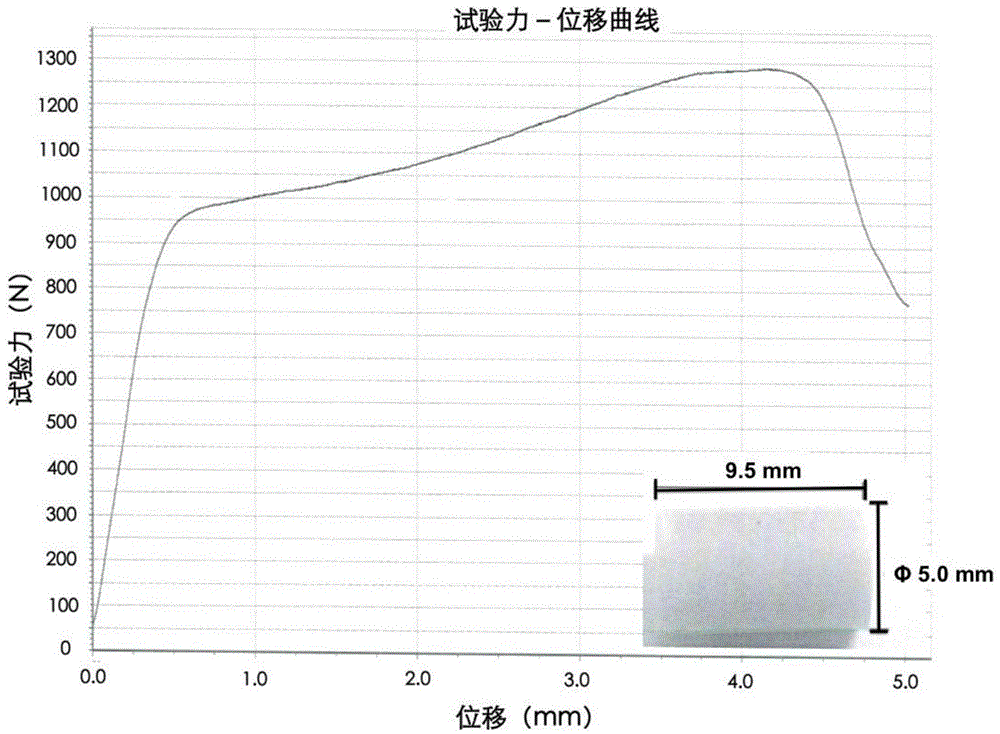

Injectable bone cement containing strontium and preparation method of bone cement

The invention relates to injectable bone cement containing strontium and a preparation method of the injectable bone cement. The injectable bone cement comprises solid phase and liquid phrase, wherein the solid phrase comprises polymethylmethacrylate, calcium sulfate hemihydrate, tetracalcium phosphate, strontium hydrogenphosphate, barium sulfate and benzoyl peroxide; the liquid phrase comprises a methyl methacrylate monomer, N,N dimethyl paratoluidine and hydroquinone; the preparation method of the injectable bone cement comprises the following steps: mixing solids and liquids at a mass ratio of 2 to 1; stirring uniformly by using a bone cement mixing and stirring system; using an injecting system to inject the bone cement; in the injectable bone cement containing the strontium, the calcium sulfate hemihydrate, the tetracalcium phosphate and the strontium hydrogenphosphate are distributed uniformly; after the injectable bone cement is implanted into a body, calcium ions and strontium ions are degraded and released gradually in the body to form a honeycomb structure and guide cells to ingrow, so that joint connection is formed so as to prevent looseness; the compressive strength of the prepared injectable bone cement containning the strontium are higher than 50 MPa. The injectable bone cement containing the strontium can be used in fracture fixation caused by osteoporosis and the like and bone defect filling.

Owner:山东明德生物医学工程有限公司

Bio-activity tricalcium silicate/semi water calcium sulphate composite self-solidification material, preparation and application

InactiveCN1911458AImprove biological activityGood biocompatibilityProsthesisInorganic saltsSimulated body fluid

A self-solidifying bioactive composition in the form of paste for repairing bone and tooth is proportionally prepared from the mingling liquid chosen from deionized water, simulative body fluid, inorganic salt solution and gelatin, and the composite powder consisting of tricalcium silicate and semi-hydrated calcium sulfate.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

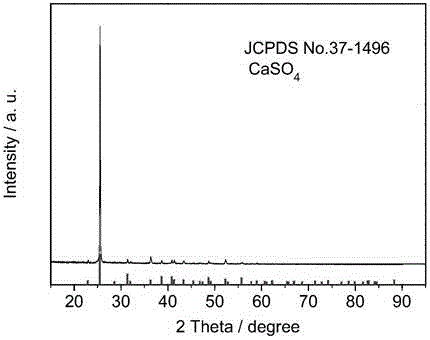

Mixed additives and method for producing anhydrous dead-burned type of calcium sulfate whisker

ActiveCN104928758AReduce energy consumptionReduce environmental stressPolycrystalline material growthFrom normal temperature solutionsFiltrationCalcination

The invention relates to a mixed additive for producing an anhydrous dead-burned type of calcium sulfate whisker, and belongs to the technical field of inorganic chemical materials production. The mixed additive of the invention comprises a morphology controlling agent, an auxiliary controlling agent and a reaction system pH controlling agent. The mass ratio of the morphology controlling agent, the auxiliary controlling agent and the reaction system pH modulator is 1:0-20:30-70. The mixed additive can speed up growth of crystals, shorten reaction time, and at the same time can implement control of whisker morphology to acquire high aspect ratio hemihydrate calcium sulfate whisker. The invention further relates to a method for producing an anhydrous dead-burned type of calcium sulfate whisker. The method comprises: using calcium sulfate dihydrate, water and the mixed additive as raw materials, performing a hydrothermal reaction to acquire hemihydrate calcium sulfate whisker; after filtration, drying,calcination and cooling, acquiring the anhydrous dead-burned type of calcium sulfate whisker with calcium sulfate content being more than 98wt%. The invention is simple in process, zero in pollution, low in production cost, high in operability, good in product quality and good in stability.

Owner:四川康升晶须科技有限公司

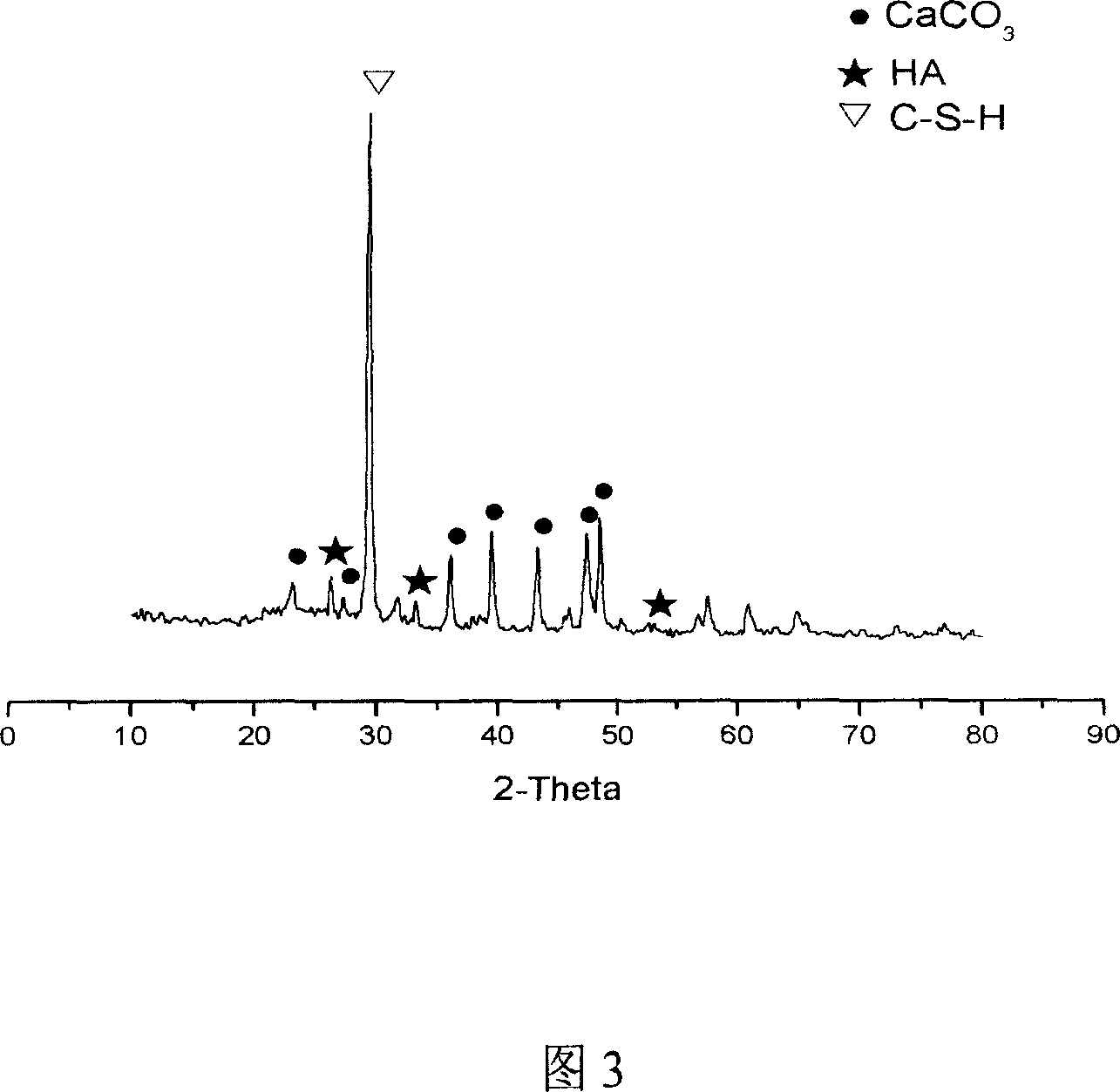

Injectable active bone repair material and preparation method thereof

InactiveCN102600511AEasy to makeThe preparation method is simpleProsthesisHemihydrate Calcium SulfateBiocompatibility

The invention provides an injectable active bone repair material and a preparation method thereof. The material is characterized by comprising a mixture of calcium sulfate hemihydrate, hydroxyapatite and BMP (bone morphogenetic proteins)-2 active peptide, and a curing liquid, wherein the weight ratio of calcium sulfate hemihydrate to hydroxyapatite to BMP-2 active peptide is (0.1-10000):(0.1-10000):0.1; and the dosage range of the curing liquid is 0.01-20ml for per gram of the mixture of calcium sulfate hemihydrate, hydroxyapatite and BMP-2 active peptide. The preparation method is characterized in that the pulpy injectable active bone repair material can be obtained by fully stirring and mixing the mixture with the curing liquid. The preparation method is simple in formula and the preparation process is practical; and the required repair material can be prepared within 24 hours, has good injectability, is cured within half an hour, is simple to prepare, has good biocompatibility and has the characteristics of low temperature, low vacuum, low energy consumption and low pollution.

Owner:北京博恩康生物科技有限公司

Modified landplaster as a wallboard filler

InactiveUS20070044687A1Improve performanceDelay exposureThin material handlingHemihydrate Calcium SulfateDihydrate Calcium Sulfate

A gypsum slurry includes calcium sulfate hemihydrate, water and calcium sulfate dihydrate is coated with a hydrophilic, dispersible coating. The coating is less soluble than the calcium sulfate hemihydrate to delay exposure of the landplaster to the remainder of the slurry, preventing premature crystallization and the early stiffening that accompanies it. Another embodiment is a gypsum slurry that includes calcium sulfate hemihydrate, a polycarboxylate dispersant, water and coated calcium sulfate dihydrate. In this case, the hydrophilic, dispersible coating is selected to serve as a modifier to enhance the ability of the dispersant to fluidize the gypsum slurry.

Owner:UNITED STATES GYPSUM CO

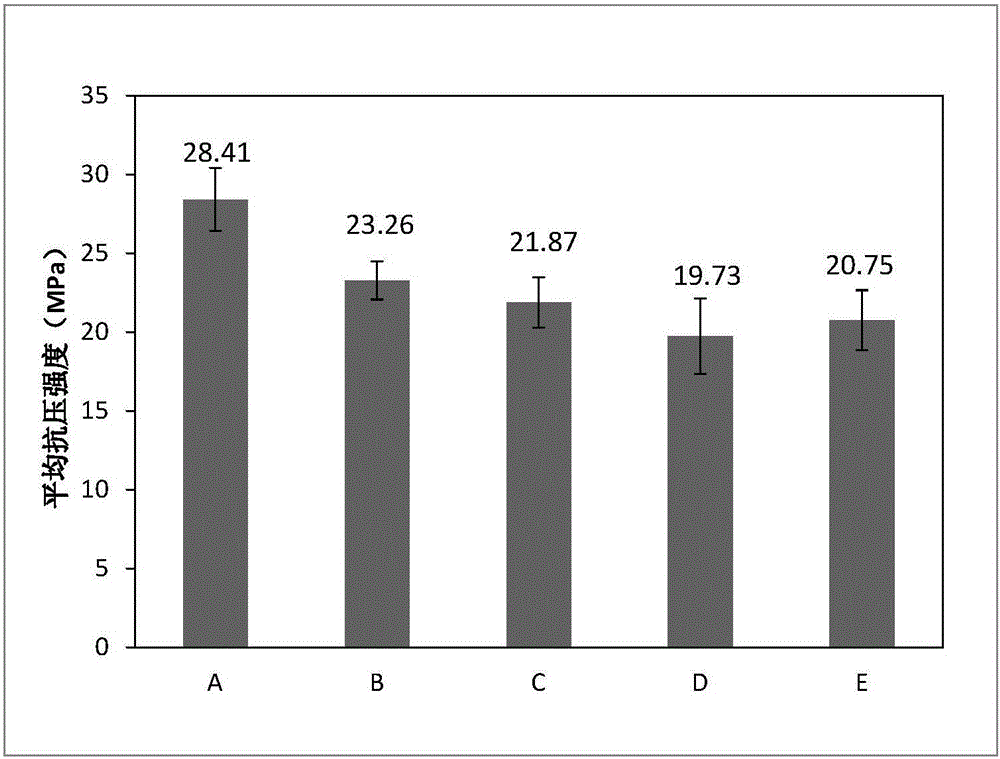

Alpha-calcium sulfate hemihydrates/beta-tertiary calcium phosphate porous granular-type composite artificial bones and preparation method thereof

The invention discloses a method for preparing alpha-calcium sulfate hemihydrates (alpha-CSH) / beta-tertiary calcium phosphate (beta-TCP) porous granular-type composite artificial bones, which is characterized in that the alpha-CSH is directly synthesized on the surface and / or in the pores of the beta-TCP granules synchronously by the hydrothermal synthesis process and finally the alpha-CSH / beta-TCP porous granular-type artificial bones is prepared. The invention has the advantages that the preparation process is simpler, the preparation period can be effectively reduced, and the preparation efficiency is improved; the proportion between alpha-CSH and beta-TCP phases of the granular-type composite artificial bones can be effectively controlled, thereby controlling the pore structure of the artificial bone granules; meanwhile, the invention guarantees the in-situ solidifying performance and degrading performance of the composite artificial bones, controls the evenness of the product and the porosity and pore diameter of the beta-TCP granules, improves the bone-formation performance and degrading performance of the composite artificial bones and further improves the quality of the product, thereby finally obtaining the composite artificial bones having self-solidifying performance and controllable degradation and having a certain biomechanical strength. The invention has good application and market prospect.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

Injection moldable bone repair composite material and preparation method thereof

InactiveCN101716380ARelieve painAppropriate selection rangeProsthesisIn situ polymerizationBiocompatibility Testing

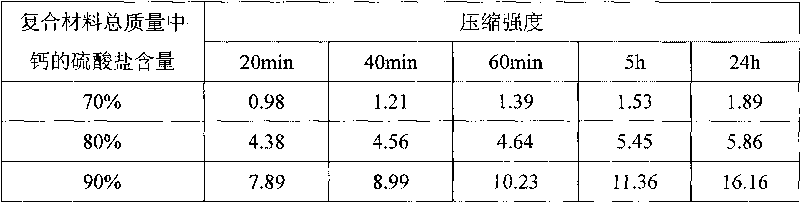

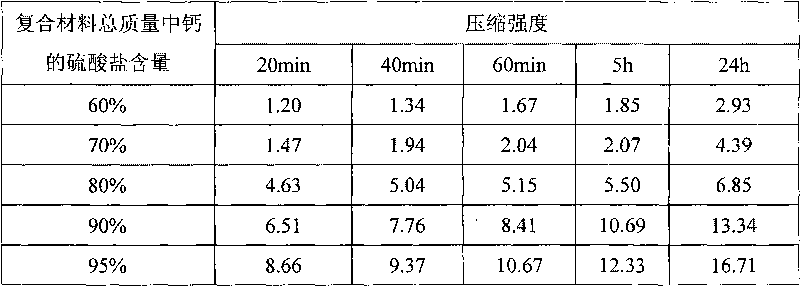

The invention relates to an injection moldable bone repair composite material and a preparation method and a using method thereof. The composite material is a powder material consisting of a copolymer of multiple amino acids and a sulfate component of calcium, the sulfate component of the calcium accounts for 60-95% of total weight of the component material, and the balance is the copolymer of the multiple amino acids. The sulfate component of the calcium comprises alpha-hemihydrated calcium sulfate which accounts for 15%-60% of the total weight of the composite material and the balance of other sulfates of the calcium. The copolymer of the multiple amino acids is formed by polymerizing epsilon-aminocaproic acid and at least two types of other amino acids, and the molar ratio of each amino acid in the other amino acids is not less than 1% of the total weight of the amino acids. When in preparation, an intermediate parent body is obtained by in-situ polymerization and composition of other sulfates of the calcium and the amino acid monomers under inert gas protection and heating, and the composite material is prepared by smashing and then being composed with the alpha-hemihydrated calcium sulfate. The composite material powder is mixed with curing liquid, and then the composite material can be used by injection. The composite material can be fast molded after the injection and has the strength which is equivalent to that of cancellous bone, good biocompatibility and adjustable degradation speed, thereby being applicable to fixation and repair of clinical orthopedic complicated and irregular traumas.

Owner:SICHUAN UNIV

Bone repairing material for personalized treatment

The invention relates to a bone repairing material for a personalized treatment. The material is prepared from a solid phase material which is prepared from a phosphoric acid calcium salt, alpha-hemihydrate calcium sulfate and reinforcing fibers and a liquid phase material which is prepared from one or more of citric acid, sodium phosphate, dibastic sodium phosphate, de-ionized water, physiological saline and blood of patient, wherein the volume ratio of the solid phase to the liquid phase is 5 to 10: 1. The bone repairing material can promote the regeneration of bone defects and can be processed into various complicated shapes and sizes according to the actual requirements of patients to meet the surgical requirements of the clinic personalized treatment or plastic operation.

Owner:SHENZHEN LANDO BIOMATERIALS

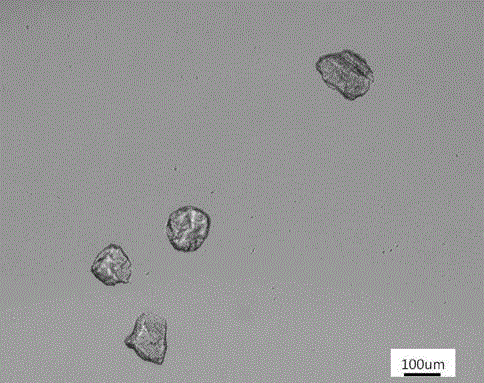

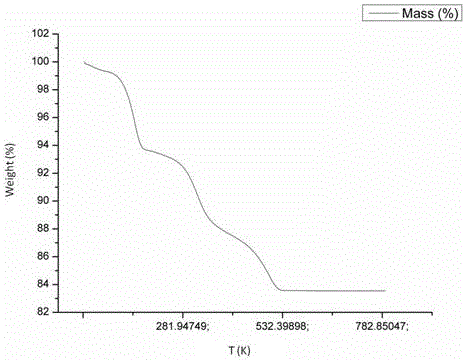

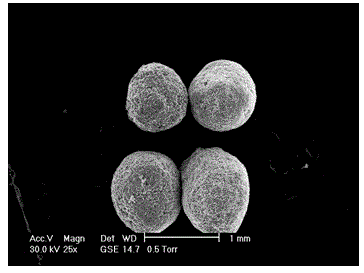

Method for hydrothermal technology synthesis of calcium sulfate hemihydrates powder particles

InactiveCN105948096AParticle size controllableGuaranteed liquidityCalcium/strontium/barium sulfatesSupercritical dryingPolyvinyl alcohol

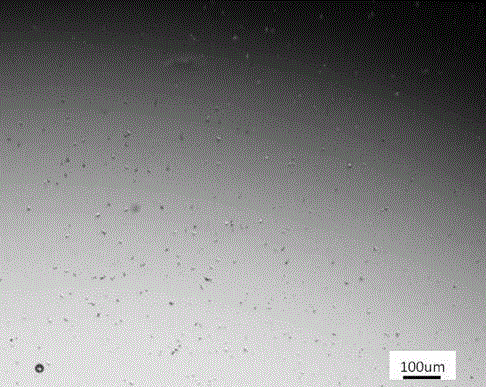

The invention provides a method for hydrothermal technology synthesis of calcium sulfate hemihydrates powder particles. The method concretely comprises the following steps: mixing a calcium chloride and sodium sulfate mixed solution with polyvinyl alcohol and polyvinylpyrrolidone, carrying out a hydrothermal reaction, and carrying out supercritical drying on the above obtained reaction product to obtain final powder. The method utilizes a polyvinyl alcohol and polyvinylpyrrolidone composite surfactant to modify, so the particle size and the surface morphology of the hydrothermal synthesized powder can be effectively regulated; and a supercritical drying technology finally adopted in the invention simultaneously guarantees the fluidity and the dispersibility of the powder. The method has the advantages of green and mild reaction conditions, simplicity in operation, short time and strong repeatability. The calcium sulfate hemihydrates powder particles prepared through the method have the advantages of uniform dimensions, high degree of sphericity, controllable particle size, excellent fluidity and dispersibility, and wide application prospect in 3D printing gypsum powder materials.

Owner:宁波道乐新材料科技有限公司

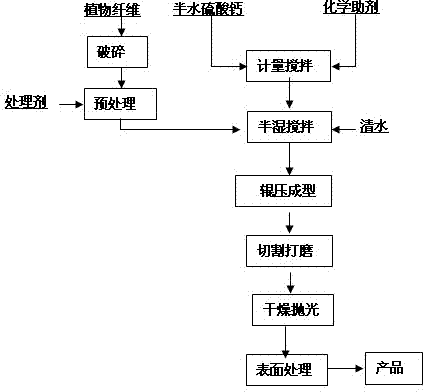

Fibrous gypsum ecological wood material and preparation method thereof

ActiveCN102503335ARetain plasticityPreserve environmental protection functionalityInorganic saltsHemihydrate Calcium Sulfate

The invention relates to a fibrous gypsum ecological wood material and a preparation method thereof. The material is characterized in that the material is prepared from raw materials of calcium sulfate hemihydrate, dispersible plant fiber, a chemical auxiliary agent, and clear water with a weight ratio of 100:6.0-20.0:2-3.6:18.63-20. The clear water is reaction water required by calcium sulfate hemihydrate hydration. The plant fiber is processed through inorganic salt and alkaline solution steaming and impregnation, such that the surface of the plant fiber is deactivated, and the groups of the fiber are disintegrated. The material does not adopt cement, resin or plastic as a bonding agent, such that inherent plasticity and environment-protection functionality of the gypsum-based plant fiber material are sufficiently preserved. No high-temperature hot-melting harsh technology is adopted. No toxic substance exists or is released. High-temperature thermal mismatch of plant fibers is avoided. The material can be subject to continuous rolling shaping, such that a solid-core sheet material can be obtained. The solid-core sheet material has sawing, nailing, and planning-feeling textures.The material is advantaged in low cost and environment friendliness. With the material, natural resource can be saved.

Owner:湖北格林森绿色环保材料股份有限公司

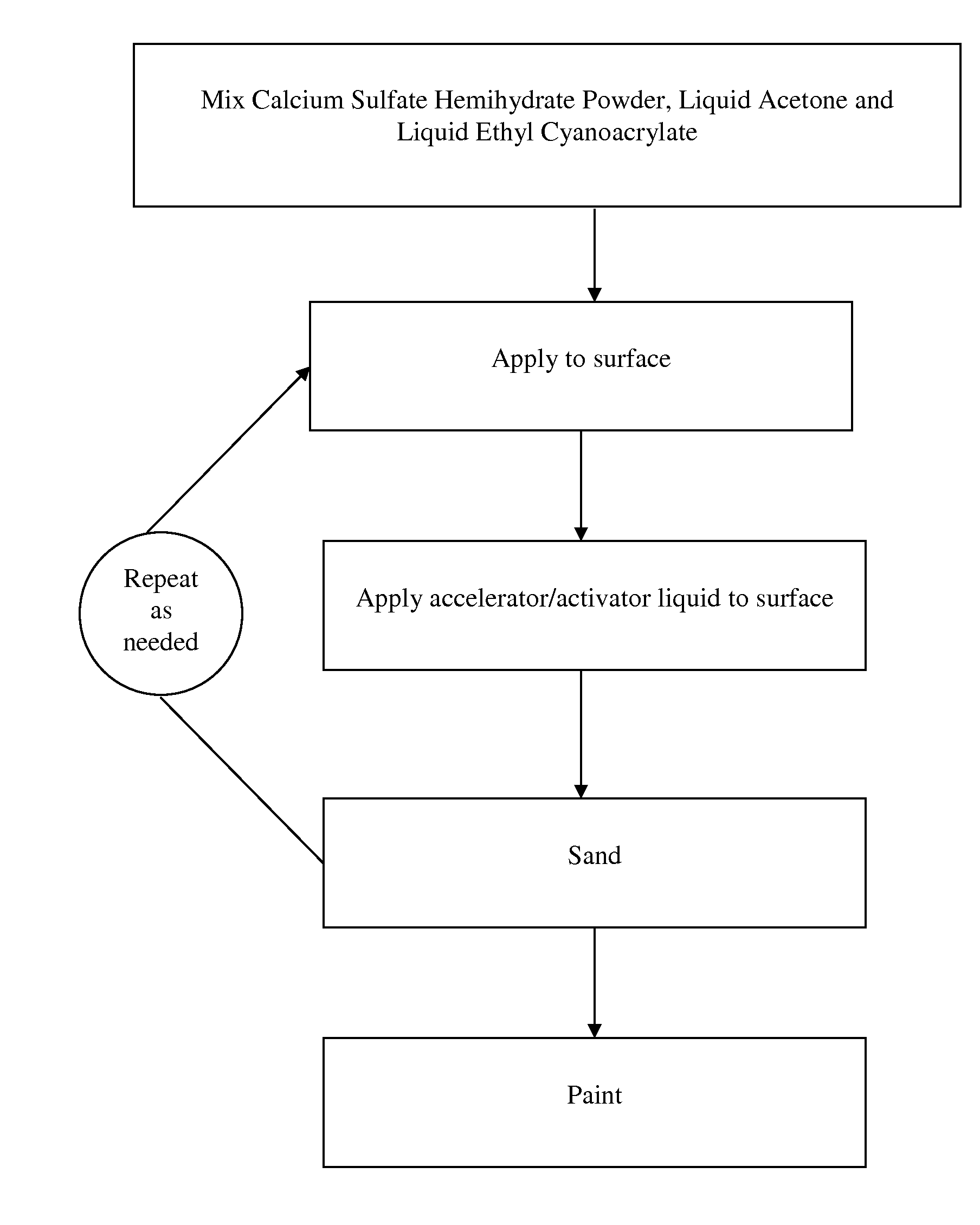

Non-aqueous rapid setting drywall compound and method of use

A non-aqueous drywall compound being the combination of a first component mixture of acetone, a non-aqueous liquid adhesive containing ethyl cyanoacrylate, and a powder containing calcium sulfate hemihydrate (plaster of Paris), the mixture being a pliable putty capable of adhering to gypsum wallboard or similar work surfaces. The second component of the drywall compound is an accelerator or activator containing acetone and toluene. The first component is applied to a defect in a work surface using a spreading tool and the second component is then applied to the exposed surface of the first component, such as by spraying or brushing, whereupon the drywall compound cures, hardens or sets within less than ten minutes to a state capable of being sanded into a smooth, hard surface and painted.

Owner:TRUDEAU WALTER

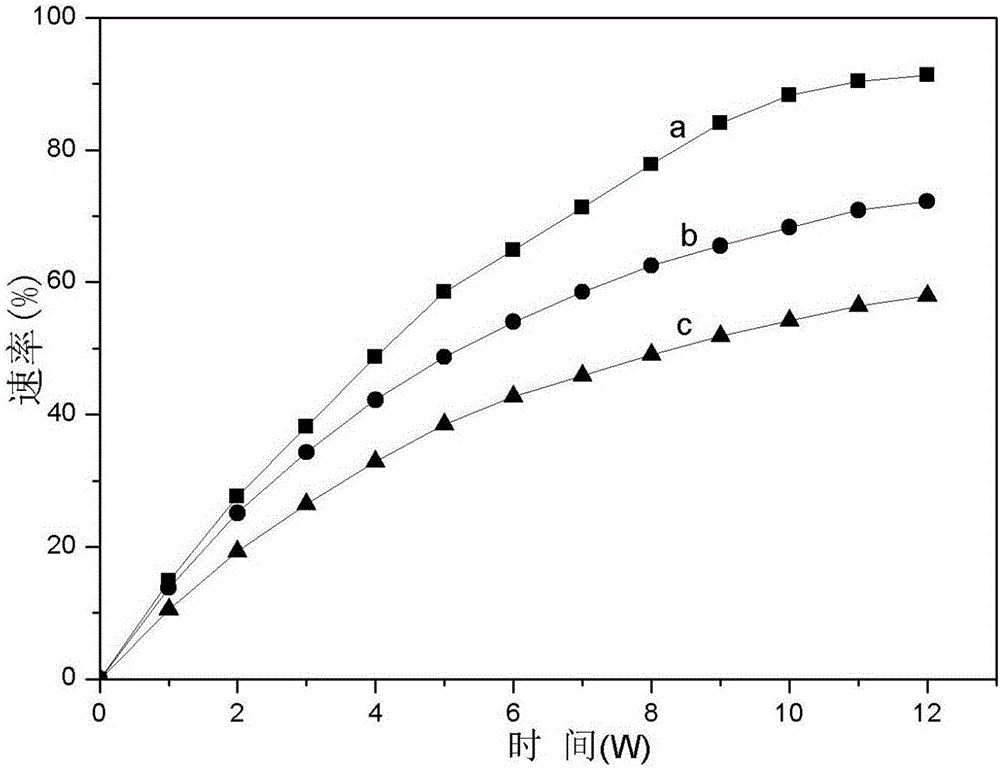

Calcium sulfate spherical particle alveolar bone repair material and preparation method and application thereof

ActiveCN103055345AImprove biological activityFully degradableProsthesisBULK ACTIVE INGREDIENTDrug biological activity

The invention relates to a calcium sulfate spherical particle alveolar bone repair material and a preparation method thereof. The calcium sulfate spherical particle alveolar bone repair material is mainly used for alveolar bone defect repair and also can be used for other bone defect repair, and belongs to the field of biomedical material. The calcium sulfate spherical particle alveolar bone repair material is characterized in that active ingredients are prepared from the following raw materials: (a) calcium sulfate, (b) molding liquid, and (c) surface modification liquid; and the size of the spherical particle is 0.5-2.0mm. The calcium sulfate is alpha type hemihydrate calcium sulfate powder. The surface modification liquid is soluble silicate aqueous solution. The calcium sulfate spherical particle alveolar bone repair material and the preparation method thereof have the following advantages: the provided calcium sulfate spherical particle alveolar bone repair material has the advantages of being excellent in biological activity, being capable of completely being degraded for a controllable period, and the like; good space can be provided for the growth of bone cells through big holes with the diameters of 183-732 microns produced by piling of spherical calcium sulfate particles in specific sizes; and the material is simple in preparation technology, short in preparation period and low in cost.

Owner:KUNMING UNIV OF SCI & TECH

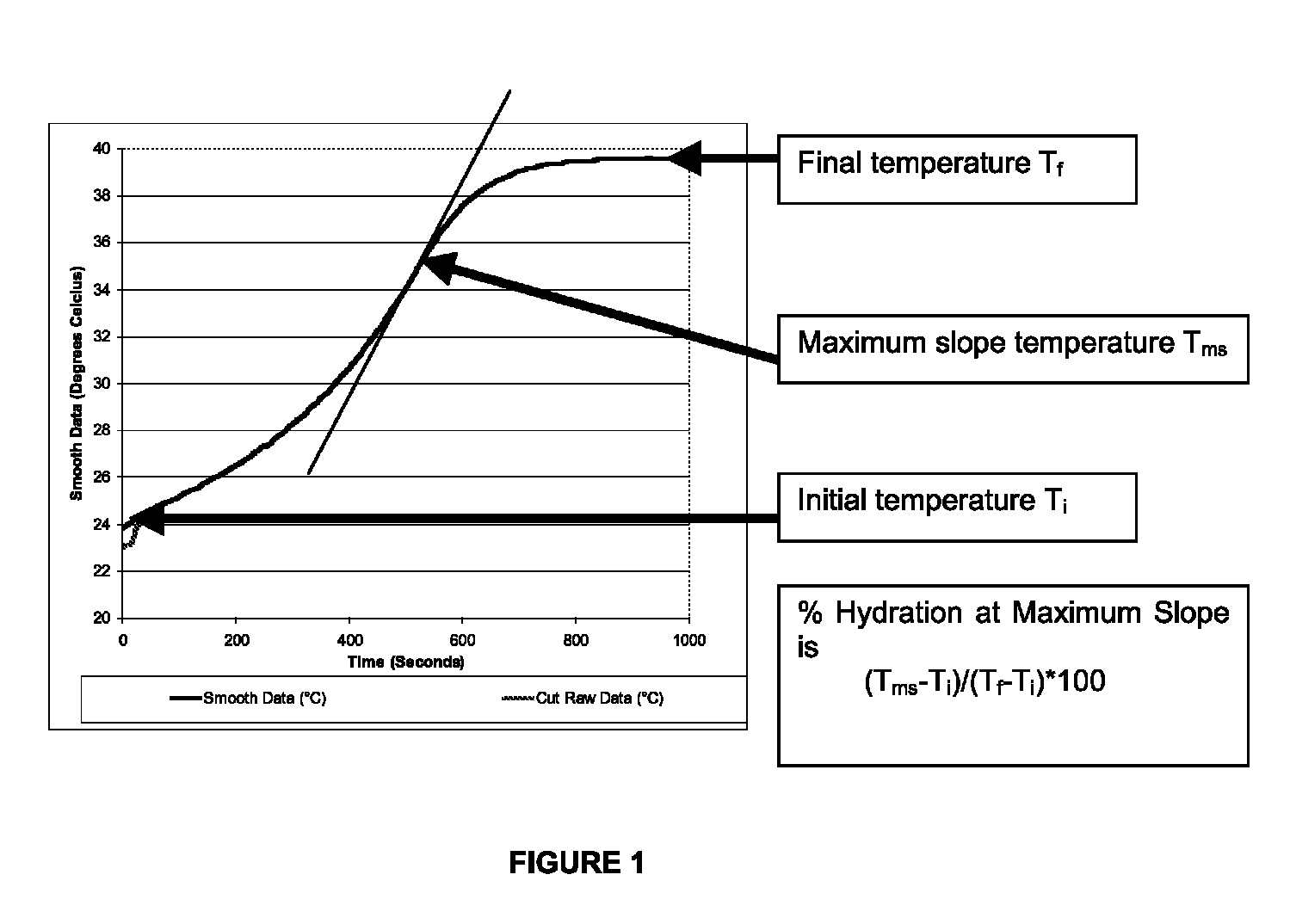

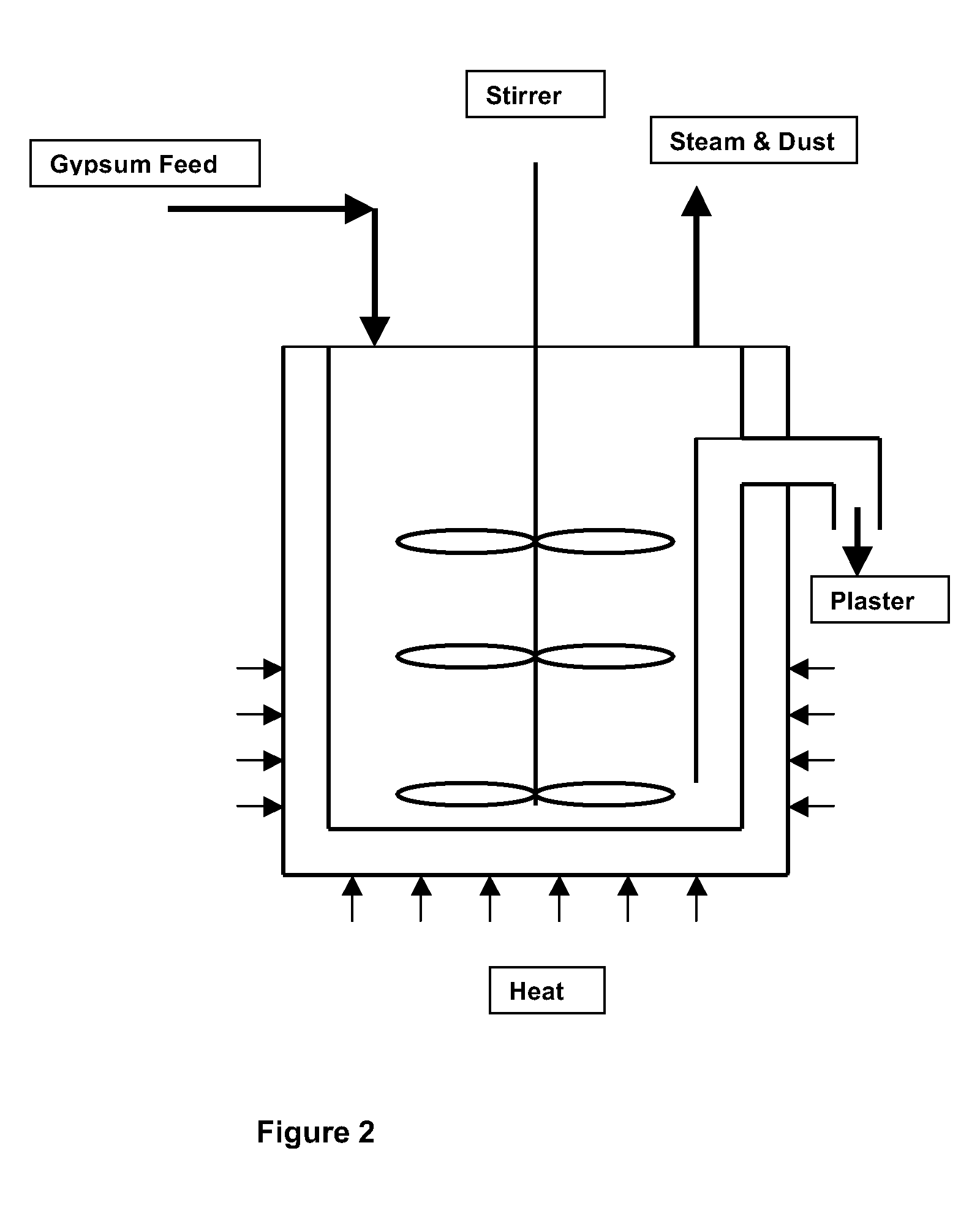

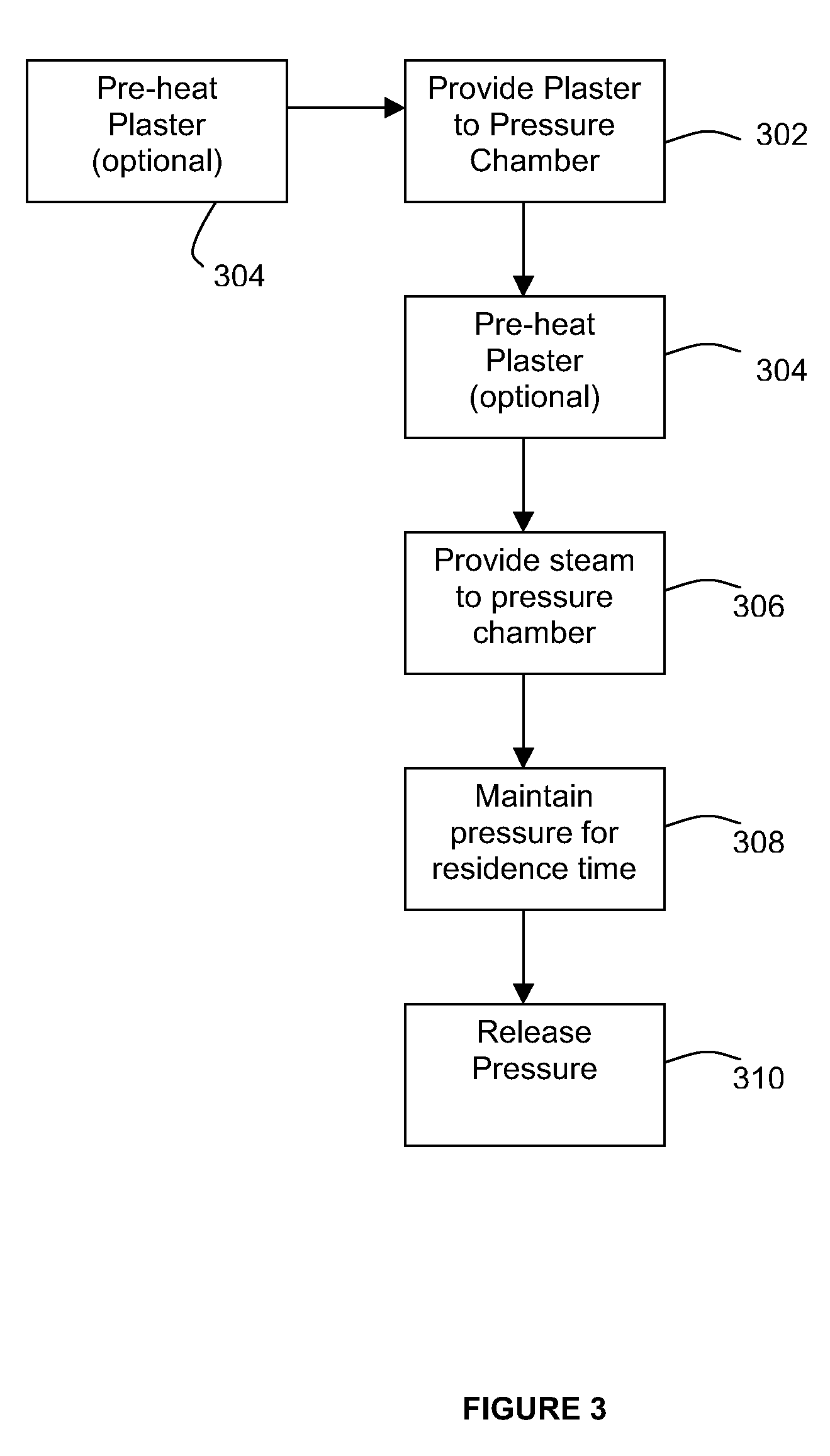

Calcium sulfate hemihydrate treatment process

ActiveUS7824490B2Reduce water demandReduces water demandCalcium/strontium/barium sulfatesHemihydrate Calcium SulfateEnvironmental engineering

A process for treating beta calcium sulfate hemihydrate is disclosed. The process comprises exposing beta calcium sulfate hemihydrate to steam at a pressure above atmospheric pressure.

Owner:GYPSUM THECHNOLOGIES INC

Calcium salt bone cement and preparation method thereof

InactiveCN106581746AImproving Distillation Transformation Reaction ProcessImprove the difficult problem of compactionPharmaceutical delivery mechanismTissue regenerationTri calcium phosphateMass content

The invention provides calcium salt bone cement and a preparation method thereof. The calcium salt bone cement comprises powder and a liquid; the powder comprises calcium sulfate hemihydrate and calcium phosphate; and the liquid is 0.05 to 5% of a sodium chloride solution or water. The calcium sulfate hemihydrates is prepared by crystal transformation, induced by calcium sulfate itself as a template, of calcium sulphate dehydrate, the hardening and difficult treatment problems of the calcium sulfate after the crystal transformation reaction can be improved, pressure is discharged rapidly, the temperature of the prepared calcium sulfate hemihydrate is kept not lower than the drying temperature, and the compressive strength of the calcium sulfate hemihydrate is enhanced. In the bone cement powder, a certain amount of calcium sulphate dehydrate powder is introduced into the prepared hemihydrate calcium sulfate powder, the percentage mass content of tricalcium phosphate in the bone cement is controlled for balancing, improvement and optimization of the injection and curing properties of the absorbable bone cement, the injection time of the bone cement is prolonged, the curing of the bone cement is accelerated, the compressive strength of the prepared bone cement is more than 15MPa, and the prepared bone cement can meet the needs of human cancellous bone repair, and is an excellent bone repair material.

Owner:山东明德生物医学工程有限公司

Citric acid half-H2O calcium sulphate bone substitute, its composition and its preparation method and uses

InactiveCN1879899AHas degradable absorption propertiesReduce heat productionProsthesisProphylactic treatmentHigh pressure

The invention relates to a citrate calcium sulfate skeleton replaceable material, relative compound, preparation and application, wherein it comprises: adding citrate into calcium sulphate dehydrate, or still adding metal crystallize agent, to mixed and arranged inside the vaporize kettle, to process high-temperature high-pressure reaction, to be obtained and dried. The invention can be used repair the skeleton, treat the osteoporosis, bone cancer, etc, with simple process, slow degrade speed, high strength, and low cost.

Owner:GENERAL HOSPITAL OF PLA

Method for preparing a-calcium sulfate hemihydrate with calcium sulfate dihydrate

ActiveUS20170247262A1Low raw material costDirectly appliedCalcium/strontium/barium sulfatesInorganic saltsOrganic acid

A method for preparing α-calcium sulfate hemihydrate with calcium sulfate dihydrate includes steps of: uniformly mixing the calcium sulfate dihydrate with an additive solution, and obtaining a mixture, wherein weight percentages of the calcium sulfate dihydrate and the additive solution in the mixture are respectively 90.00-95.00% and 5.00-10.00%, and the additive solution contains water, inorganic salt, organic salt, organic acid, surfactant, and seed crystal; rising a temperature of the mixture to 130-150° C., keeping for 20-120 minutes, and the calcium sulfate dihydrate in the mixture transforming to the α-calcium sulfate hemihydrate; drying the mixture after reaction at 105-160° C., and thereafter obtaining α-calcium sulfate hemihydrate product. The used calcium sulfate dihydrate can be natural raw materials and industrial by-products. The industrial by-products can be directly applied. Through utilizing characteristics of the industrial by-products, a dehydration reaction time and a drying time are shortened, and a product quality is obviously increased.

Owner:SHANDONG BORUI NEW MATERIAL TECH CO LTD

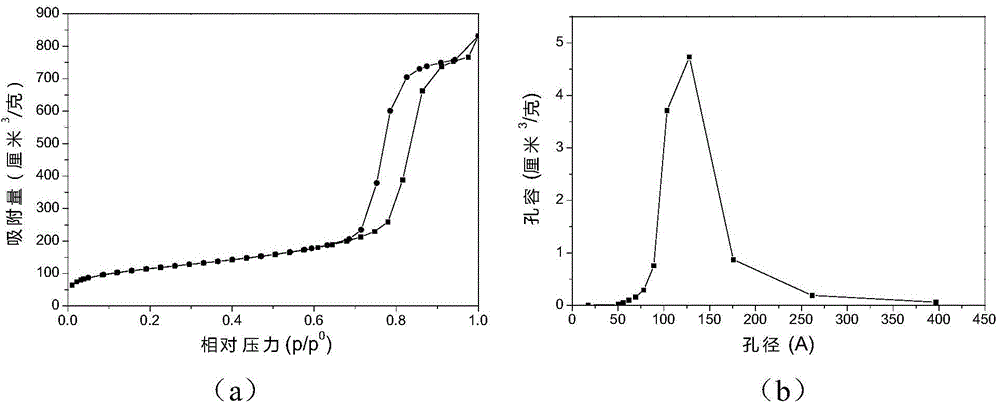

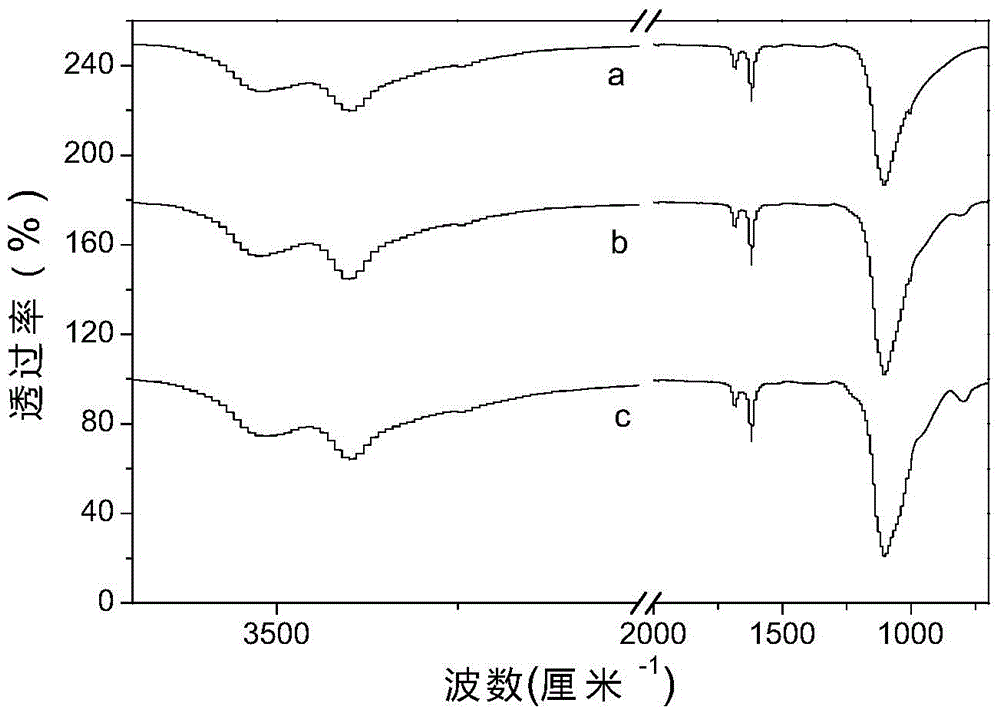

Mesoporous magnesium silicate-calcium sulfate hemihydrate composite material, and preparation method and application thereof

InactiveCN104649284AUniform mesopore size distributionSimple manufacturing processAlkaline-earth metal silicatesProsthesisPowder mixtureFiltration

The invention discloses a mesoporous magnesium silicate-calcium sulfate hemihydrate composite material, and a preparation method and application thereof. The preparation method comprises the following steps: (1) adding hydrochloric acid into a P123-water mixture, uniformly mixing, adding soluble magnesium salt, dropwisely adding TEOS (tetraethyl orthosilicate) into the solution, stirring until the solution has white turbidity, and continuing stirring to obtain a sol-gel white emulsion; (2) aging the white emulsion, carrying out vacuum filtration to remove the supernatant liquid, drying the precipitate, and sintering to obtain mesoporous magnesium silicate; and mixing the mesoporous magnesium silicate-calcium sulfate hemihydrate powder mixture with a solidifying solution, carrying out compression molding, solidifying and baking to obtain the calcium sulfate hemihydrate composite material. The calcium sulfate hemihydrate composite material has favorable application prospects in bone prosthesis, has favorable bioactivity and biocompatibility especially when being used as bone cement, and can stimulate the bone growth and shorten the healing time after implanting the material into the bone.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of alpha-calcium sulfate hemihydrate crystal whisker by one-step autocatalysis and application thereof

InactiveCN104562209AUniform sizeReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsPtru catalystWater of crystallization

The invention provides a preparation method of an alpha-calcium sulfate hemihydrate crystal whisker by one-step autocatalysis, belonging to the field of materials. The method comprises the following steps: reacting calcium chloride and anhydrous sodium sulfate to obtain calcium sulfate dihydrate; and by using the byproduct sodium chloride in the reaction as a catalyst (crystal transforming agent) to accelerate the next reaction, carrying out normal-temperature hydrothermal reaction under the condition of high-speed stirring under the action of sodium chloride to remove 1.5-molecule crystalline water, thereby obtaining the alpha-calcium sulfate hemihydrate crystal whisker. The alpha-calcium sulfate hemihydrate crystal whisker has uniform particle size. The reaction process is an autocatalysis process without adding any additional crystal transforming agent, thereby effectively solving the problems of complex reaction system, higher cost and difficulty in operation in the alpha-calcium sulfate hemihydrate crystal whisker production process. The method is convenient for production and application, has the characteristics of low vacuum, low energy consumption and low pollution, conforms to the material synthesis requirements by the soft processing mode, and has wide application prospects.

Owner:HENAN INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com