Injectable bone cement containing strontium and preparation method of bone cement

A bone cement and strontium source technology, applied in the field of strontium-containing injectable bone cement and its preparation, can solve the problems of non-absorption and degradation, weak integration with bone, and no osteogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

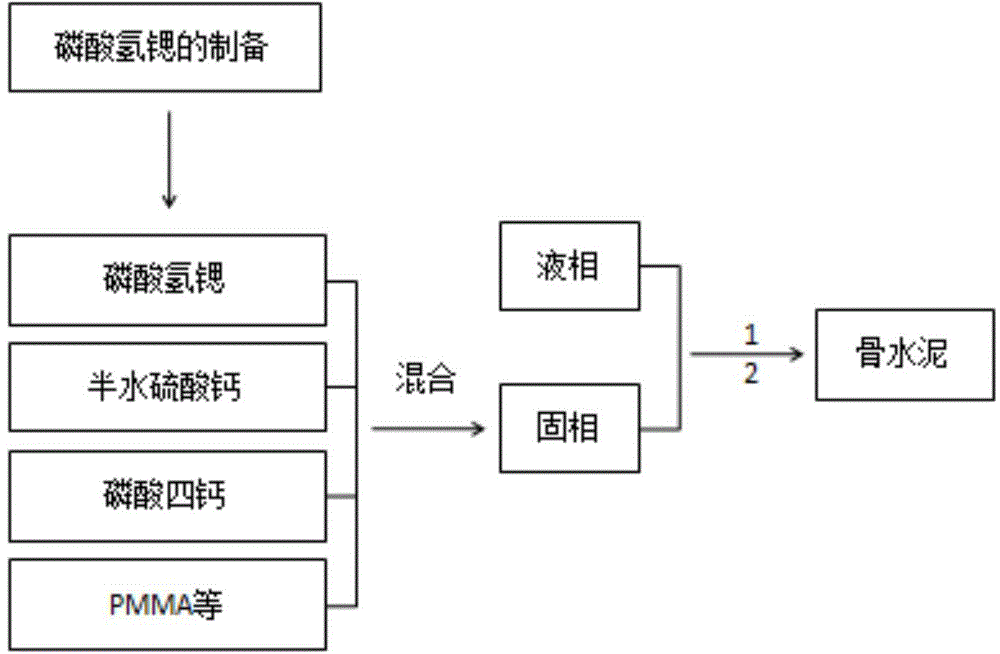

Method used

Image

Examples

Embodiment 1

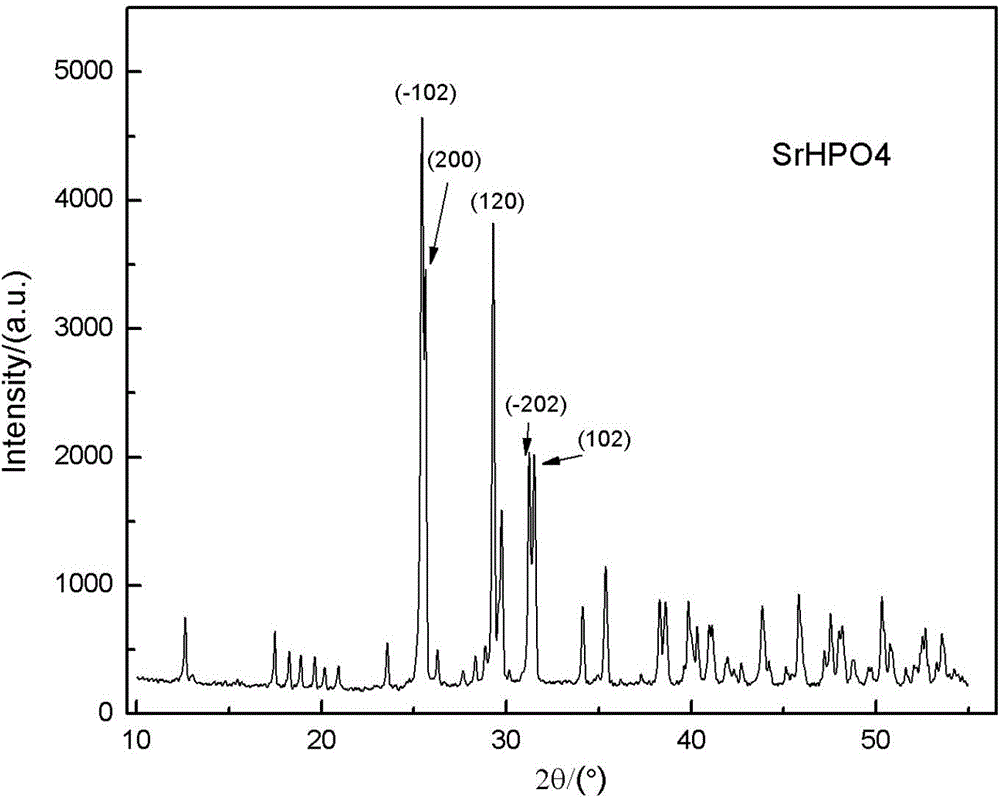

[0035] (1) The preparation method of strontium hydrogen phosphate powder: configure 200ml of 0.5mol / L strontium nitrate solution, and add 0.6mol urea into it and stir to dissolve to obtain A solution; configure 200ml of 0.5mol / L diammonium hydrogenphosphate solution, Obtain B solution; Pour B solution into A solution, stir and mix, the solution becomes a turbid suspension, add concentrated nitric acid (65-68%), adjust the pH value to 2, the solution becomes clear; put the clear solution into In a water bath at 80°C, react at a constant temperature for 4 hours, pour out the supernatant, wash repeatedly, filter the white precipitate, dry and grind at a constant temperature in an oven at 100°C to obtain a powder product. The prepared product was characterized by XRD, as attached figure 1 As shown, the absorption peak corresponds well to the standard peak (PDF33-1335), and it can be determined that the prepared product is strontium hydrogen phosphate.

[0036] (2) The preparation...

Embodiment 2

[0039](1) The preparation method of strontium hydrogen phosphate powder: configure 200ml of 0.3mol / L strontium nitrate solution, add 0.3mol urea into it and stir to dissolve to obtain A solution; configure 200ml of 0.3mol / L diammonium hydrogenphosphate solution, Obtain B solution; Pour B solution into A solution, stir and mix, the solution becomes a turbid suspension, add concentrated nitric acid (65-68%), adjust the pH value to 2, the solution becomes clear; put the clear solution into In a water bath at 90°C, react at a constant temperature for 3 hours, pour out the supernatant, wash repeatedly, filter the white precipitate with suction, dry and grind at a constant temperature in an oven at 85°C to obtain a powder product. According to Example 1, the product was subjected to phase analysis.

[0040] (2) The preparation method of bone cement: at room temperature, according to proportioning, take by weighing 5.75gPMMA (57.5%) respectively, 0.25gBPO (2.5%), CSH (2.1g, 60%) of 3...

Embodiment 3

[0042] (1) The preparation method of strontium hydrogen phosphate powder: configure 200ml of 0.05mol / L strontium nitrate solution, and add 0.04mol urea into it and stir to dissolve to obtain A solution; configure 200ml of 0.05mol / L diammonium hydrogenphosphate solution, Obtain B solution; Pour B solution into A solution, stir and mix, the solution becomes a turbid suspension, add concentrated nitric acid (65-68%), adjust the pH value to 3, the solution becomes clear; put the clear solution into In a water bath at 100°C, react at a constant temperature for 2 hours, pour out the supernatant, wash repeatedly, filter the white precipitate with suction, dry and grind at a constant temperature in an oven at 85°C to obtain a powder product. According to Example 1, the product was subjected to phase analysis.

[0043] (2) The preparation method of bone cement: at room temperature, according to proportioning, take by weighing 4.95gPMMA (49.5%) respectively, 0.05gBPO (0.5%), CSH (1.35g,...

PUM

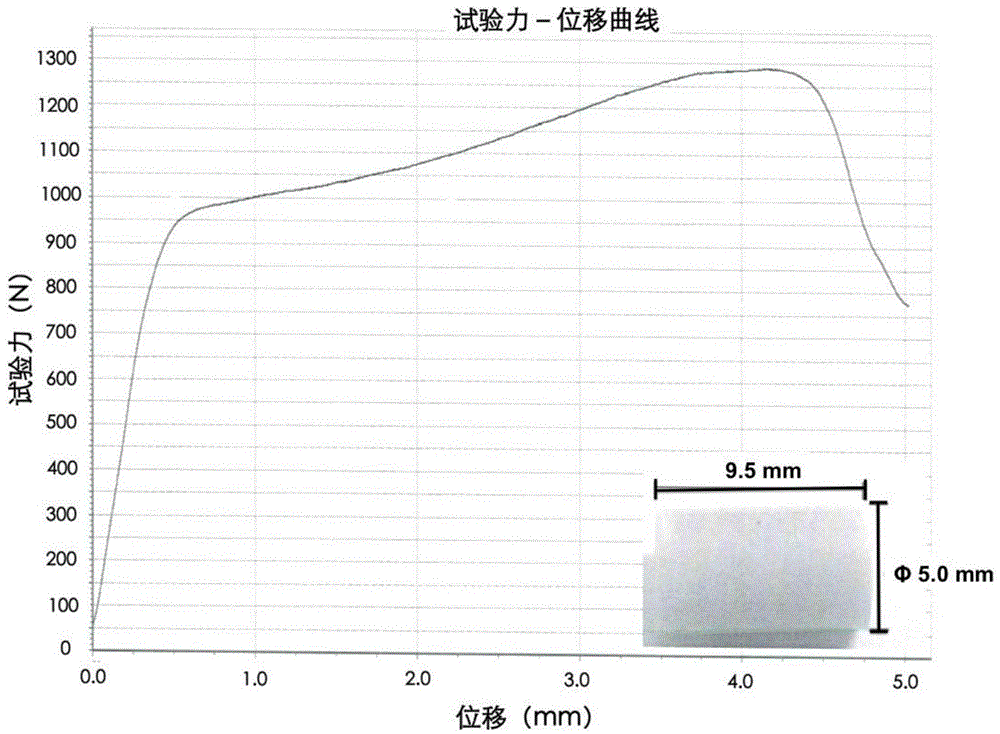

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com