Calcium sulfate semihydrate group combined self-curing bio-active material, preparation and application thereof

A calcium sulfate hemihydrate, bioactive technology, applied in the field of human hard tissue defect filling repair materials, human bone and tooth defect filling and repairing bioactive materials, can solve the lack of long-term structural support, poor injectability of bone cement paste, Metabolism and other issues, to achieve excellent biological activity and biocompatibility, excellent biological performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Blending liquid preparation

[0042] Weigh 1.0 g of analytically pure sodium bicarbonate and dissolve it in 99.0 mL of deionized water to obtain a 1.0% sodium bicarbonate solution, sterilize, seal it in a sterile bottle, and set aside.

[0043] 2) Preparation of β-calcium sulfate hemihydrate / tricalcium silicate composite bone defect filling material:

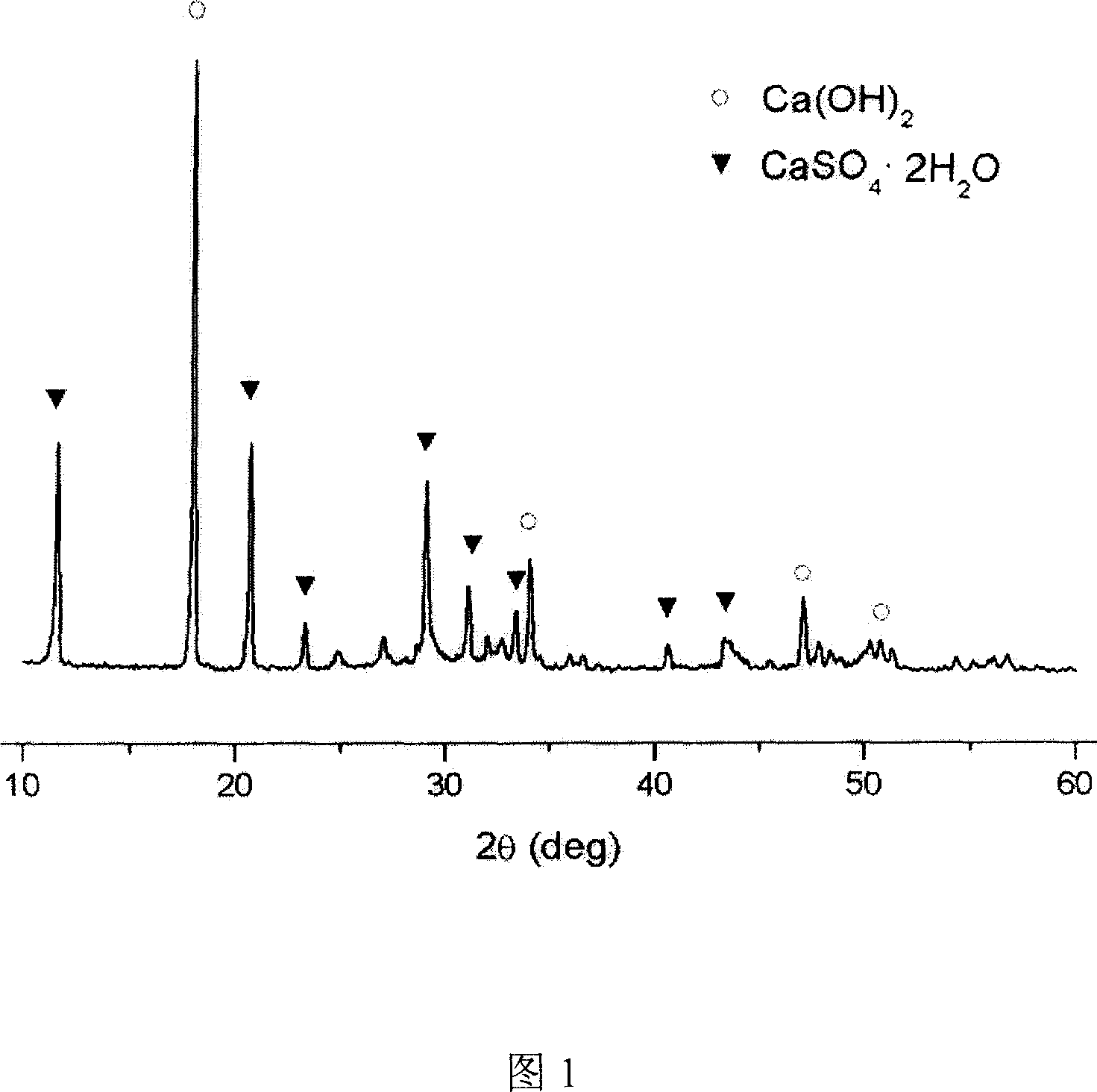

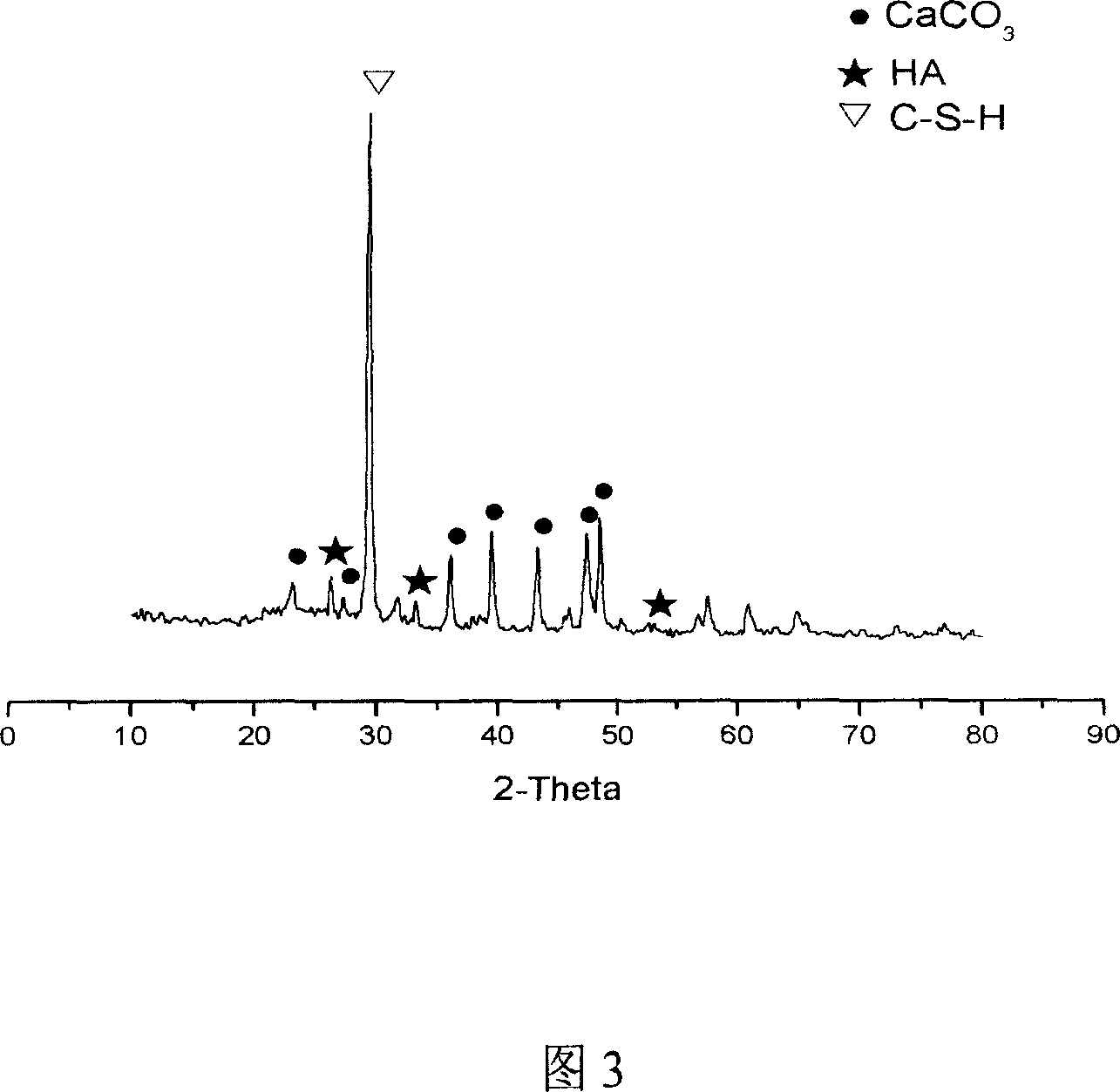

[0044] The β-calcium sulfate hemihydrate / tricalcium silicate composite material powder with a tricalcium silicate content of 20wt.% and the blending solution are fully blended at a ratio of liquid-solid mass ratio of 1.0:1 for 0.5-1 minute, and injected into the mold. Cured at 37°C and 100% humidity for more than 7 days (see Figure 1 for the XRD figure), and then the mold was released to obtain the β-calcium sulfate hemihydrate / tricalcium silicate composite pellets ( CSH / C 3 Spellets). The compressive strength of the pellets can reach 7.0-9.0 MPa, and the degradation rate can reach over 90% after 21 days, while havi...

Embodiment 2

[0046] 1) Blending liquid preparation

[0047] Weigh 1.0 g of analytically pure sodium bicarbonate and dissolve it in 99.0 mL of deionized water to obtain a 1.0% sodium bicarbonate solution, sterilize, seal it in a sterile bottle, and set aside.

[0048] 2) Preparation of β-calcium sulfate hemihydrate / tricalcium silicate composite self-curing material:

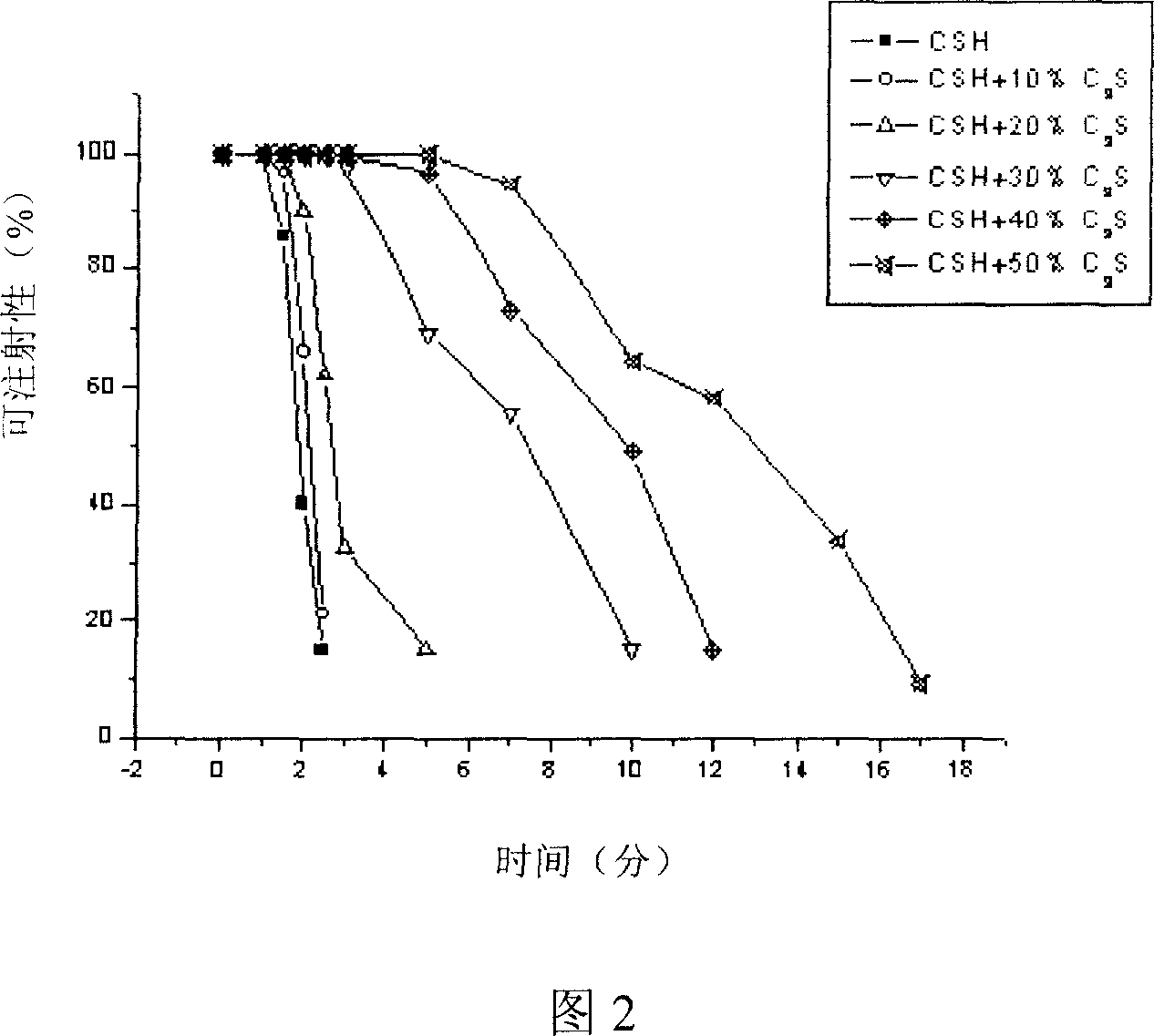

[0049] Fully blend the β-calcium sulfate hemihydrate / tricalcium silicate composite material powder with a tricalcium silicate content of 40wt.% and the blending solution at a ratio of liquid-solid mass ratio of 1.0:1 for 0.5-1 minute to obtain a usable β-calcium sulfate hemihydrate / tricalcium silicate composite self-curing material for minimally invasive treatment. The self-curing material can reach the initial setting in about 18 minutes after being injected into the defect site, the self-curing material slurry can be injected within 15 minutes, the compressive strength of the self-curing material can reach 10.0-12.0MPa, and...

Embodiment 3

[0051] 1) Blending liquid preparation

[0052] Weigh 1.0 g of analytically pure sodium bicarbonate and dissolve it in 99.0 mL of deionized water to obtain a 1.0% sodium bicarbonate solution, sterilize, seal it in a sterile bottle, and set aside.

[0053] 2) Preparation of β-calcium sulfate hemihydrate / tricalcium silicate composite degradable material

[0054] The β-calcium sulfate hemihydrate / tricalcium silicate composite material powder with a tricalcium silicate content of 30wt.% and the blending solution are fully blended for 0.5-1 minute according to the ratio of liquid-solid mass ratio of 0.8:1, according to the embodiment 1, the β-calcium sulfate hemihydrate / tricalcium silicate composite particle used for bone defect repair materials can be obtained, the compressive strength can reach 10.0-12MPa, and the degradation rate can reach more than 90% after 21 days; The tricalcium acid content is 30wt.% β-calcium sulfate hemihydrate / tricalcium silicate composite material powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com