Algae calcium compound material, decorative panel and production method

A technology of composite materials and algae calcium, which is applied in the field of building materials, can solve the problems that the crystal transformation technology has not been reported in the literature, the product performance is low, the weather resistance is low, and the technology is not integrated. It achieves significant surface activity and adsorption, good mechanical properties, and excellent The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

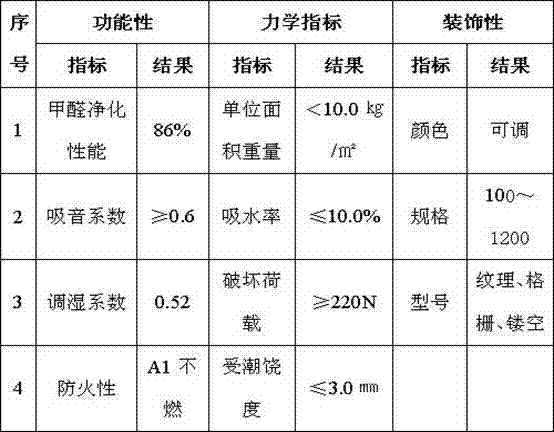

[0034] 1. Formula composition (substances are measured in parts by weight):

[0035] (1) 100 parts of natural β-calcium sulfate hemihydrate (or calcium phosphate, calcium aluminate);

[0036] (2) Modified diatomite: 15 parts of ground diatomite powder with a particle size of 400-1000 mesh;

[0037] (3) Reinforced fiber chopped strands: 1.5 parts of non-alkali glass fiber with a length of 18-20 mm;

[0038] (4) Water-based glue solution: 62 parts of dispersible latex powder aqueous solution with a weight concentration of 1.0%;

[0039] (5) Chemical modifier: 5 parts, compounded before use, compounded composition: 100 parts of water, 0.8 parts of potassium citrate, 0.7 parts of potassium aluminum sulfate, 0.5 parts of silicon alkoxide, and 0.5 parts of tributyl phosphate .

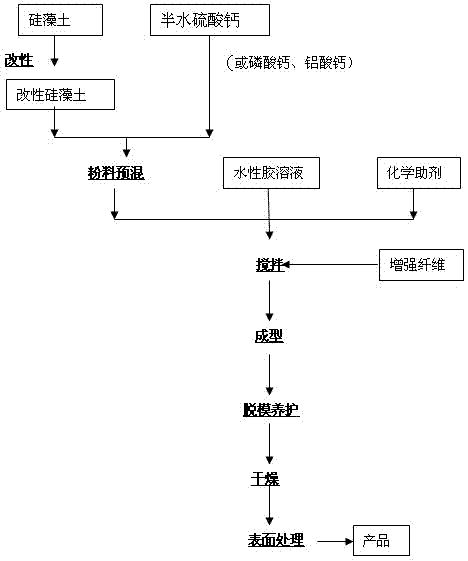

[0040] 2. Production and preparation process:

[0041] (1) Raw material pretreatment: β-calcium sulfate hemihydrate (or calcium phosphate, calcium aluminate) and diatomite are pre-mixed at a ratio of 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com