Preparation method of calcium sulfate hemihydrate crystal whiskers high in length diameter ratio

A technology of calcium sulfate hemihydrate and calcium sulfate whiskers, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as uneven morphology, small long diameter, and coexistence of agglomerates, and achieve product The effect of regular shape, large aspect ratio and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

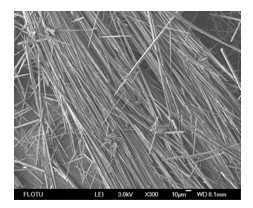

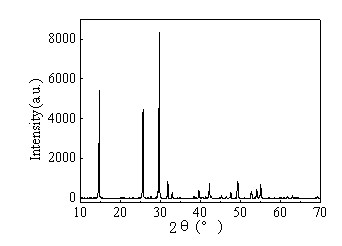

[0020] Embodiment 1: the preparation method of this high aspect ratio calcium sulfate hemihydrate whisker , Specific steps are as follows:

[0021] Prepared with 1.5 mol / L Ca(NO 3 ) 2 A solution of 30 mL and 1.5 mol / L (NH 4 ) 2 SO 4 60 mL of the solution of (NH 4 ) 2 SO 4 The solution was added (8 mL / min) Ca(NO 3 ) 2 solution, maintaining Ca(NO 3 ) 2 : (NH 4 ) 2 SO 4 The molar ratio was 1:2 to obtain a white precipitate, which was filtered and washed until the pH was neutral to obtain a primary precursor; the primary precursor was activated at 150°C for 1 hour to obtain a hydrothermal precursor; the hydrothermal precursor was formulated into 12 The suspension slurry with % solid content was placed in a hydrothermal reaction kettle, and 10 wt% ferric nitrate as a precursor was added. After sealing, the temperature was raised (10 ℃ / min) to 80 ℃, and the reaction was performed at a constant temperature under the condition of stirring (120 rpm / min). After cooling f...

Embodiment 2

[0022] Embodiment 2: the preparation method of this high aspect ratio calcium sulfate hemihydrate whisker , Specific steps are as follows:

[0023] Formulated with saturated Ca(OH) 2 and 0.2 mol / L H 2 SO 4 60 ml of the solution of H 2 SO 4 The solution was added dropwise (1 mL / min) to saturated Ca(OH) 2 solution, maintaining Ca(OH) 2 : H 2 SO 4 The molar ratio is 1:0.5 to obtain a white precipitate, which is filtered and washed until the pH is neutral to obtain a primary precursor; the primary precursor is activated at 40°C for 6 hours to obtain a hydrothermal precursor; the hydrothermal precursor is made into 1 The suspension slurry with % solid content is placed in a hydrothermal reaction kettle, and 0.1wt% ferric chloride is added as a precursor. After sealing, the temperature is raised (10 ℃ / min) to 180 ℃, and the temperature is kept constant under stirring (120 rpm / min). After reacting for 2 h, cooling, filtering, and washing until the pH was neutral, the hydrot...

Embodiment 3

[0024] Embodiment 3: the preparation method of this high aspect ratio calcium sulfate hemihydrate whisker , Specific steps are as follows:

[0025] Prepared with 0.8 mol / L CaCl 2 and 0.8 mol / L Na 2 SO 4 60 ml of the solution of Na 2 SO 4 The solution was added (10 mL / min) with CaCl 2 solution, maintaining CaCl 2 : Na 2 SO 4 The molar ratio is 1:1 to obtain a white precipitate, which is filtered and washed until the pH is neutral to obtain a primary precursor; the primary precursor is activated at 110°C for 3 hours to obtain a hydrothermal precursor; the hydrothermal precursor is made into 3 The suspended slurry with a solid content of % is placed in a hydrothermal reaction kettle, and 4.6 wt% ferric sulfate is added as a precursor. After sealing, the temperature is raised (10°C / min) to 130°C, and the temperature is reacted under the condition of stirring (120 rpm) After cooling for 4 h, filtering, and washing until the pH was neutral, the hydrothermal product was obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com