Calcium salt bone cement and preparation method thereof

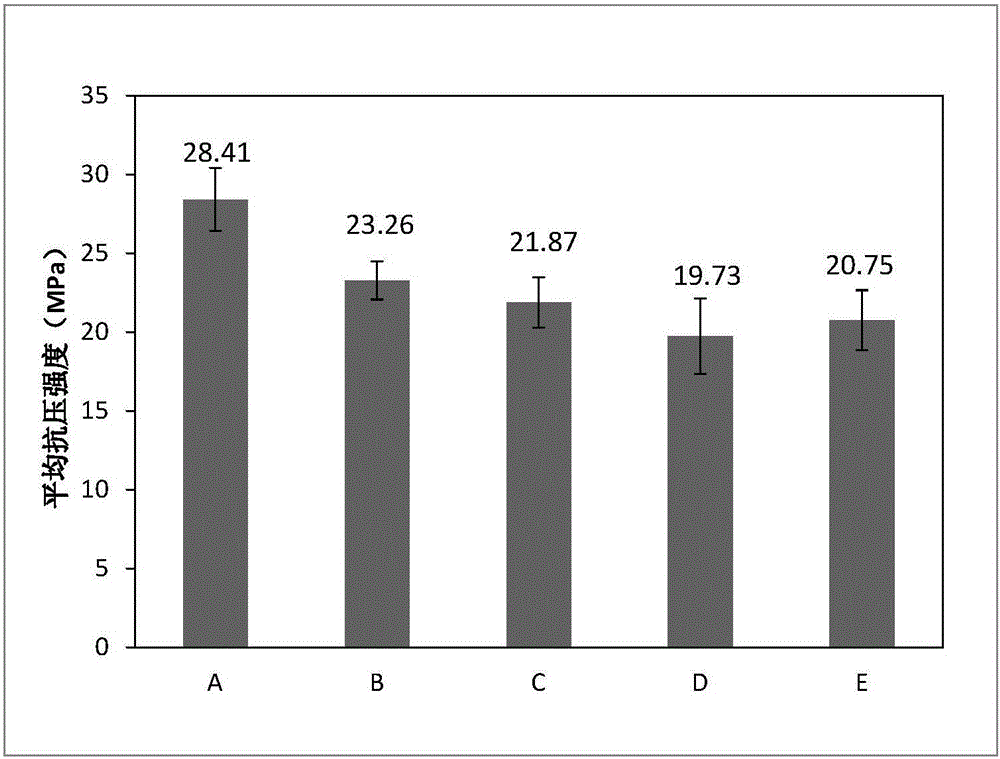

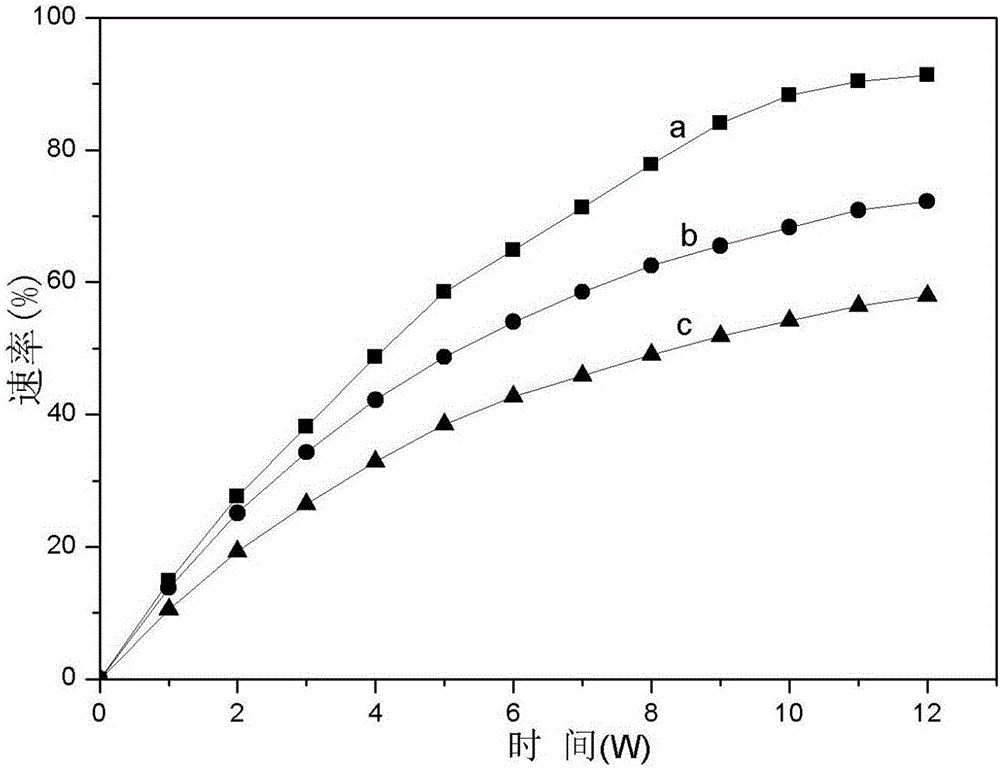

A technology of bone cement and calcium salt, which is applied in the fields of medical formula, medical science, tissue regeneration, etc. It can solve the problems of increasing the contact area between calcium sulfate and steam environment, reducing the mechanical properties of bone cement, and the strength cannot reach the strength, etc., to achieve Improve injectability and curing performance, accelerate curing, and enhance compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

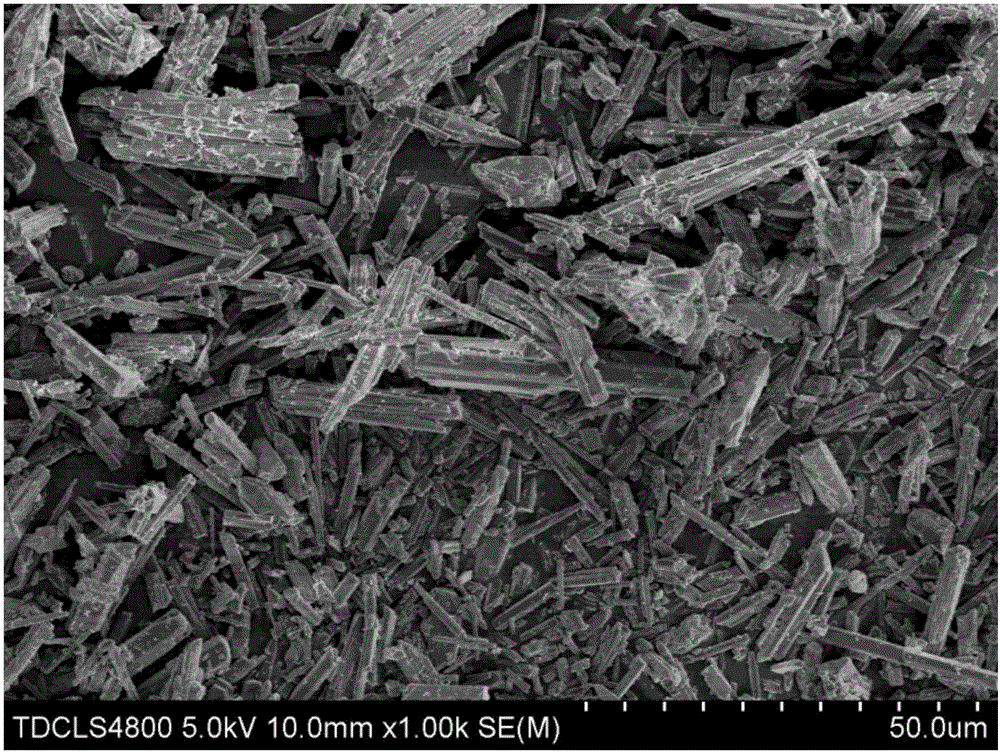

[0032] The bone cement powder is composed of 95% calcium sulfate hemihydrate and 5% calcium phosphate tribasic, wherein 0.5% calcium sulfate dihydrate is added to the calcium sulfate hemihydrate; The particle size distribution range of calcium is 0.5-50 μm; the bone cement liquid is 0.05% sodium chloride liquid.

[0033] Bone cement was prepared according to the following steps:

[0034] (1) The mixture of calcium sulfate is put into the distillation device, and the temperature is 200°C, and the pressure is 10MPa in a reactor for crystallization reaction, and the reaction time is 2h; in the calcium sulfate mixture, the mass percentage of calcium sulfate dihydrate is 95%, calcium sulfate hemihydrate is 5%;

[0035] (2) After the reaction, the discharge pressure is put into an oven at 130° C. for drying, and the grinding is uniform to obtain calcium sulfate hemihydrate powder; during the discharge pressure, keep the temperature of calcium sulfate hemihydrate as 150° C.;

[003...

Embodiment 2

[0042] The bone cement powder is composed of 90% calcium sulfate hemihydrate and 10% calcium phosphate tribasic in mass percentage, wherein 2% calcium sulfate dihydrate is added to the calcium sulfate hemihydrate; The particle size distribution range of calcium is 1-20 μm; the bone cement liquid is 1% sodium chloride liquid.

[0043] Bone cement was prepared according to the following steps:

[0044] (1) The mixture of calcium sulfate is put into the distillation device, and the temperature is 140° C., and the pressure is 0.53 MPa in a reactor for crystallization reaction, and the reaction time is 5 hours; in the calcium sulfate mixture, the mass percentage of calcium sulfate dihydrate The content is 99%, calcium sulfate hemihydrate is 1%;

[0045] (2) After the reaction, the discharge pressure is put into an oven at 107° C. for drying, and the grinding is uniform to obtain calcium sulfate hemihydrate powder; during discharge pressure, the temperature of calcium sulfate hemih...

Embodiment 3

[0049] The bone cement powder is composed of 50% calcium sulfate hemihydrate and 50% tricalcium phosphate, wherein 5% anhydrous calcium sulfate is added to the calcium sulfate hemihydrate; The particle size distribution range of calcium is 5-20 μm; the bone cement liquid is 5% sodium chloride liquid.

[0050] Bone cement was prepared according to the following steps:

[0051] (1) Calcium sulfate dihydrate is put into the distillation device, and the temperature is 132°C, and the pressure is 0.2MPa in a reaction kettle, and the reaction time is 4h;

[0052] (2) After the reaction, the discharge pressure is put into an oven at 110° C. for drying, and the grinding is uniform to obtain calcium sulfate hemihydrate powder; during discharge pressure, the temperature of calcium sulfate hemihydrate is kept at 110° C.;

[0053] (3) Weigh the corresponding powder according to the mass percentage of calcium sulfate hemihydrate and calcium phosphate and mix evenly, and add the liquid into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com