3D (three-dimensional) printing mesoporous bioactivity glass modified biological ceramic support, and preparation method and application thereof

A technology of bioactive glass and bioceramics, which is applied in medical science, prosthesis, additive processing, etc., can solve the problems of lack of micro-nano structure, lack of multi-functionality, and unsatisfactory interfacial activity, and achieve good mechanical properties and process simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

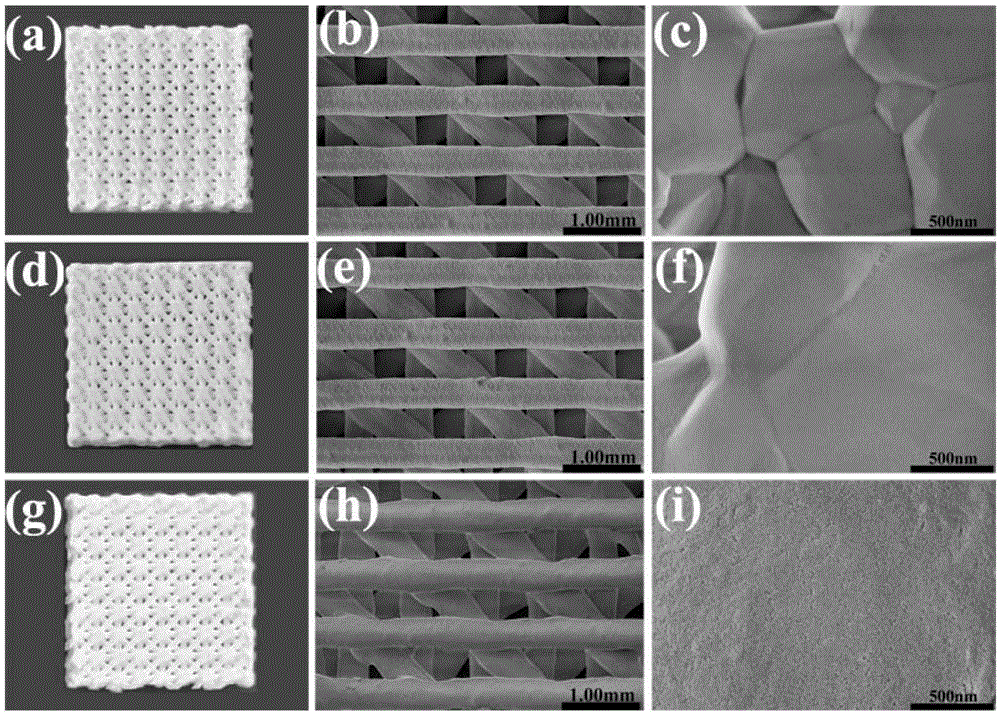

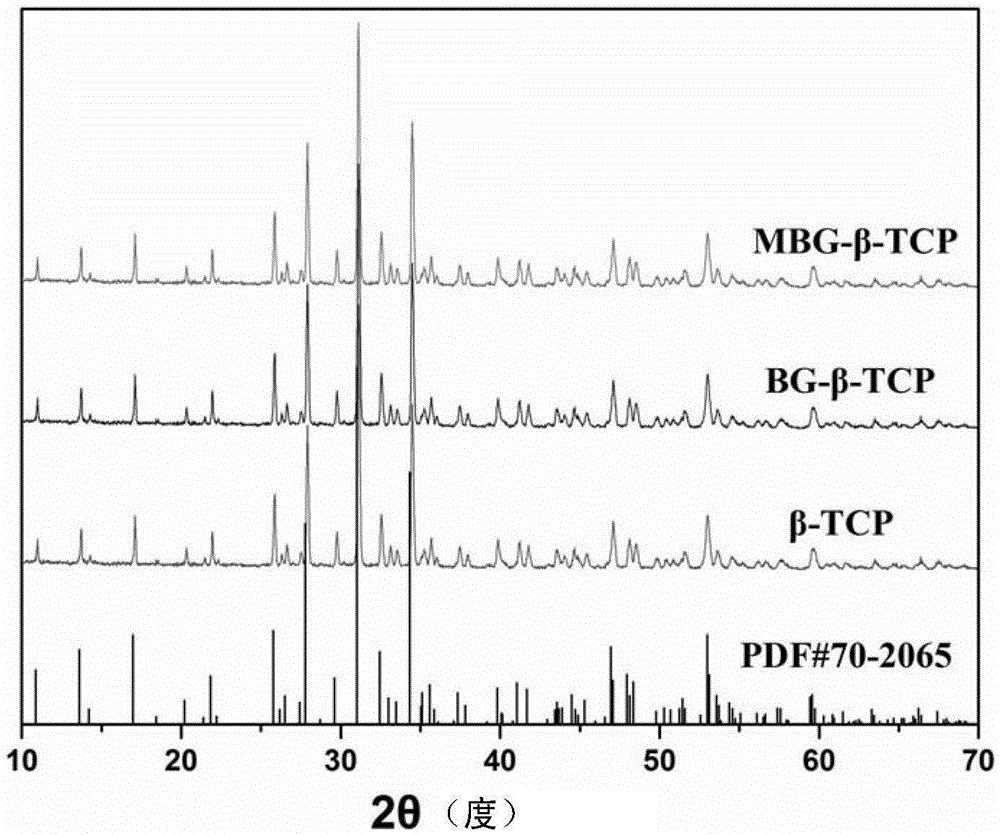

[0066] (1) Mix 6g P123 with 90g ethanol, dissolve and stir for 1 hour, add 2.1g 10.05g ethyl orthosilicate, calcium nitrate tetrahydrate, 1.10g triethyl phosphate, 1.5g hydrochloric acid and stir for 24 hours to obtain mesoporous biological activity glass precursor;

[0067] (2) 4.5g of pure β-tricalcium phosphate powder, after fully mixing with 3g of PVA, use three-dimensional printing technology to prepare scaffold materials;

[0068] (3) Calcining the printed scaffold at 1100°C for 3 hours to obtain a pure β-tricalcium phosphate ceramic scaffold;

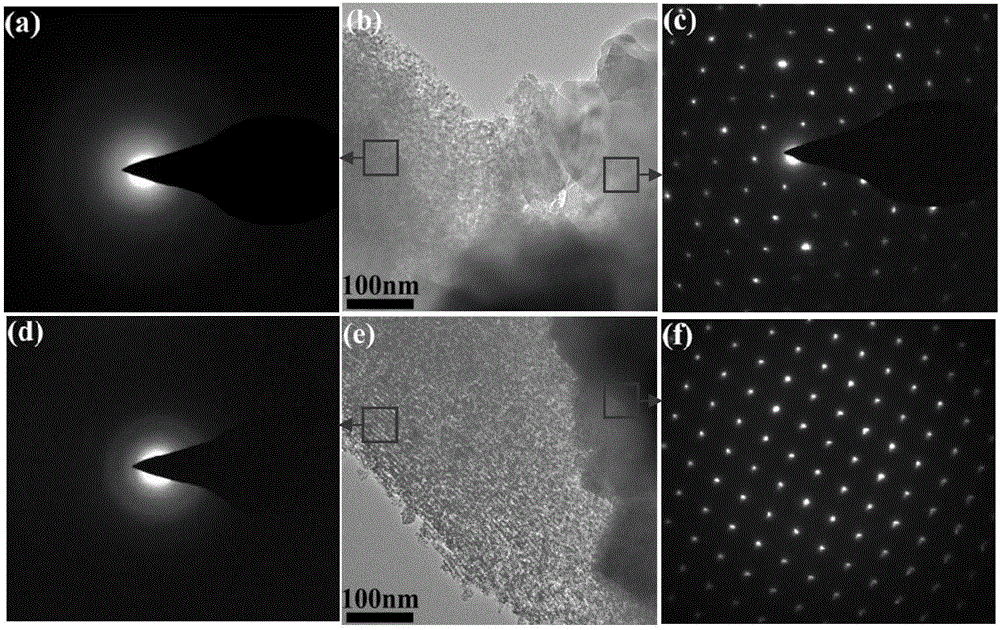

[0069] (4) The mesoporous bioactive glass precursor was spin-coated on the surface of the pure β-TCP scaffold for 3 times, and sintered at 650°C for 5 hours to obtain the mesoporous bioactive glass-on-β-TCP ceramic scaffold.

[0070] Mechanical properties, osteogenic activity and angiogenic activity were then evaluated as described above. For the structural and performance characterization of the mesoporous bioactive glass modi...

Embodiment 2

[0072] (1) Mix 6g P123 with 100g ethanol, dissolve and stir for 1 hour, add 10.05g ethyl orthosilicate, 2.1g calcium nitrate tetrahydrate, 1.10g triethyl phosphate, 1.5g hydrochloric acid and stir for 24 hours to obtain mesoporous biological activity glass precursor;

[0073] (2) 4.5g of pure β-tricalcium phosphate powder, after fully mixing with 2g of PVA, use three-dimensional printing technology to prepare scaffold materials;

[0074] (3) Calcining the printed scaffold at 1150°C for 3 hours to obtain a pure β-tricalcium phosphate ceramic scaffold;

[0075] (4) The mesoporous bioactive glass precursor was spin-coated on the surface of the pure β-TCP scaffold for 6 times, and sintered at 600°C for 6 hours to obtain the mesoporous bioactive glass-modified β-TCP ceramic scaffold.

[0076] Mechanical properties, osteogenic activity and angiogenic activity were then evaluated as described above. The results also confirmed that the modification of the mesoporous bioactive glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com