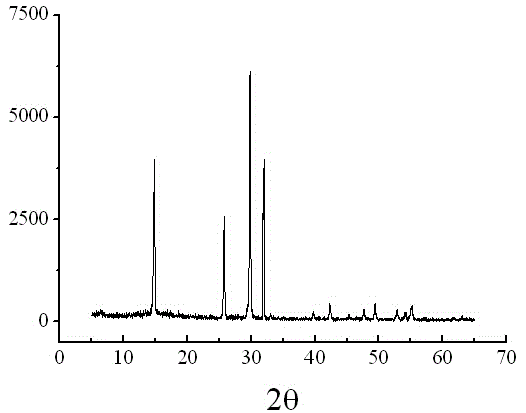

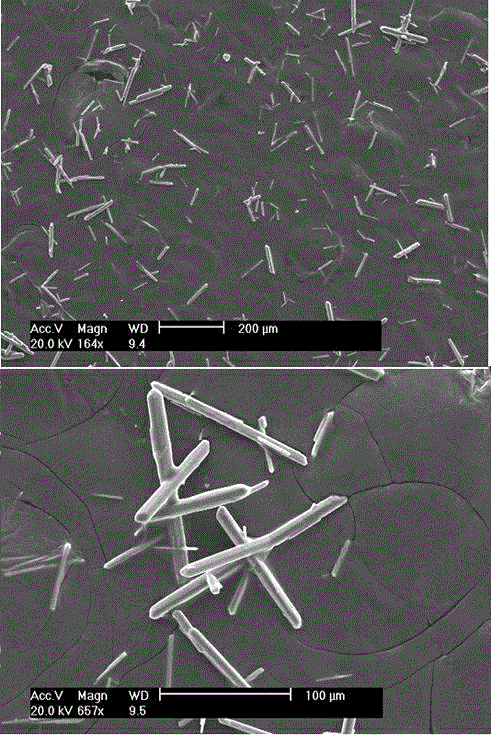

Preparation method of alpha-calcium sulfate hemihydrate crystal whisker by one-step autocatalysis and application thereof

A calcium sulfate hemihydrate and autocatalysis technology, applied in the field of materials, can solve the problems of complex system and high cost, and achieve the effects of broad application prospect, short production cycle and complex system solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

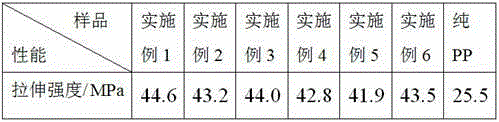

Examples

Embodiment 1

[0021] The preparation method of the one-step autocatalytic α-calcium sulfate hemihydrate whisker of the present embodiment, the steps are as follows:

[0022] Weigh 27.5g CaCl 2 (0.25mol) dissolved in 100mL deionized water to prepare 2.5mol / L CaCl 2 solution, weighing 35.5g Na 2 SO 4 (0.25mol) was dissolved in 200mL deionized water to prepare 1.25mol / L Na 2 SO 4 solution, and then the two solutions were filtered separately.

[0023] the above Na 2 SO 4 Pour into a three-necked flask, stir mechanically, and then add CaCl at a speed of 5mL / min 2 Add to the three-necked flask, wait for the CaCl 2 After the solution was added dropwise, stirring was continued for 0.5 h. Then the temperature of the solution was raised to 104° C., the mechanical stirring speed was 1500 rpm, and the reaction was continued for 4 h while maintaining the mechanical stirring speed and the temperature of the solution. After the reaction was complete, the reaction liquid was filtered while it was...

Embodiment 2

[0026] The preparation method of the one-step autocatalytic α-calcium sulfate hemihydrate whisker of the present embodiment, the steps are as follows:

[0027] Weigh 55.0g CaCl 2 (0.5mol) dissolved in 200mL deionized water to prepare 2.5mol / L CaCl 2 solution, weighing 35.5g Na 2 SO 4 (0.25mol) was dissolved in 200mL deionized water to prepare 1.25mol / L Na 2 SO 4 solution, and then the two solutions are filtered respectively;

[0028] the above Na 2 SO 4 Pour into a three-necked flask, stir mechanically, and then pour CaCl at a speed of 10mL / min 2 Add to the three-necked flask, wait for the CaCl 2 After the solution was added dropwise, stirring was continued for 0.5 h. Then the solution was heated to 104° C., the mechanical stirring speed was 1800 rpm, and the reaction was continued for 4 h while maintaining the mechanical stirring speed and the temperature of the solution. After the reaction was complete, the reaction liquid was filtered while it was hot, and then wa...

Embodiment 3

[0030] The preparation method of the one-step autocatalytic α-calcium sulfate hemihydrate whisker of the present embodiment, the steps are as follows:

[0031] Weigh 27.5g CaCl 2 (0.25mol) dissolved in 100mL deionized water to prepare 2.5mol / L CaCl 2 solution, weighing 35.5g Na 2 SO 4 (0.25mol) was dissolved in 200mL deionized water to prepare 1.25mol / L Na 2 SO 4 solution, and then the two solutions are filtered respectively;

[0032] the above Na 2 SO 4 Pour into a three-necked flask, stir mechanically, and then add CaCl at a speed of 5mL / min 2 Add to the three-necked flask, wait for the CaCl 2 After the solution was added dropwise, stirring was continued for 0.5 h. Then the solution was heated to 104° C., the mechanical stirring speed was 800 rpm, and the reaction was continued for 8 h while maintaining the mechanical stirring speed and the temperature of the solution. After the reaction was complete, the reaction liquid was filtered while it was hot, and then wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com