Method for recycling phosphorus and fluoride in sewage residue of phosphorus fertilizer plant

A technology of sewage and phosphate fertilizer, applied in chemical instruments and methods, phosphate fertilizer, water/sewage treatment, etc., can solve the problems of phosphorus and fluorine not being recycled, unreachable, polluting the surrounding environment, etc., achieving strong demonstration significance and promotion value, improving utilization value, and improving the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

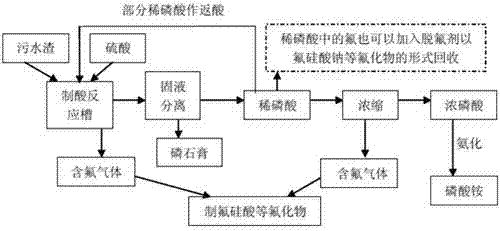

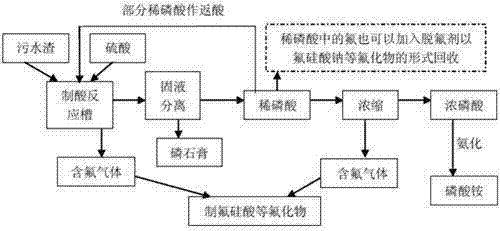

Method used

Image

Examples

Embodiment 1

[0024] Weigh 1000g of sewage residue (P 2 o 5 content 22.7%, F content 7.8%, CaO content 46.5%, free water 5%), 98% sulfuric acid 855g, phosphoric acid back acid 6625g (P 2 o 5 Content 20.0%) quantitatively and continuously fed into the acid reaction tank, referring to the traditional method of sulfuric acid decomposition of phosphate rock, the reaction conditions are: control SO 3 The concentration is about 45g / L, the reaction temperature is 80°C, the reaction time is 4 hours, and the liquid-solid ratio is about 4:1. After the reaction is completed, filter, wash, and filter the obtained dilute phosphoric acid P 2 o 5 The content is about 25.5%, and the F content is about 8.1%. Take 830g of dilute phosphoric acid as dilute phosphoric acid product and enter the concentration section.

[0025] Concentrate the above 830g of dilute phosphoric acid at an absolute pressure of 10kPa and a temperature of 75°C to obtain 455g of concentrated phosphoric acid (P 2 o 5 conte...

Embodiment 2

[0027] Weigh 1667g of sewage residue (P 2 o 5 content 13.6%, F content 4.7%, CaO content 27.9%, free water 40%), 98% sulfuric acid 846g, phosphoric acid back acid 5100g (P 2 o 5 Content 14.8%) quantitatively and continuously fed into the acid reaction tank, referring to the traditional method of sulfuric acid decomposition of phosphate rock, the reaction conditions are: control SO 3 The concentration is about 25g / L, the reaction temperature is 75°C, the reaction time is 3 hours, and the liquid-solid ratio is about 3.5:1. After the reaction is completed, filter, wash, and filter the obtained dilute phosphoric acid P 2 o 5 The content is about 17.2%, and the F content is about 5.5%. Take 1251g of dilute phosphoric acid as dilute phosphoric acid product and enter the concentration section.

[0028] Concentrate the above 1251g of dilute phosphoric acid at an absolute pressure of 11kPa and 80°C to obtain 608g of concentrated phosphoric acid (P 2 o 5content of about 35.4%...

Embodiment 3

[0030] Weigh 1333g of sewage residue (P 2 o 5 content 24.8%, F content 8.63%, CaO content 35.3%, free water 25%), 98% sulfuric acid 1007g, phosphoric acid back acid 2377g (P 2 o 5 Content 20.9%) quantitatively and continuously fed into the acid reaction tank, referring to the traditional method of sulfuric acid decomposition of phosphate rock, the reaction conditions are: control SO 3 The concentration is about 80g / L, the reaction temperature is 95°C, the reaction time is 1 hour, and the liquid-solid ratio is about 2:1. After the reaction is completed, filter, wash, and filter the obtained dilute phosphoric acid P 2 o 5 The content is about 28%, and the F content is about 9.1%. Take 1109g of dilute phosphoric acid as dilute phosphoric acid product and enter the concentration section.

[0031] Concentrate the above 1109g of dilute phosphoric acid at an absolute pressure of 10kPa and 78°C to obtain 577g of concentrated phosphoric acid (P 2 o 5 content of about 53.6%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com