Mixed additives and method for producing anhydrous dead-burned type of calcium sulfate whisker

A technology of calcium sulfate whiskers and mixed additives, which is applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of unrealized water circulation, cumbersome process, increased cost, etc., and achieve energy saving, The process is simple and the effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

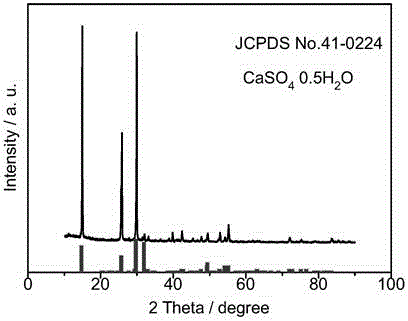

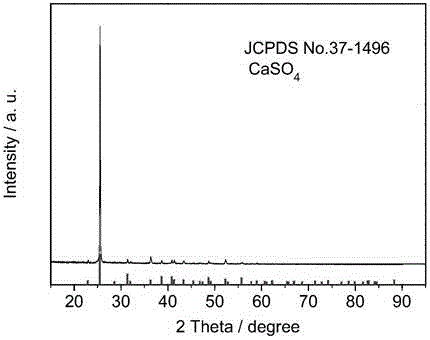

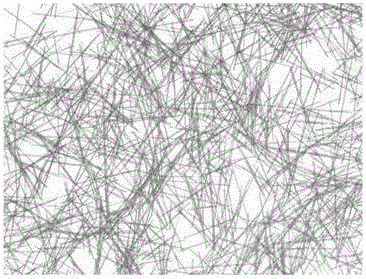

Embodiment 1

[0056] Calcium sulfate dihydrate (content 97wt%) was ground through an 80-mesh sieve, and 96 kilograms of calcium sulfate dihydrate were weighed and mixed in 480 kilograms of water, and mixed additives (shape control agent: dodecylbenzenesulfonate) were added while stirring at normal temperature. Sodium acid sodium 50g; Auxiliary control agent: magnesium sulfate 500g; Reaction system pH regulating agent: 1.2 liters of 98% industrial grade sulfuric acid), after continuing to stir for 10 minutes, the slurry injection volume is in the hydrothermal reactor of 680L, at 115 ℃ , hydrothermal reaction at a stirring speed of 50 rpm for 30 minutes. After the reaction stopped, the material was unloaded and centrifuged. The sample was dried under the action of hot air at 150°C. Finally, the sample was calcined at 650°C for 1 hour to obtain an average length of 300 μm and an average diameter of Anhydrous dead-burned calcium sulfate whiskers with an aspect ratio of about 1 μm, an aspect rati...

Embodiment 2

[0058] Calcium sulfate dihydrate (content 97wt%) was ground through an 80-mesh sieve, and 48 kilograms of calcium sulfate dihydrate were weighed and mixed in 480 kilograms of water, and mixed additives were added while stirring at normal temperature (morphological control agent: 35 g of polyvinylpyrrolidone; auxiliary Controlling agent: magnesium chloride 650g; Reaction system pH regulating agent: 98% technical grade sulfuric acid 1.2 liters), after continuing to stir for 10 minutes, the slurry injection volume is in the hydrothermal reactor of 680L, and at 125 ℃, stirring speed is 50 rpm Under the condition of 10 minutes, the hydrothermal reaction was carried out for 40 minutes. After the reaction stopped, the material was unloaded and centrifuged, and the sample was dried under the action of hot air at 150°C. Finally, the sample was calcined at 700°C for 1 hour to obtain an average length of 400 μm, an average diameter of about 2 μm, and an aspect ratio of 200, anhydrous dead...

Embodiment 3

[0062] Calcium sulfate dihydrate (content 97wt%) was ground through a 120 mesh sieve, 48 kg of calcium sulfate dihydrate was weighed and mixed in 480 kg of water, and mixed additives were added while stirring at normal temperature (morphology control agent: 45g, Tween and poly Vinylpyrrolidone mass ratio 1:1; auxiliary control agent: 640g, magnesium chloride and sodium chloride mass ratio 20:1; reaction system pH regulator: 2000g, citric acid and formic acid mass ratio 1:1), after continuing to stir for 10 minutes, Pour the slurry into a hydrothermal reaction kettle with a volume of 680L, and conduct a hydrothermal reaction at 130°C with a stirring speed of 100 rpm for 40 minutes. After the reaction stops, unload and centrifuge, and dry the sample under the action of hot air at 150°C , the final sample was calcined at 700°C for 1 hour to obtain anhydrous dead-burned calcium sulfate whiskers with an average length of 200 μm, an average diameter of about 1.5 μm, an aspect ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com