Bi-directional powder pressing forming device capable of demoulding automatically

A two-way pressing and automatic demoulding technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve problems such as automatic demoulding and difficult two-way pressing, so as to improve equipment utilization and production efficiency. Improve production speed and improve the effect of density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

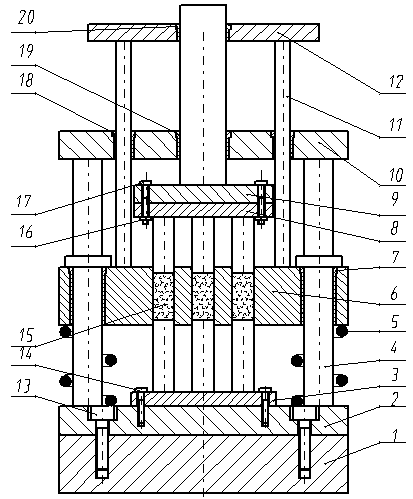

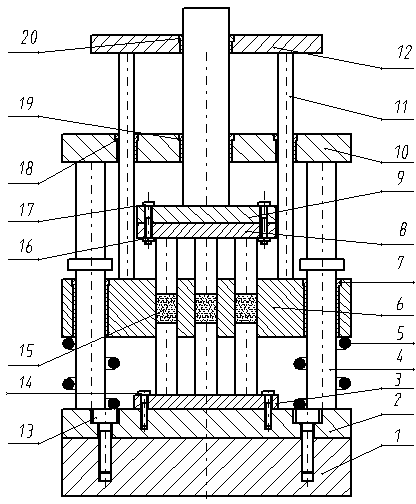

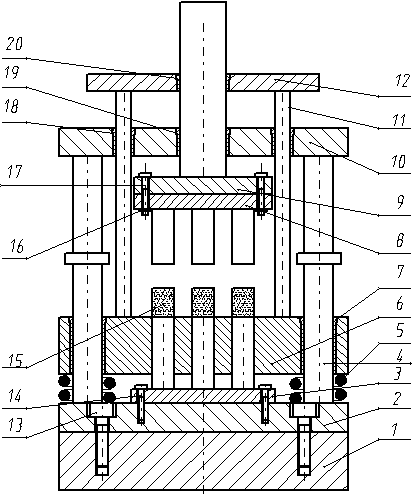

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as Figure 1~Figure 7 As shown, upper mold frame 10 of the present invention is connected with lower mold frame 2 with guide post 4, and lower mold frame 3 is fixed on the base plate 1 with screw 13; connection, the upper mold connecting rod 9 is connected with the first hydraulic cylinder; the lower mold punch 3 is fixed on the lower mold frame 2 with screws 14; the female mold 6 is installed on the respective guide columns through four holes on both sides (two holes on each side) 4, the bottom of the female mold 6 and the respective guide pillars 4 above the lower mold frame 2 are all covered with springs 5, the female mold 6 can float on the spring 5, and the female mold 6 is equipped with heating rods 21 and thermocouples 23; four One end of the ejector rod 11 is fixed on the ejector rod fixed plate 12, the other end of the four ejector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com