Synchronous uninterrupted wire feeding all-solid-phase friction stir additive manufacturing method and synchronous uninterrupted wire feeding all-solid-phase friction stir additive manufacturing device

A friction stir and additive manufacturing technology, applied in the direction of manufacturing tools, additive processing, metal processing equipment, etc., can solve the problems of weakened bonding force between additive layers, serious interface bonding defects, and low additive manufacturing efficiency. The effect of improving efficiency and homogenizing tissue composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

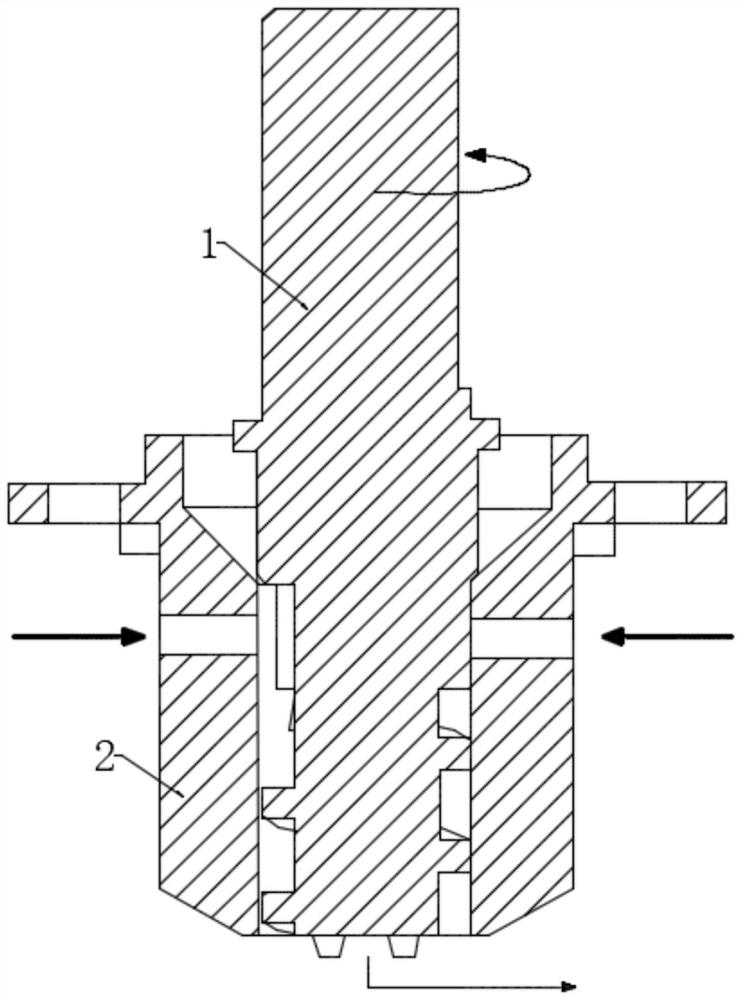

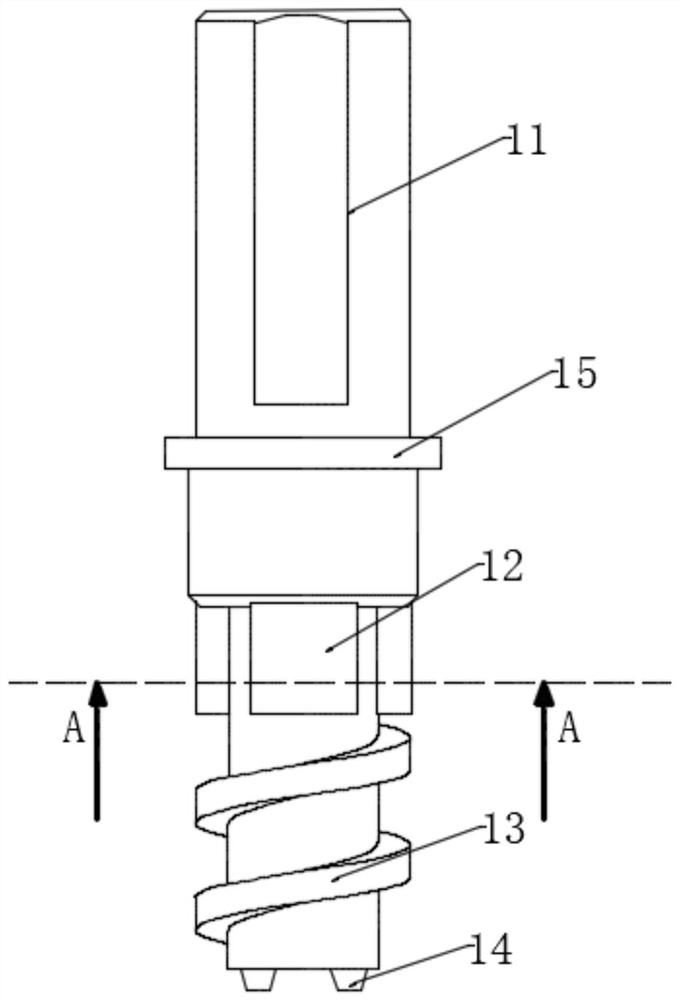

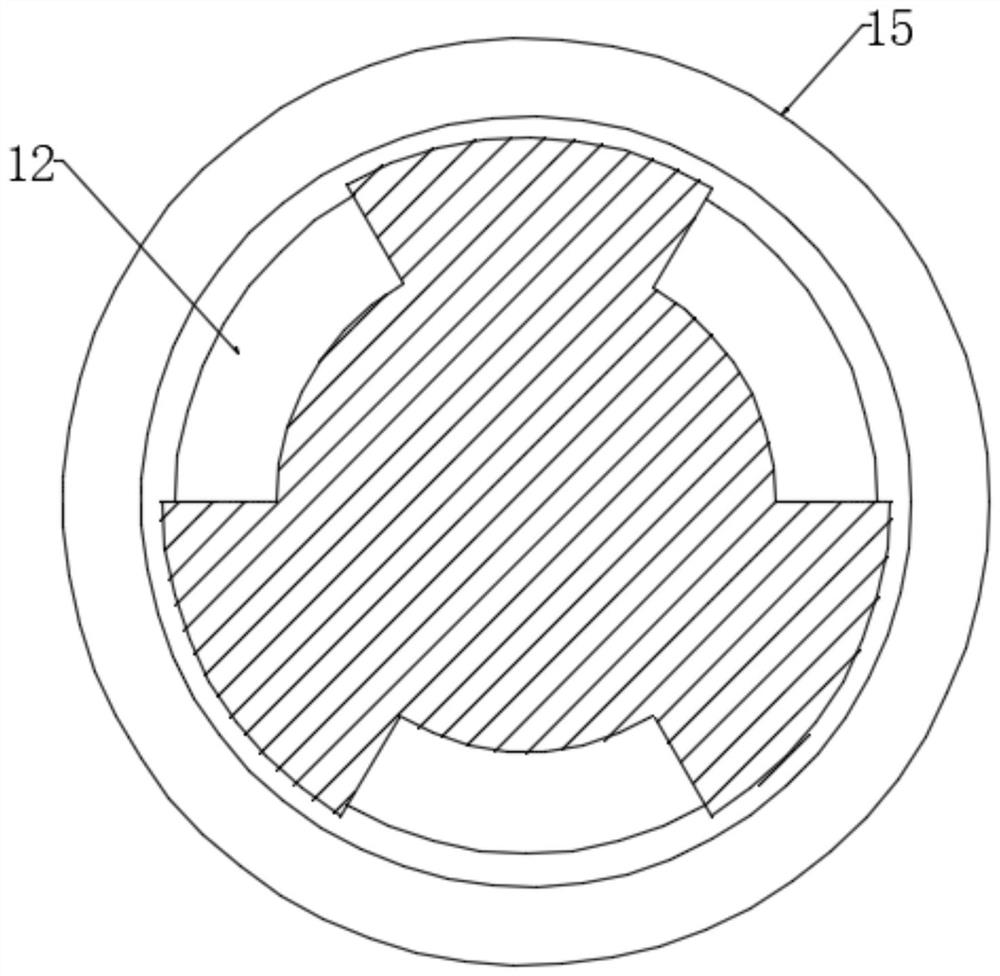

[0040] A synchronous uninterrupted wire feeding full solid-phase friction stir additive manufacturing device, comprising a friction stir device 1 and a wire feeding device 2, the friction stir device 1 comprising a clamping part 11, a scrap blade 12, a screw part 13, and a boss 14 and the mounting base 15, the upper end of the mounting base 15 is drilled with a clamping portion 11, the lower end of the mounting base 15 is mounted with a plurality of evenly distributed scrap blades 12, the lower end of the mounting base 15 is mounted with a screw portion 13, and the plurality of scrap blades 12 are located in the screw Outside the portion 13 , a plurality of evenly distributed bosses 14 are fixedly connected to the lower end of the screw portion 13 .

[0041] see Figure 1-4 , the upper end of the clamping part 11 is provided with a positioning plane, and the positioning plane is processed according to the clamping requirements of the friction stir welding machine tool shank. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com