Method for metallizing surface of alumina ceramic substrate

A technology on the surface of alumina ceramics and substrates, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc. It has catalytic activity, can not be applied to patch skeleton and other problems, and achieves the effect of good membrane base bonding, good coating compactness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

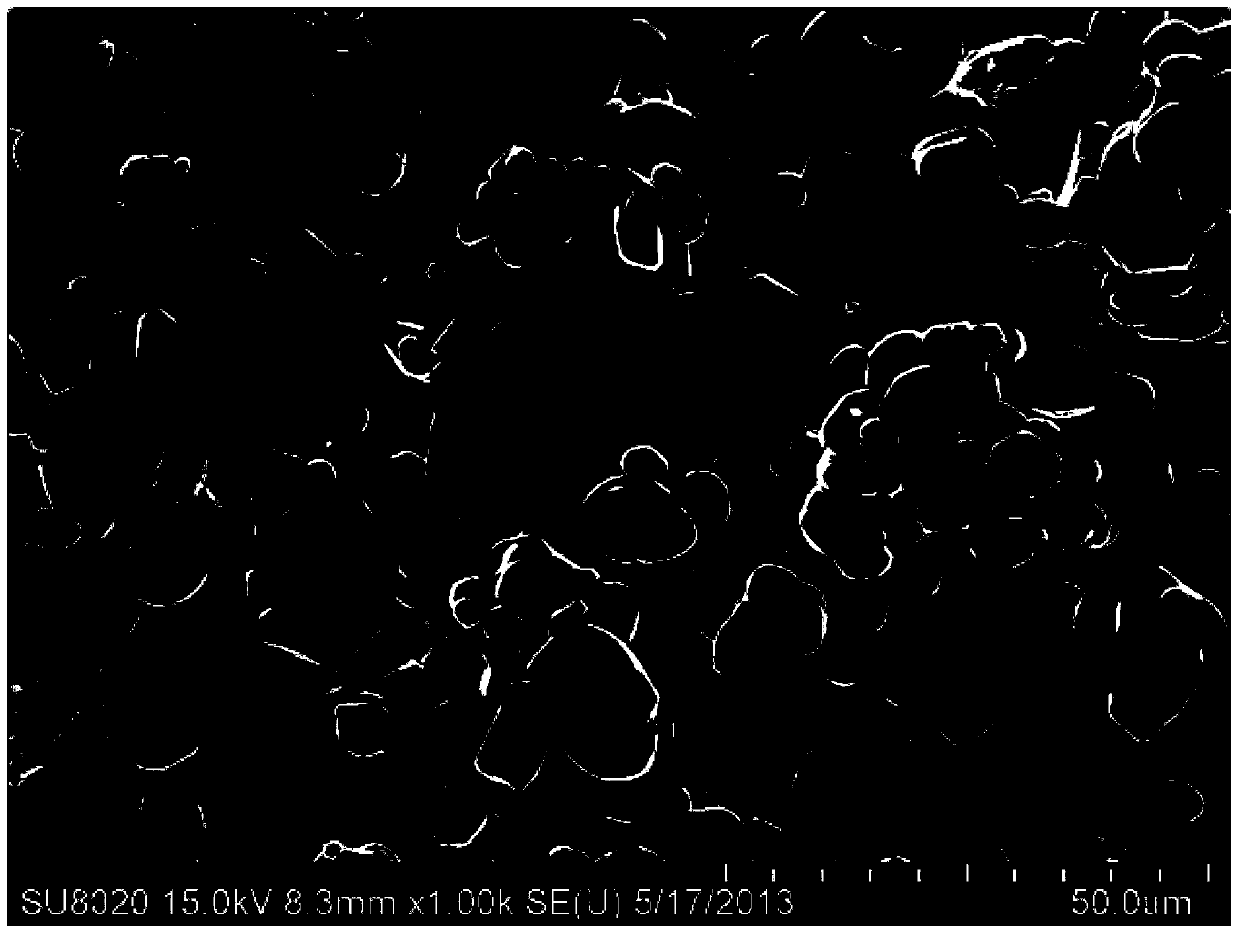

[0023] 1. Coarsening preprocessing

[0024] The alumina ceramic substrate was placed in the roughening solution at room temperature and in an air atmosphere, ultrasonically treated for 30 minutes, and then rinsed with deionized water to obtain a pretreated substrate.

[0025] The roughening solution is an aqueous solution of hydrofluoric acid and ammonium fluoride, the concentration of hydrofluoric acid in the roughening solution is 40ml / L, and the concentration of ammonium fluoride is 2g / L.

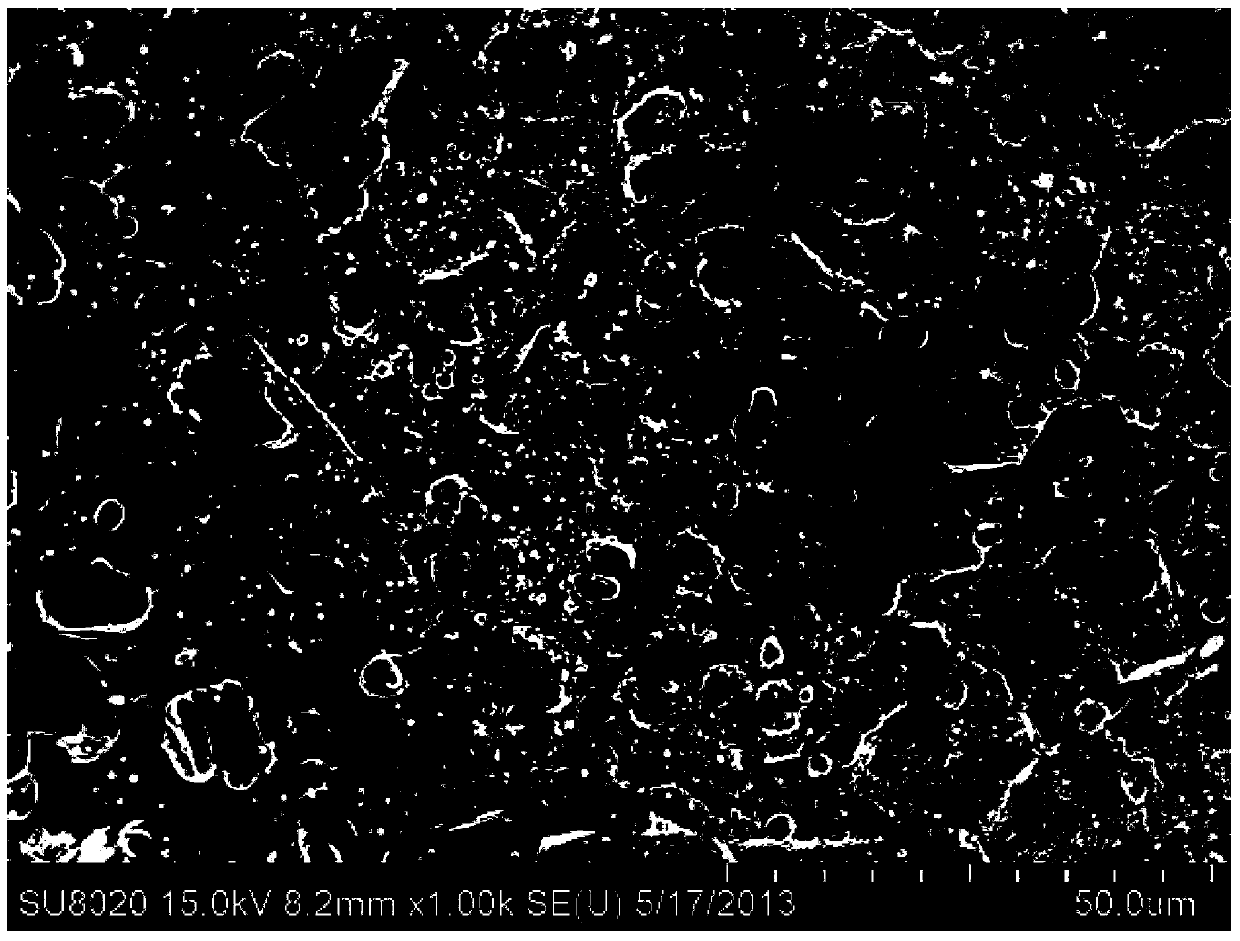

[0026] 2. Primary nickel plating

[0027] Put the pretreated alumina ceramic sample into the plating solution Ⅰ, adjust the pH to 10 with sodium hydroxide, and conduct ultrasonic deposition for 50 minutes. The ultrasonic frequency of ultrasonic deposition is 40KHz, and the power is 300W. After the reaction is completed, the sample , washed with deionized water, dried in an oven at 90° C. for 3 hours, and cooled at room temperature to obtain a nickel-plated substrate.

[0028] Described...

Embodiment 2

[0034] 1. Coarsening preprocessing

[0035] The alumina ceramic substrate was placed in the roughening solution at room temperature and in an air atmosphere, ultrasonically treated for 40 minutes, and then rinsed with deionized water to obtain a pretreated substrate.

[0036] The roughening solution is an aqueous solution of hydrofluoric acid and ammonium fluoride, the concentration of hydrofluoric acid in the roughening solution is 60ml / L, and the concentration of ammonium fluoride is 4g / L.

[0037] 2. Primary nickel plating

[0038] Put the pretreated alumina ceramic sample into the plating solution Ⅰ, adjust the pH to 11 with sodium hydroxide, and conduct ultrasonic deposition for 40 minutes. The ultrasonic frequency of ultrasonic deposition is 40KHz and the power is 300W. After the reaction is completed, take out the sample , washed with deionized water, dried in an oven at 100° C. for 4 hours, and cooled at room temperature to obtain a nickel-plated substrate.

[0039] ...

Embodiment 3

[0045] 1. Coarsening preprocessing

[0046] The alumina ceramic substrate was placed in the roughening solution at room temperature and in an air atmosphere, ultrasonically treated for 20 minutes, and then rinsed with deionized water to obtain a pretreated substrate.

[0047] The roughening solution is an aqueous solution of hydrofluoric acid and ammonium fluoride, the concentration of hydrofluoric acid in the roughening solution is 20ml / L, and the concentration of ammonium fluoride is 1g / L.

[0048] 2. Primary nickel plating

[0049]Put the pretreated alumina ceramic sample into the plating solution Ⅰ, adjust the pH to 11 with sodium hydroxide, and conduct ultrasonic deposition for 60 minutes. The ultrasonic frequency of ultrasonic deposition is 40KHz, and the power is 300W. Take out the sample after the reaction is completed , washed with deionized water, dried in an oven at 80° C. for 2 hours, and cooled at room temperature to obtain a nickel-plated substrate.

[0050] De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com