Non-vacuum smelting and continuous casting technology for copper-iron alloy

A copper-iron alloy, non-vacuum technology, applied in the non-vacuum smelting and continuous casting process of copper-iron alloys, can solve the problems of high cost and inability to realize mass production, and achieve the effects of stable tissue composition, improved product quality, and reduced friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

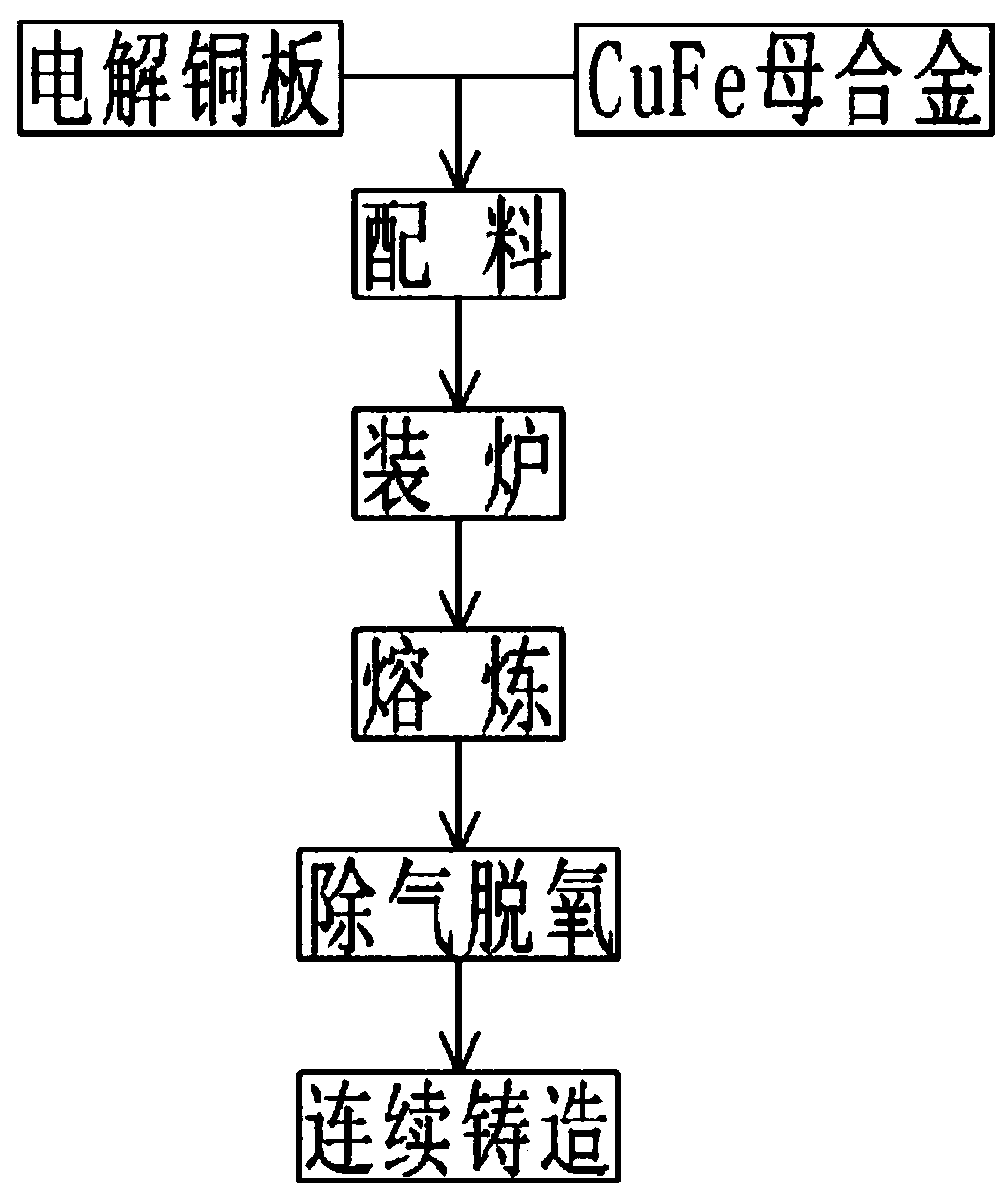

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of technology that adopts non-vacuum mode smelting and continuous casting copper-iron alloy, comprises the following steps:

[0027] 1) Ingredients: by weight percentage, the percentage content of Fe element in the raw material is 5%, and the percentage content of Cu element is 95%; wherein the raw material Fe is CuFe master alloy, and the raw material Cu is electrolytic copper plate; wherein, CuFe The preparation method of the master alloy is as follows: (1) first heat the melting furnace, and at the same time feed helium, when the temperature in the melting furnace is higher than 850 ° C, put the copper-containing raw material and the covering agent into the crucible in the melting furnace, Raise the temperature of the smelting furnace to 1100° C. to melt the copper-containing raw materials into copper water, and heat preservation treatment for 5 minutes, wherein the amount of covering agent added is 0.8% of the total amount of copper-containing ra...

Embodiment 2

[0032] Embodiment 2: a kind of technology that adopts non-vacuum mode melting and continuous casting copper-iron alloy, comprises the following steps:

[0033] 1) Ingredients: by weight percentage, the percentage content of Fe element in the raw material is 15%, and the percentage content of Cu element is 85%; wherein the raw material Fe is CuFe master alloy, and the raw material Cu is electrolytic copper plate; wherein, CuFe The preparation method of the master alloy is as follows: (1) first heat the melting furnace, and at the same time feed helium, when the temperature in the melting furnace is higher than 850 ° C, put the copper-containing raw material and the covering agent into the crucible in the melting furnace, Raise the temperature of the smelting furnace to 1200°C to melt the copper-containing raw material into copper water, and heat-preserve it for 12 minutes, wherein the addition of the covering agent is 1.5% of the total amount of the copper-containing raw materia...

Embodiment 3

[0038] Embodiment 3: a kind of technology that adopts non-vacuum mode smelting and continuous casting copper-iron alloy, comprises the following steps:

[0039] 1) Ingredients: by weight percentage, the percentage content of Fe element in the raw material is 20%, and the percentage content of Cu element is 80%; wherein the raw material Fe is CuFe master alloy, and the raw material Cu is electrolytic copper plate; wherein, CuFe The preparation method of the master alloy is as follows: (1) first heat the melting furnace, and at the same time feed helium, when the temperature in the melting furnace is higher than 850 ° C, put the copper-containing raw material and the covering agent into the crucible in the melting furnace, Raise the temperature of the smelting furnace to 1350° C. to melt the copper-containing raw materials into copper water, and heat preservation treatment for 15 minutes, wherein the amount of covering agent added is 2.2% of the total amount of copper-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com