Preparation method for CuFe mother alloy material by adopting vacuum induction melting

A vacuum induction melting and vacuum melting furnace technology, applied in the field of new material preparation, can solve the problems of high cost and inability to realize mass production, and achieve the effects of less inclusions, optimized melting steps, and low gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method adopting vacuum induction melting CuFe master alloy material, comprising the following steps:

[0024] Step 1. Load the ingredients into the furnace

[0025] Weigh Cu and Fe raw materials with a purity greater than 99.9% according to the content percentage of 1:1, mix them evenly, put them into a zirconia crucible and put them in a vacuum melting furnace, close the vacuum melting furnace cover, close the vent valve, and clean the observation window ;

[0026] Step 2. Vacuum induction melting

[0027] Turn on the mechanical pump, open the low-vacuum baffle valve to evacuate, and when the vacuum pressure in the vacuum melting furnace is P=0.08MPa, turn on the Roots pump. When the vacuum degree reaches P=4Pa, heat up and the power of the vacuum melting furnace rises to 25KW, keep warm for 8 minutes, the power of the vacuum melting furnace is raised to 15KW, keep warm for 8 minutes, the heating power of the vacuum melting furnace is raised to 65KW, af...

Embodiment 2

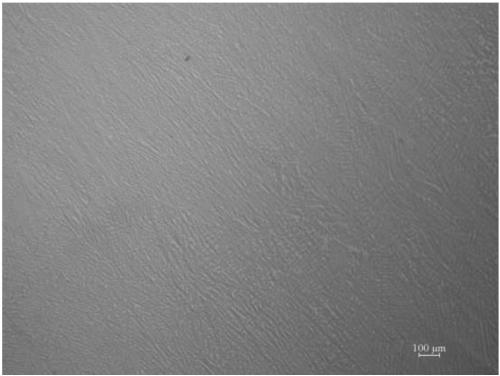

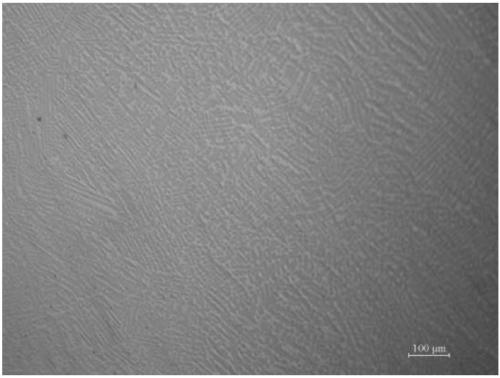

[0031] Utilize the CuFe alloy metallographic structure prepared by the vacuum induction melting method of embodiment 1 as Figure 1-2 Shown:

[0032] Figure 1-2 In the middle, the gray part is the iron phase, and the white part is the copper phase, from Figure 1-2 It can be seen from the figure that the iron phase is mainly granular or dendritic, and is evenly dispersed in the copper matrix without obvious segregation.

[0033] Conclusion: The CuFe alloy prepared by the vacuum induction melting method in Example 1 has uniform structure and no segregation.

Embodiment 3

[0035] Utilize the CuFe master alloy chemical content detection of the vacuum induction melting method preparation in embodiment 1 as shown in table 1:

[0036] Table 1 CuFe master alloy chemical content detection table

[0037]

[0038] Conclusion: The CuFe alloy prepared by the vacuum induction melting method in Example 1 has few inclusions and uniform structure composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com