Copper-based amorphous composite coating and preparation method thereof

A composite coating and copper-based alloy technology, which is applied in the coating, metal material coating process, etc., can solve the problems of amorphous composite coating, and achieve the effect of no hole defect, uniform structure and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the atomic percent of each composition of described copper-based alloy is: (Cu 0.6 f 0.25 Ti 0.15 ) 90 Nb 10 .

[0029] (1) Preparation of copper-based alloy powder

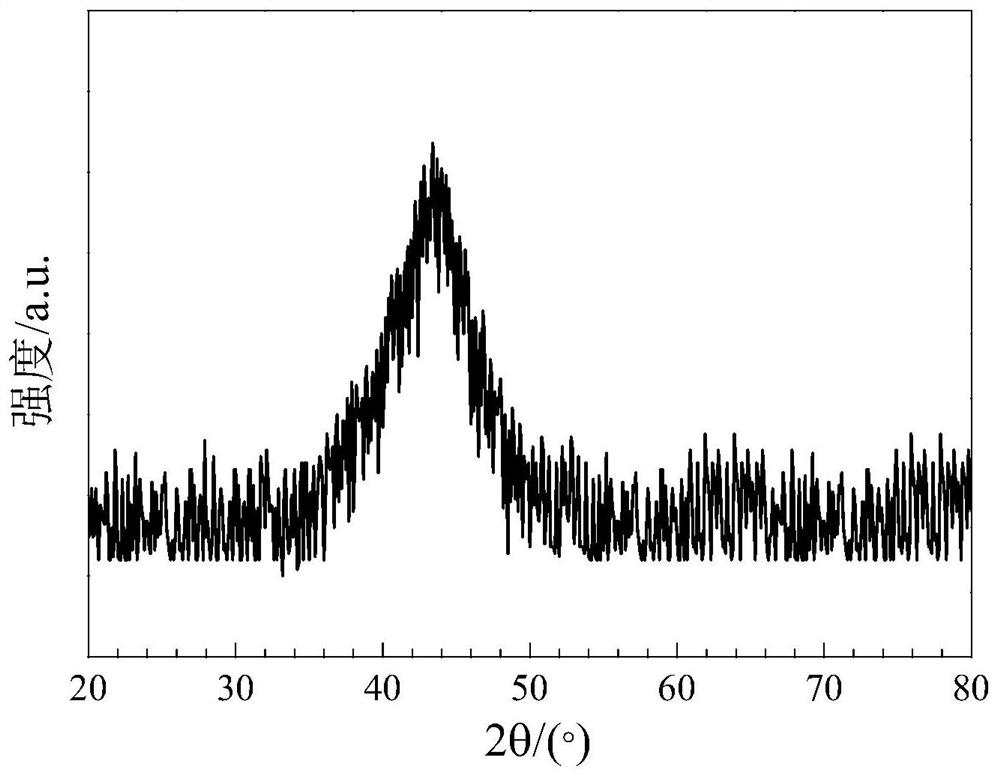

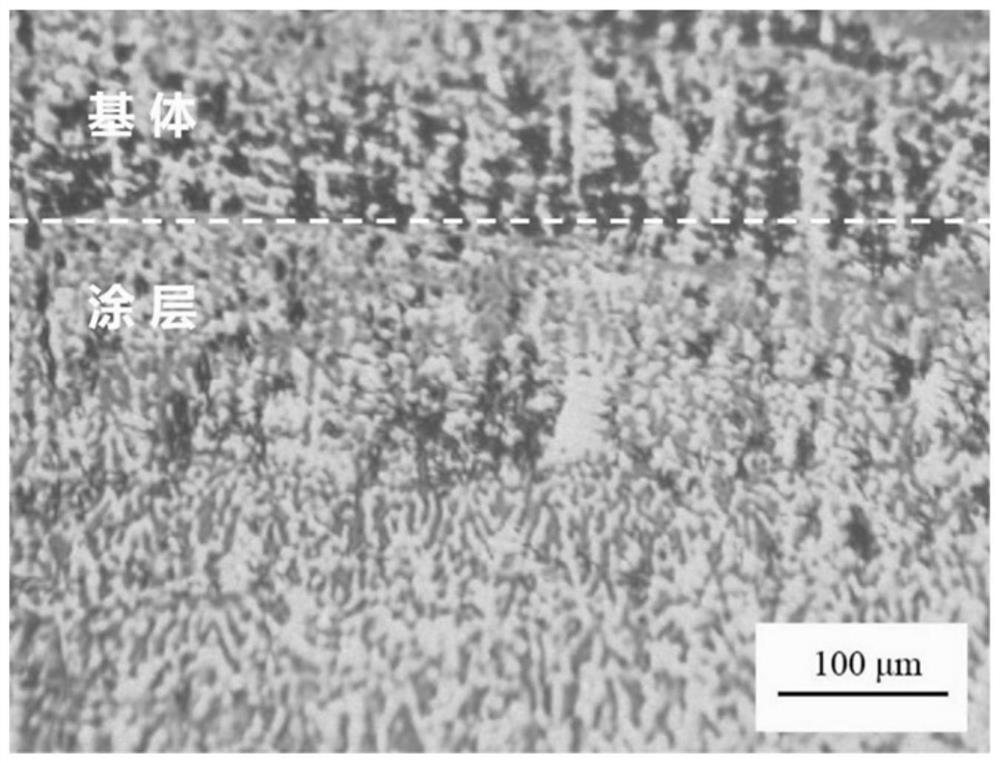

[0030] Convert the atomic percentage of each component of the copper-based alloy into the corresponding mass percentage, then weigh the corresponding mass of metal Cu, Hf, Ti and Nb according to the mass percentage, and put it into a water-cooled copper crucible after configuration, and the vacuum degree is less than 1×10 -3 Pa, for vacuum arc melting. In order to ensure uniform distribution of elements, the alloy was smelted three times. After cooling, the alloy ingot is put into a vibration mill for mechanical crushing, sieved with a 200-mesh sieve and a 400-mesh sieve, and the powder with a particle size range of 38-75 μm is taken for laser cladding. X-ray diffraction pattern of copper-based alloy powder figure 1 shown by figure 1 It can be seen that diffuse scattering packets (br...

Embodiment 2

[0041] Embodiment 2: the atomic percent of each composition of described copper-based alloy is: (Cu 0.6 f 0.25 Ti 0.15 ) 98 Nb 2 .

[0042] (1) Preparation of copper-based alloy powder

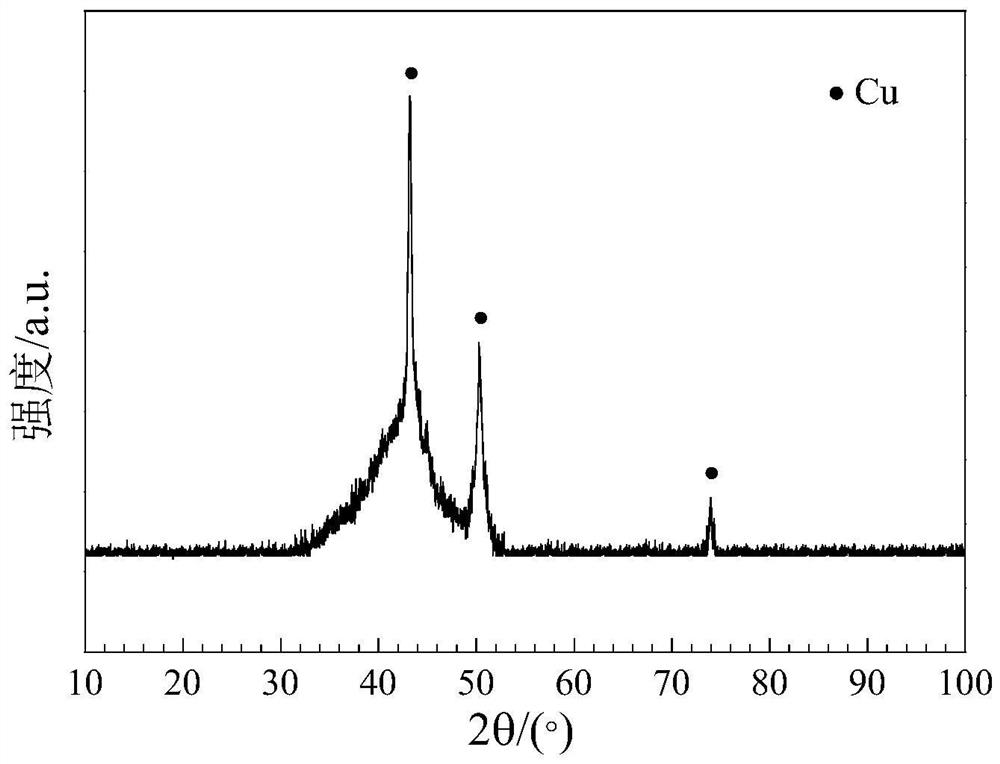

[0043] Copper-based alloy powders were synthesized by vacuum arc melting and mechanical crushing. Convert the atomic percentage of each component of the copper-based alloy into the corresponding mass percentage, then weigh the corresponding mass of metal Cu, Hf, Ti and Nb according to the mass percentage, and put it into a water-cooled copper crucible after configuration, and the vacuum degree is less than 1×10- 3Pa, for vacuum arc melting. In order to ensure uniform distribution of elements, the alloy was smelted three times. After cooling, the alloy ingot is put into a vibration mill for mechanical crushing, sieved with a 200-mesh sieve and a 400-mesh sieve, and the powder with a particle size range of 38-75 μm is taken for laser cladding. X-ray diffraction pattern of copper-based al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com