Extrusion die with an equal-passage spiral cavity for molding magnesium alloy square rods and extrusion method

A technology of extrusion dies and magnesium alloys, applied in the direction of metal extrusion dies, metal extrusion, metal extrusion control equipment, etc., can solve the problems of uneven material structure, limited experimental research, etc., and achieve uniform composition and safety The effect of high coefficient and light equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

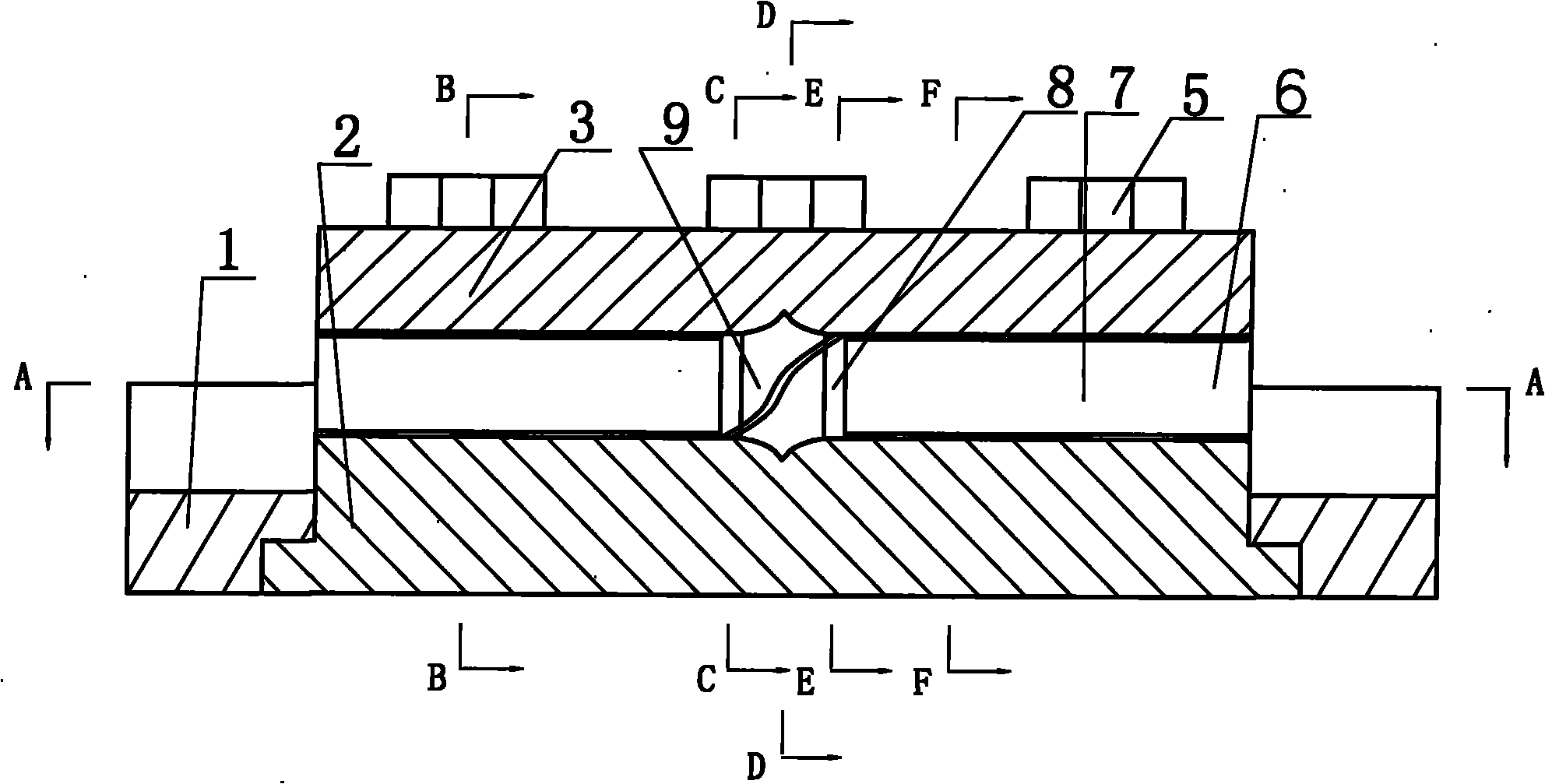

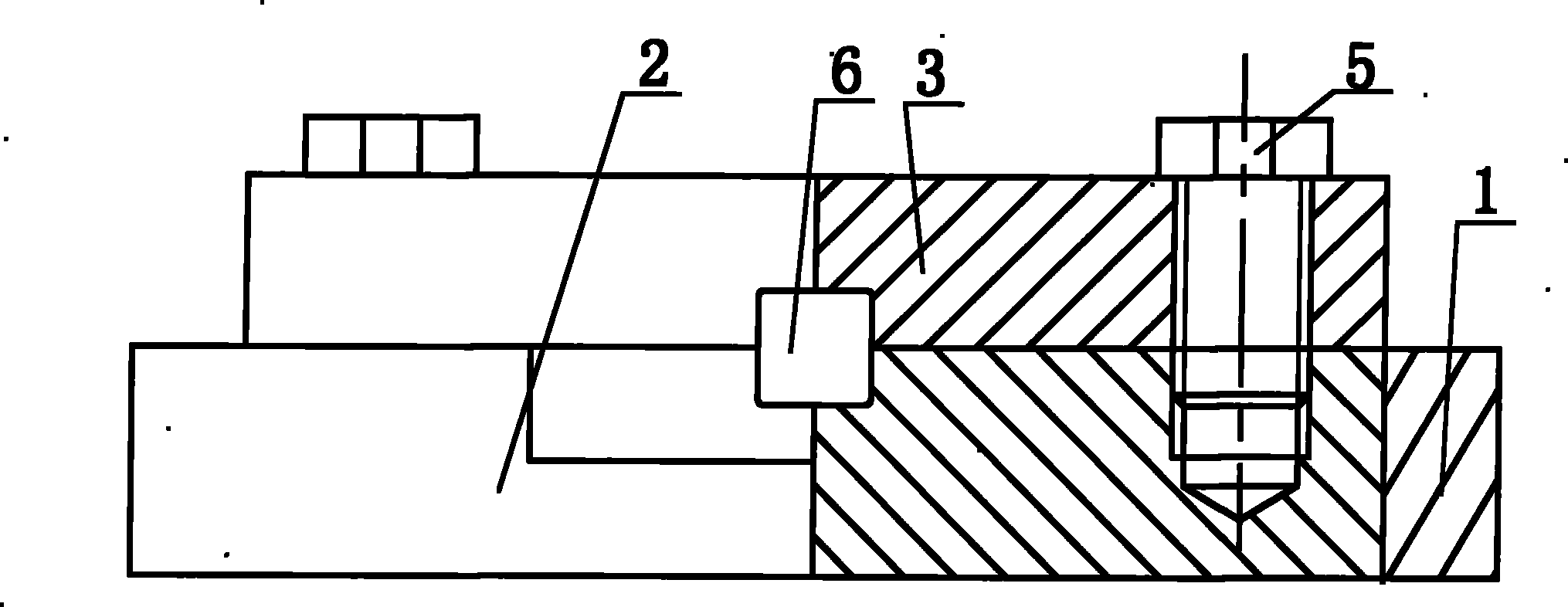

[0022] The extrusion die of the magnesium alloy square rod and other channels with a spiral cavity is composed of: a fixed plate 1, the fixed plate is connected and fixed to the lower die 2, and the lower die and the upper die 3 are fixed with positioning pins 4 and Connected together by bolts 5 , the curved surfaces of the opposite end surfaces of the upper mold and the lower mold form a channel 6 , and the middle section of the channel is a spiral channel 9 .

Embodiment 2

[0024] In the above-mentioned extrusion die of magnesium alloy square rod with equal-channel spiral cavity, the channels are formed by connecting the spiral channels with straight channels 7 at both ends and connecting channels 8 with rounded corners.

[0025] The passage is composed of straight passages, rounded connecting passages, spiral passages, rounded connecting passages, and straight passages connected in sequence. The cross-section of the channel is a square of 20 mm × 20 mm, and the corners are rounded by 1 mm.

[0026] The composition of the passage includes: two straight passages, two connecting rounded passages and one spiral passage. The straight channel is located at both ends of the mold, which are the inlet and outlet of the material respectively; the spiral channel is located in the middle of the mold and is the main deformation area of extrusion molding; the rounded connecting channel is located at both ends of the spiral channel, respectively The straigh...

Embodiment 3

[0028] In the above-mentioned extrusion die for magnesium alloy square rods with equal-channel helical cavity, the channel is a right-handed 90° channel or a left-handed 90° channel.

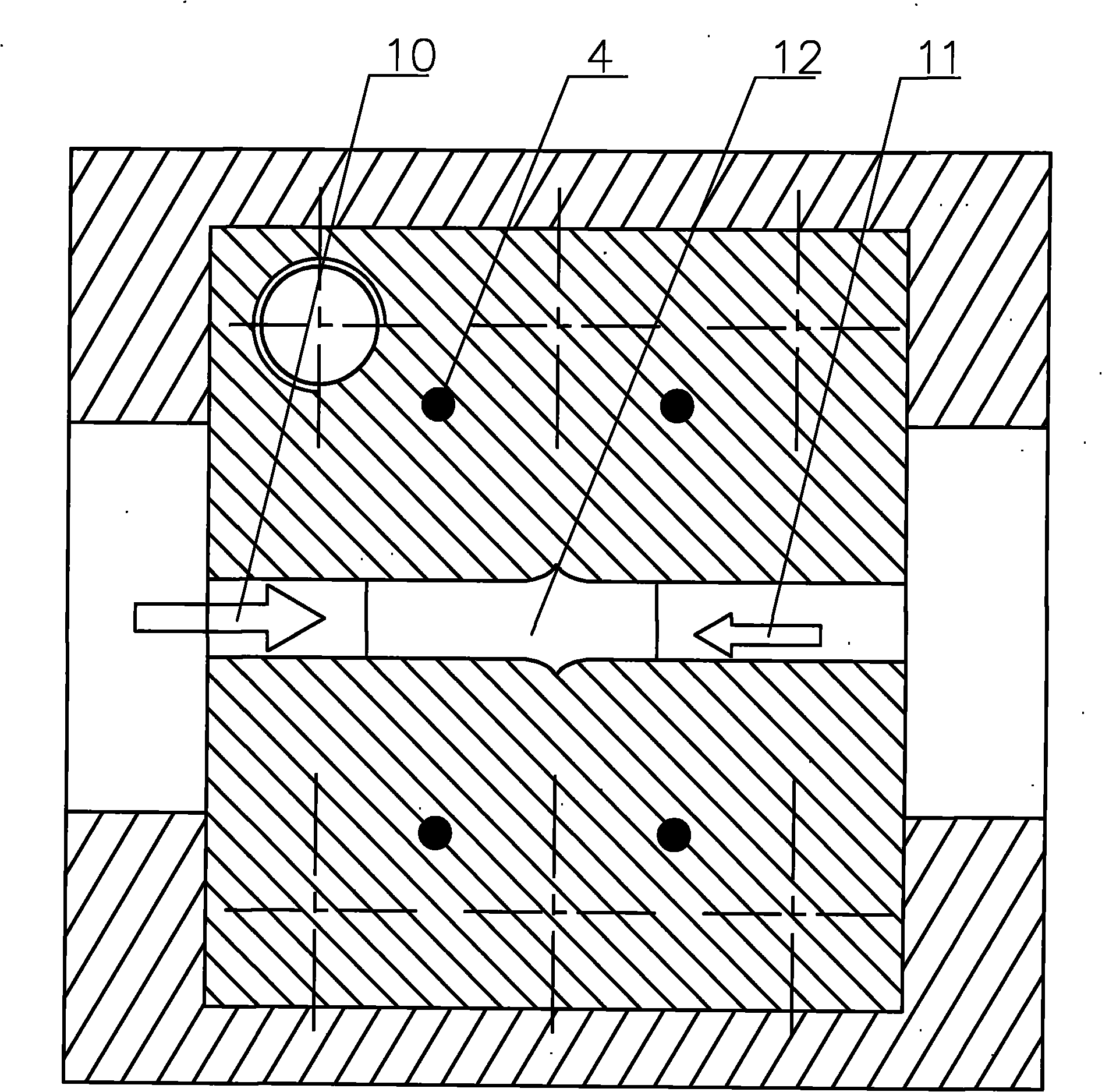

[0029] attached figure 2 The middle arrow 10 indicates the back pressure direction, the arrow 11 indicates the extrusion direction, and the arrow 12 indicates the bad material to be processed.

[0030] When the blank enters from the right end of the channel, it passes through a group of channels in sequence to complete the left-handed 90°rotary extrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com