Method for carrying out nano ceramic coating laser cladding on surface of metal under assistance of ultrasonic fixed-point focusing

A technology of laser cladding and auxiliary metal, applied in metal material coating process, coating and other directions, can solve the problems that the effect cannot be precisely controlled, unfavorable for mass production and application, and the material processing process is cumbersome, etc. Strength and wear resistance, overcoming the effect of cladding thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

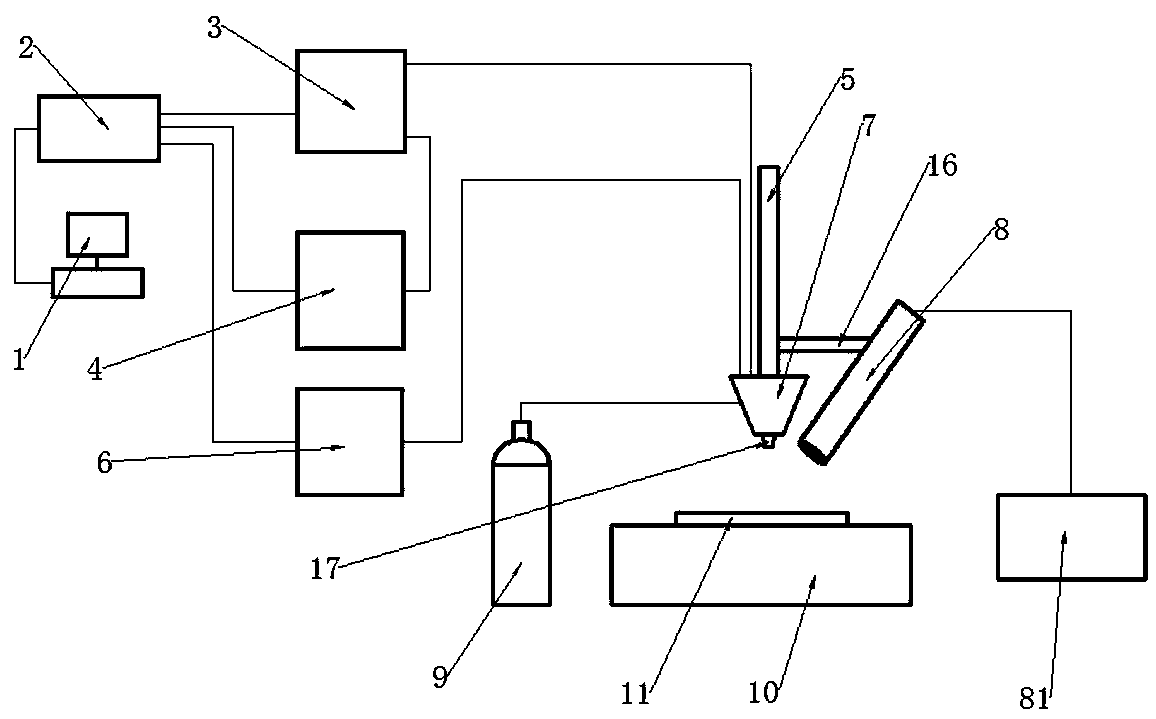

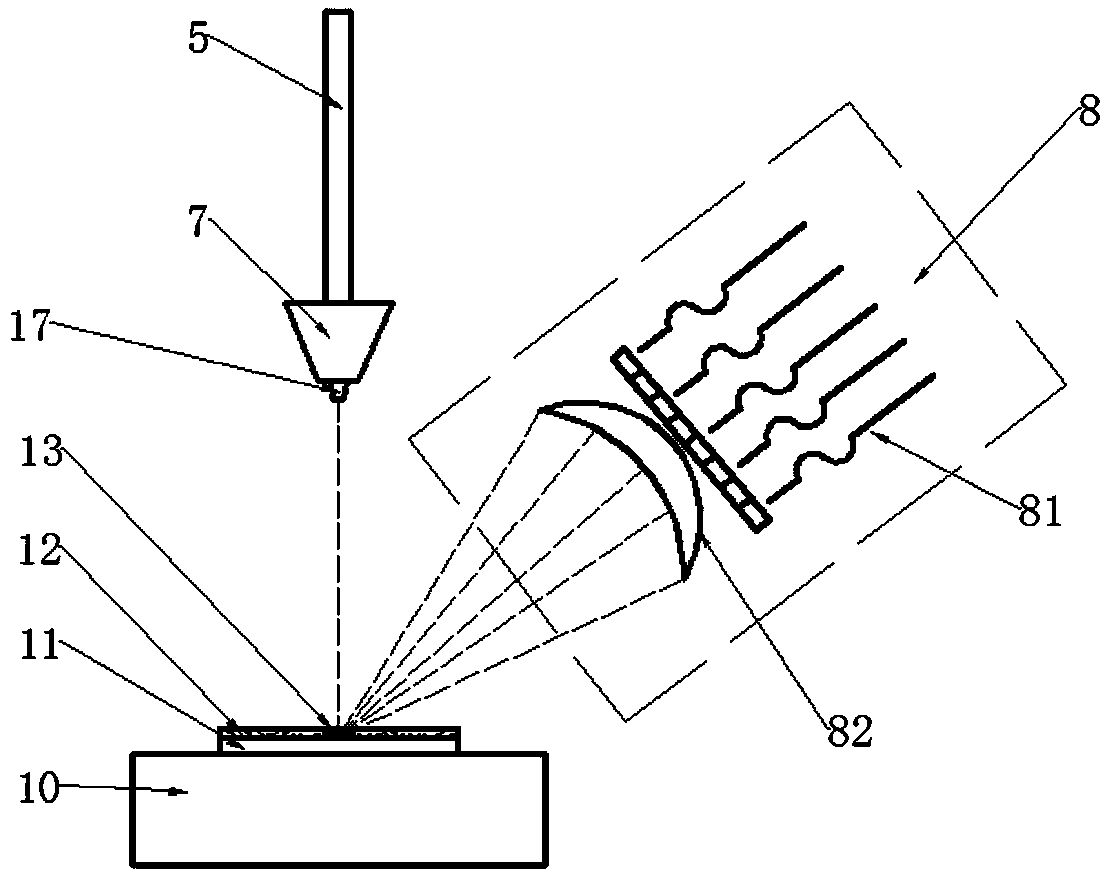

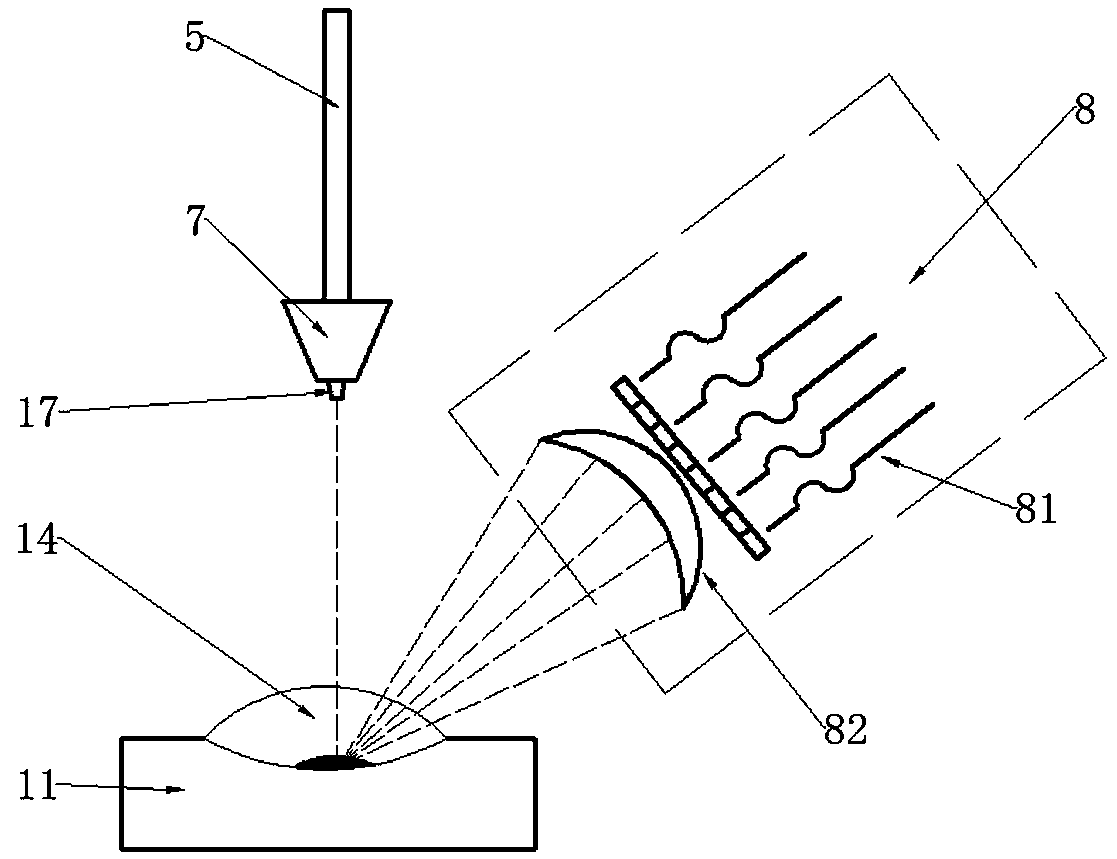

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Specifically, this example uses this method to prepare zirconia and yttrium oxide ceramic thin-walled parts on the surface of a high-temperature titanium alloy. The actual implementation process is described in conjunction with the accompanying drawings.

[0030] see Figure 1-4 , a method for laser cladding nano-ceramic coatings on metal surfaces assisted by ultrasonic fixed-point focusing, comprising the following steps:

[0031] A. Cut the high-temperature titanium alloy substrate (that is, the metal substrate 11) to 70×15×6mm on a wire cutting machine, then polish the high-temperature titanium alloy substrate, and then clean the high-temperature titanium alloy substrate with 99.7% absolute ethanol, and then The cleaned high-temperature titanium alloy substrate is fixed at the zero coordinate on the upper end surface of the test be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com