Pollution-free and efficient method for refining titanium-aluminum alloy

A titanium-aluminum alloy, pollution-free technology, applied in the field of pollution-free and efficient refinement of titanium-aluminum alloy, can solve the problems of poor plasticity at room temperature, coarse structure, high brittleness, etc., and achieve the goals of avoiding melt pollution, refining structure and improving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

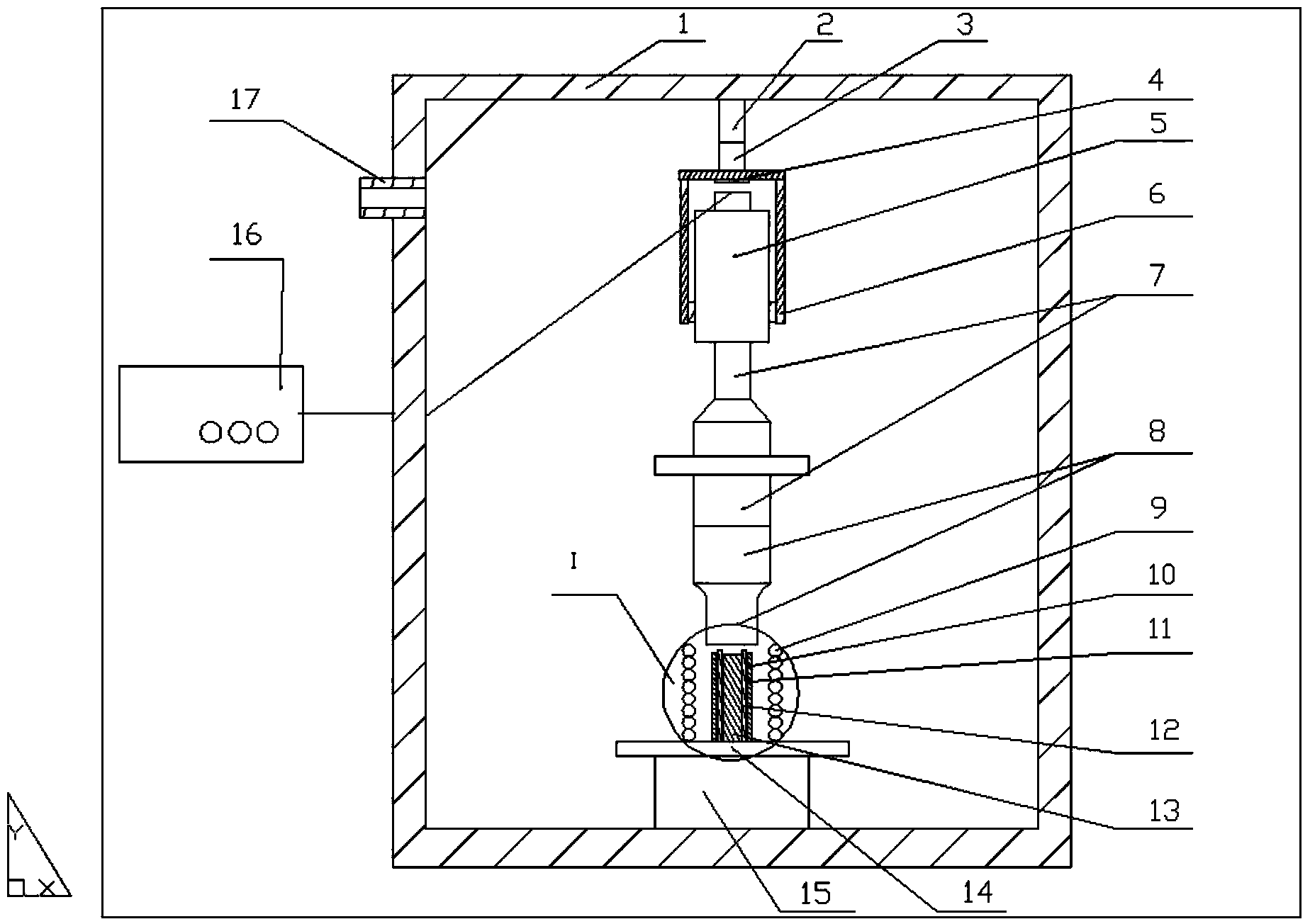

[0030] Specific implementation mode 1: A pollution-free and high-efficiency refining titanium-aluminum alloy method according to this implementation mode, which is realized according to the following steps:

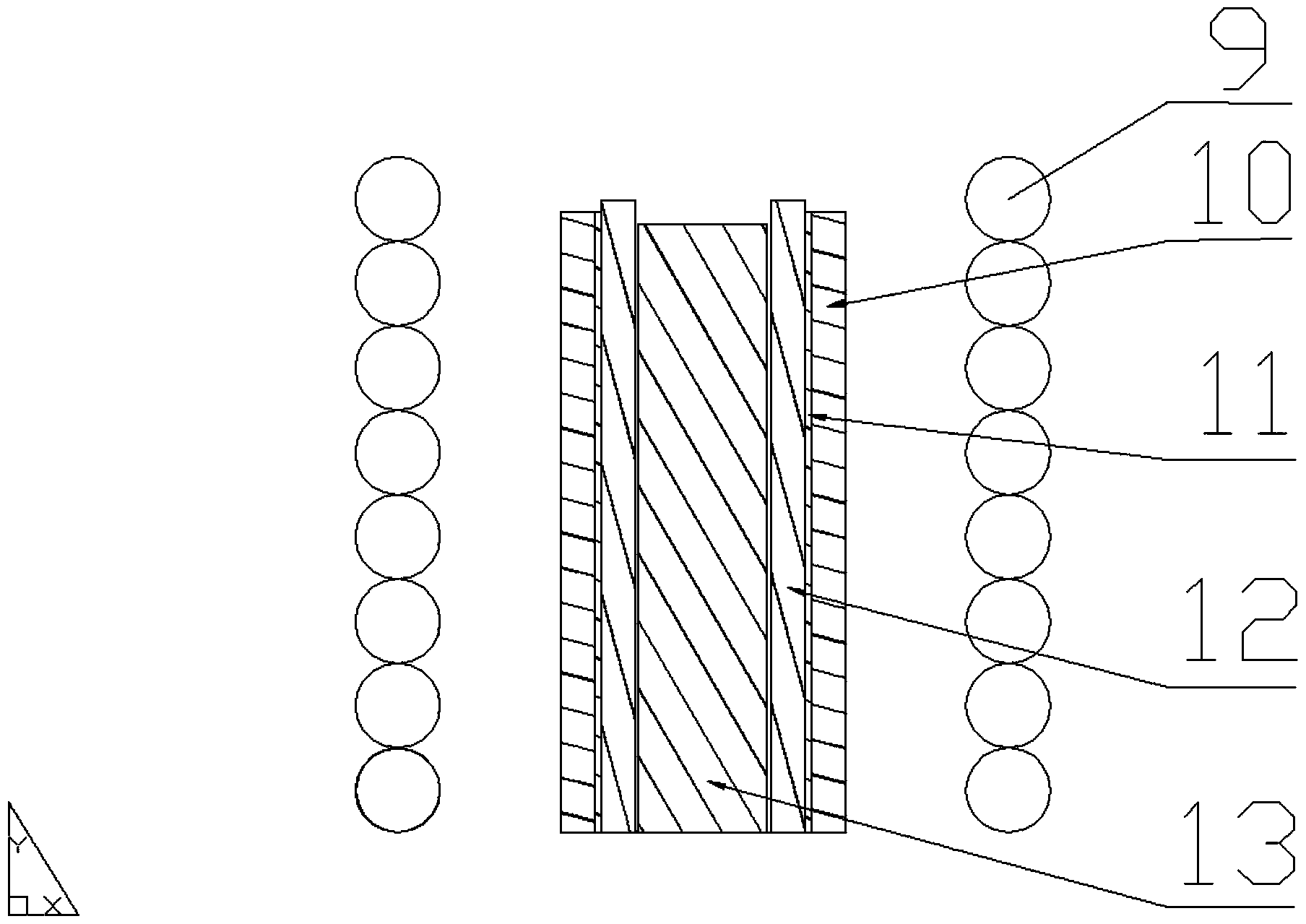

[0031] Step 1. In the vacuum chamber, the material is placed in the bar material layer 13 of the titanium-aluminum alloy melt melting device, and placed in the middle of the coil 9;

[0032] Step 2, connecting the coil 9 with the electrode; wherein, the inner diameter of the coil 9 is The number is 8 turns, and the electrodes are single-phase alternating current;

[0033] Step 3: Fix the ultrasonic generator on the upper positioning device 2 through the connecting rod 3;

[0034] Step 4, contact the T8 steel tool head 8 with the top surface of the formwork 12 through the upper positioning device 2;

[0035] Step 5. Turn on the vacuum pump 17, evacuate the air pressure in the vacuum chamber to below 1Pa, then backfill high-purity argon to 300Pa, repeat the operation 3 t...

specific Embodiment approach 2

[0044] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ultrasonic generator described in step 4 generates an oscillating electrical signal with a frequency of 20 KHz.

[0045] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0046] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the non-polluting and highly efficient titanium-aluminum alloy device described in step 1 is an yttrium oxide formwork.

[0047] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com