PE wood plastic particle processing device

A processing device and particle technology, which is applied in the field of industrial manufacturing, can solve the problems of reduced extrusion quality and output of composite materials, affecting the internal quality and appearance of products, and prolonging residence time, so as to achieve increased mixing effect, uniform product composition, The effect of improving abrasion resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

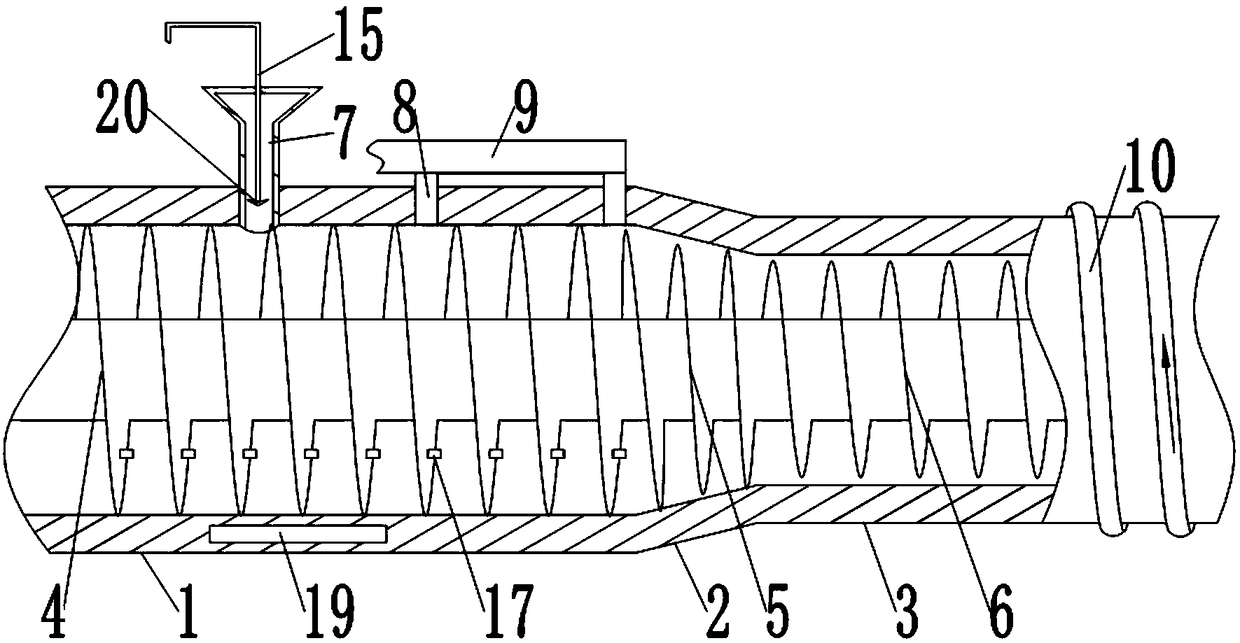

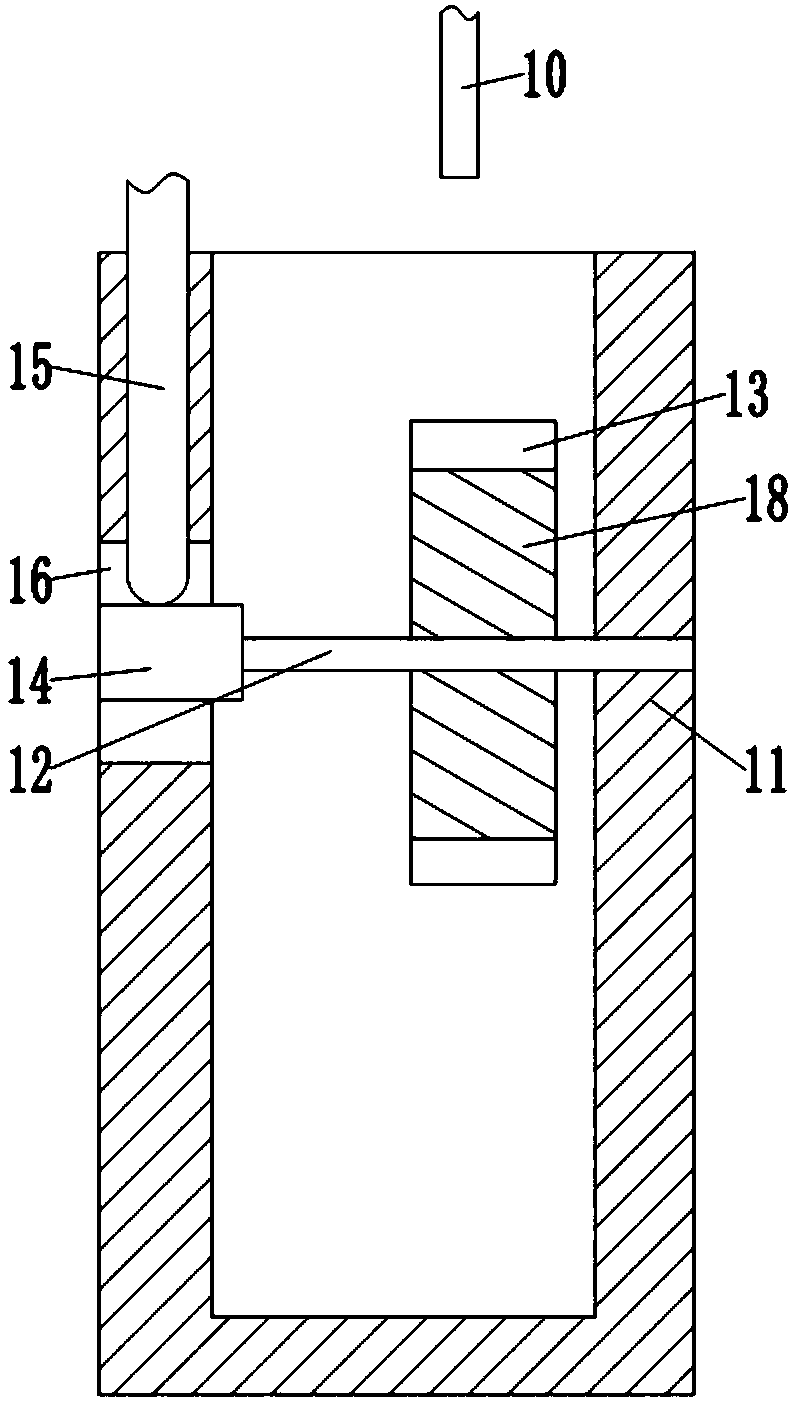

[0029] The reference signs in the accompanying drawings of the specification include: the first material barrel 1, the connecting part 2, the second material barrel 3, the high spiral blade 4, the mixing element 5, the low spiral blade 6, the feed hopper 7, and the exhaust hole 8 , Exhaust pipe 9, cooling water pipe 10, water collecting tank 11, rotating shaft 12, plank 13, prism 14, slide bar 15, through hole 16, stirring bar 17, connecting rod 18, heating block 19, stirring part 20.

[0030] The embodiment is basically as attached figure 1 Shown: The processing device of PE wood-plastic particles, including a barrel and a screw that rotates inside the barrel. The barrel includes a first barrel 1 with a larger diameter, a second barrel 3 with a smaller diameter, and a connecting The connecting part 2 of the first material barrel 1 and the second material barrel 3, the screw rod als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com