Organic-inorganic composite emulsion for metal surface treatment

A technology of metal surface treatment and inorganic compounding, applied in the direction of coating, etc., can solve the problems of affecting the modification effect, difficulty in uniform dispersion, etc., and achieve the effect of saving operating costs and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

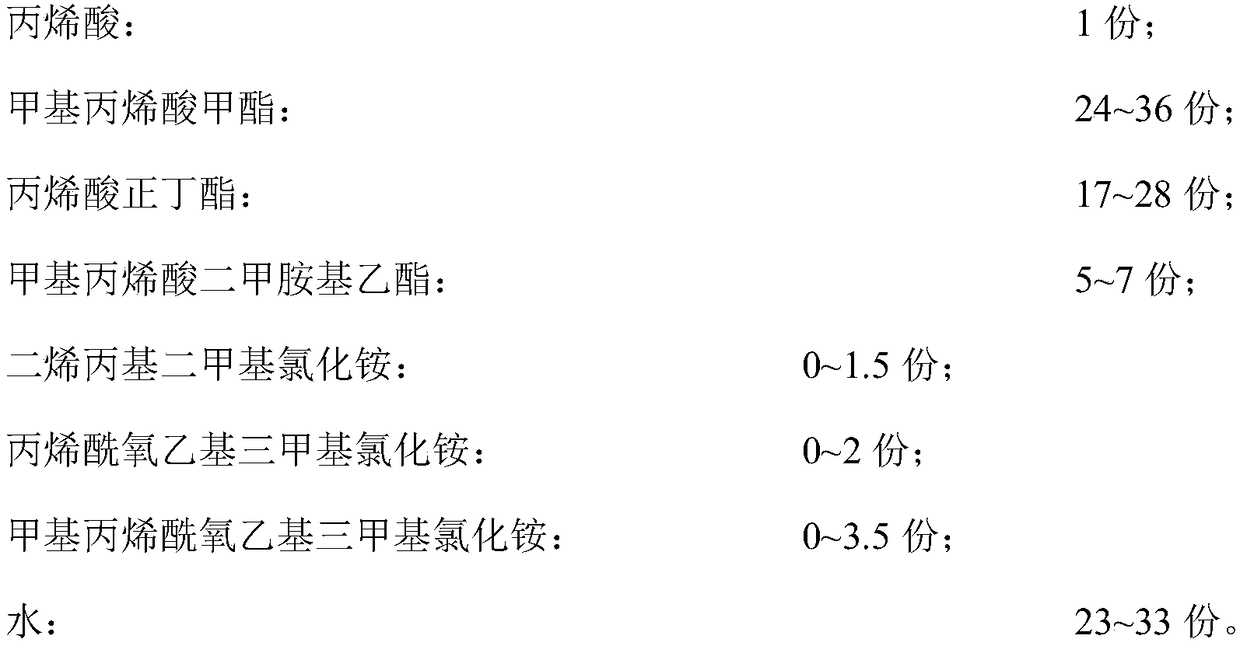

[0037] To prepare the organic-inorganic composite emulsion described in this patent, the required raw materials are as follows (parts by mass):

[0038]

[0039] Wherein, the acryloyloxyethyltrimethylammonium chloride is an aqueous mixture, and the content of acryloyloxyethyltrimethylammonium chloride is 78wt%: the methacryloyloxyethyltrimethylammonium chloride Ammonium is an aqueous mixture, and the content of methacryloxyethyltrimethylammonium chloride is 80wt%.

[0040] Concrete preparation method comprises the following steps:

[0041] 1) Drop 30 parts of deionized water and 5 parts of titanium dioxide nanoparticles into a small test reaction kettle made of quartz with 2 commercially available common high-pressure mercury lamps on the outside, and pass Nitrogen gas was used to purge the inside of the reactor.

[0042] 2) After heating up to 45±2°C under stirring, turn on the high-pressure mercury lamp to irradiate from the side of the reactor. After 15 minutes, pump 1...

Embodiment 2

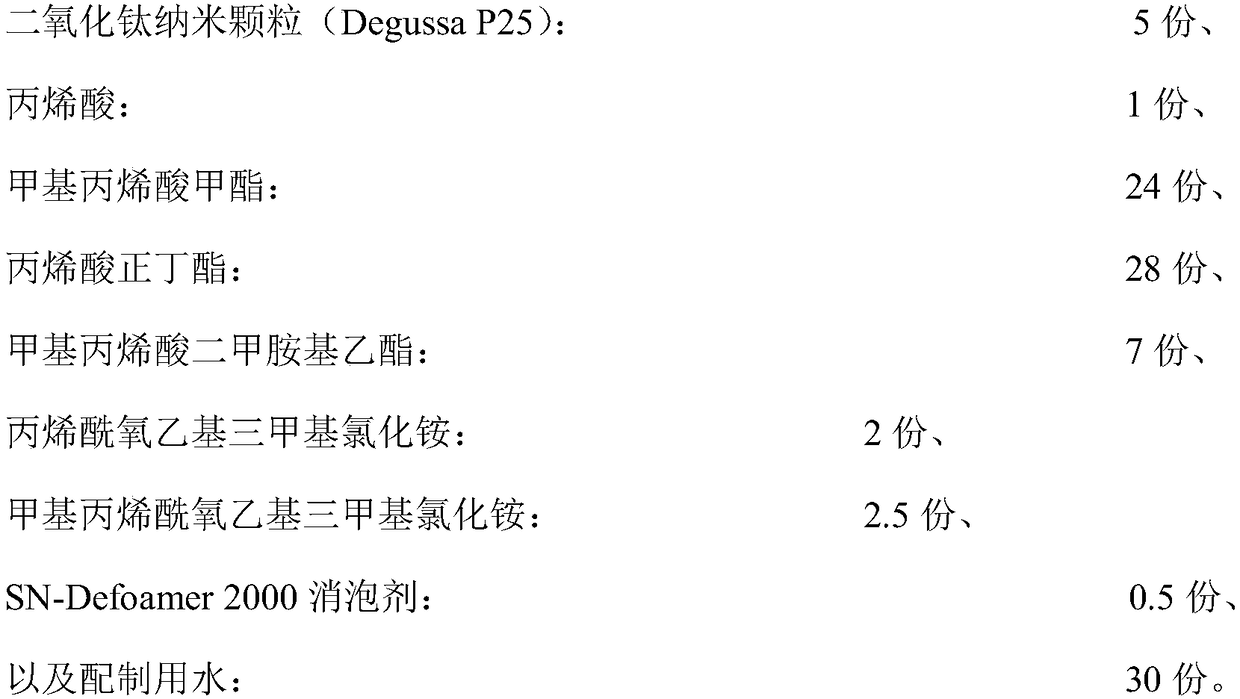

[0046] To prepare the organic-inorganic composite emulsion described in this patent, the required raw materials are as follows (parts by mass):

[0047]

[0048] Wherein, the acryloyloxyethyltrimethylammonium chloride is an aqueous mixture, and the content of acryloyloxyethyltrimethylammonium chloride is 78wt%: the methacryloyloxyethyltrimethylammonium chloride Ammonium is an aqueous mixture, and the content of methacryloxyethyltrimethylammonium chloride is 80wt%.

[0049] Concrete preparation method comprises the following steps:

[0050] 1) Put 23 parts of deionized water and 15 parts of neutral titanium sol into a reaction kettle equipped with a jacketed water bath device, a stirring device and a feeding device, and an explosion-proof LED ultraviolet lamp for photocuring is installed on the inside of the top cover, and pass into Nitrogen was used to purge the interior of the device.

[0051] 2) After heating up to 45±2°C under stirring, turn on the ultraviolet light so...

Embodiment 3

[0055] To prepare the organic-inorganic composite emulsion described in this patent, the required raw materials are as follows (parts by mass):

[0056]

[0057] Wherein, said diallyl dimethyl ammonium chloride is an aqueous mixture, and the content of diallyl dimethyl ammonium chloride is 65 wt%.

[0058] Concrete preparation method comprises the following steps:

[0059] 1) Put 33 parts of deionized water and 15 parts of neutral titanium sol into a reaction kettle equipped with a jacketed water bath device, a stirring device and a feeding device, and an explosion-proof LED ultraviolet lamp for photocuring is installed on the inside of the top cover, and pass into Nitrogen was used to purge the interior of the device.

[0060] 2) After heating up to 45±2°C under stirring, turn on the ultraviolet light source to irradiate above the liquid level in the kettle, and pump 1 part of acrylic acid and 24 parts of methyl methacrylate pre-mixed into the reaction kettle at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com