A kind of rare earth niobate high-entropy powder, porous high-entropy ceramic and preparation method and application

A niobate and rare earth technology, which is applied in the field of porous high-entropy ceramics and preparation, rare earth niobate high-entropy powder, can solve the problems of poor mechanical properties and lower lattice thermal conductivity, and achieve lower thermal conductivity, Effect of increasing phonon scattering and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0069] Below for embodiment 1-7 do specific description:

Embodiment 1

[0071] Step 1, ball mill 223.80g nanometer dysprosium oxide, 226.72g nanometer holmium oxide, 231.52g nanometer thulium oxide, 229.51g nanometer erbium oxide, 236.45g nanometer ytterbium oxide, 265.81g nanometer niobium pentoxide and 3576.11g absolute ethanol for 48h , the ball milling speed is 250r / min;

[0072] Step 2, after drying at 60°C for 24h, a mixed material was obtained;

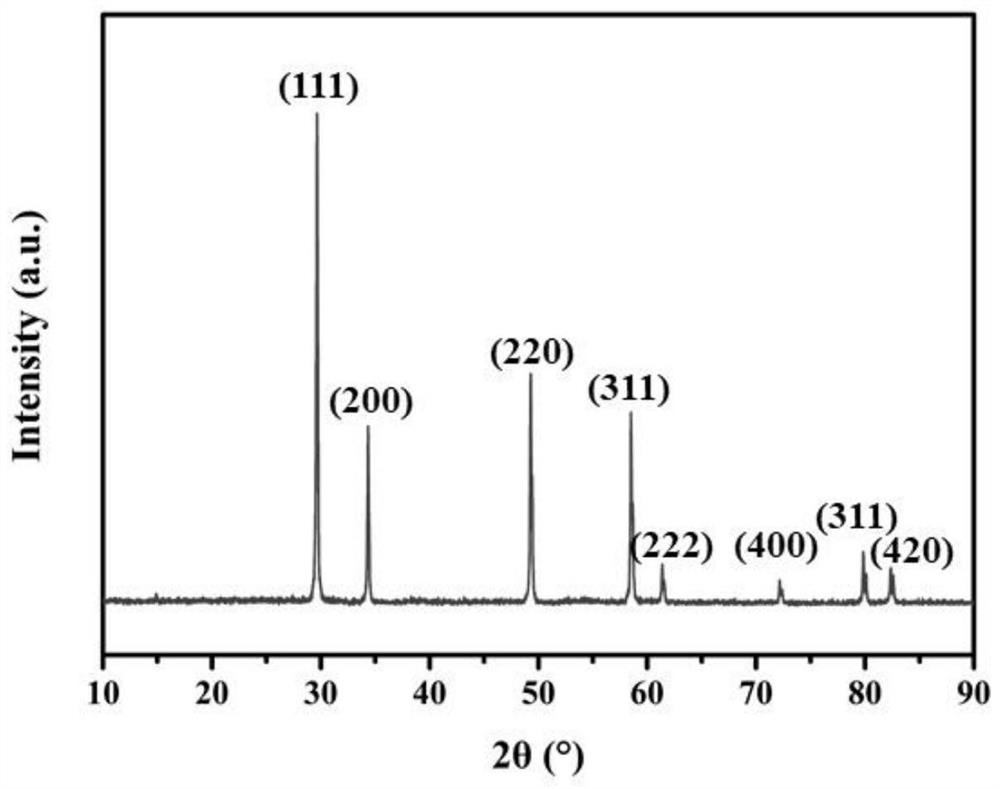

[0073] In step 3, the mixture was calcined at 1450 ° C for 4 h to obtain (Dy 0.2 Ho 0.2 Tm 0.2 Er 0.2 Yb 0.2 ) 3 NbO 7 High entropy powder;

[0074] Step 4, the 100g (Dy 0.2 Ho 0.2 Tm 0.2 Er 0.2 Yb 0.2 ) 3 NbO 7 High-entropy powder, 1000g tert-butanol, 0.5g ammonium citrate and 300g ethylene glycol diglycidyl ether mixed ball milling preparation (Dy 0.2 Ho 0.2 Tm 0.2 Er 0.2 Yb 0.2 ) 3 NbO 7 For high-entropy ceramic suspension, the ball milling speed is 300r / min, and the ball milling time is 24h;

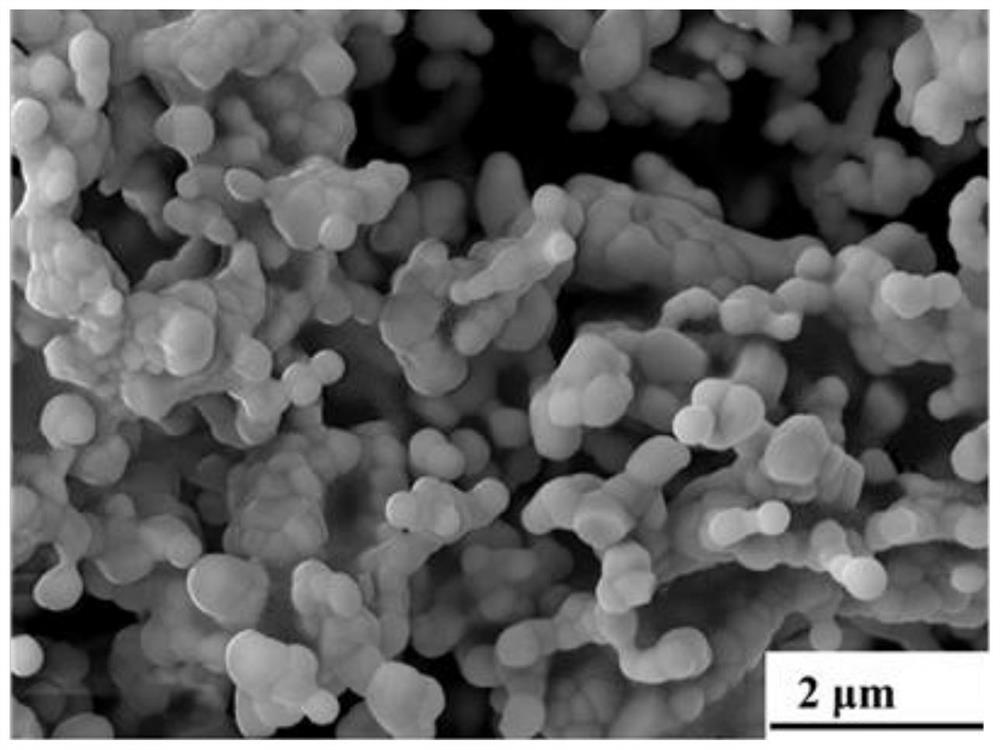

[0075] Step 5, adding 150g of 3,3'-diaminodipropylamine to the high-entropy cera...

Embodiment 2

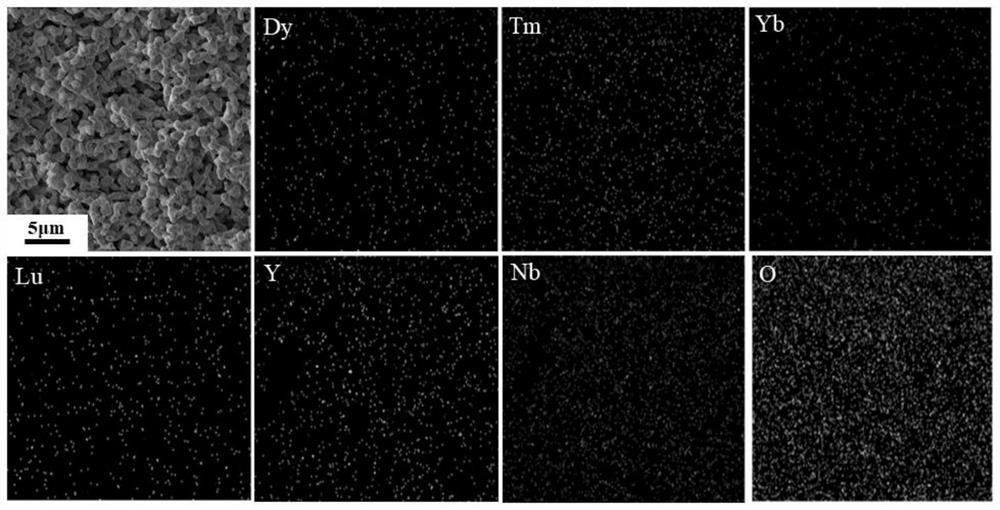

[0080] Step 1, ball mill 205.60g nanometer dysprosium oxide, 212.69g nanometer thulium oxide, 217.22g nanometer ytterbium oxide, 219.34g nanometer lutetium oxide, 124.47g nanometer yttrium oxide, 244.19g nanometer niobium pentoxide and 3285.29g anhydrous ethanol for 36h , the ball milling speed is 300r / min;

[0081] Step 2, after drying at 60°C for 24h, a mixed material was obtained;

[0082] In step 3, the mixture was calcined at 1500 ° C for 4 h to obtain (Dy 0.2 Tm 0.2 Yb 0.2 Lu 0.2 Y 0.2 ) 3 NbO 7 High entropy powder;

[0083] Step 4, the 500g (Dy 0.2 Tm 0.2 Yb 0.2 Lu 0.2 Y 0.2 ) 3 NbO 7 High-entropy powder, 1000g tert-butanol, 2g polyethyleneimine and 100g ethylene glycol diglycidyl ether mixed ball milling preparation (Dy 0.2 Tm 0.2 Yb 0.2 Lu 0.2 Y 0.2 ) 3 NbO 7 High entropy ceramic suspension;

[0084] Step 5, adding 20 g of 3,3'-diaminodipropylamine to the high-entropy ceramic suspension, curing at 60°C for 12 hours, and drying at 100°C for 24 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com