Patents

Literature

32results about How to "Sufficient vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

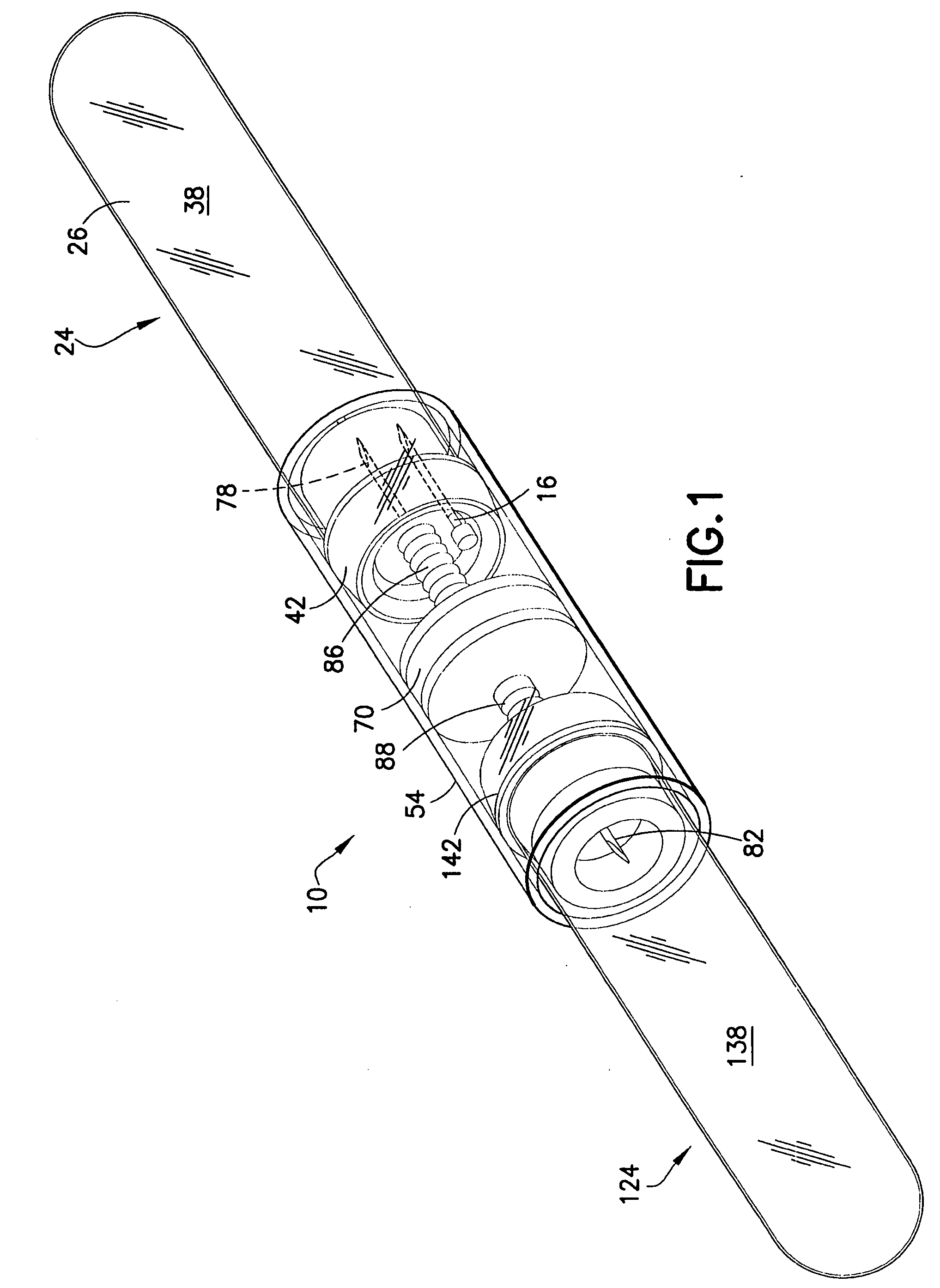

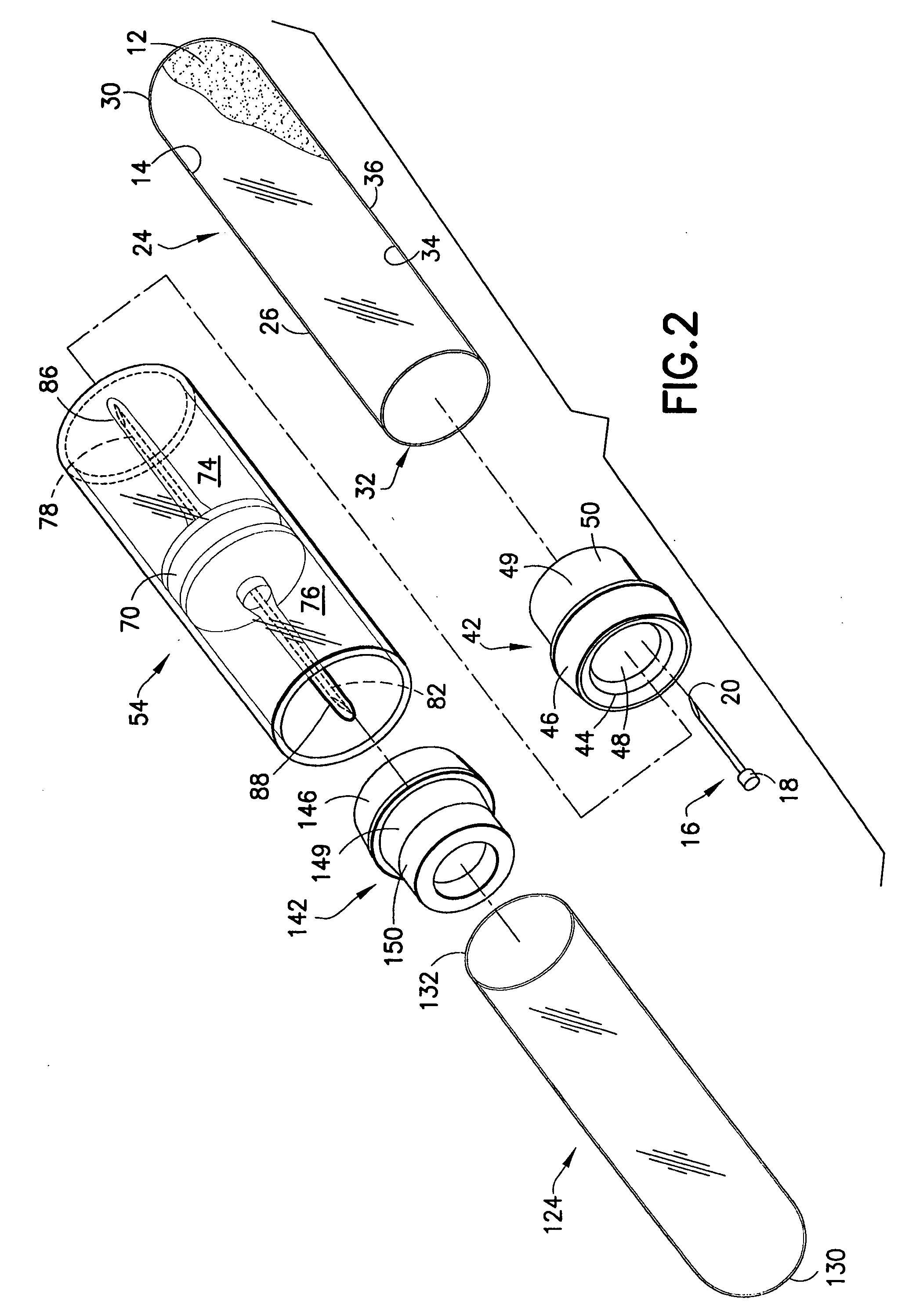

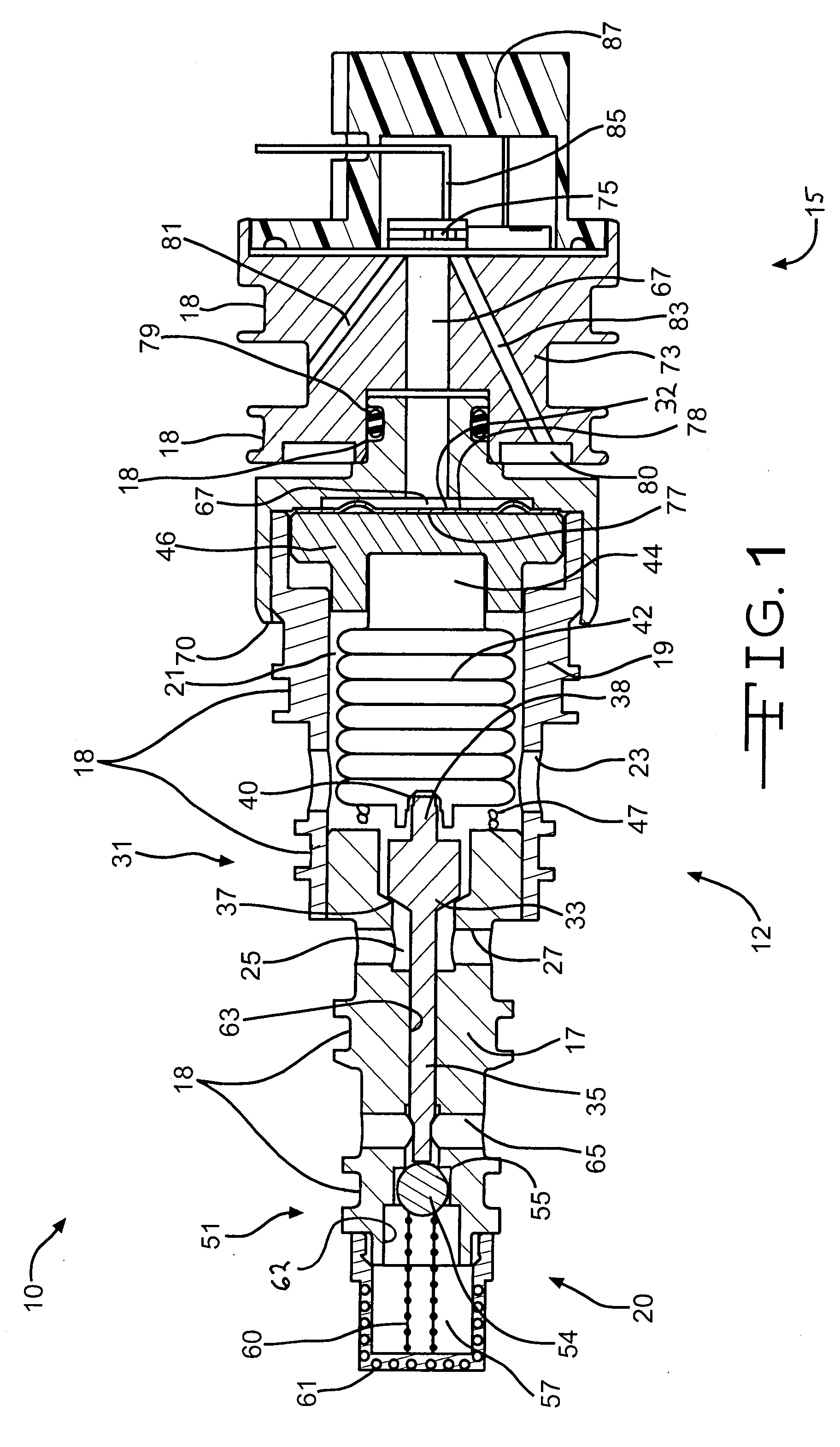

Plasma on demand tube

ActiveUS20050139547A1Avoid easy cloggingEasy to useCapsClosure lidsEvacuated blood collection tubeMedicine

A device for separating plasma from whole blood is provided having an evacuated primary collection chamber capable of fluid communication through a porous filter to an evacuated secondary collection chamber. An agglutinating agent is provided within the primary collection chamber so as to aggregate blood cells within a whole blood sample. The porous filter has a pore size which is small enough to capture the aggregated blood cells therein, yet large enough to permit plasma to transfer therethrough under pressures associated with conventional evacuated blood collection tubes. The primary and secondary collection chambers may be provided in separate containers or tubes, with transfer occurring therebetween through a transfer device including the porous filter therein.

Owner:BECTON DICKINSON & CO

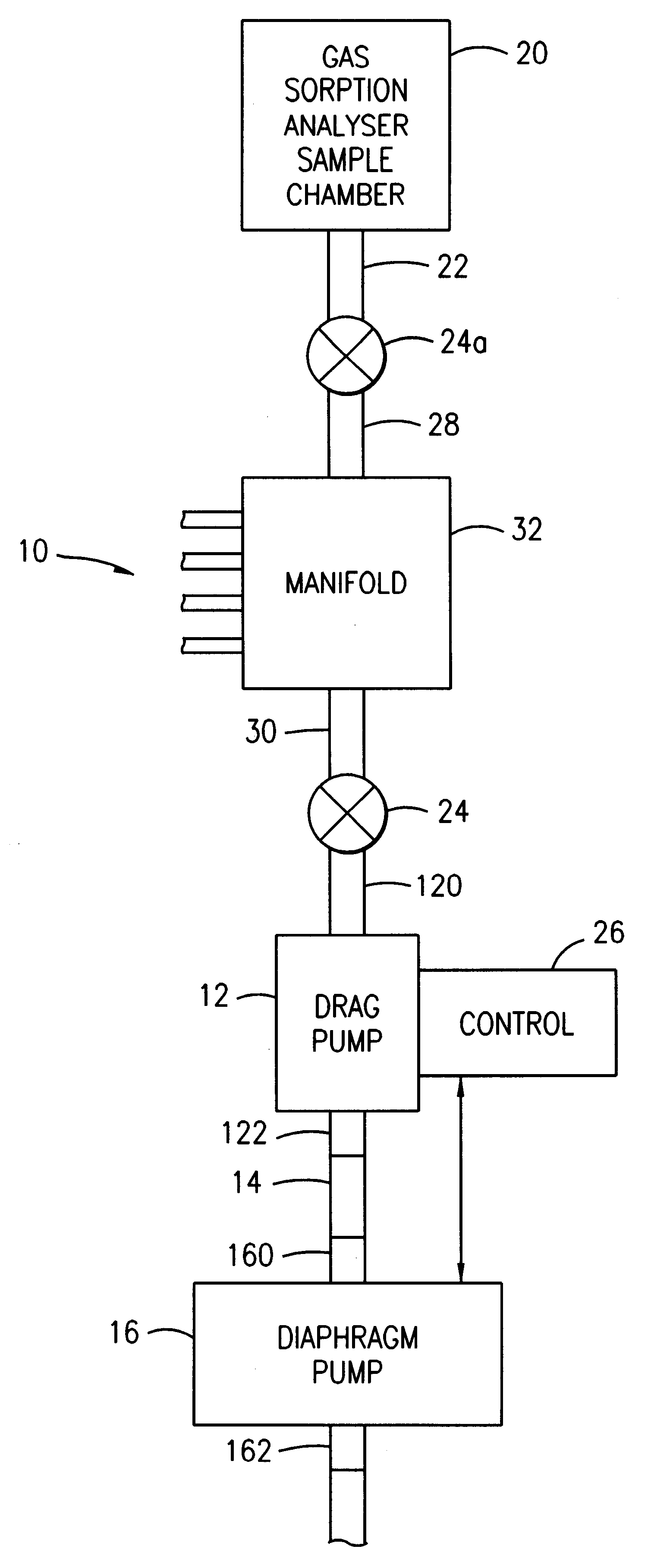

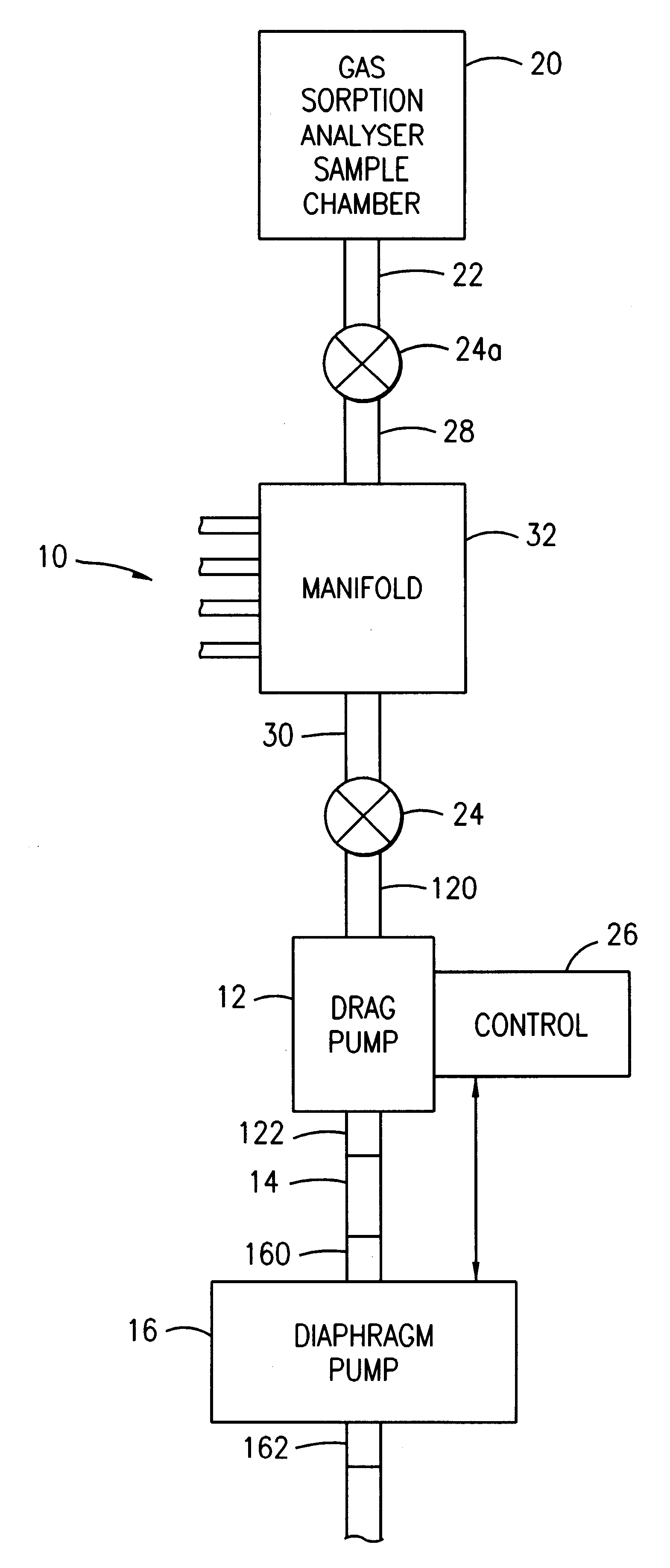

Dry vacuum pump system for gas sorption analyzer

InactiveUS6257835B1Eliminate needIncrease vacuumParticle separator tubesIsotope separationPorosityTorr

A vacuum pump system for creating a high vacuum (below 10-7 TORR) especially useful for vacuum volumetric measurements such as are performed using a gas sorption analyzer on a particulate sample to determine particulate surface area and porosity using a dry, non-lubricant oil-free vacuum pumping system that includes a turbomolecular drag pump having its high vacuum side connected to a vessel that contains the particulate sample to be analyzed, and in series with a dry, oil-free diaphragm pump whose inlet or vacuum side is connected to the high pressure exhaust side of the turbomolecular drag pump thereby eliminating any possibility of oil vapor contamination of the sample since the turbomolecular drag pump and the diaphragm pump use essentially no oil as lubricants.

Owner:QUANTACHROME

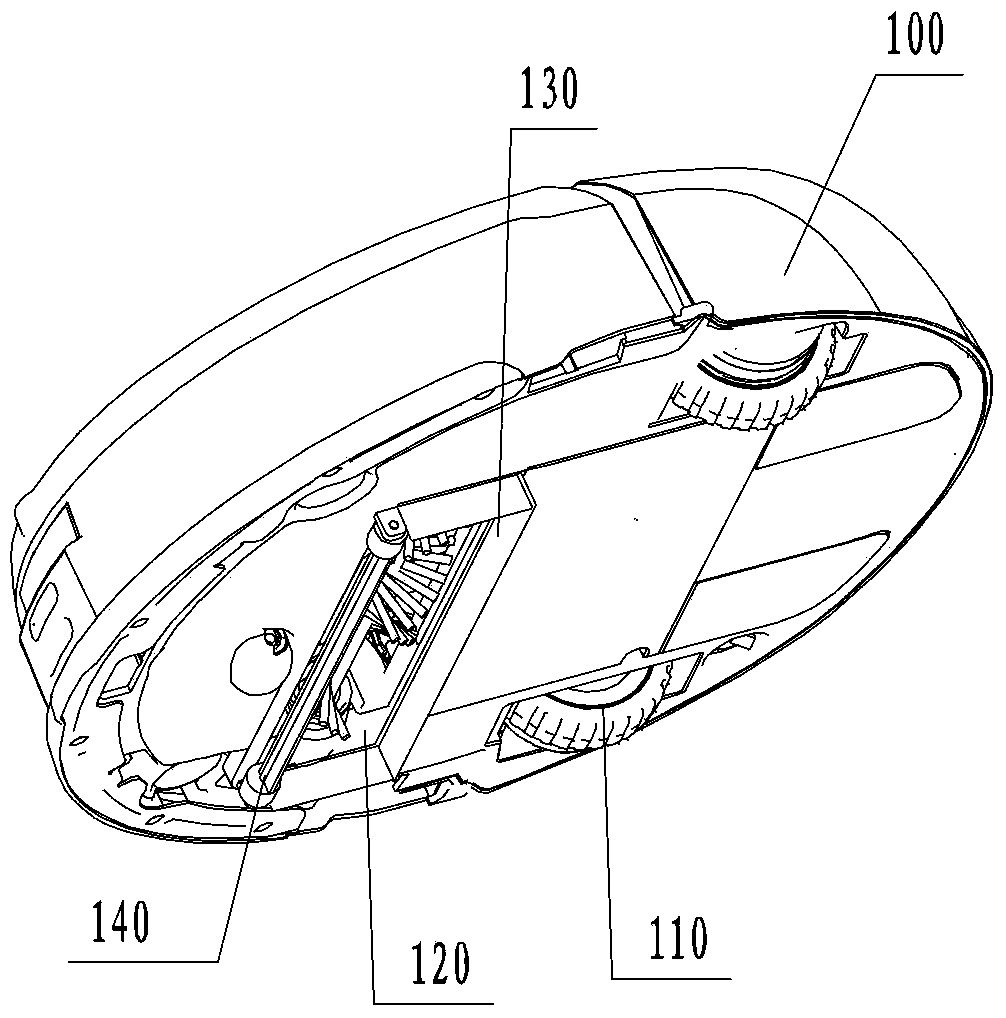

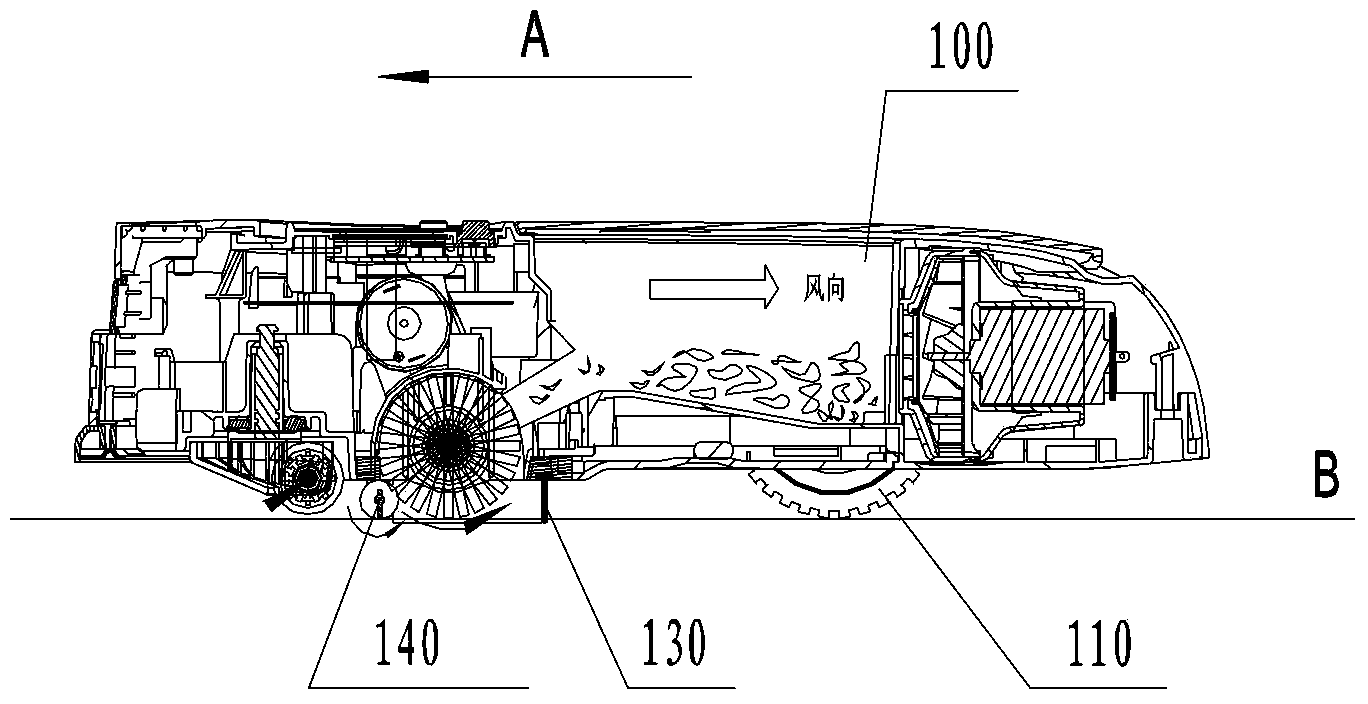

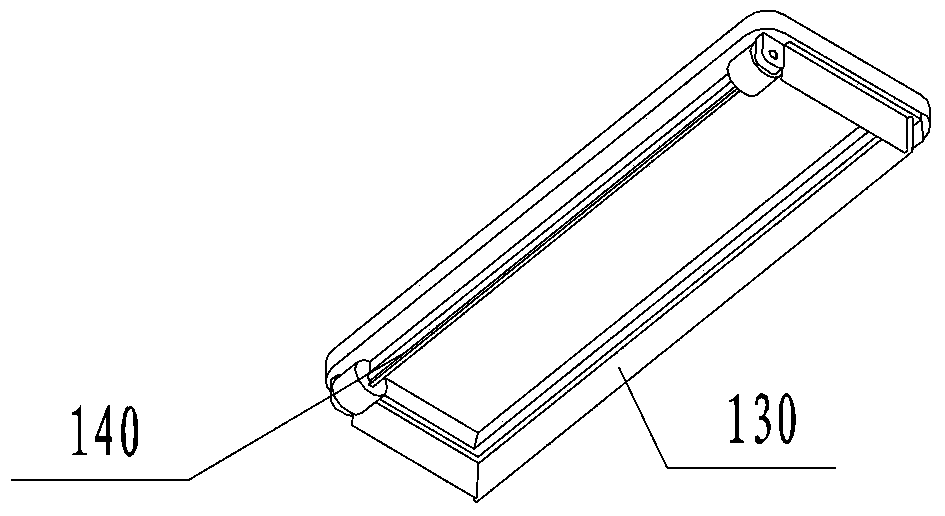

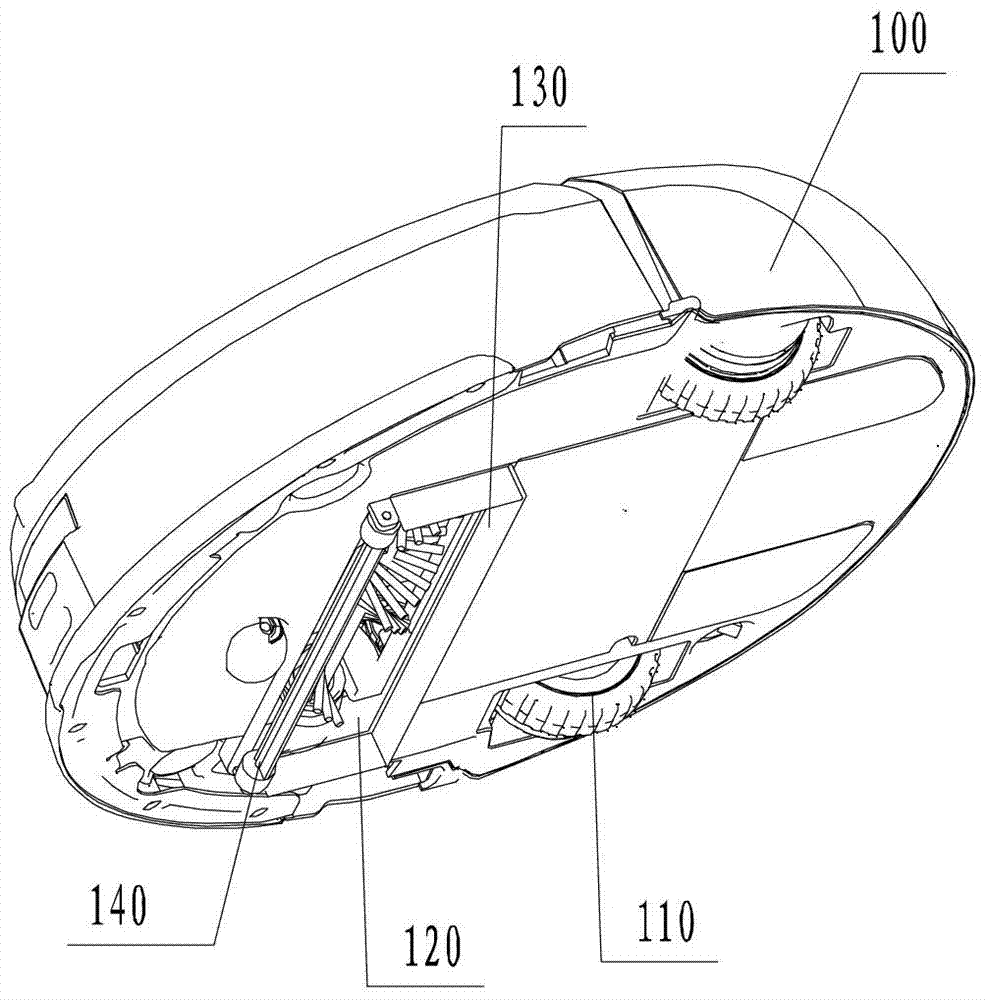

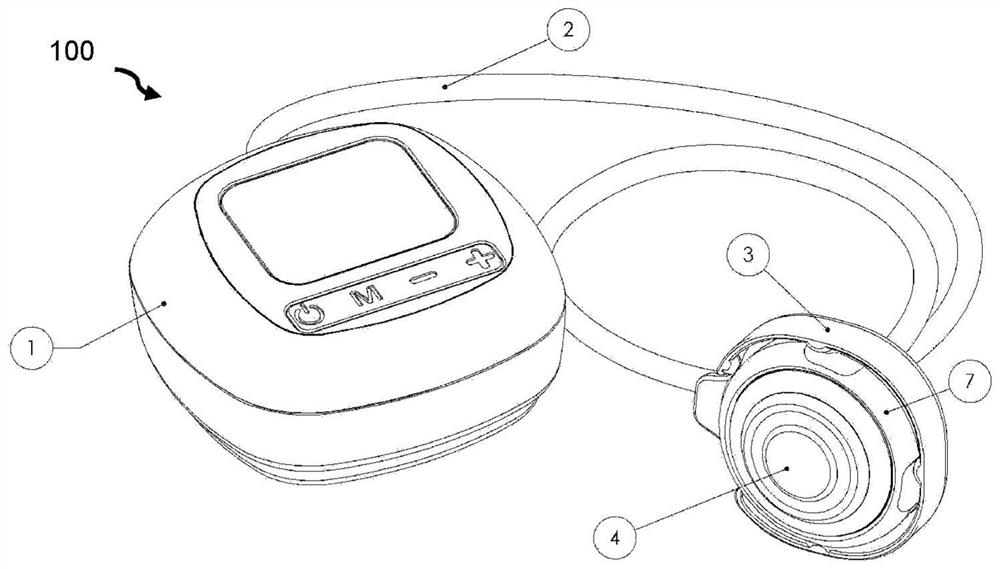

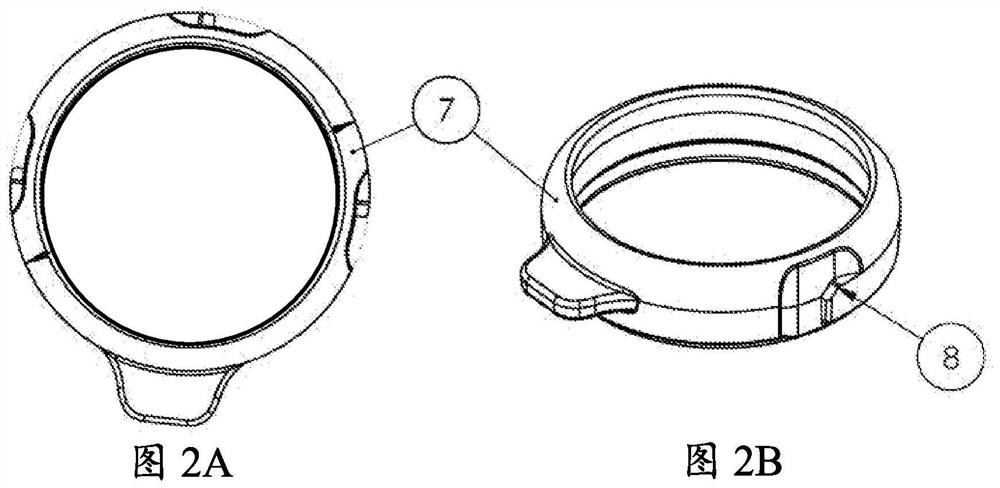

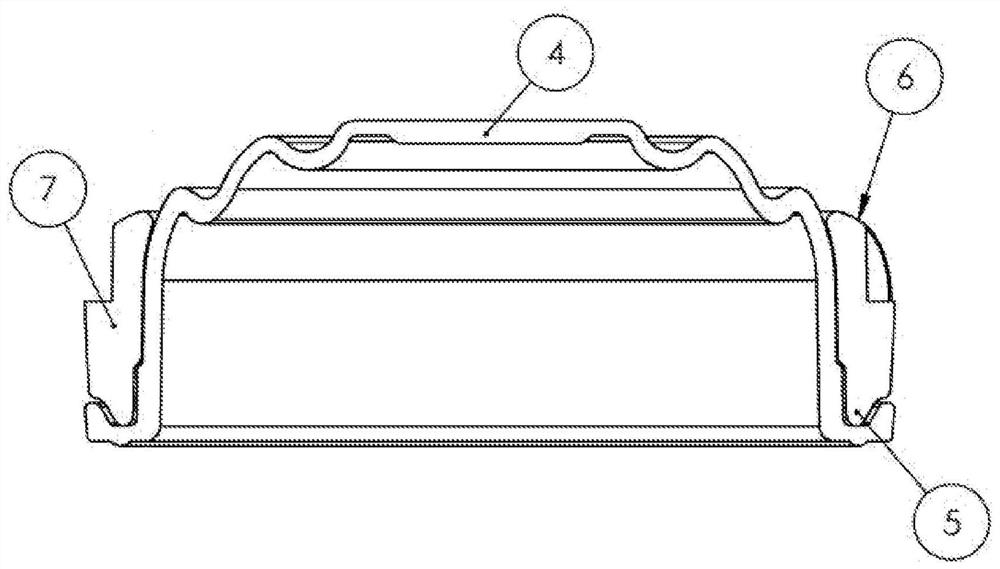

Cleaning robot and floor treatment device

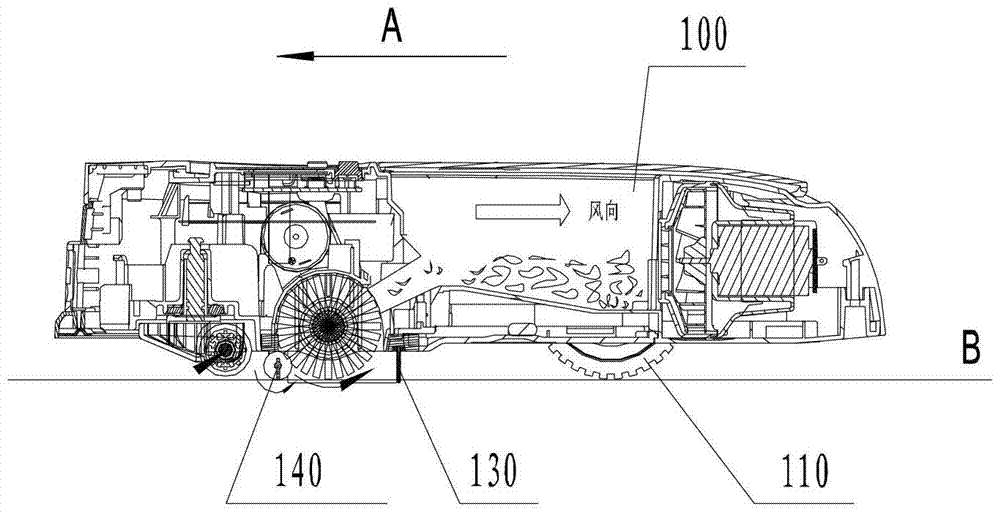

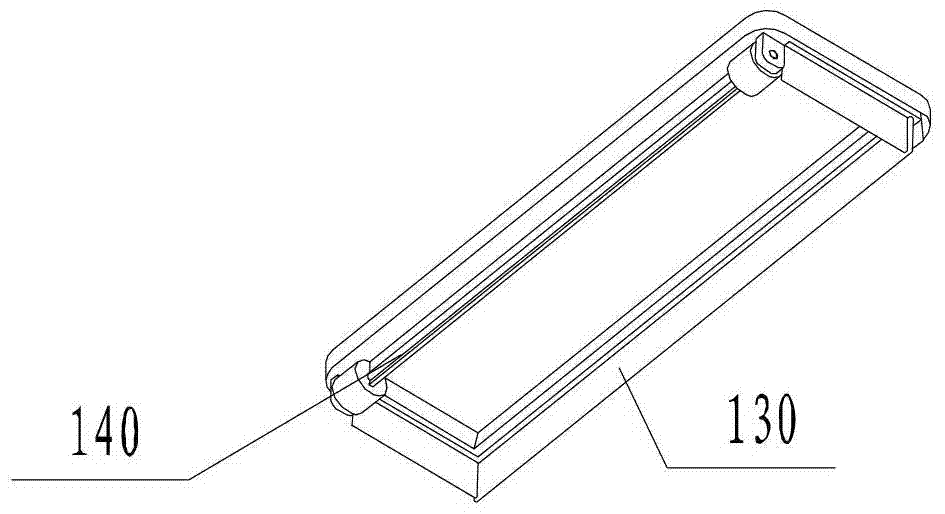

ActiveCN104138238ASufficient vacuumWon't hinder reachSuction nozzlesCleaning equipmentDrive wheelEngineering

A cleaning robot comprising a robot machine body (100). Drive wheels (110) are arranged on the machine body (100). A dust intake opening (120) is provided at the bottom part of the machine body (100). With the direction in which the cleaning robot travels serving as the front (A), a static seal (130) is arranged at the rear and two sides of the dust intake opening (120). The lower edge of the static seal (130) extends towards a to-be-cleaned work surface (B). A dynamic sealing element (140) is arranged at the front of the dust intake opening (120). The dynamic sealing element (140) comprises an actuating element (141) and a dynamic seal (142). A gap between the dynamic seal (142) and either the edge of the dust intake opening (120) and / or the to-be-cleaned work surface (B) forms an air intake opening. The dynamic seal (142) is driven by the actuating element (141) into motion, thus allowing the area of the air intake opening to change dynamically. By arranging the dynamic sealing element (140) at the dust intake opening (120), not only the dust intake opening (120) is provided with a sufficient degree of vacuum, but also the dynamic sealing element (140) does not obstruct dust particles from reaching the dust intake opening (120), thus allowing for a simplified structure and increased cleaning efficiency.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

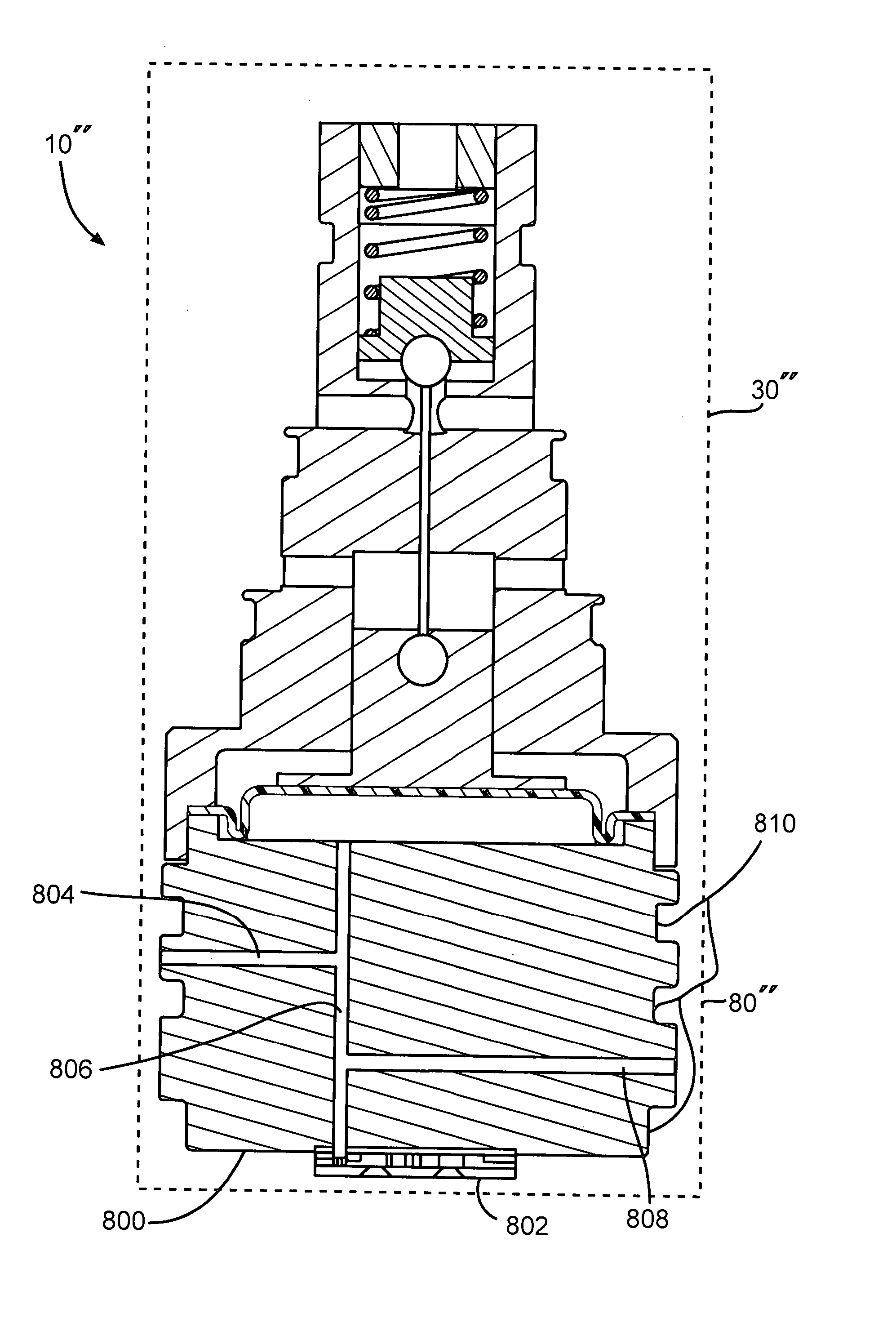

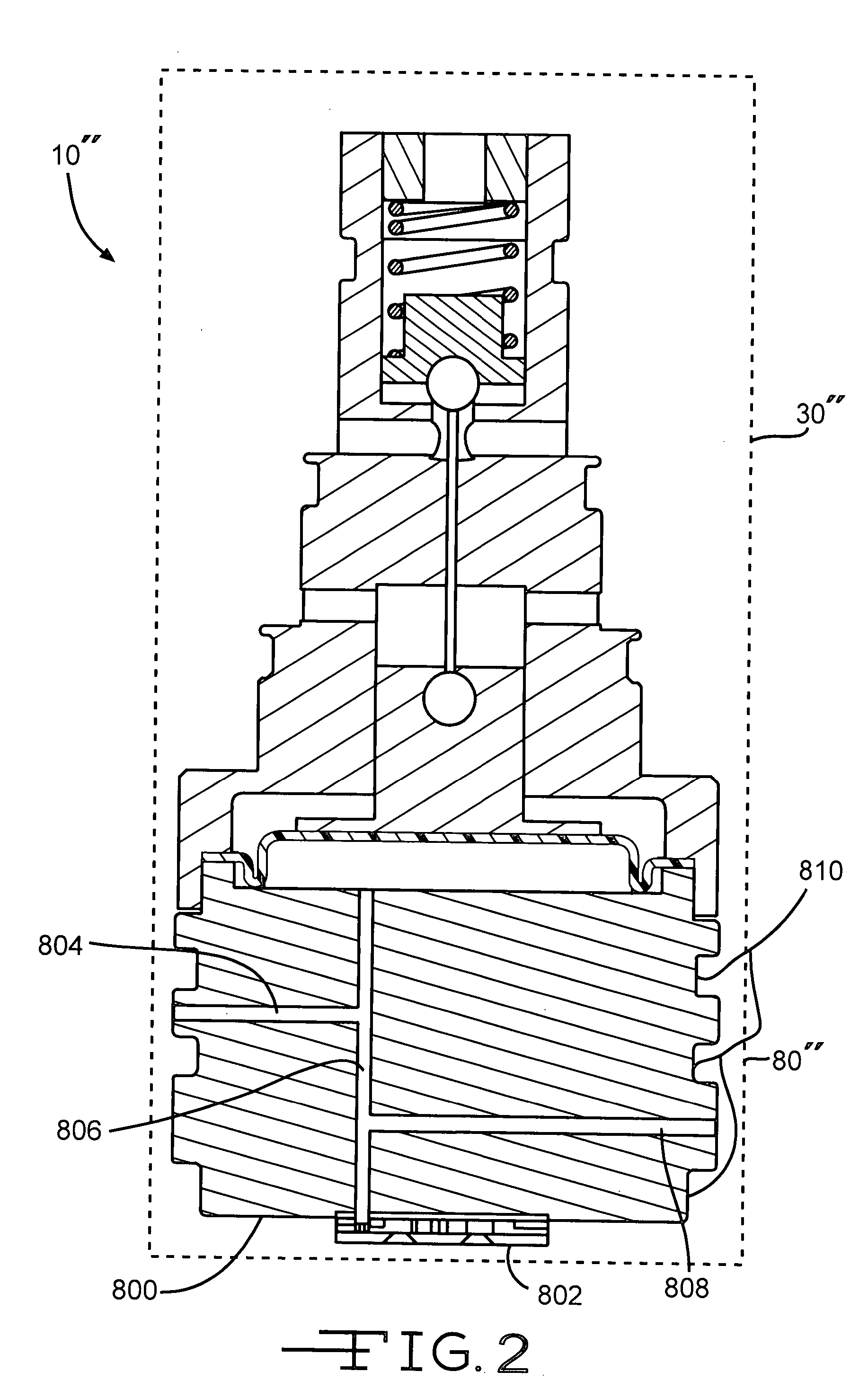

Electro-pneumatic control valve with microvalve pilot

InactiveUS20070251586A1Sufficient vacuumFluid-pressure actuator safetyValve arrangementsMicro valveEngineering

The invention relates to a MEMS (Micro Electro Mechanical Systems) device in the form of a pressure control valve suitable for controlling the operation of a refrigeration compressor. The pressure control valve is responsive to a reference pressure controlled by a microvalve.

Owner:MICROSTAQ

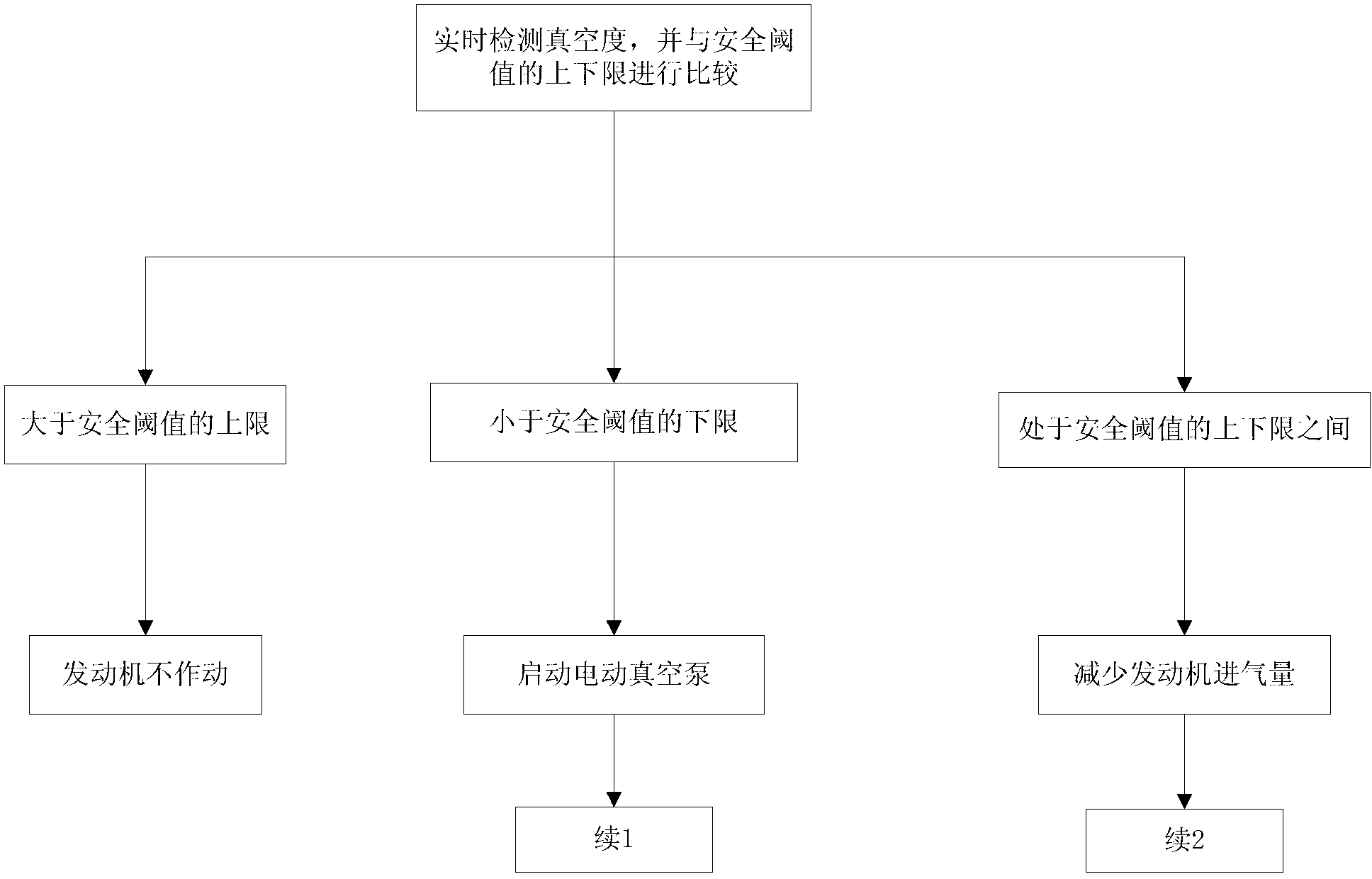

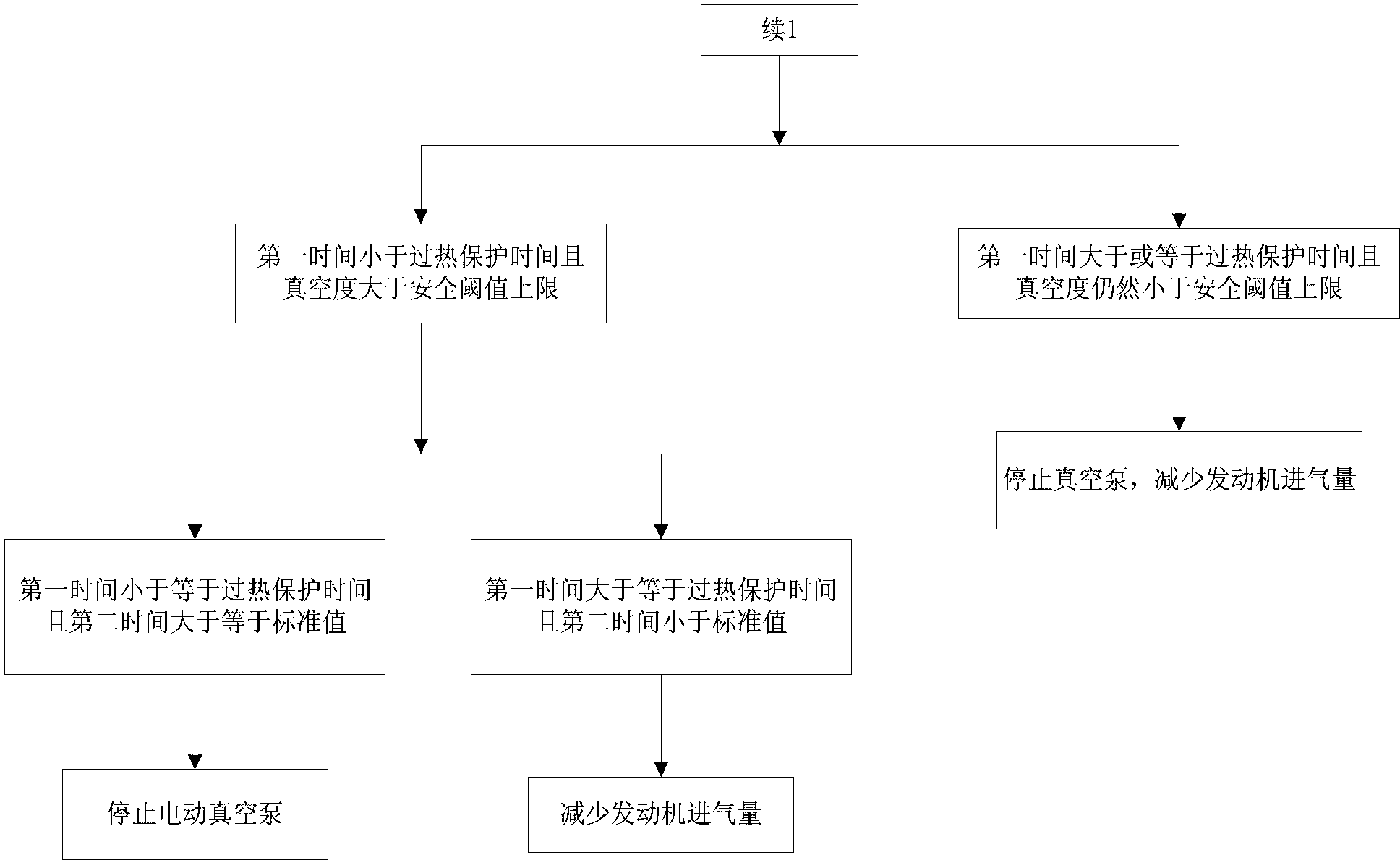

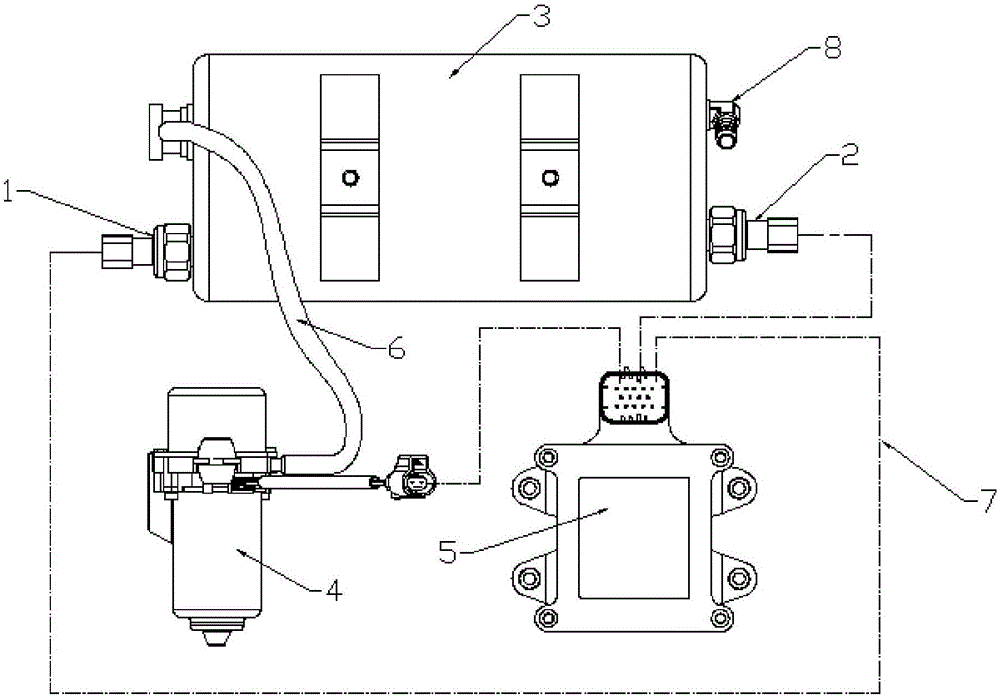

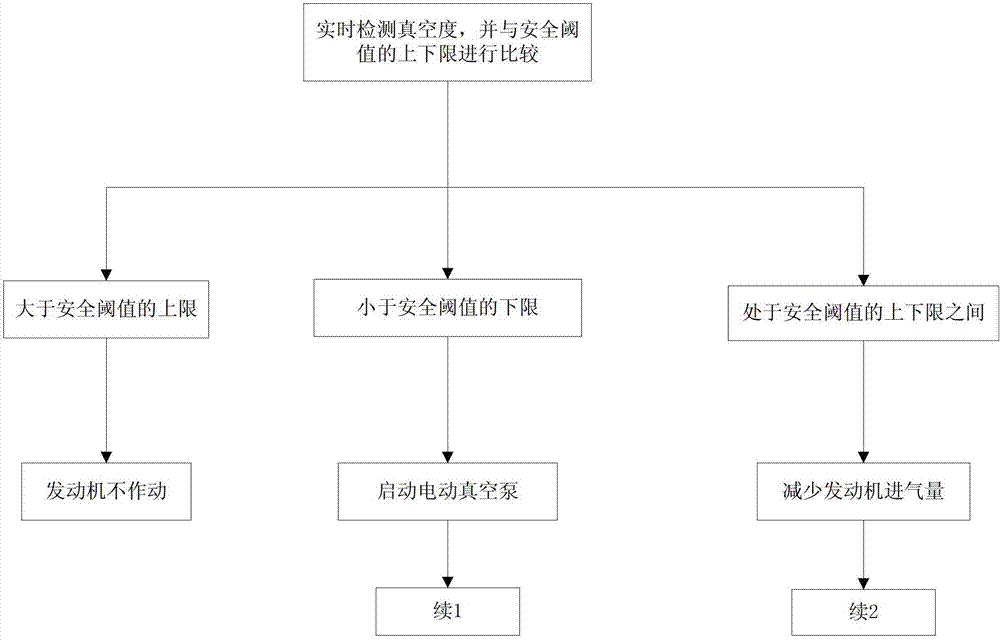

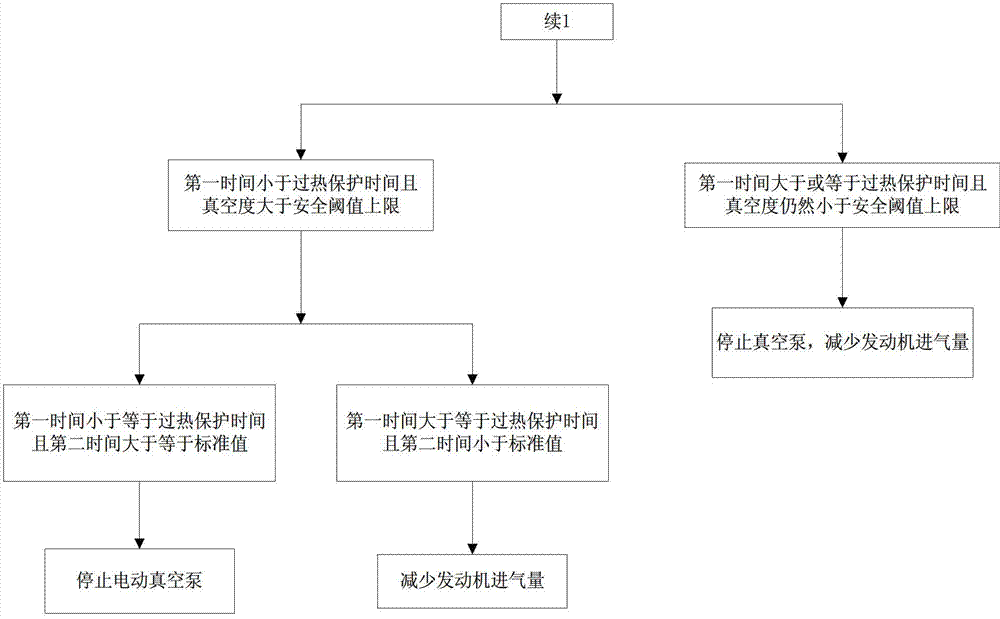

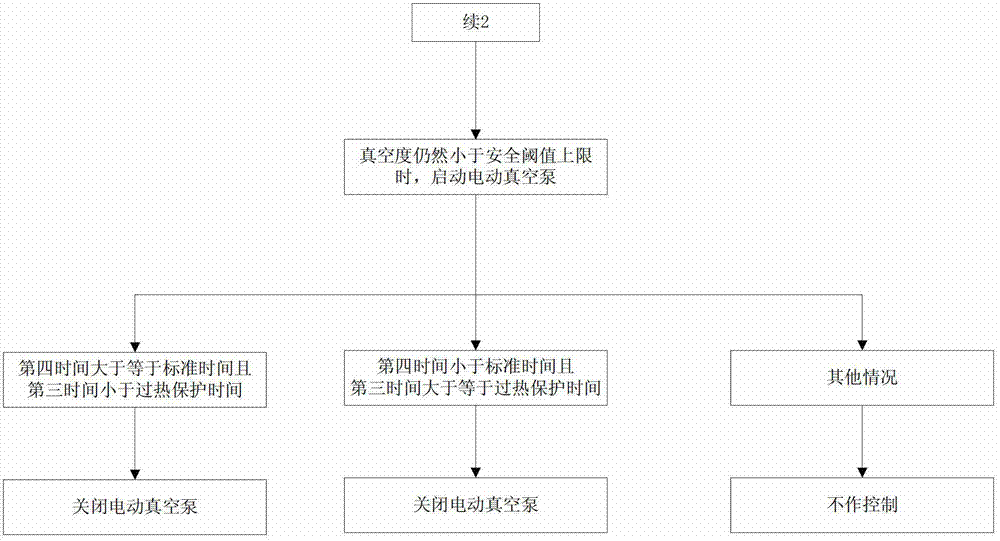

Method for controlling electric vacuum pump based on ECU (Electronic Control Unit) control

ActiveCN103072563ASufficient vacuumGet rid of dependencyBraking action transmissionLower limitEngineering

The invention provides a method for controlling an electric vacuum pump control method based on ECU (Electronic Control Unit) control. The method comprises the following steps of: detecting the vacuum degree of a vacuum booster in real time, and comparing with the upper and lower limits of a safety threshold value; and adjusting the vacuum degree of the vacuum booster according to a comparison result. Measures for adjusting the vacuum degree of the vacuum booster include starting the electric vacuum pump to assist the vacuum booster in generating a vacuum degree, and lowering an engine load to increase the vacuum degree. The control method can be implemented on the basis of an engine ECU by fully depending on the structure of the conventional vehicle model, so that the defects of excessive dependence on a mechanical structure and large modification on a vehicle existing in the conventional method are overcome, the cost is saved, and a better control effect can be achieved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

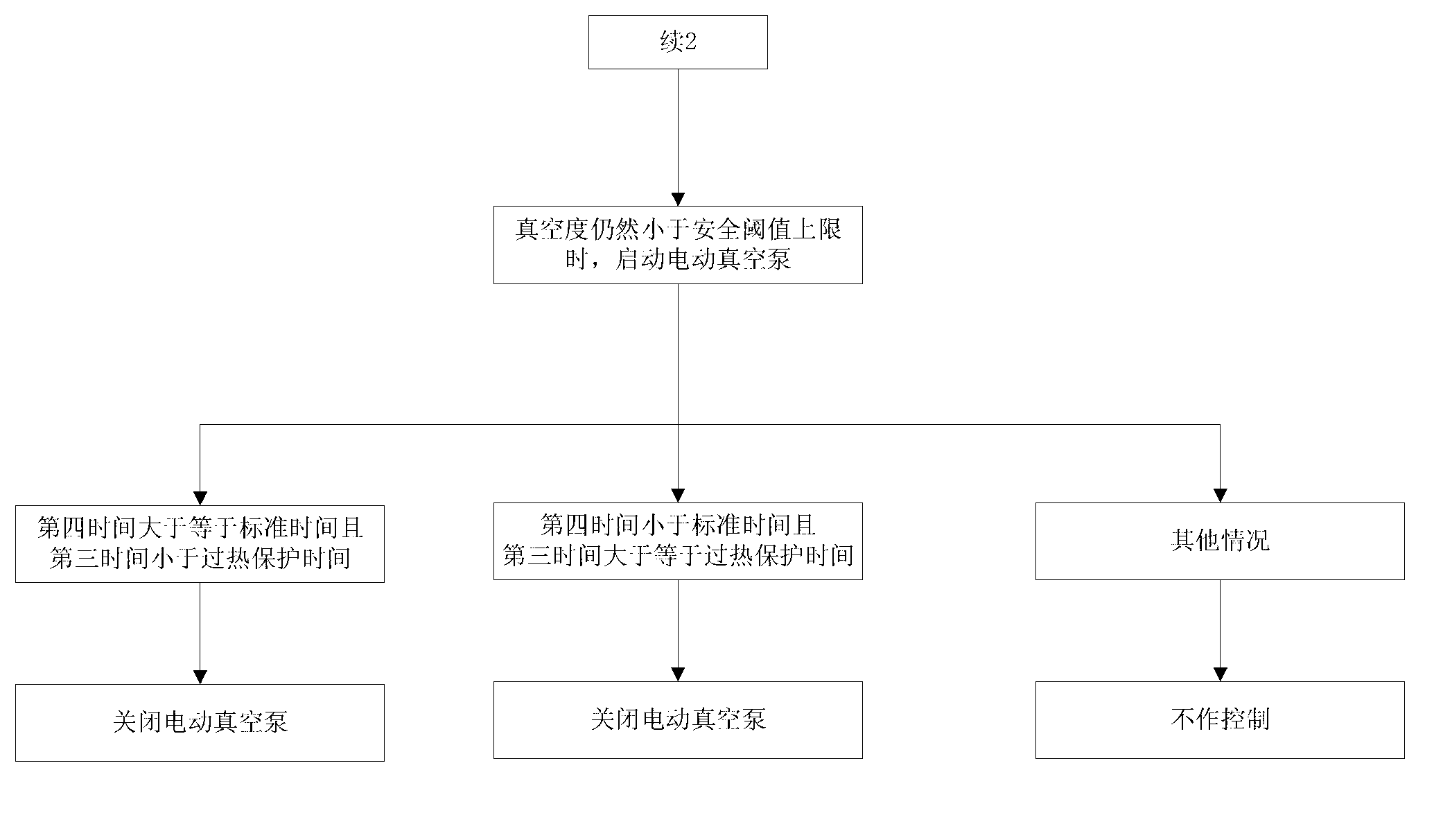

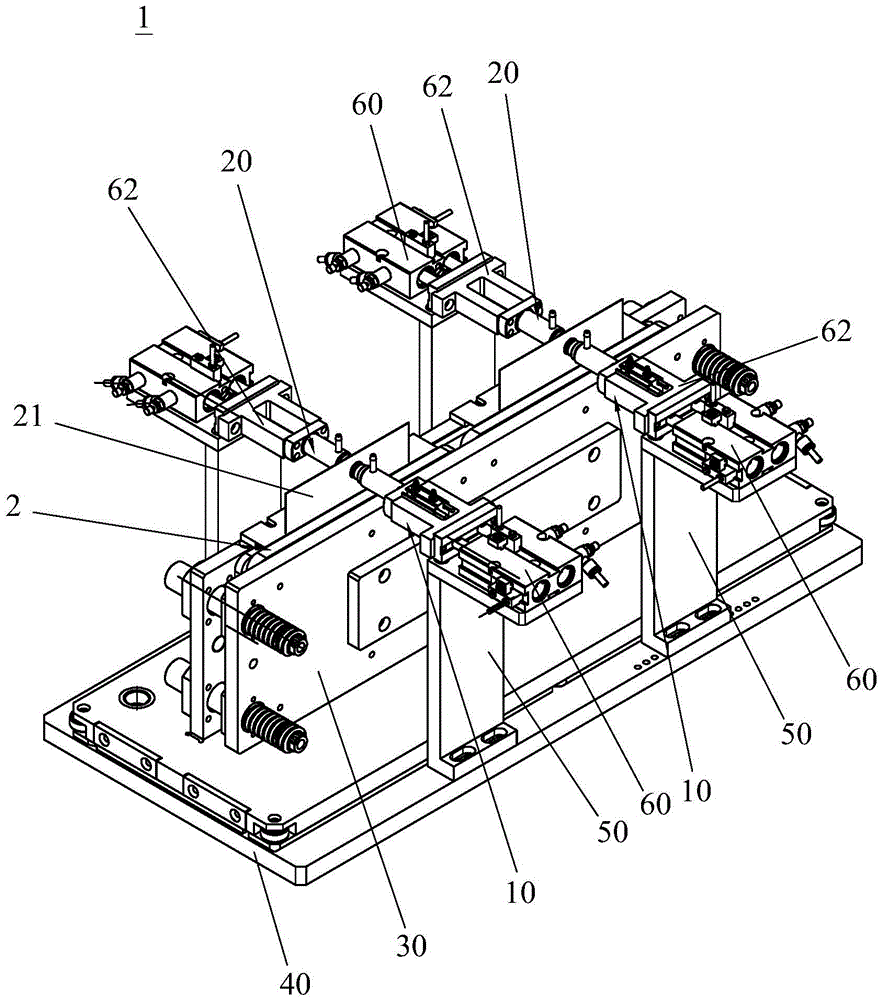

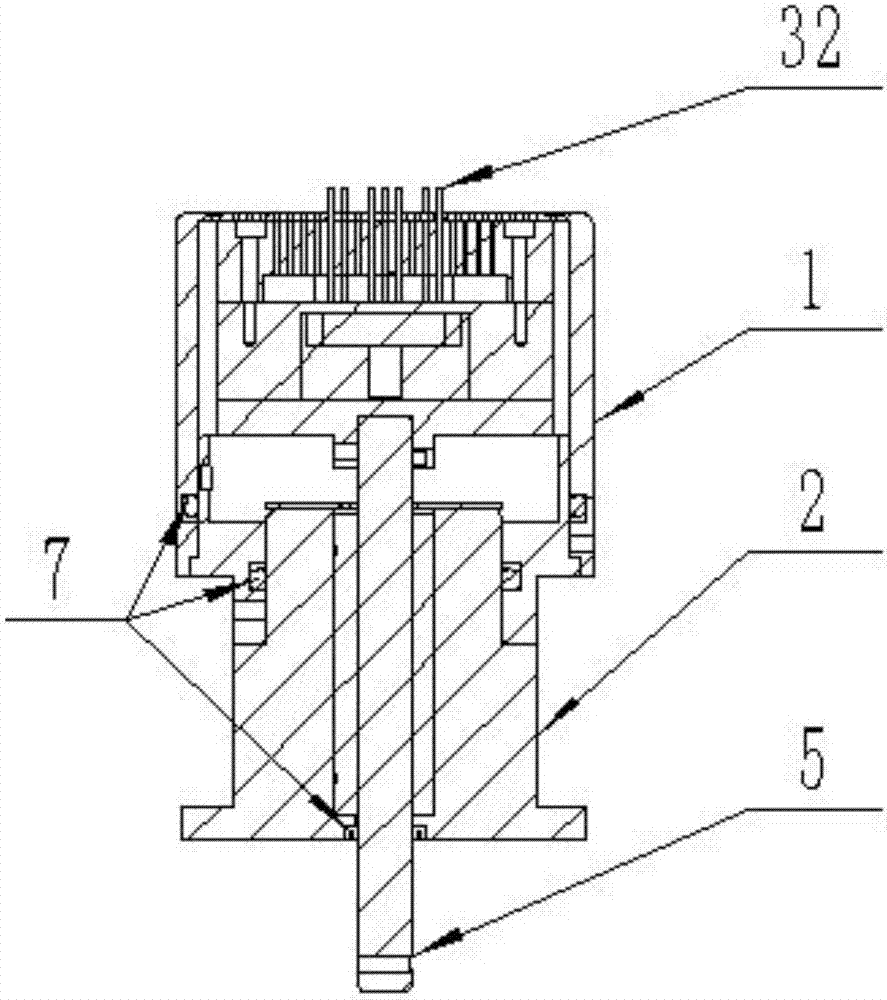

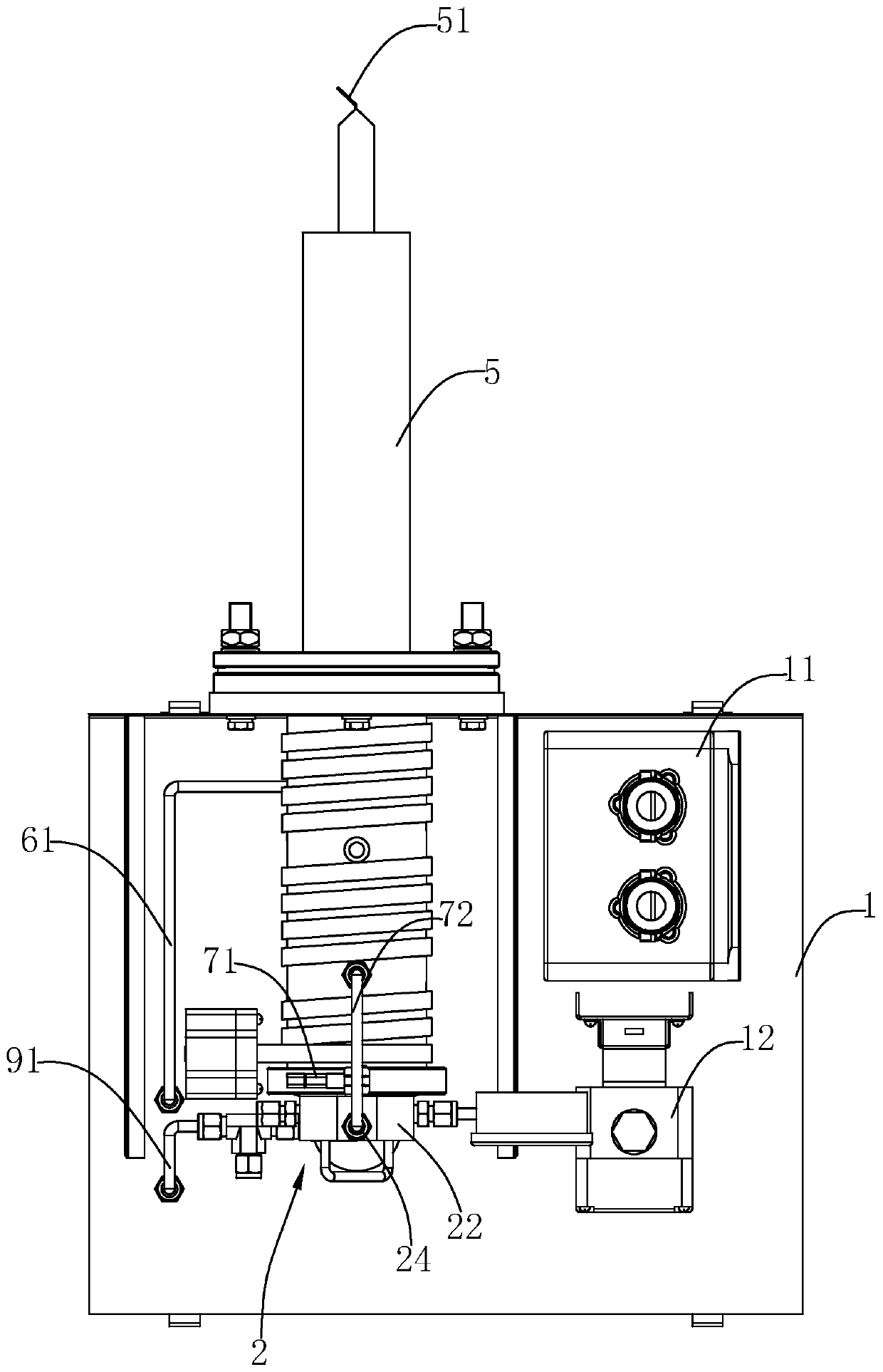

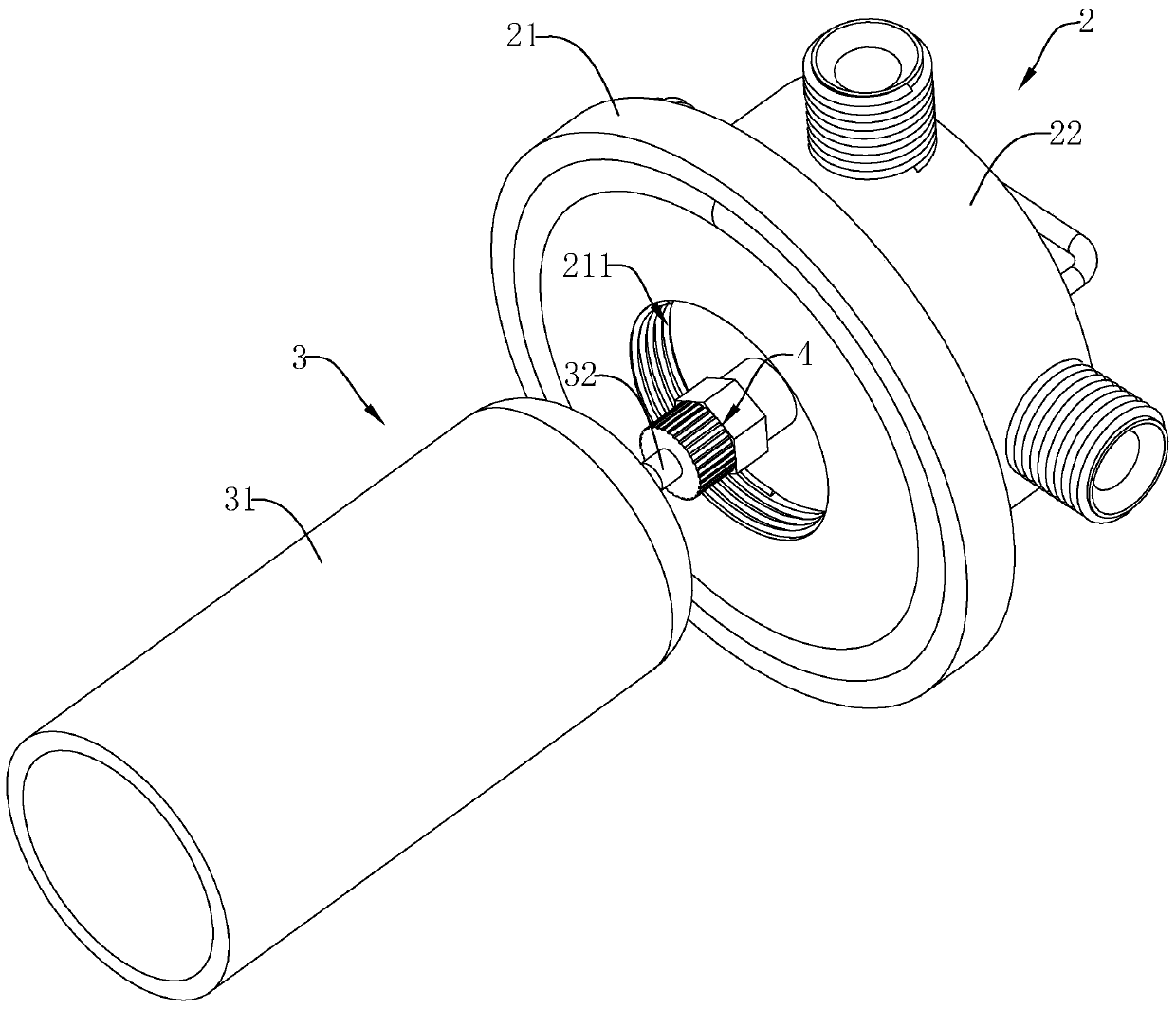

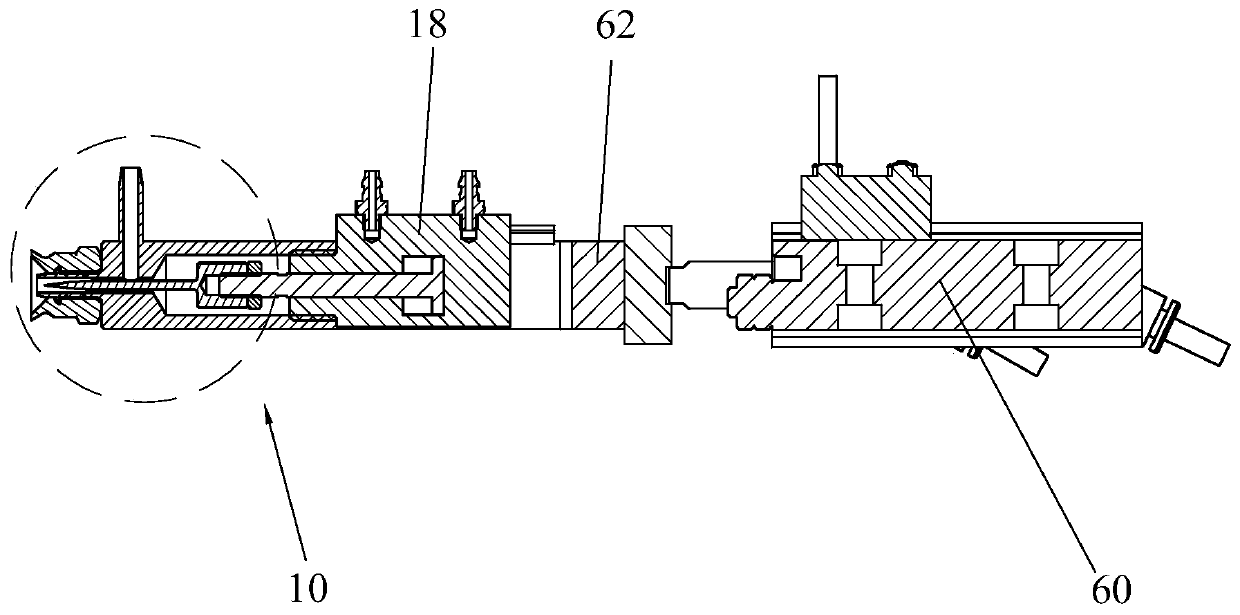

Air extraction mechanism and air extraction device with same

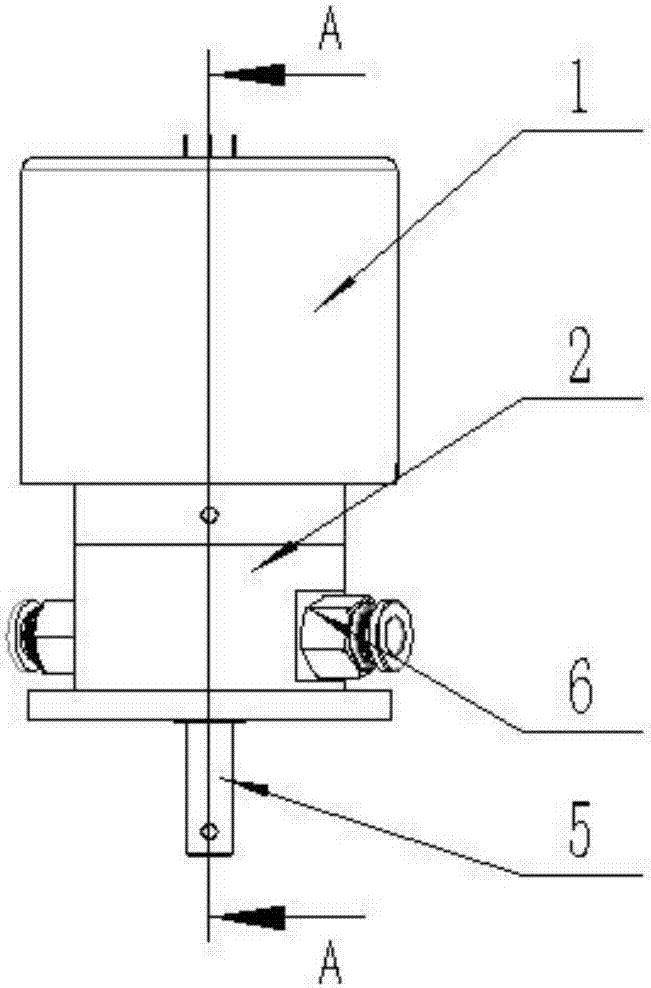

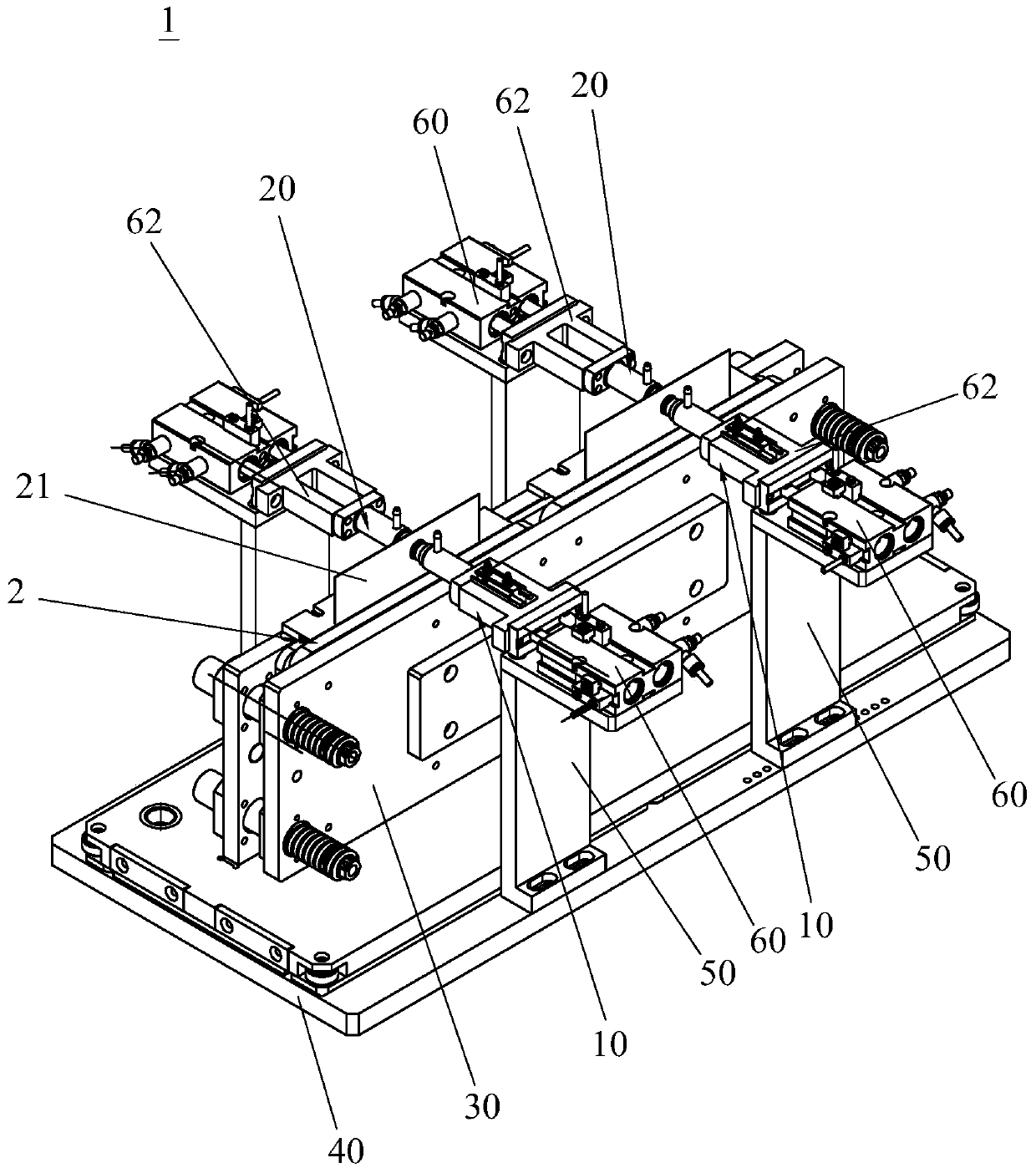

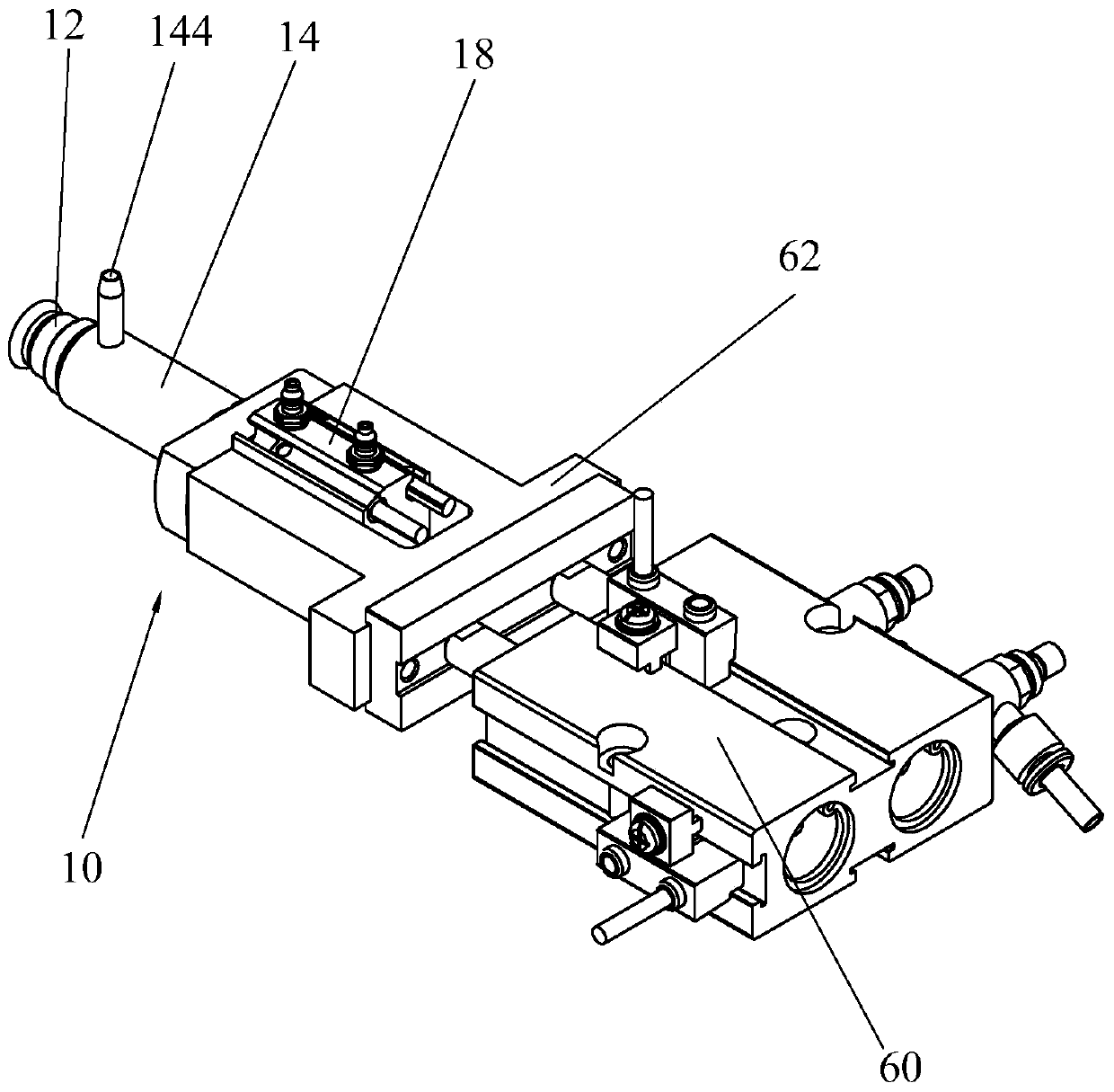

ActiveCN105489924ASimple structureSimple pumping operationFinal product manufactureNon-aqueous electrolyte cellsEngineeringMechanical engineering

The invention discloses an air extraction mechanism, which comprises a suction cup, a vacuum supply pipe, a pricking pin and a pricking pin drive mechanism, wherein the vacuum supply pipe is in a hollow structure and comprises a through cavity which extends along the length direction; the suction cup is used for being absorbed on an air bag of a soft package lithium battery; the rear end of the suction cup hermetically sleeves the front end of the vacuum supply pipe and is communicated with the through cavity of the vacuum supply pipe; the pricking pin drive mechanism is hermetically arranged at the rear end of the vacuum supply pipe and comprises an output shaft which extends into the through cavity and can slide back and forth; the pricking pin is accommodated into the through cavity; the rear end of the pricking pin is fixedly connected with an output shaft; and a vacuum supply hole which is communicated with the through cavity is formed between the front end and the rear end of the vacuum supply pipe. The air extraction mechanism disclosed by the invention is simple in structure and high in air extraction efficiency. The invention further provides an air extraction device with the air extraction mechanism.

Owner:DONGGUAN TEC RICH ENGINEERING CO LTD

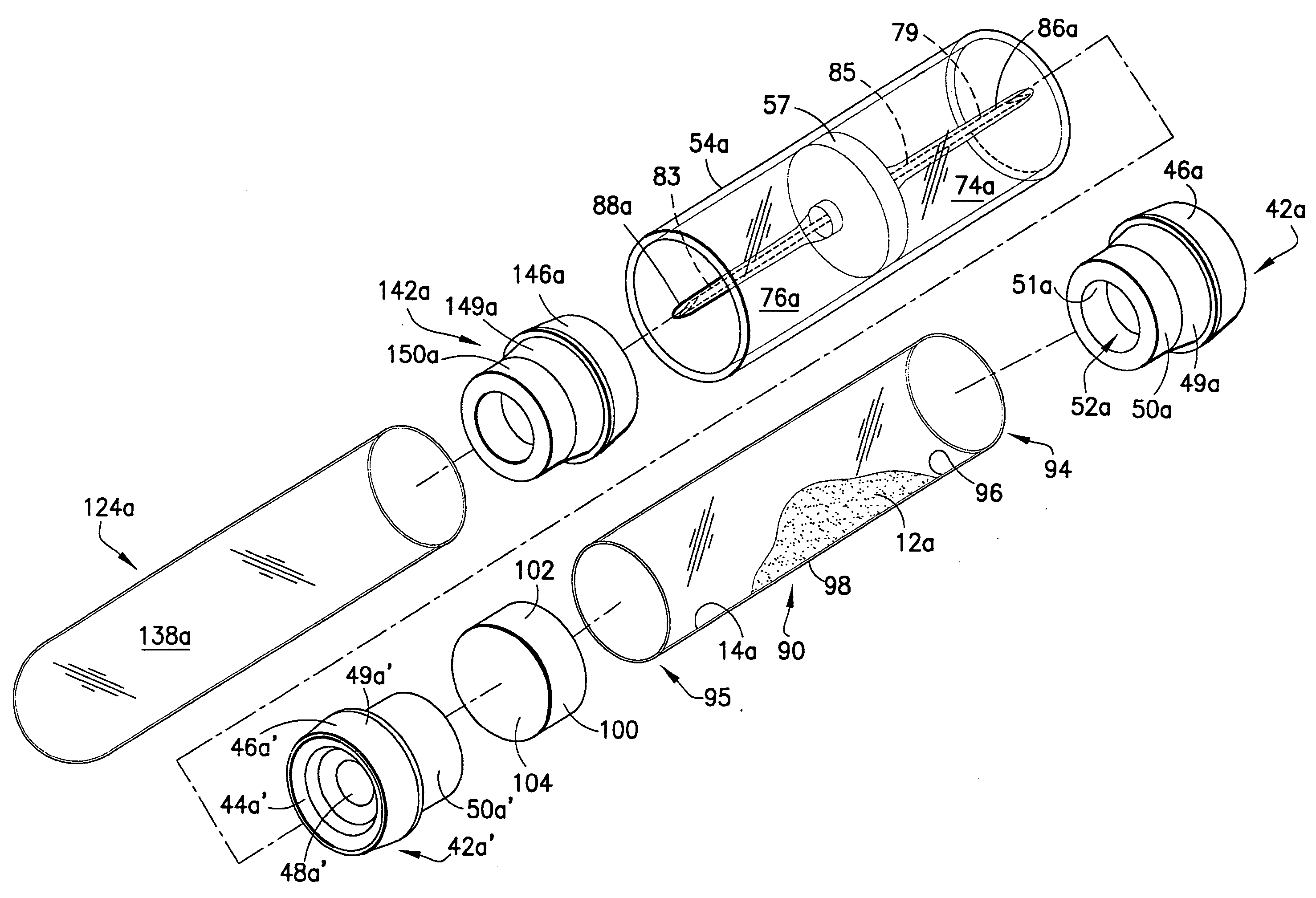

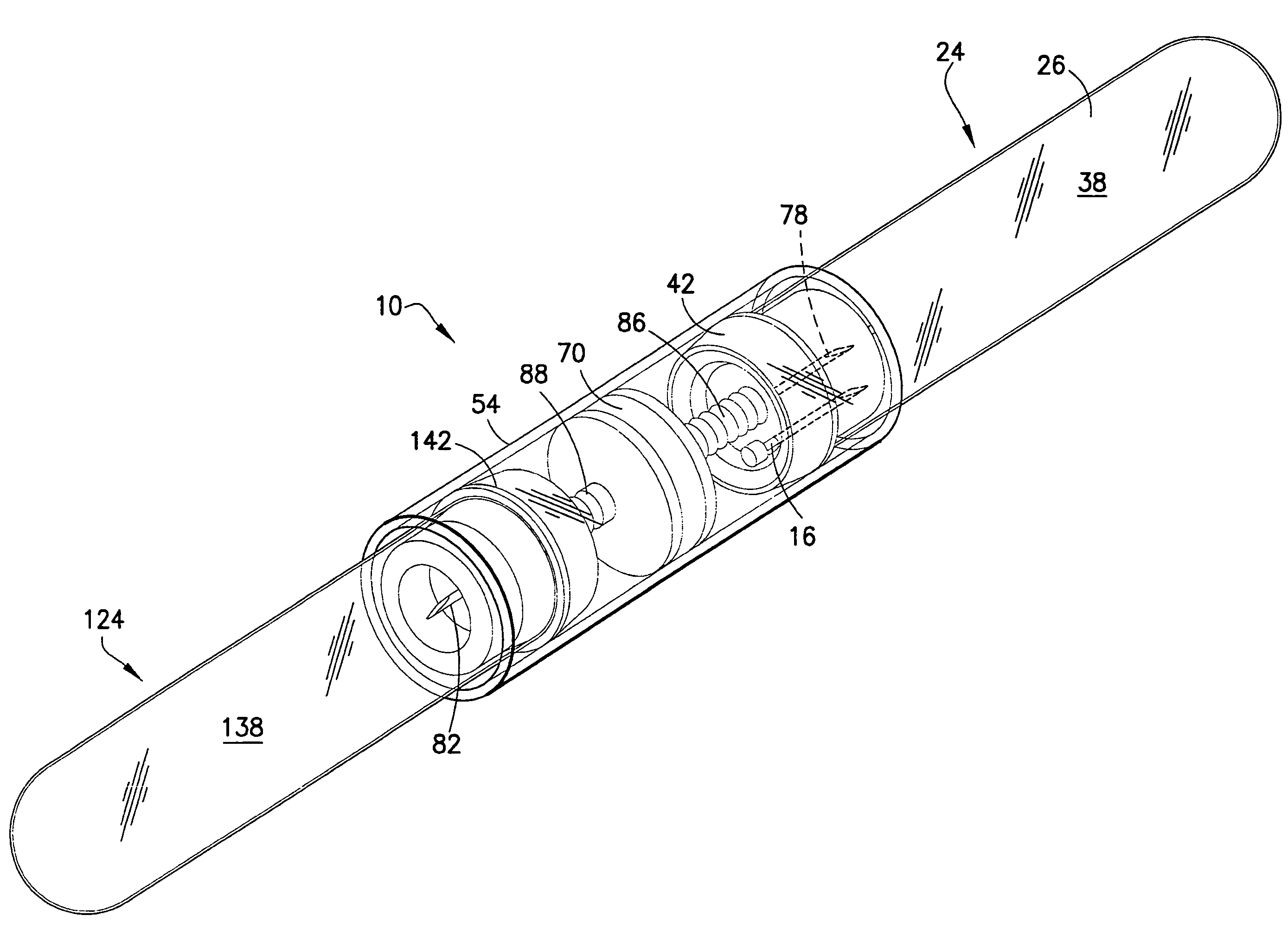

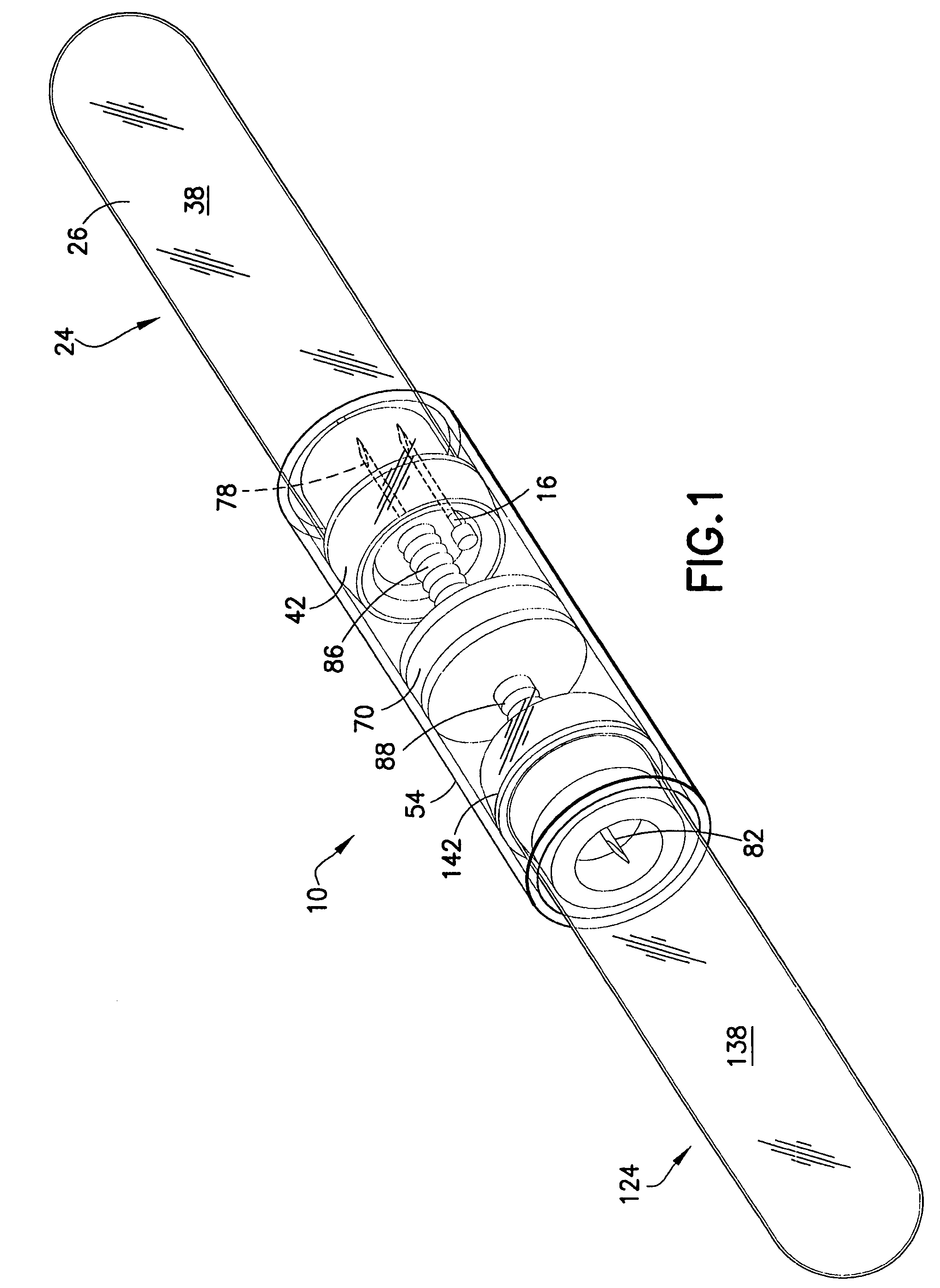

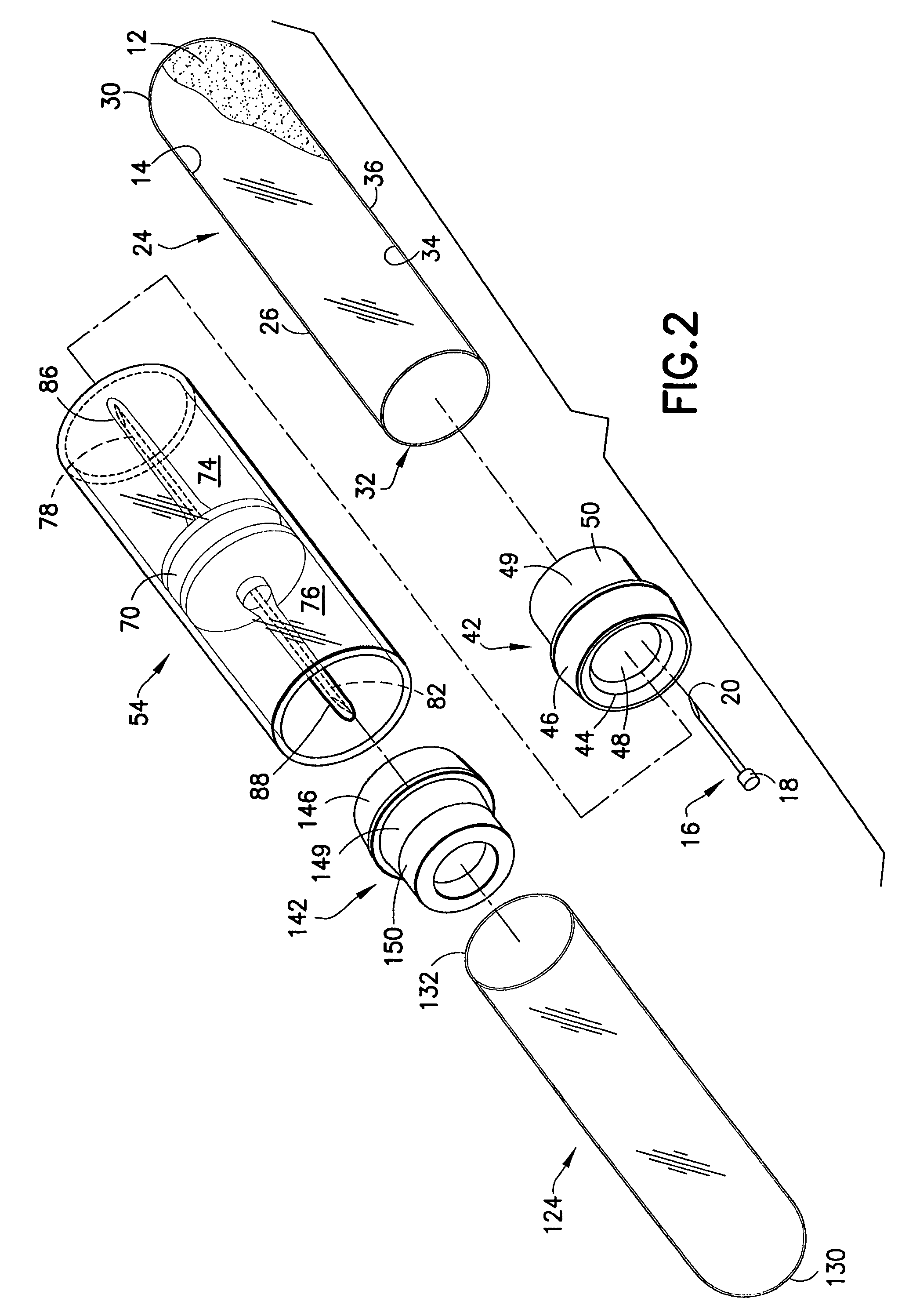

Plasma on demand tube

ActiveUS7500569B2Avoid easy cloggingEasy to useCapsClosure lidsBlood collectionEvacuated blood collection tube

A device for separating plasma from whole blood is provided having an evacuated primary collection chamber capable of fluid communication through a porous filter to an evacuated secondary collection chamber. An agglutinating agent is provided within the primary collection chamber so as to aggregate blood cells within a whole blood sample. The porous filter has a pore size which is small enough to capture the aggregated blood cells therein, yet large enough to permit plasma to transfer therethrough under pressures associated with conventional evacuated blood collection tubes. The primary and secondary collection chambers may be provided in separate containers or tubes, with transfer occurring therebetween through a transfer device including the porous filter therein.

Owner:BECTON DICKINSON & CO

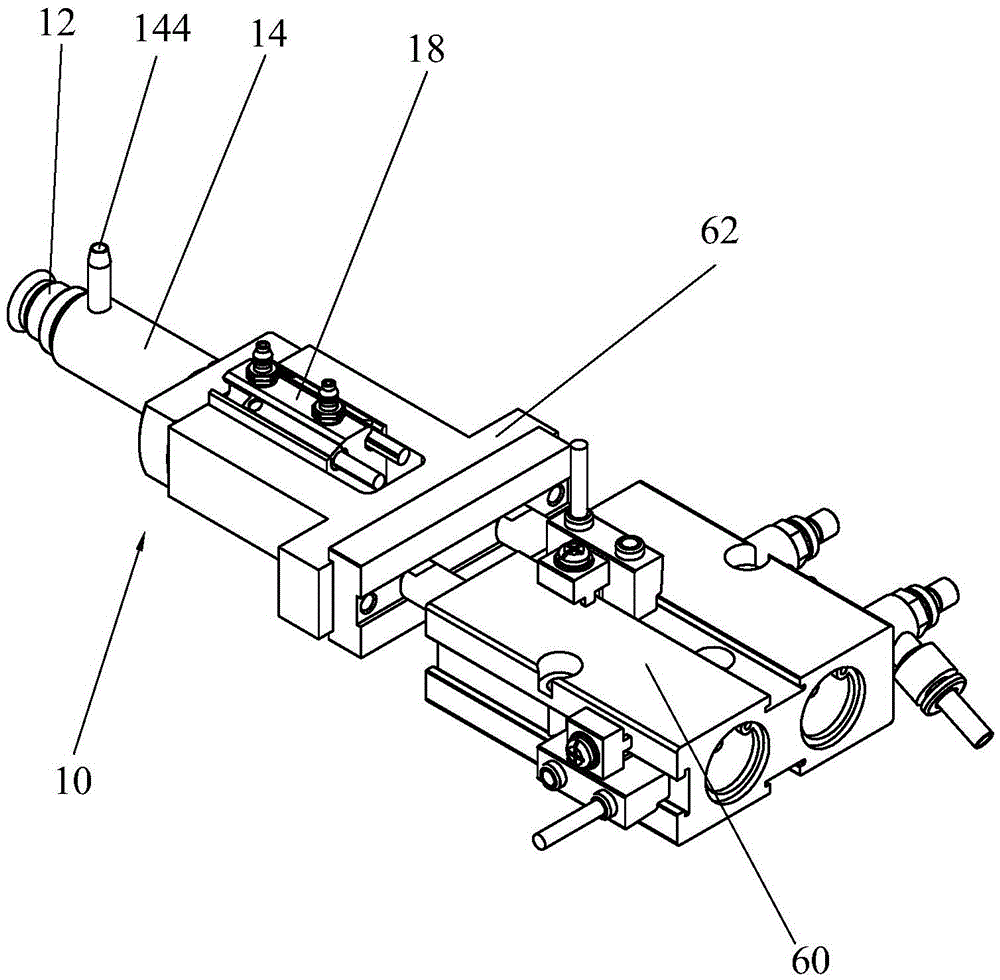

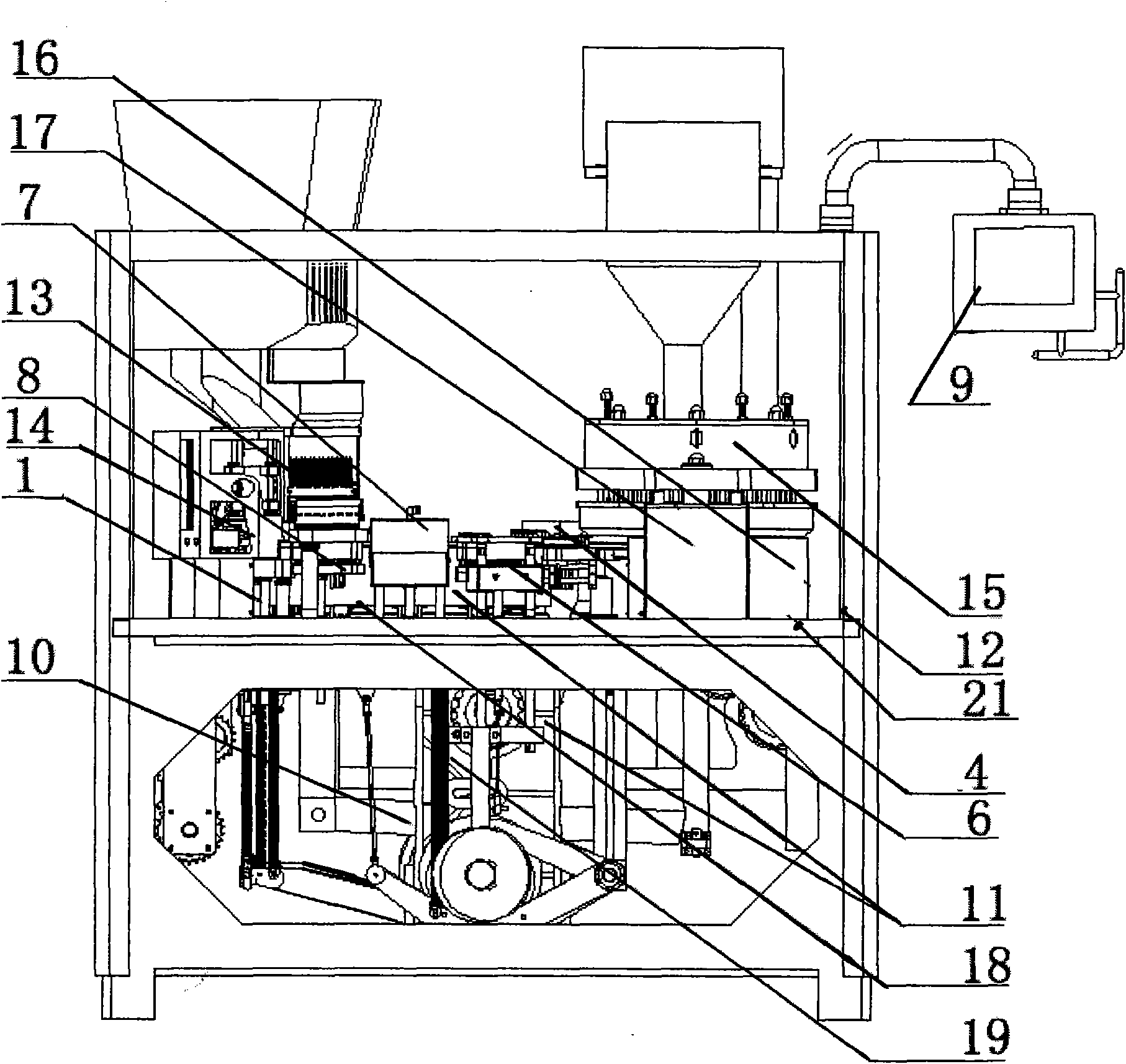

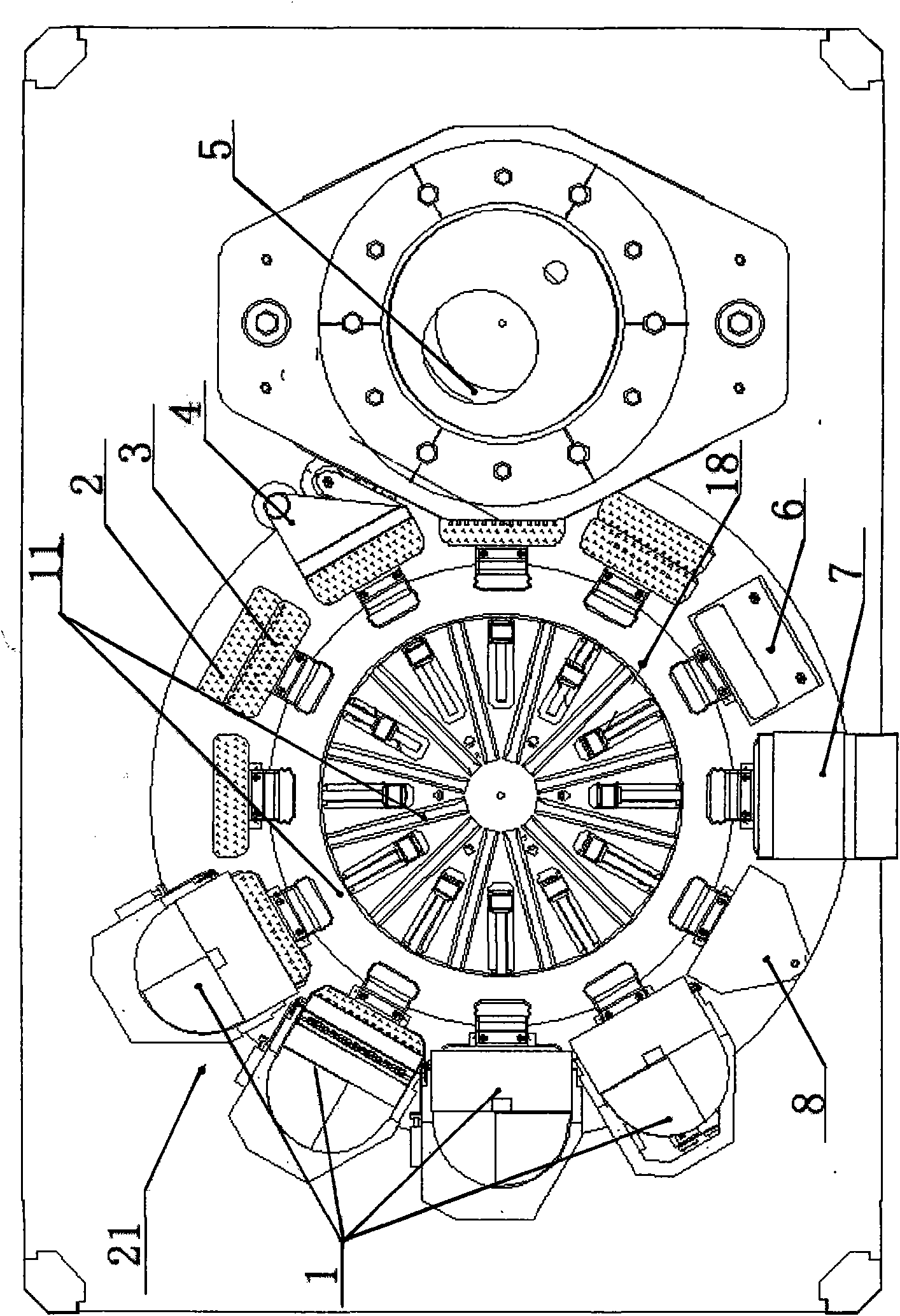

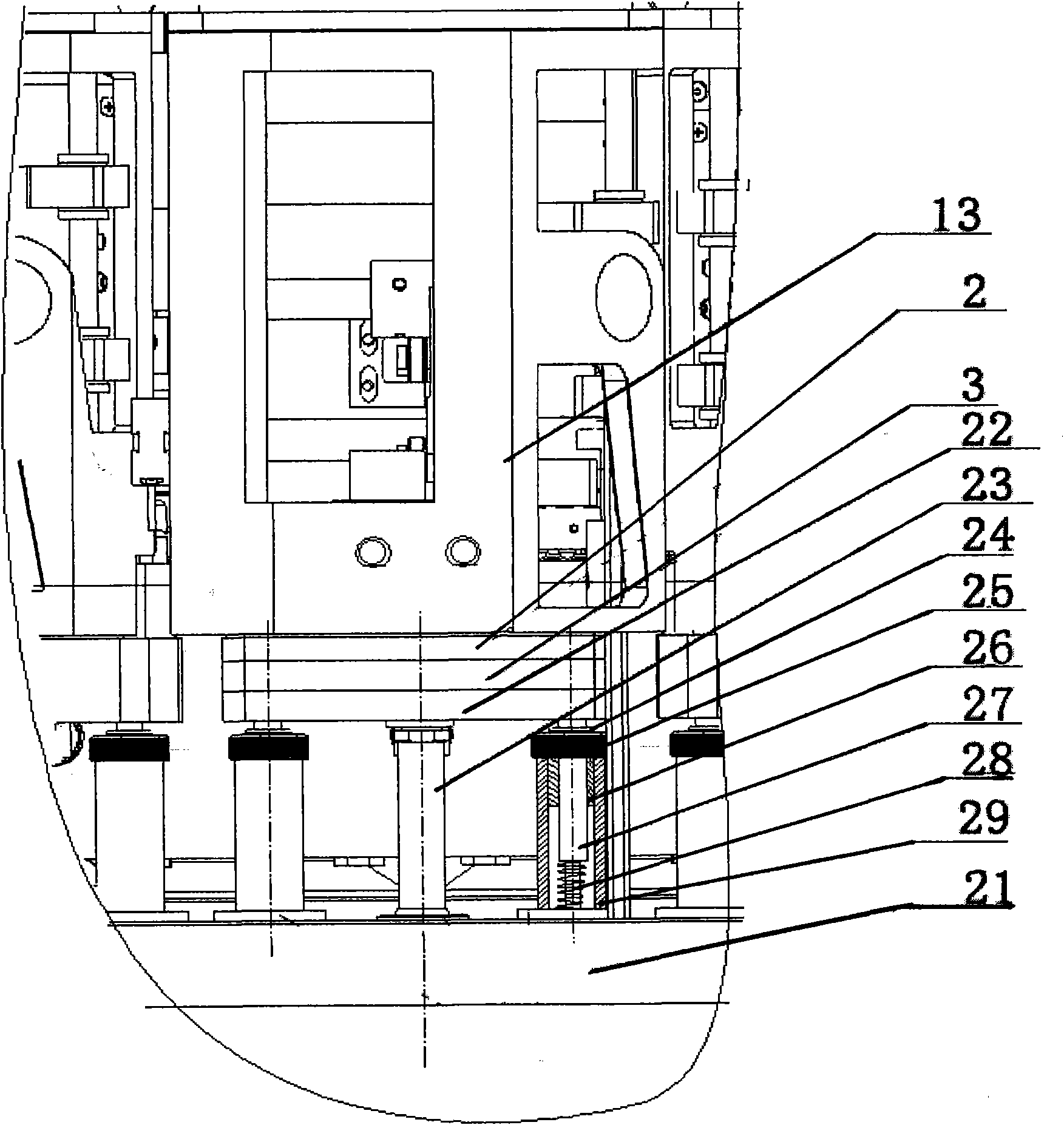

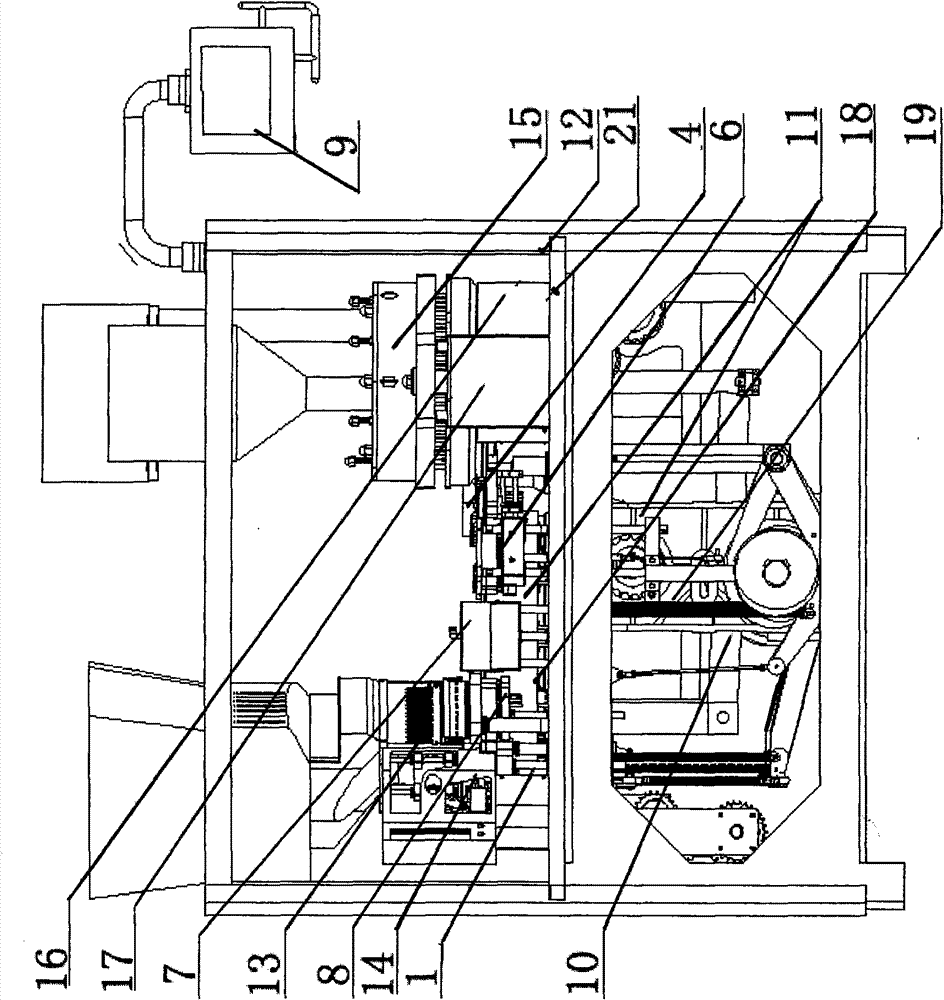

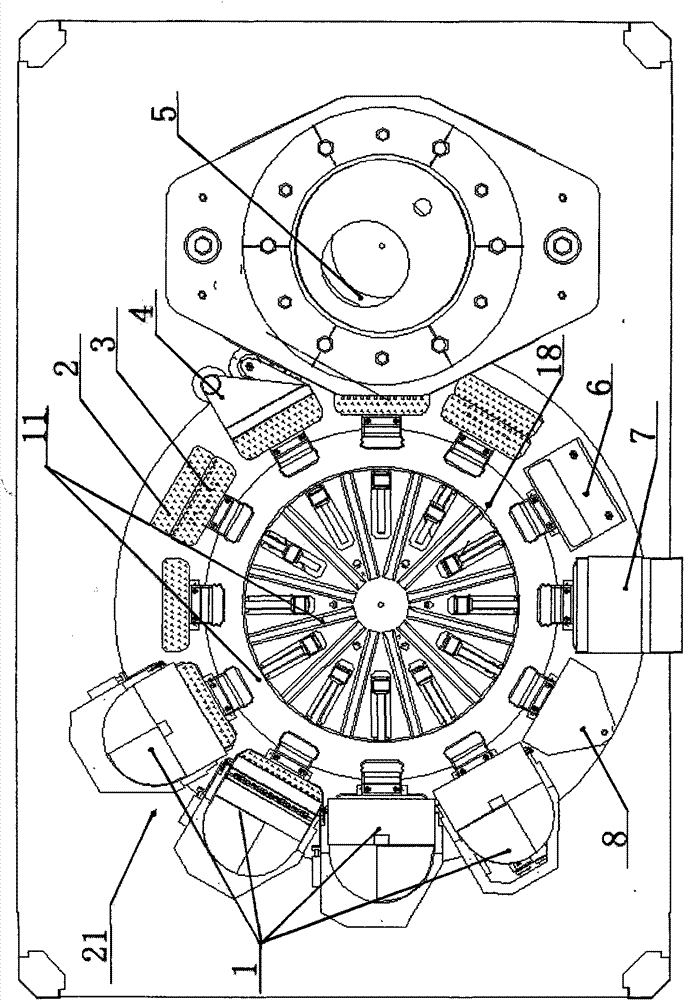

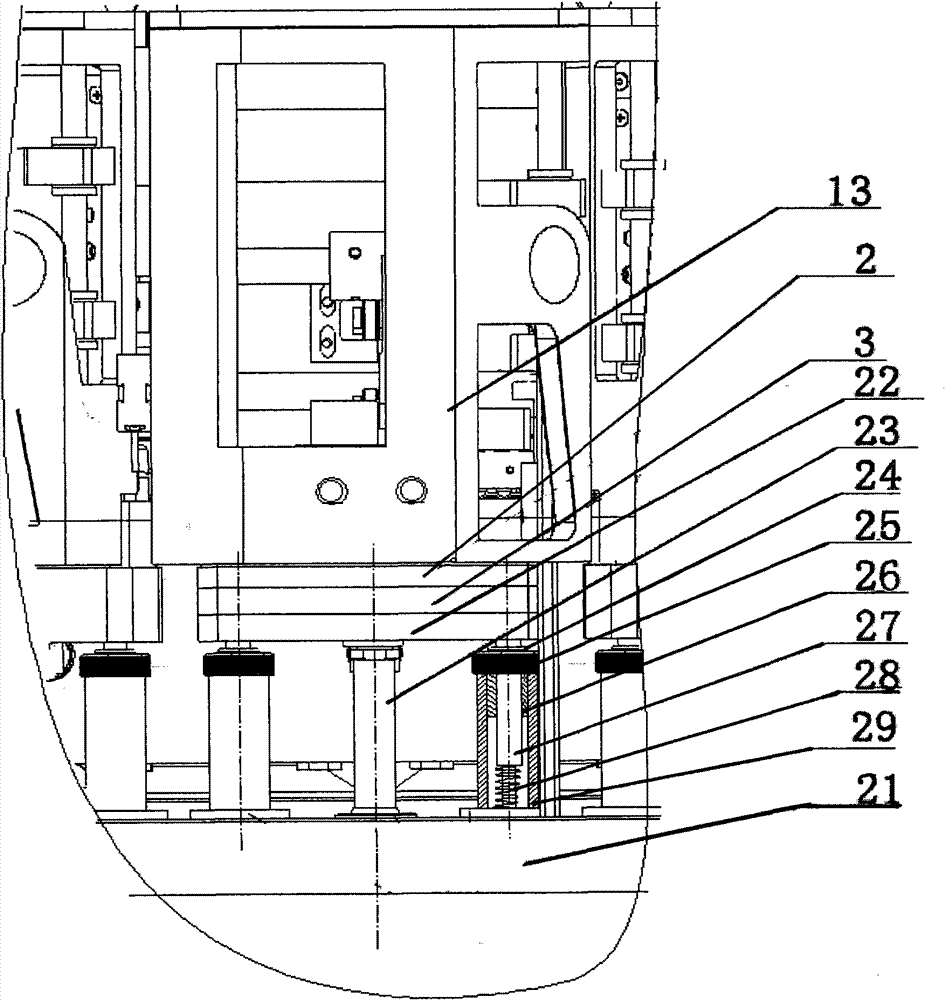

High-yield capsule filling machine

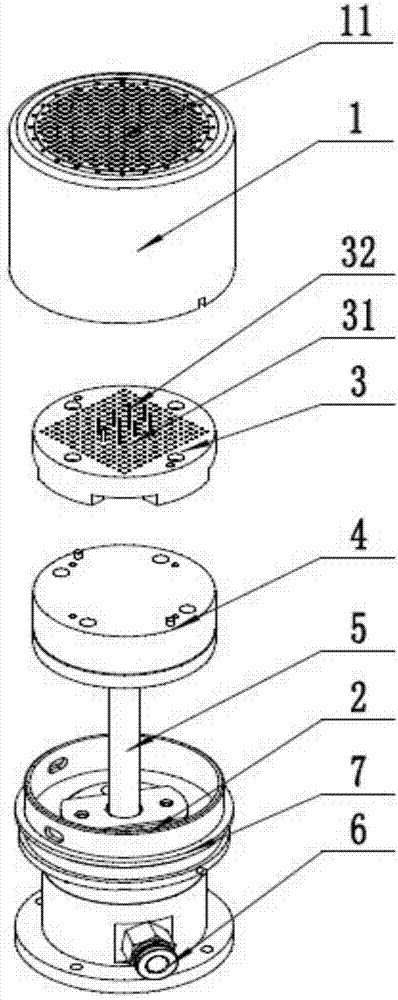

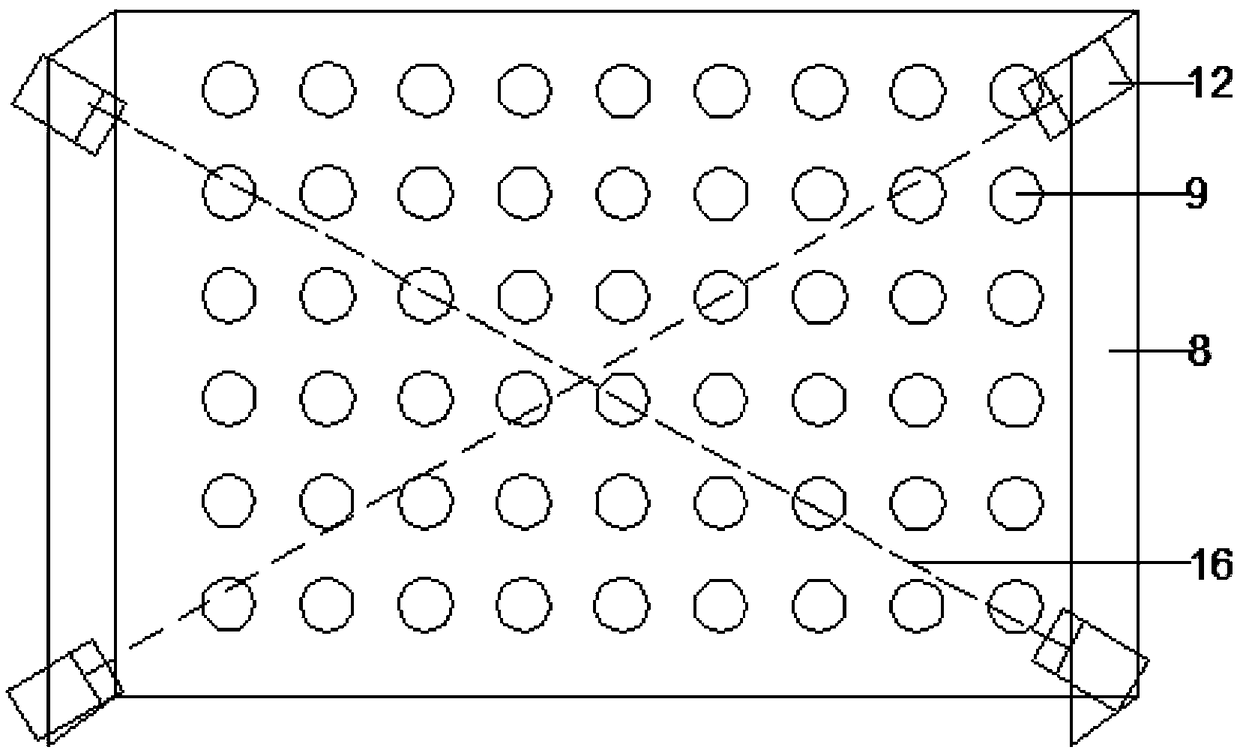

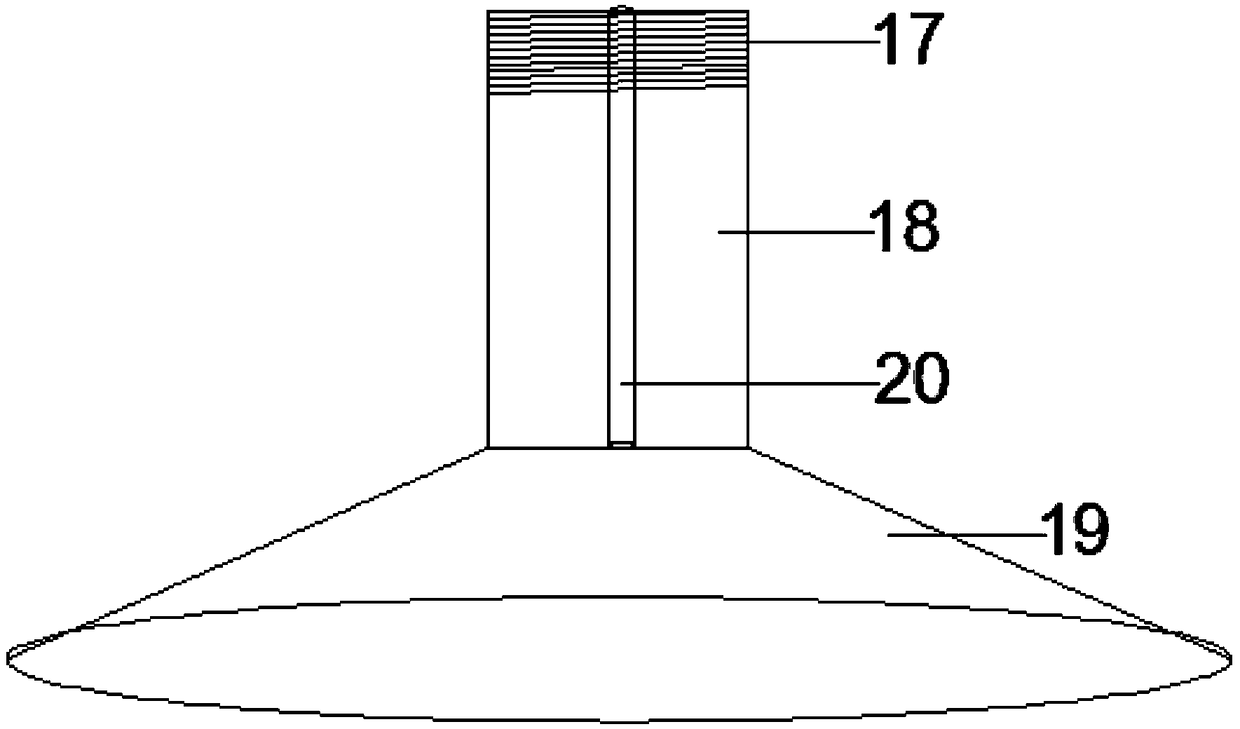

ActiveCN101829022AIncrease the total amount of fillingImprove drug filling qualityCapsule deliveryBiomedical engineeringEngineering

The invention relates to a high-yield capsule filling machine which is provided with a plurality of capsule sequencing and separating mechanisms (1) and an indexing rotating disk mechanism (11), wherein an upper module (2) and a lower module (3) of the indexing rotating disk mechanism (11) are provided with a plurality of die discharging holes corresponding to the capsule sequencing and separating mechanisms; a capsule vacuum separating and balancing device (14) of each capsule sequencing and separating mechanism comprises a vacuum suction pipe (23) and a vacuum suction base (22), balance upright poses (27) are arranged under two side edges of the vacuum suction base, and springs (28) are arranged under the balance upright posts which are arranged in hollow upright posts (29) through positioning bearing (26) and sealing pressure covers (25). The invention is used for improving and updating partial mechanisms of the capsule filling machine, and increases the operation balance degree and the sealing property of part of a machine body when in high yield so as to meet the requirement for high yield; and the yield of finished drugs filled by the filling machine can reach about 7200 grains per minute.

Owner:楚天飞云制药装备(长沙)有限公司

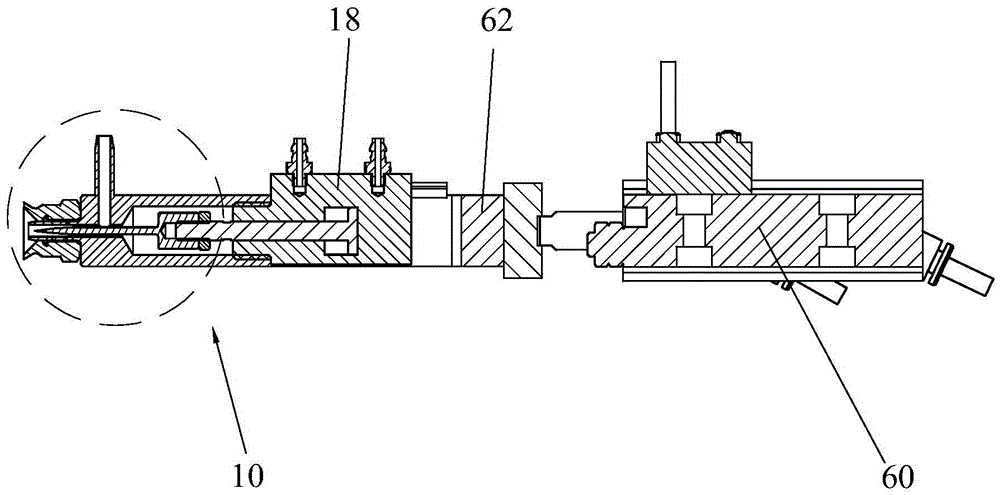

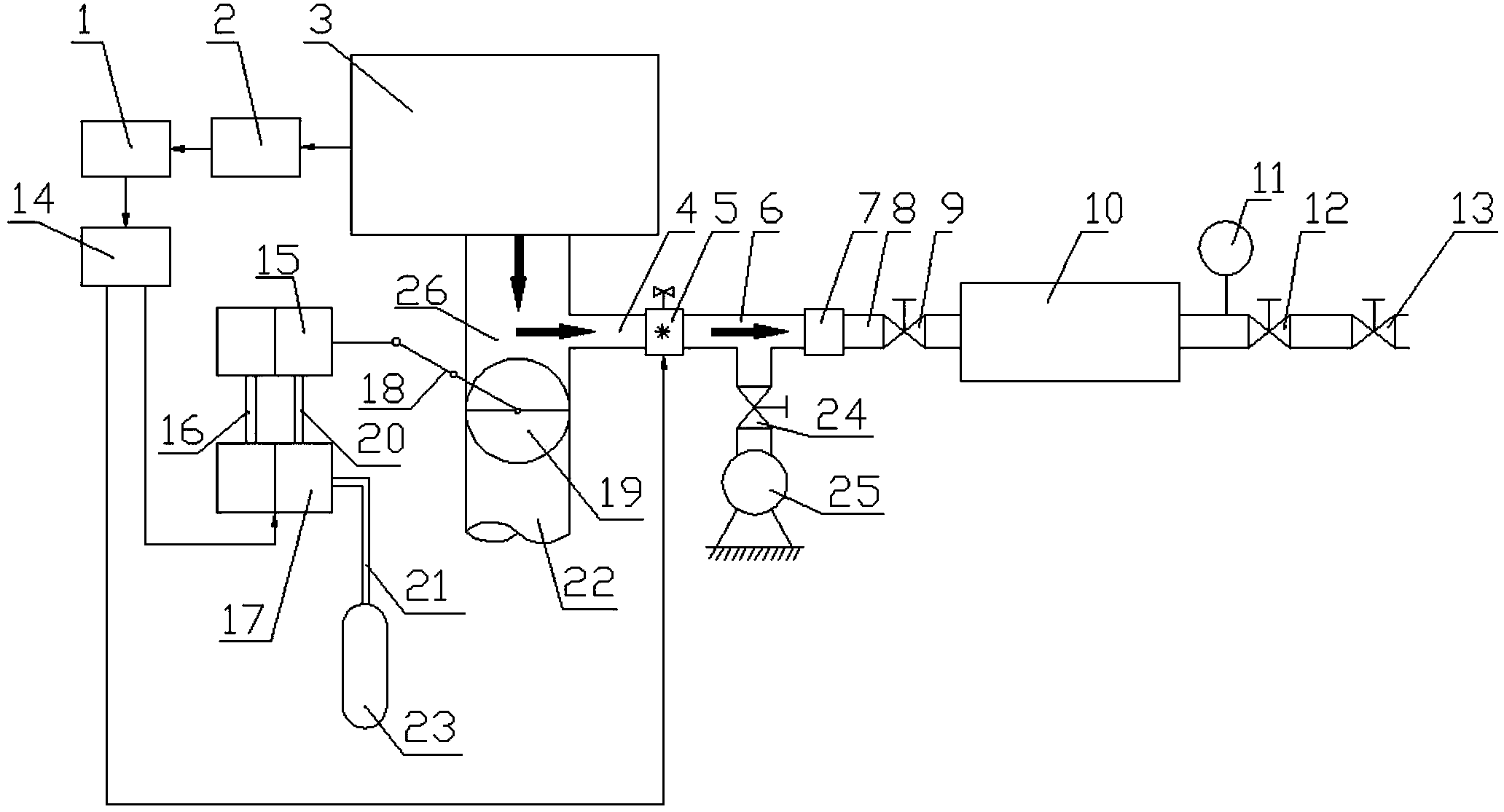

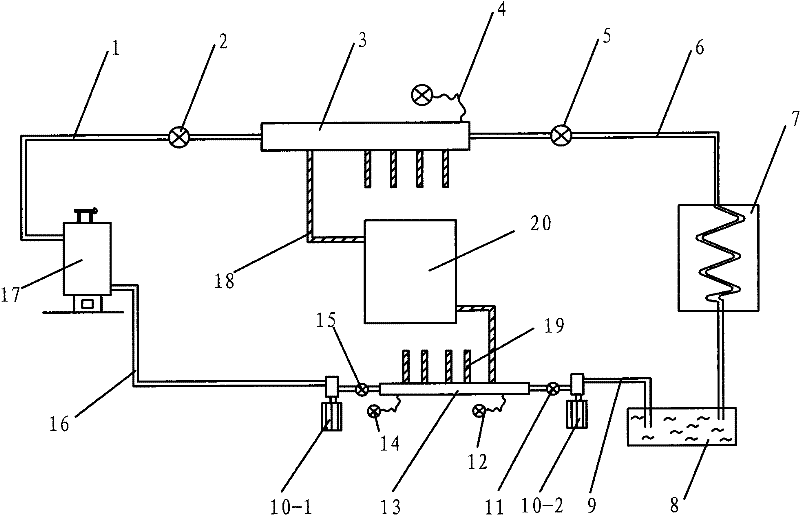

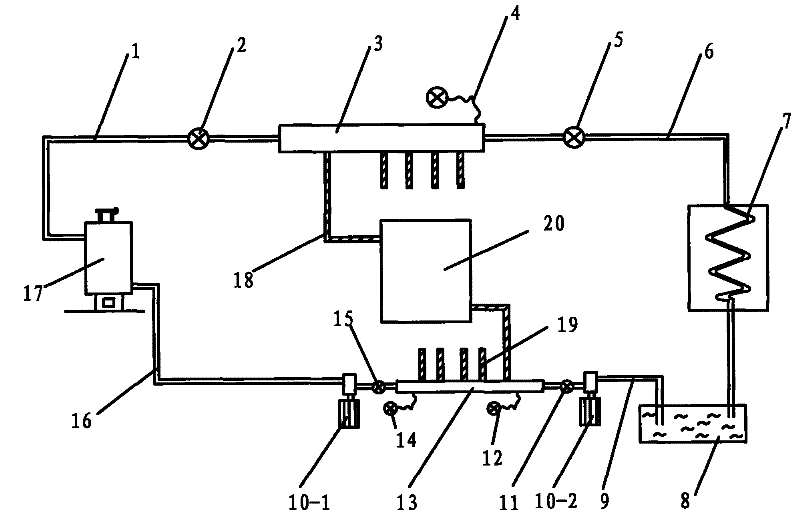

Single-cycle sampling system for engine exhaust gas

InactiveCN103759989AAccurate collection timeAvoid the effects of exhaustWithdrawing sample devicesEngineeringActuator

The invention discloses a single-cycle sampling system for engine exhaust gas so as to solve the problem that the single-cycle exhaust gas of an engine cannot be separated. The system comprises a circuit control system, an actuator, a gas storage device and a vacuum degree adjustment device, wherein the actuator comprises a high-frequency electromagnetic valve, a compressed air cylinder, a two-position five-way electromagnetic valve, a crank-link mechanism, a butterfly valve and a high-pressure gas source. The left end of the high-frequency electromagnetic valve is connected with the butterfly valve, and the right end of the high-frequency electromagnetic valve is connected with a quick connector of the gas storage device and a ball valve No.3 of the vacuum degree adjustment device; the crank-link mechanism is connected with a valve stem of the butterfly valve, and the left end of the crank-link mechanism is connected with the compressed air cylinder; the left gas inlet and outlet of the compressed air cylinder are connected with a left gas outlet pipe of the two-position five-way electromagnetic valve, the right gas inlet and outlet of the compressed air cylinder are connected with a right gas outlet pipe of the two-position five-way electromagnetic valve, the left end of the high-pressure gas source is connected with a gas inlet pipe of the two-position five-way electromagnetic valve, and the output end of a solid state relay of the circuit control system is connected with the lead wires of the two-position five-way electromagnetic valve and the high-frequency electromagnetic valve.

Owner:JILIN UNIV

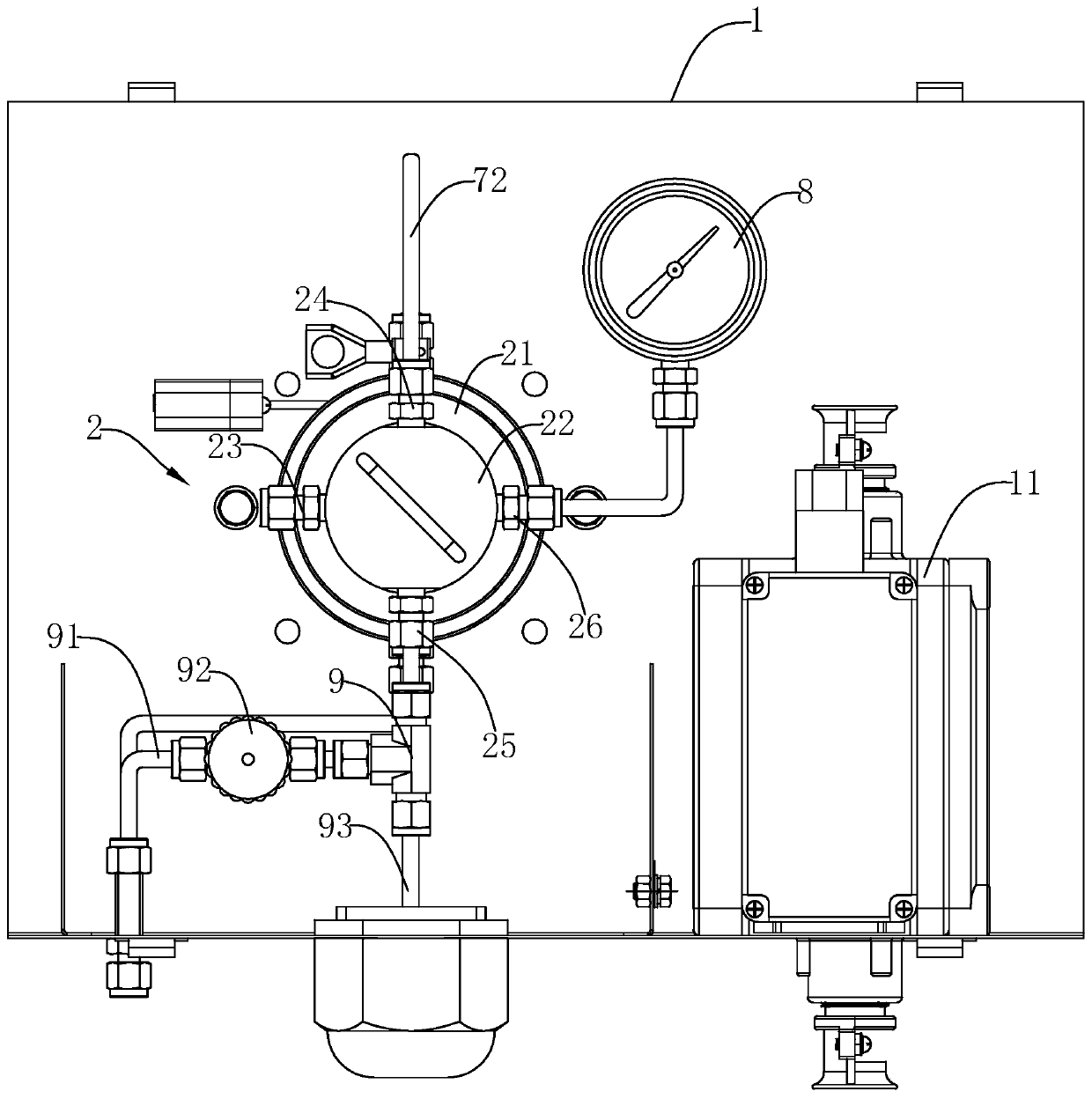

Vacuum pump control system and method for double pressure sensors

InactiveCN107521484AImprove securitySufficient vacuumBraking action transmissionBrake safety systemsEmergency planDifferential pressure

The invention discloses a vacuum pump control system and method with dual pressure sensors, comprising a vacuum tank, a vacuum pump controller, a vacuum pump connected with a hose of the vacuum tank, the signals of the vacuum pump and the vacuum pump controller are connected, and the vacuum tank is also provided with an insulating Pressure sensor, differential pressure sensor and the joint used to connect with the vehicle brake booster system, the absolute pressure sensor, differential pressure sensor and vacuum pump controller signal connection; the absolute pressure sensor is used to monitor the absolute pressure value in the vacuum tank, the differential pressure Sensors are used to monitor the difference between the pressure inside the vacuum tank and atmospheric pressure. The invention provides a vacuum pump control system and method with dual pressure sensors, which can control the pressure of the vacuum source in different regions according to the local atmospheric pressure, and can accurately judge the abnormality of the sensor and provide an emergency plan.

Owner:黄山徽熿新能源科技有限公司

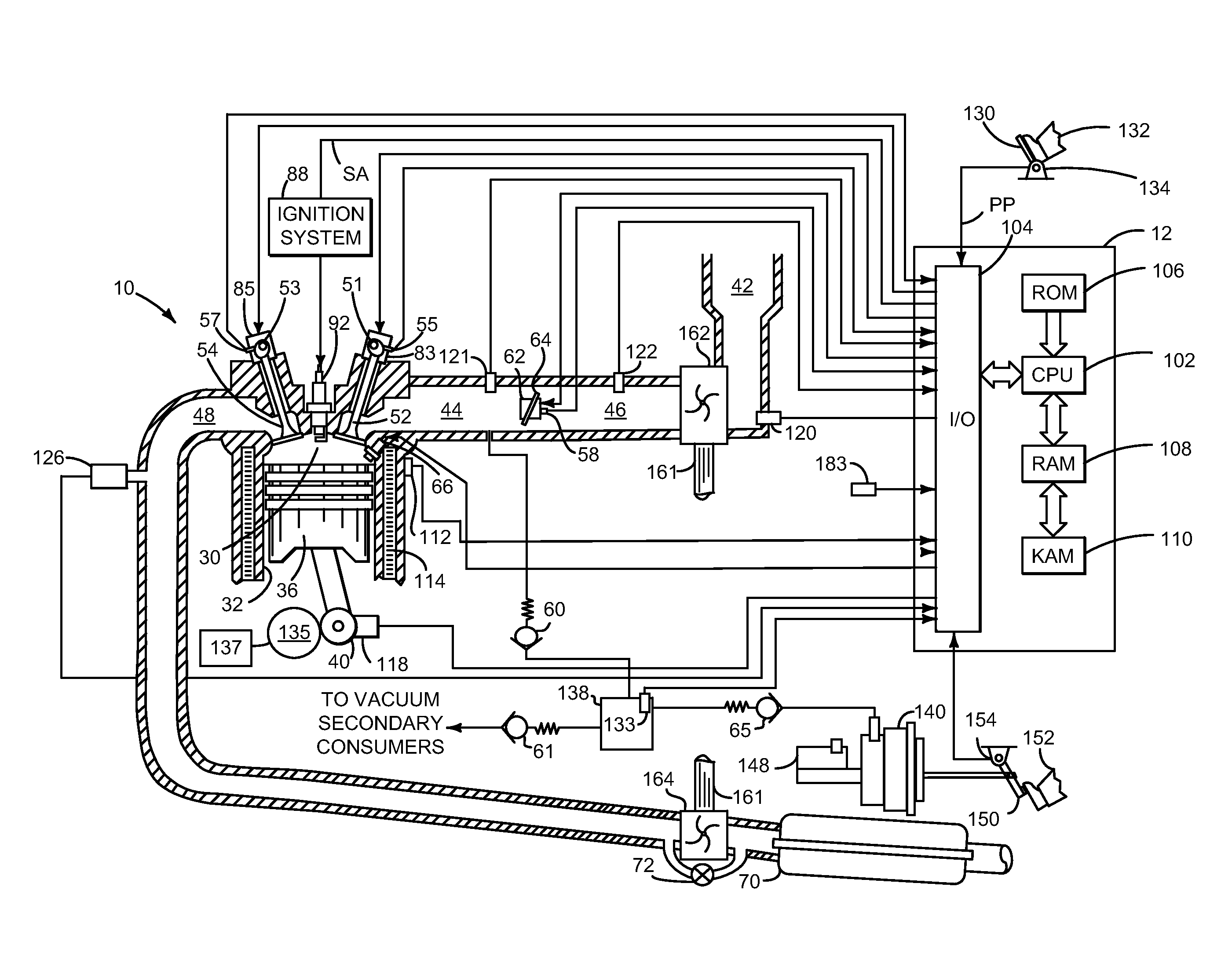

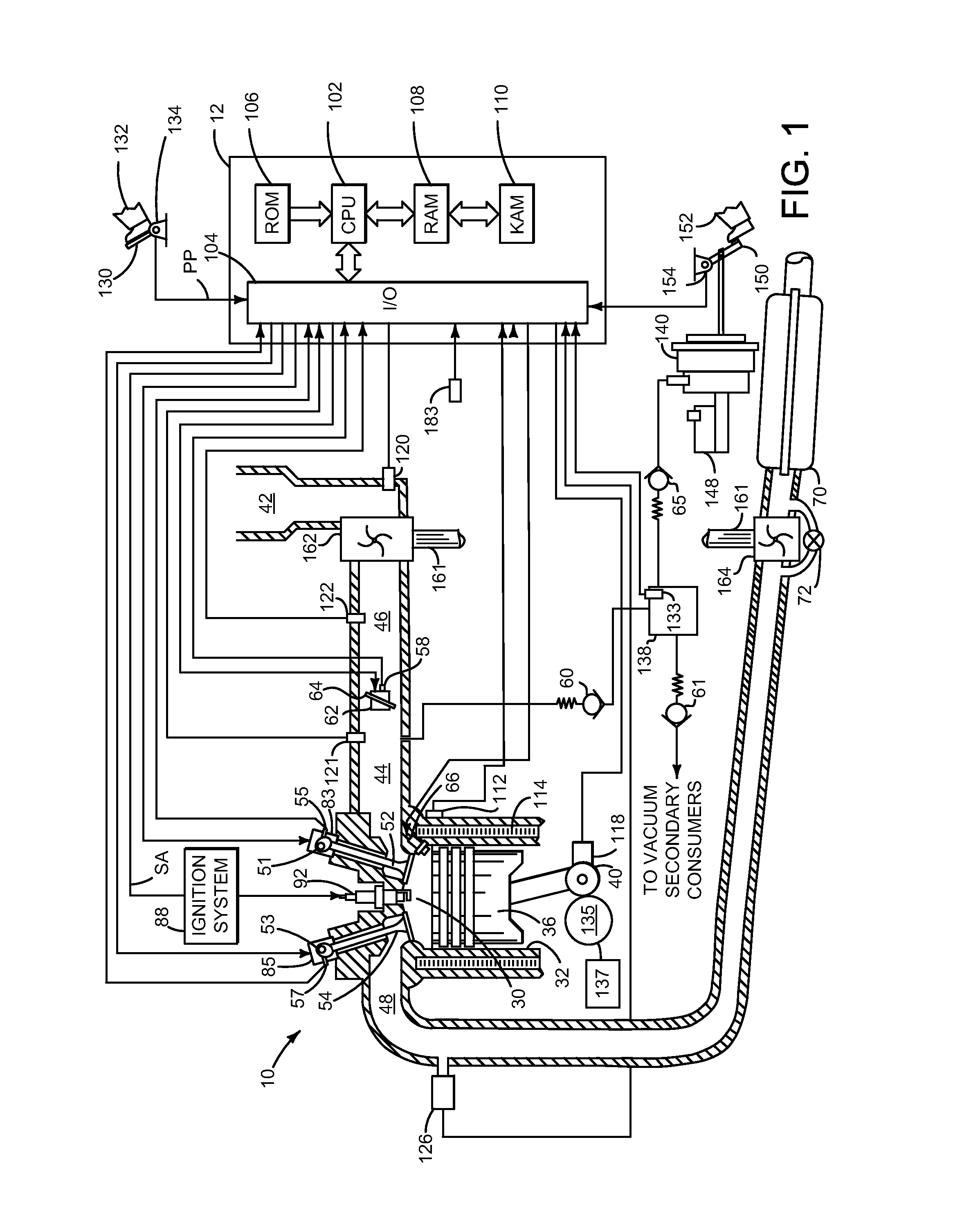

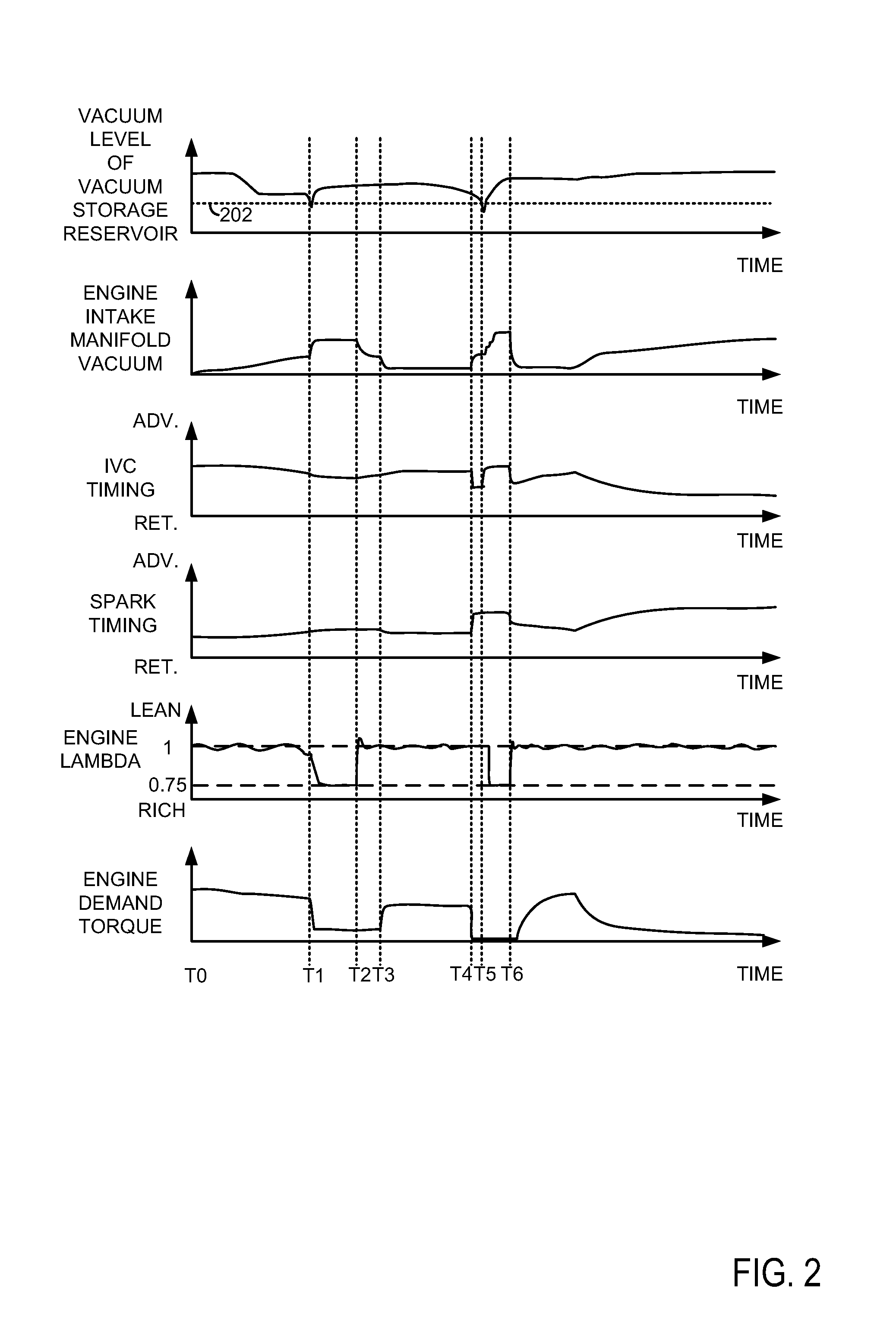

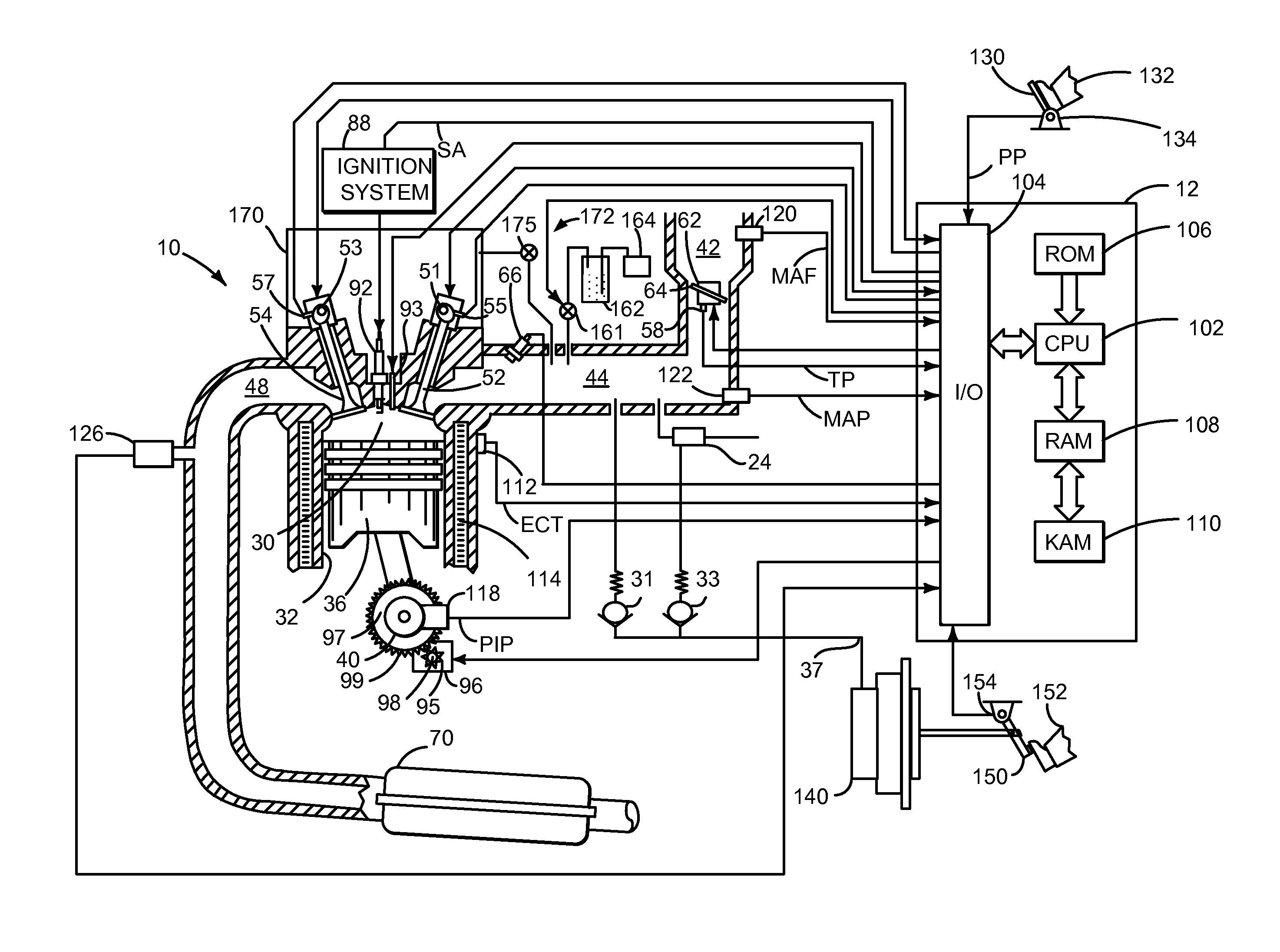

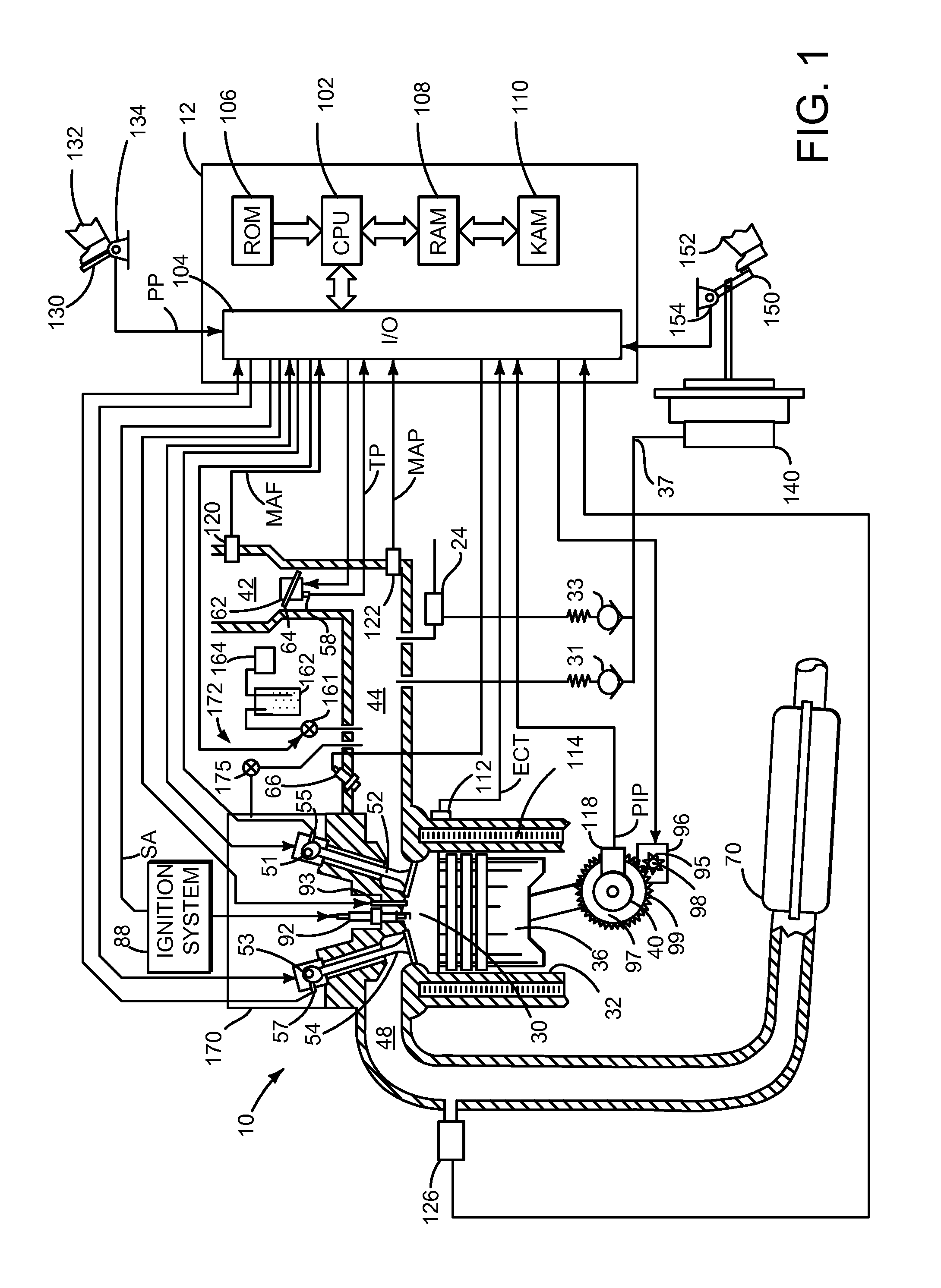

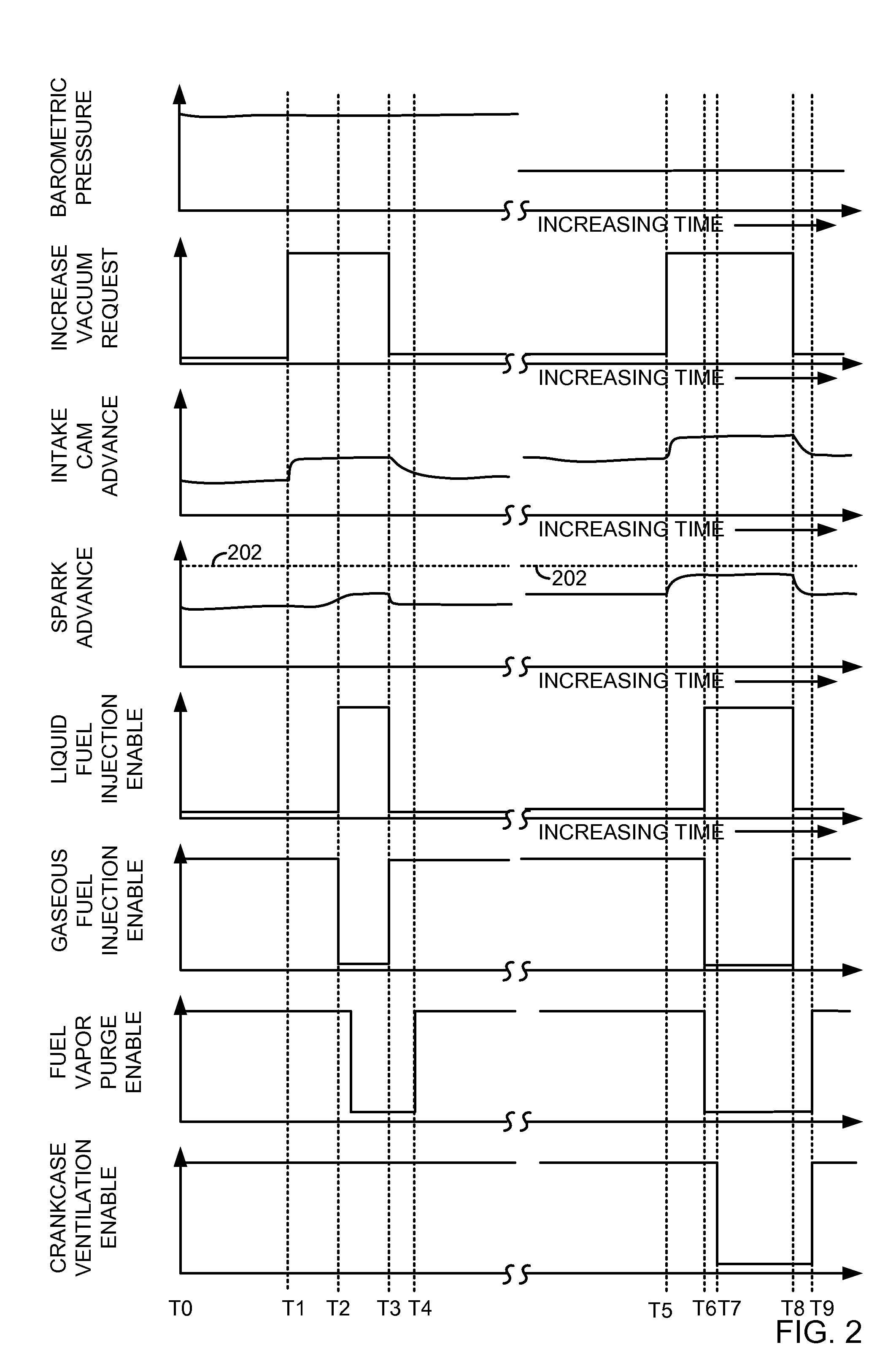

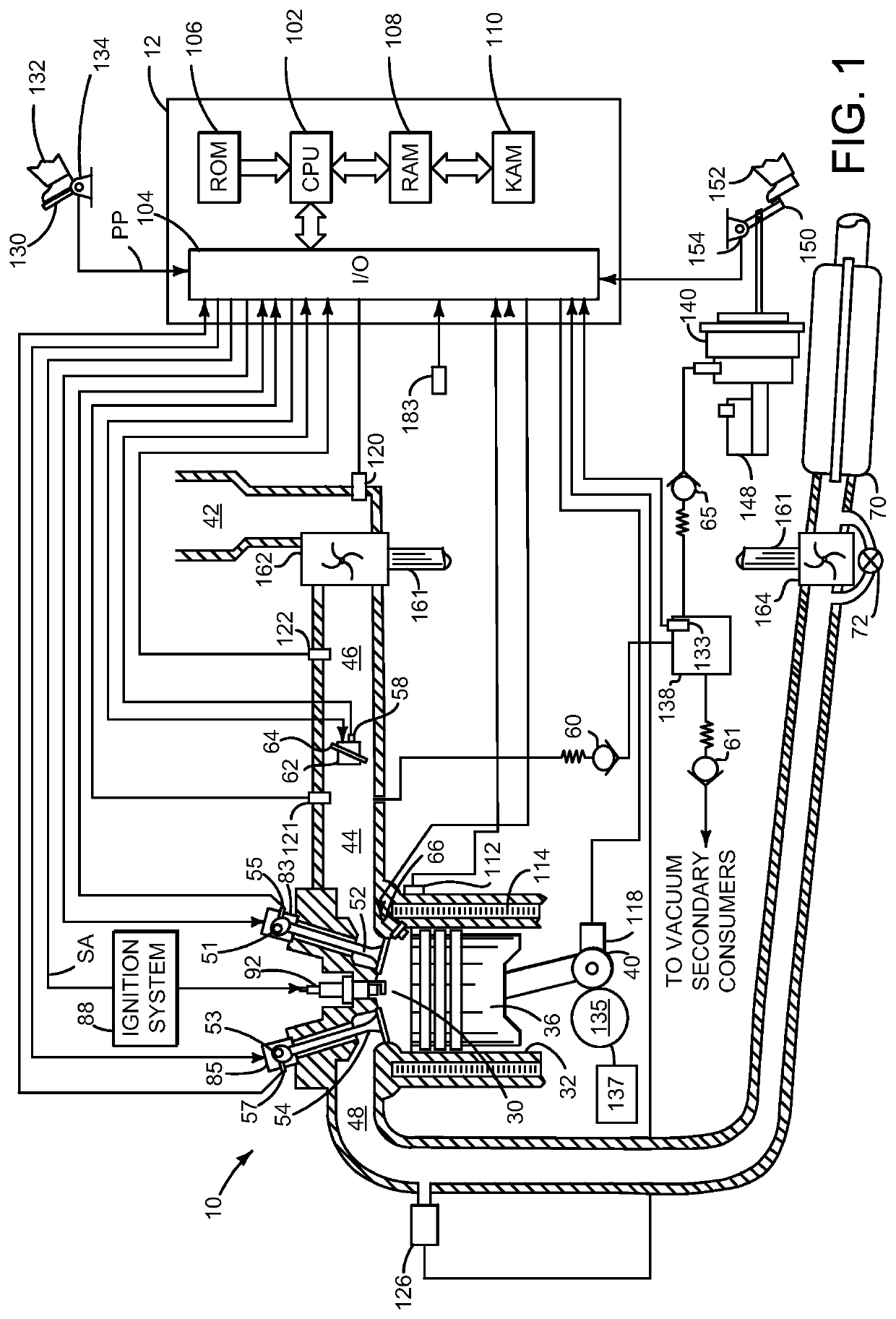

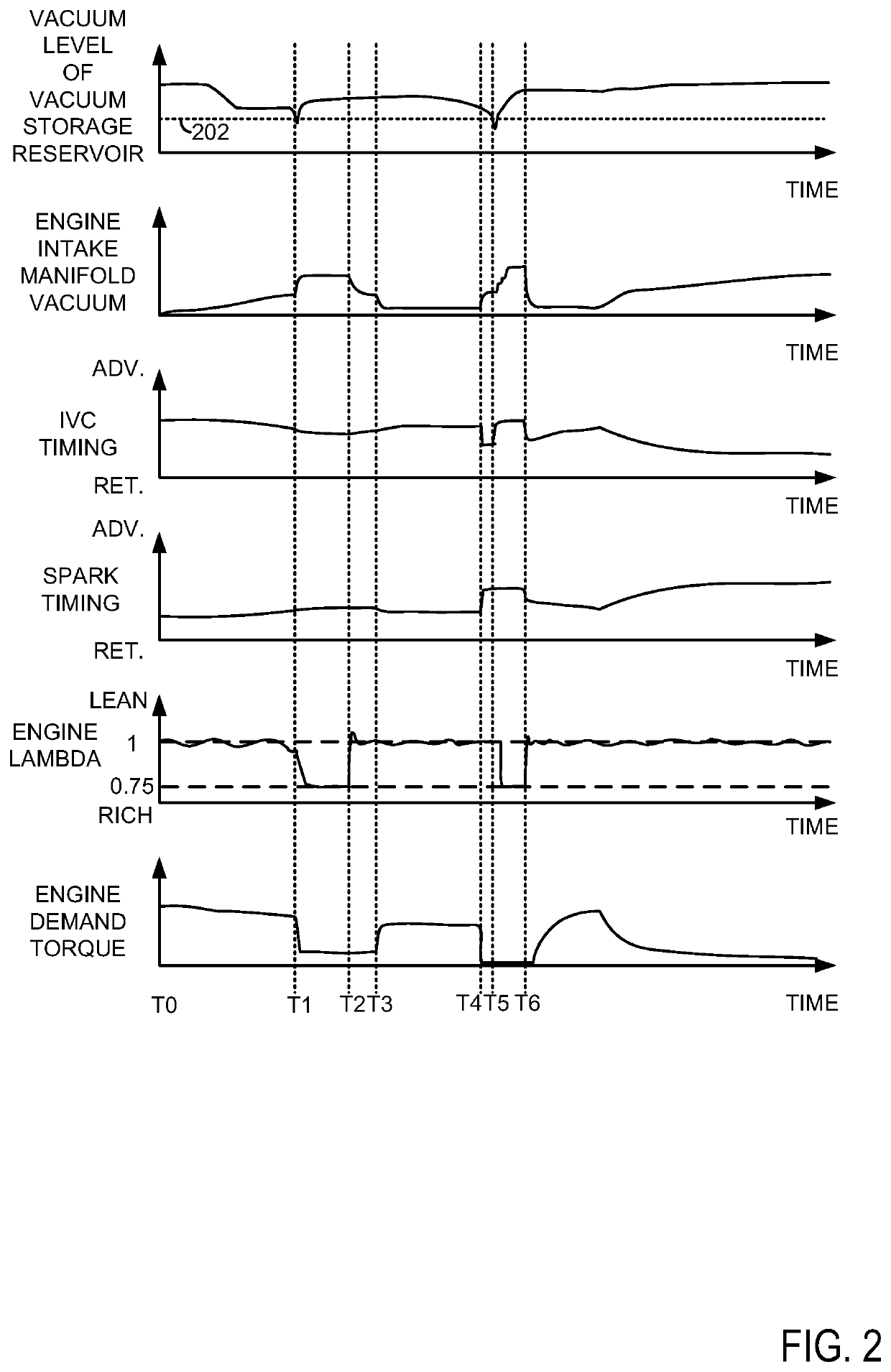

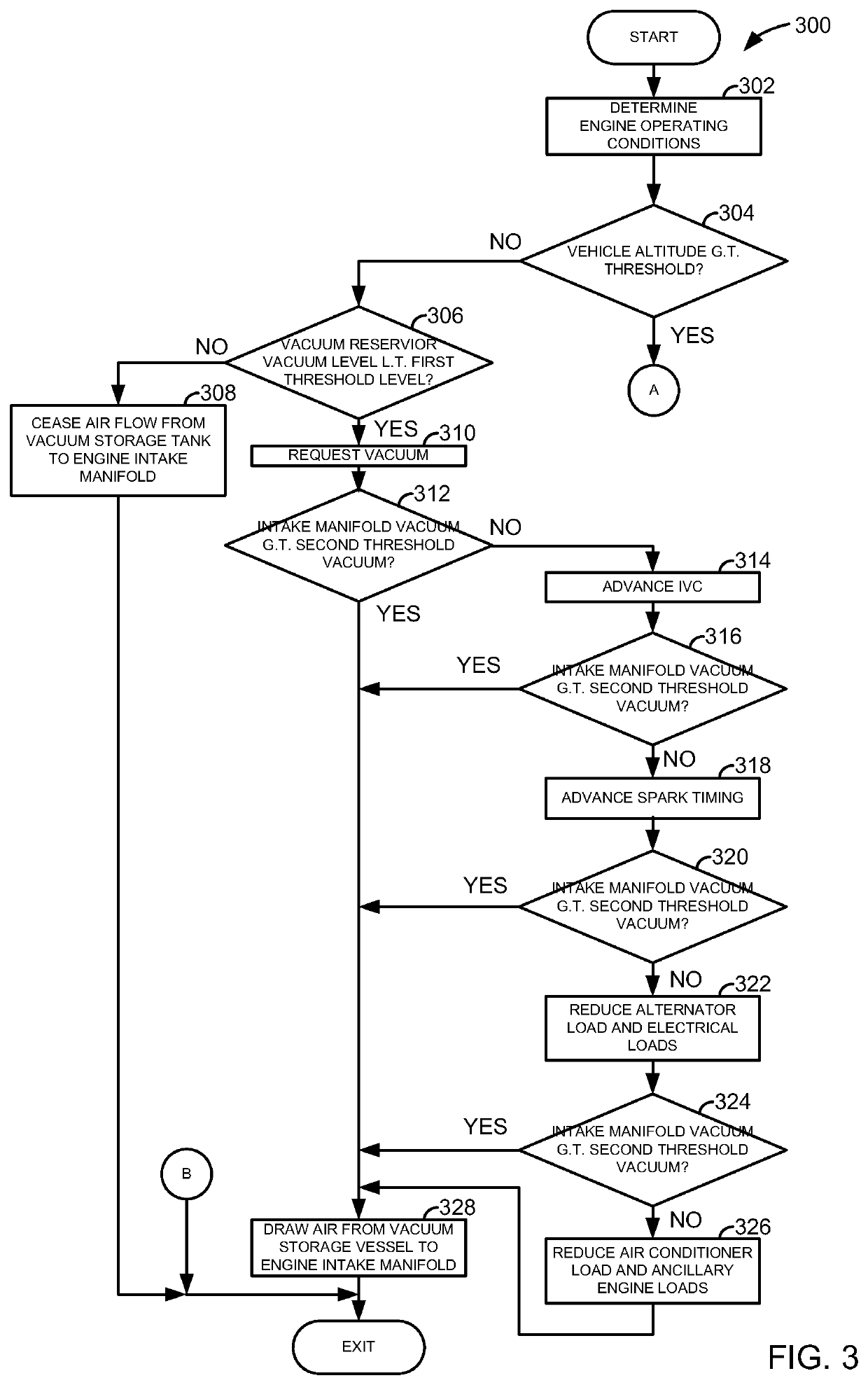

Method for increasing vacuum production for a vehicle

ActiveUS20150316002A1Save fuelSufficient vacuumElectrical controlInternal combustion piston enginesAir–fuel ratioAutomotive engineering

Owner:FORD GLOBAL TECH LLC

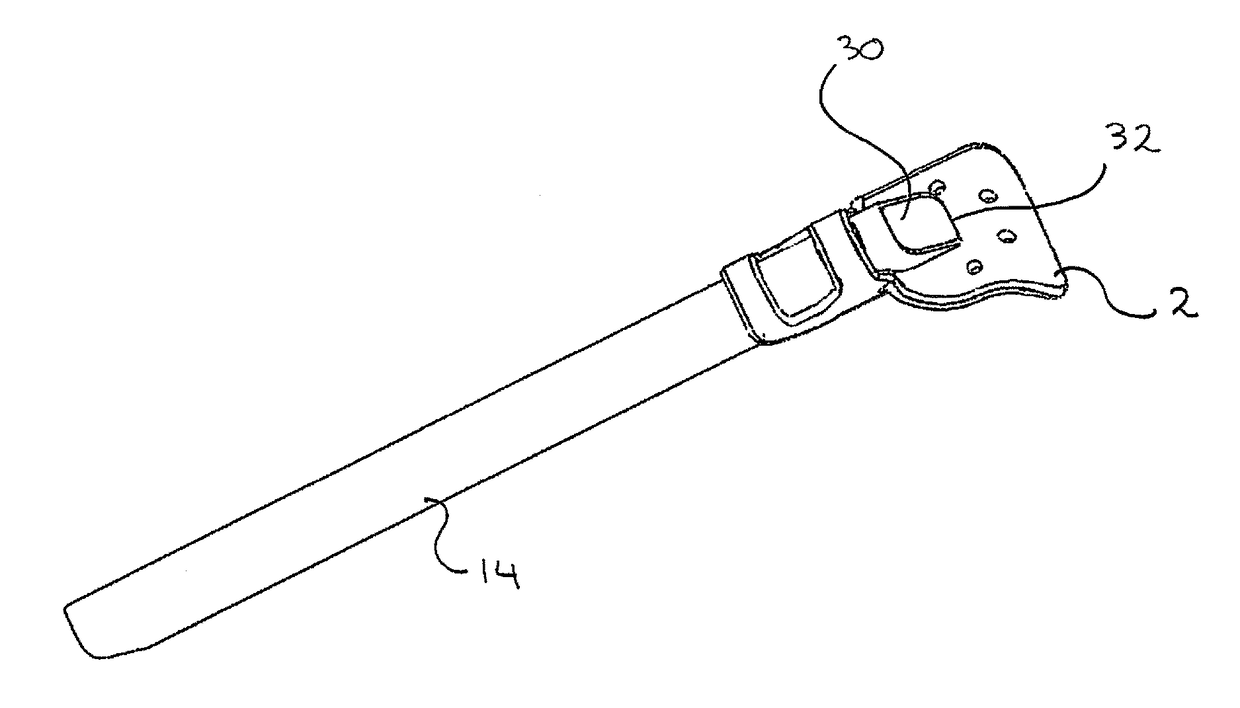

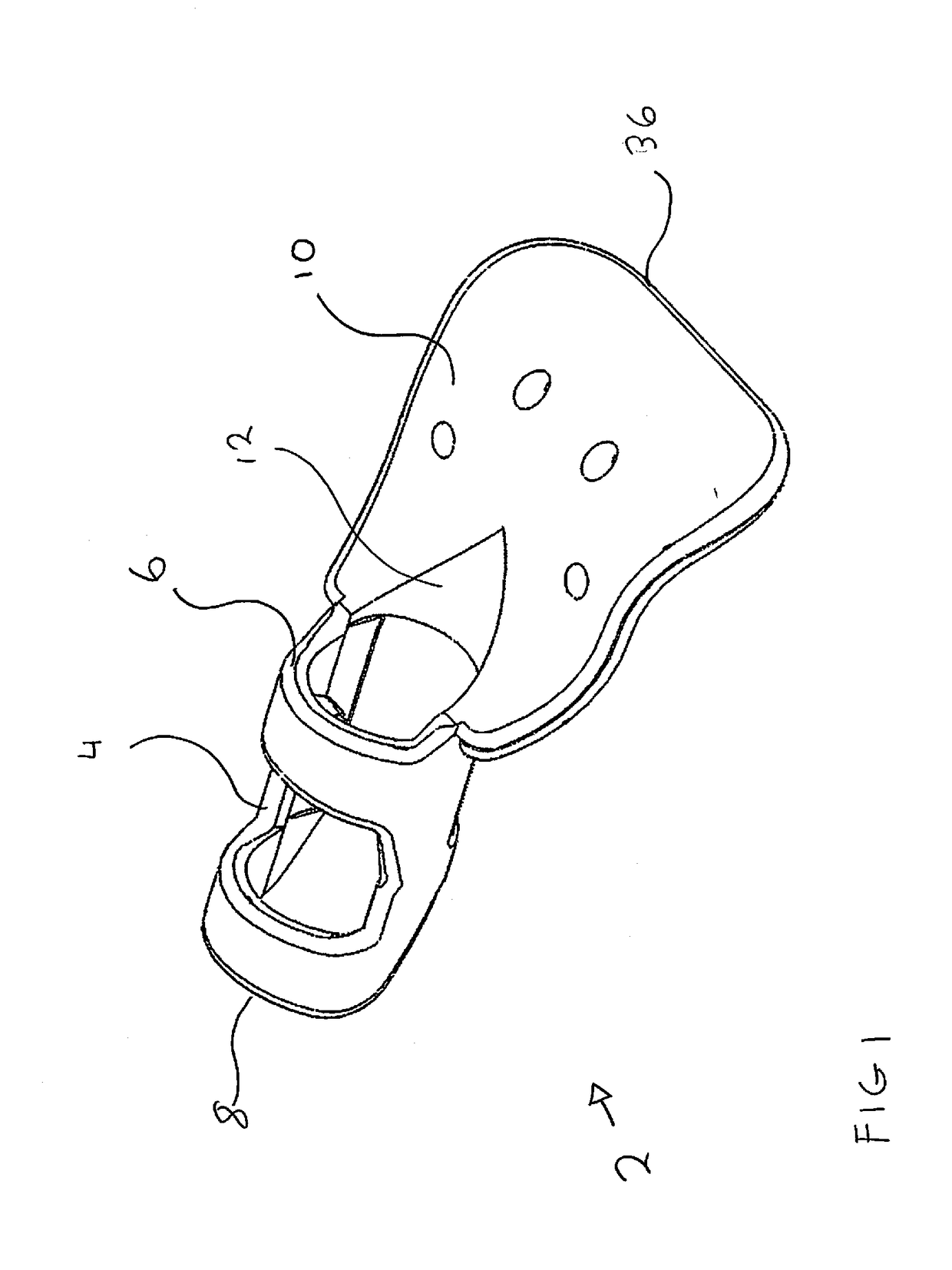

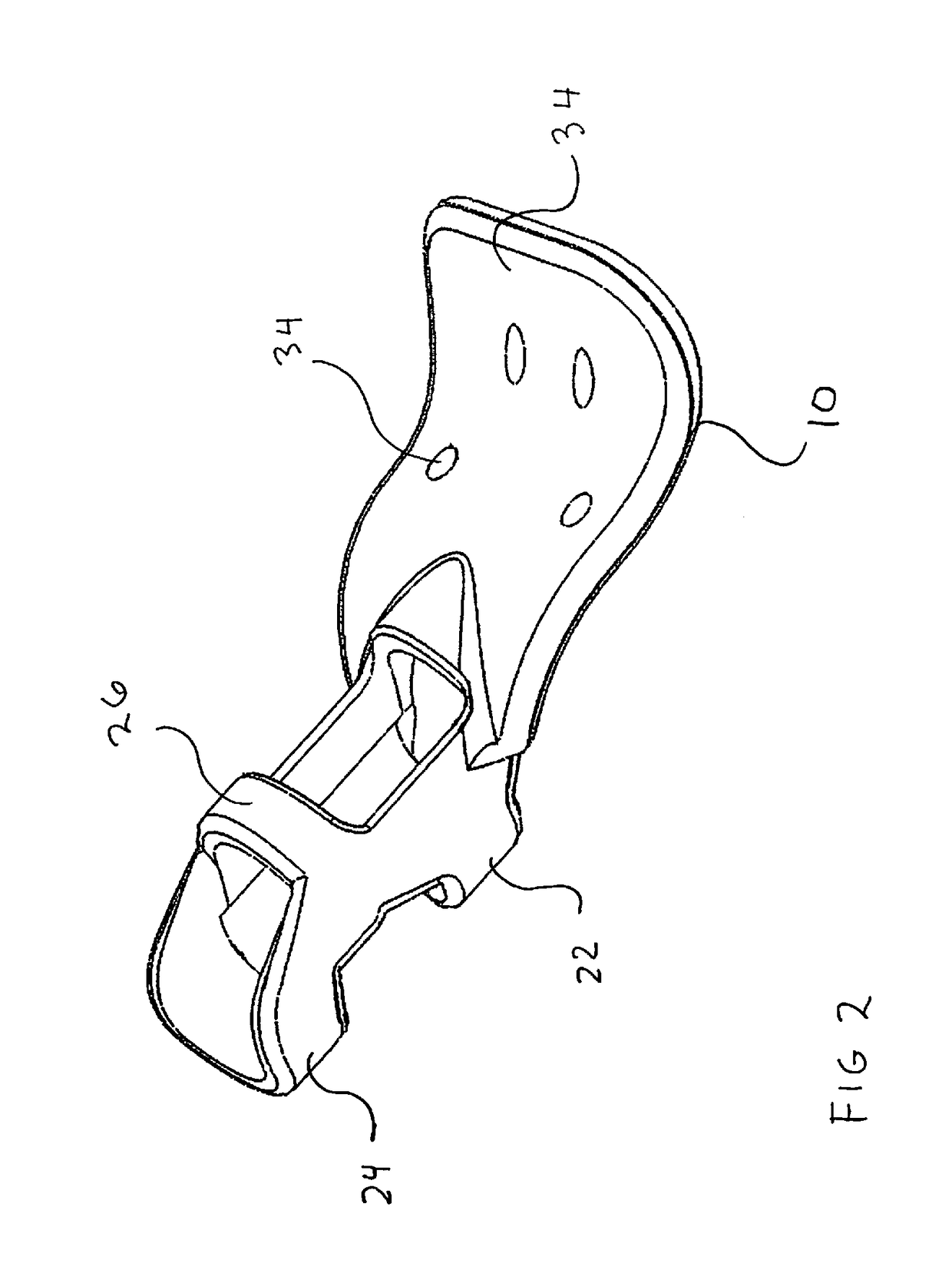

High volume evacuation straw tongue retractor

InactiveUS20170245843A1Simple and comfortable evacuationSufficient vacuumDiagnosticsSurgeryDental AssistantDrinking straw

A dental device that mates a high volume extraction unit to a tongue retractor to allow the dental assistant to remove fluids and debris from the mouth of a patient with ease and using a minimal volume of the space in a patient's mouth. The device has a straw collar that encircles the shaft of a suction straw in a “Vee” configuration with a set of opposing half-bands. A post extending inward from the front half band locks the suction straw in place. Affixed to the suction straw is a paddle shaped tongue retractor with an array of orifices there through to allow the vacuuming of fluids and debris from the bottom side of the retractor.

Owner:LINGUAGUARD LLC

Sweeping robots and floor handling units

ActiveCN104138238BSufficient vacuumWon't hinder reachSuction nozzlesCleaning equipmentDrive wheelEngineering

A cleaning robot comprising a robot machine body (100). Drive wheels (110) are arranged on the machine body (100). A dust intake opening (120) is provided at the bottom part of the machine body (100). With the direction in which the cleaning robot travels serving as the front (A), a static seal (130) is arranged at the rear and two sides of the dust intake opening (120). The lower edge of the static seal (130) extends towards a to-be-cleaned work surface (B). A dynamic sealing element (140) is arranged at the front of the dust intake opening (120). The dynamic sealing element (140) comprises an actuating element (141) and a dynamic seal (142). A gap between the dynamic seal (142) and either the edge of the dust intake opening (120) and / or the to-be-cleaned work surface (B) forms an air intake opening. The dynamic seal (142) is driven by the actuating element (141) into motion, thus allowing the area of the air intake opening to change dynamically. By arranging the dynamic sealing element (140) at the dust intake opening (120), not only the dust intake opening (120) is provided with a sufficient degree of vacuum, but also the dynamic sealing element (140) does not obstruct dust particles from reaching the dust intake opening (120), thus allowing for a simplified structure and increased cleaning efficiency.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Ejector pin system

InactiveCN107093575AEasy to remove the filmFor quick replacementSemiconductor/solid-state device manufacturingEngineering

The invention discloses an ejector pin system, which comprises an ejector pin cap and a guide base, and is characterized in that the upper end face of the ejector pin cap is provided with first ejector pin holes, and the bottom of the ejector pin cap is connected with the guide base; the upper end of the guide base is further connected to an ejector pin fixing device, the ejector pin fixing device is located in the ejector pin cap, the upper surface of the ejector pin fixing device is provided with second ejector pin holes which are used for fixing ejector pins; the ejector pin fixing device comprises an ejector pin base and a magnetic attraction base, the magnetic attraction base is located at the bottom of the ejector pin base, fixation of the ejector pins adopts of a mode of magnetic attraction, and replacement is performed quickly, simply and conveniently; and both the first ejector pin holes and the second ejector pin hole adopt array distribution, any number of ejector pins can be installed at any positions, thereby being applicable to various sizes of chips, and being easy to demould the chips.

Owner:大连佳峰自动化股份有限公司

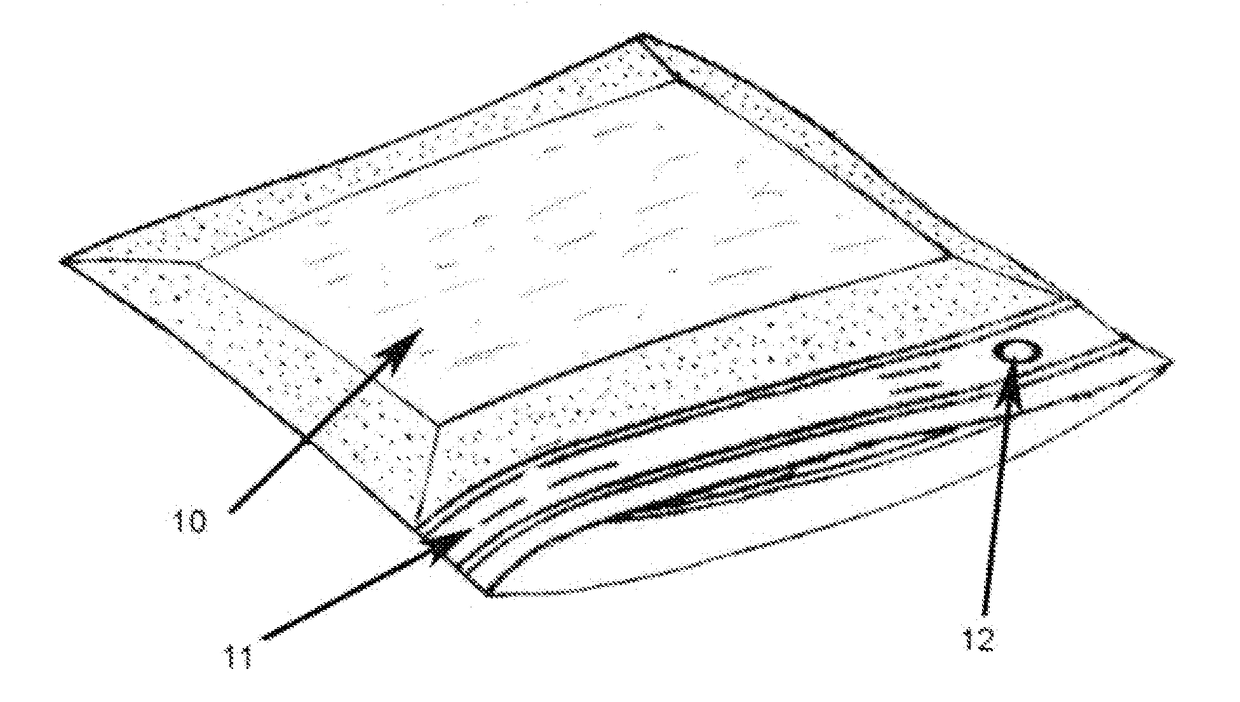

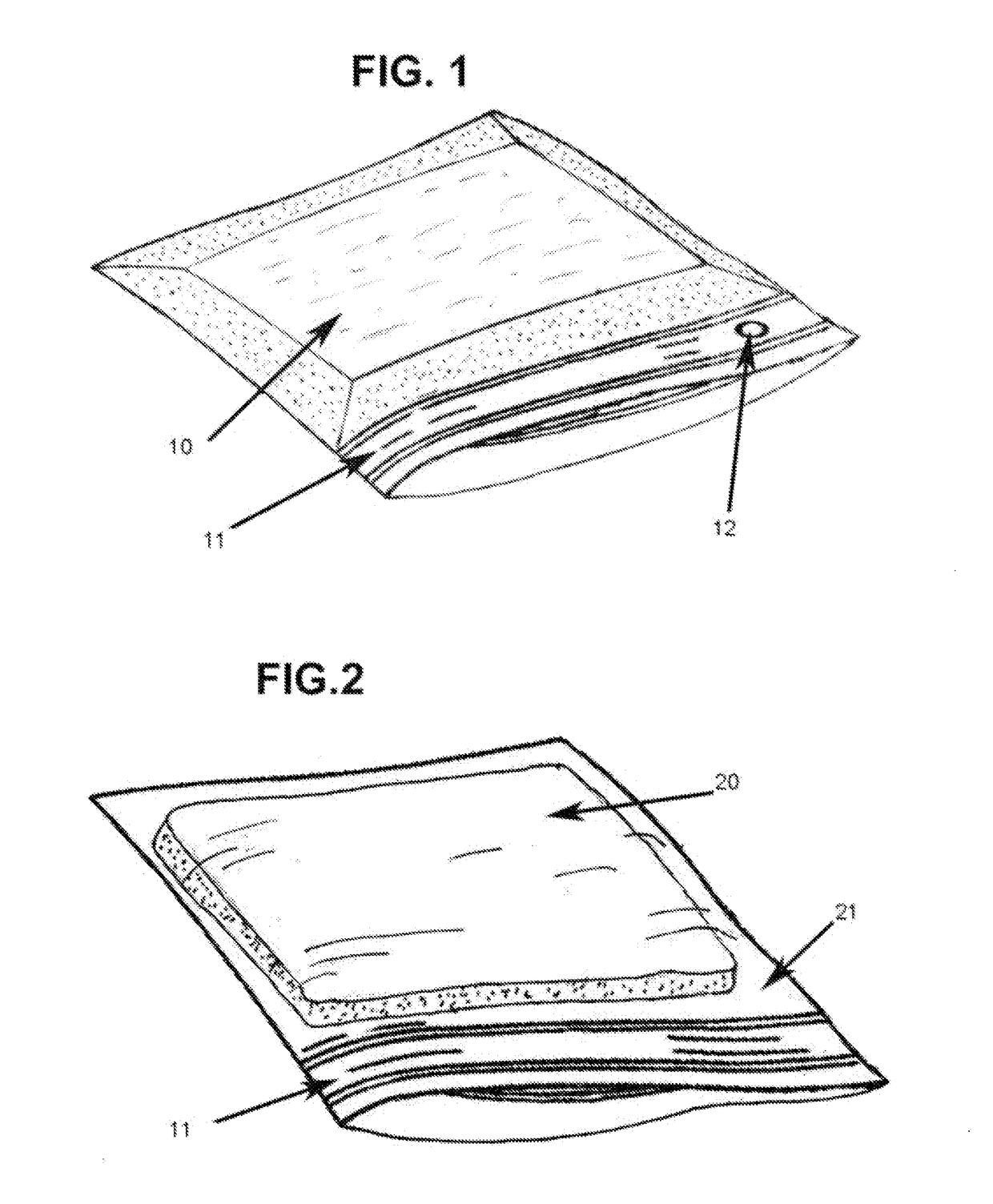

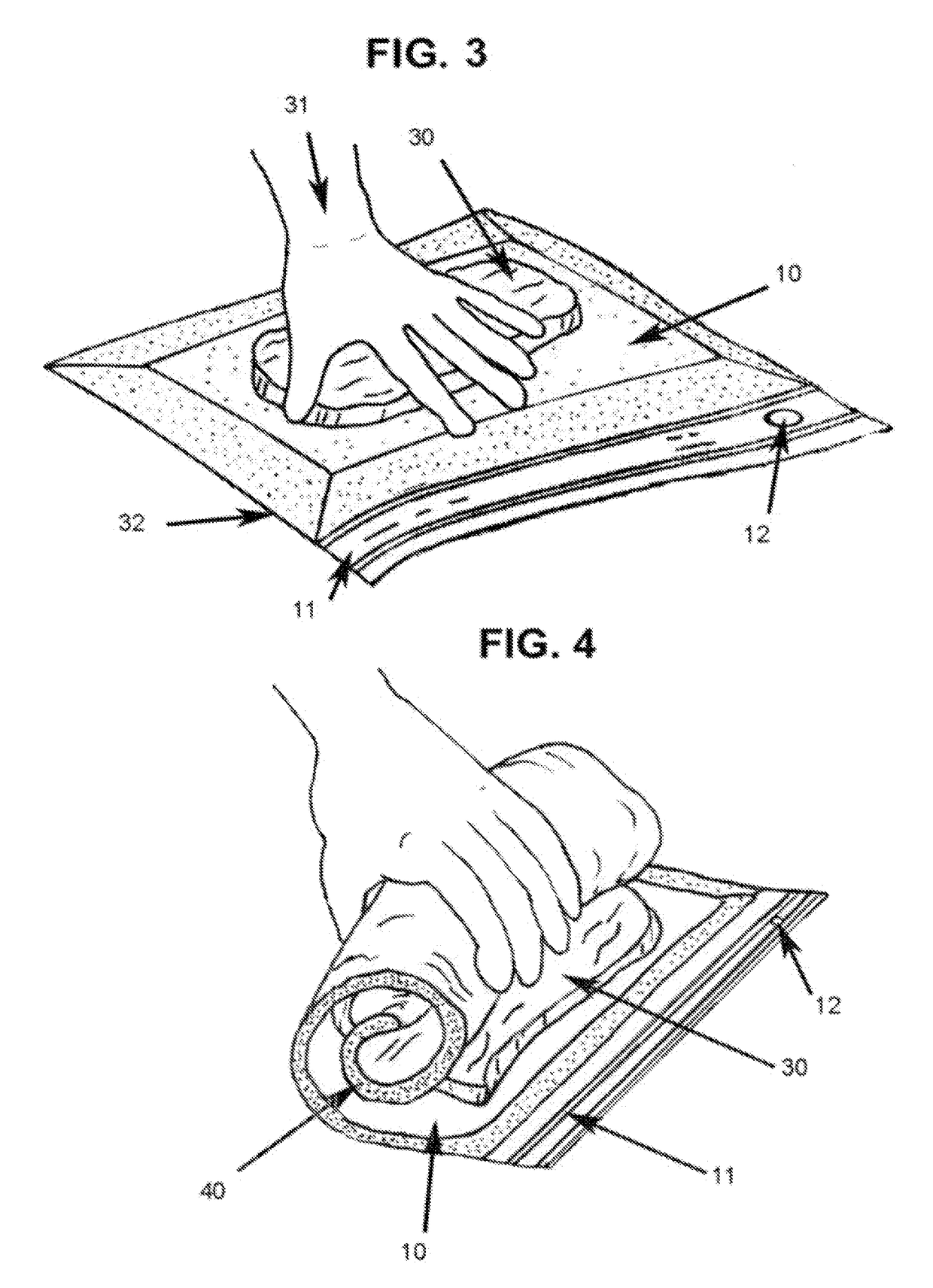

Vacuum Storage Bag

A vacuum storage bag not requiring the use of an external vacuum source. With a resilient sponge compressible polymeric material mass such as a rectangular sheet or any shape of sufficient thickness that is an integral part of an opposing wall of storage bag, a vacuum can be produced by compressing sponge within this sealable bag. The sponge being an integral part of inner bag wall will not shift and interfere with a valve or bag closure. By compressing the resilient sponge material / resilient mass flattening or rolling contents along with a food product / dry goods or any other material that is to be stored, and forcing the air volume out of the sealable bag, utilizing one of the many valved zipper closures or pinch rail valve closure systems expelling the air. Any residual air not exhausted from bag will mostly be trapped within sponge material when sponge expands.

Owner:SALAZAR DENNIS R

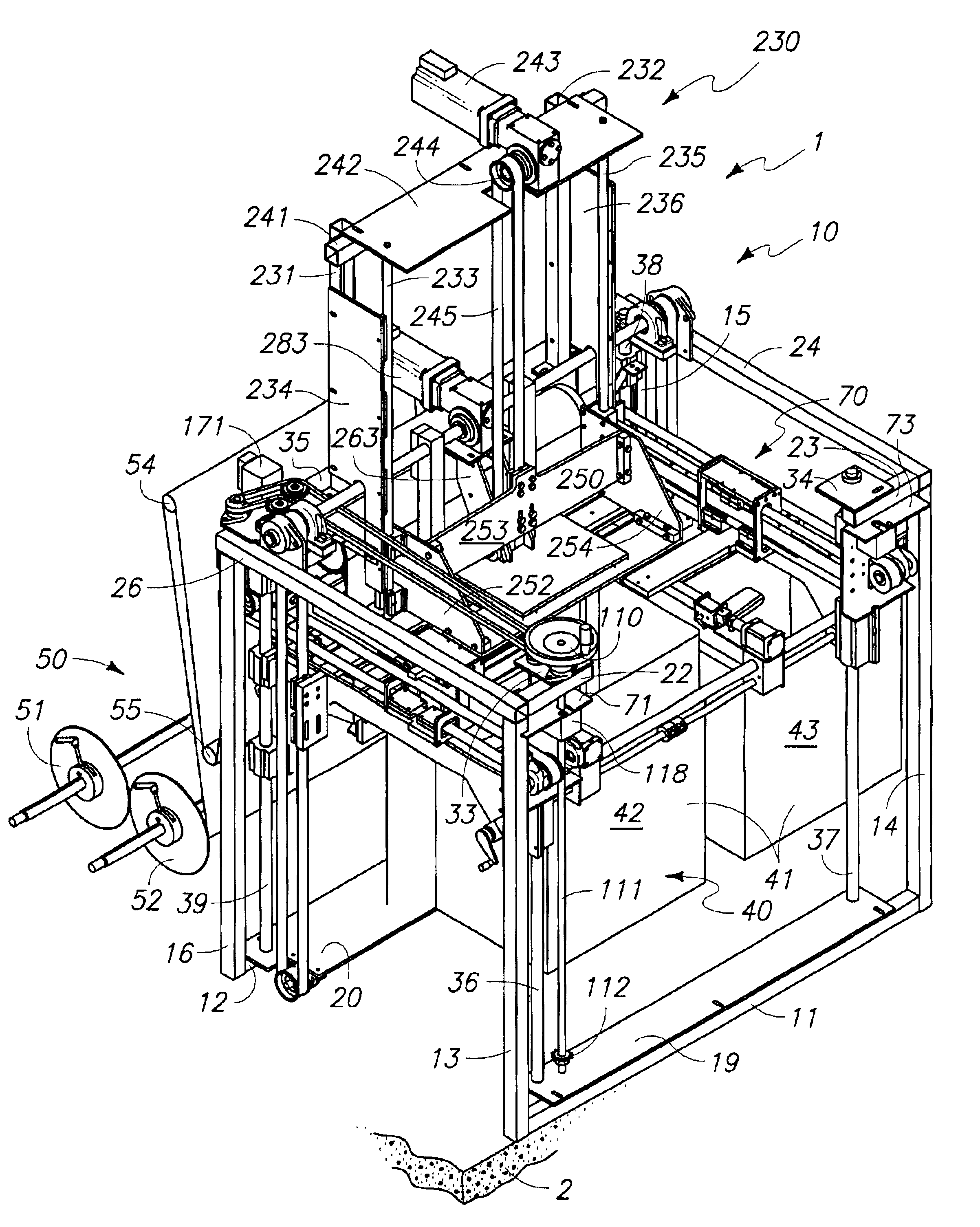

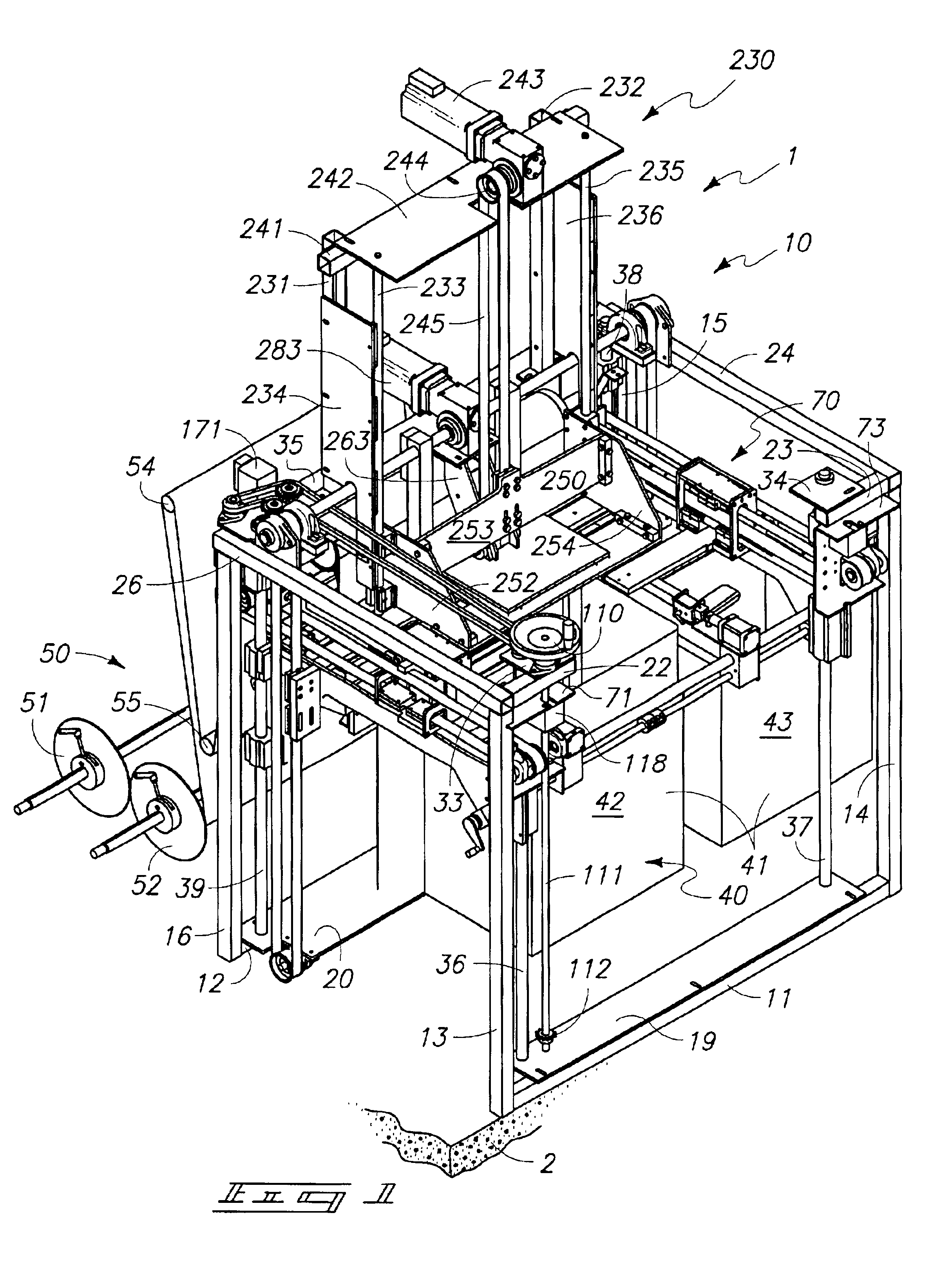

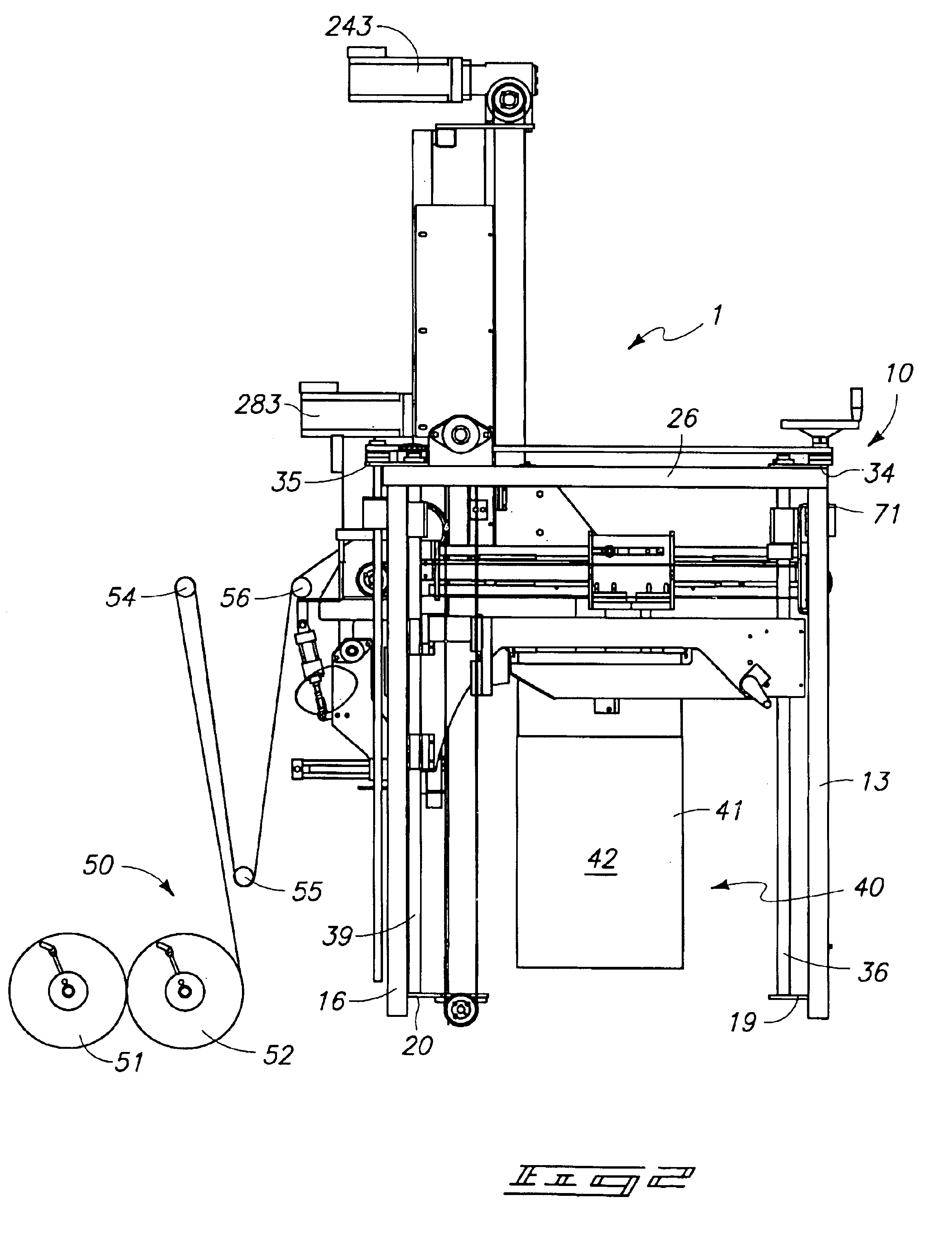

Packaging container liner insertion and cuffing apparatus and methods

InactiveUS6767316B2Operate efficiently and effectivelySufficient vacuumBoxes/cartons making machineryBox making operationsEngineeringMechanical engineering

Methods and apparatuses for inserting flexible bags into open containers, and cuffing an open end of the flexible bags about a top edge of the open containers. The method and apparatus include a vacuum assembly having at least one movable vacuum head for engaging and positioning the flexible bags in preparation for their insertion into the open containers. An insertion assembly having a mandrel inserts the flexible bags into the open containers. A cuffing assembly can be included for cuffing the open end of the flexible bags over the top edges of the open containers. The vacuum assembly may engage a flexible bag from a bag dispenser while the mandrel is in an extended position within the container. The method and apparatus also facilitate the use of a vacuum assembly, insertion assembly, and cuffing assembly which are independently driven to provide greater speed and flexibility to the bag opening, insertion and cuffing processes.

Owner:R A PEARSON

Explosion-proof dilution sampling probe

PendingCN111044332AEasy to replaceMeet different environmental requirementsWithdrawing sample devicesAcousticsGas mixing

The invention relates to an explosion-proof dilution sampling probe. The explosion-proof dilution sampling probe comprises a probe shell, a vacuum generator arranged in the probe shell, a sound speedsmall hole communicated with the vacuum generator, a fixing device and a sampling probe tube fixed on the outer wall of the probe shell and communicated with the sound speed small hole. The vacuum generator comprises a mounting plate and an air distribution disc integrally connected to one side of the mounting plate; the sound speed small hole comprises a flow stabilizing pipe and an air guide pipe integrally connected with the flow stabilizing pipe, wherein the diameter of the air guide pipe is smaller than that of the flow stabilizing pipe; the fixing device comprises a base fixedly connected to the mounting plate and communicated with the vacuum generator and a fastener that is used for fixing the air guide pipe to the base when the air guide pipe is inserted into the base. The explosion-proof dilution sampling probe has the advantages that workers can conveniently replace sound velocity small holes with different hole diameters so as to meet different environment requirements; meanwhile, the probe has an explosion-proof function and is suitable for first-area and second-area dangerous places and indoor and outdoor installation of explosive gas mixtures of IIA-IIC levels and T1-T3 groups.

Owner:BAY ENVIRONMENTAL TECH BEIJING

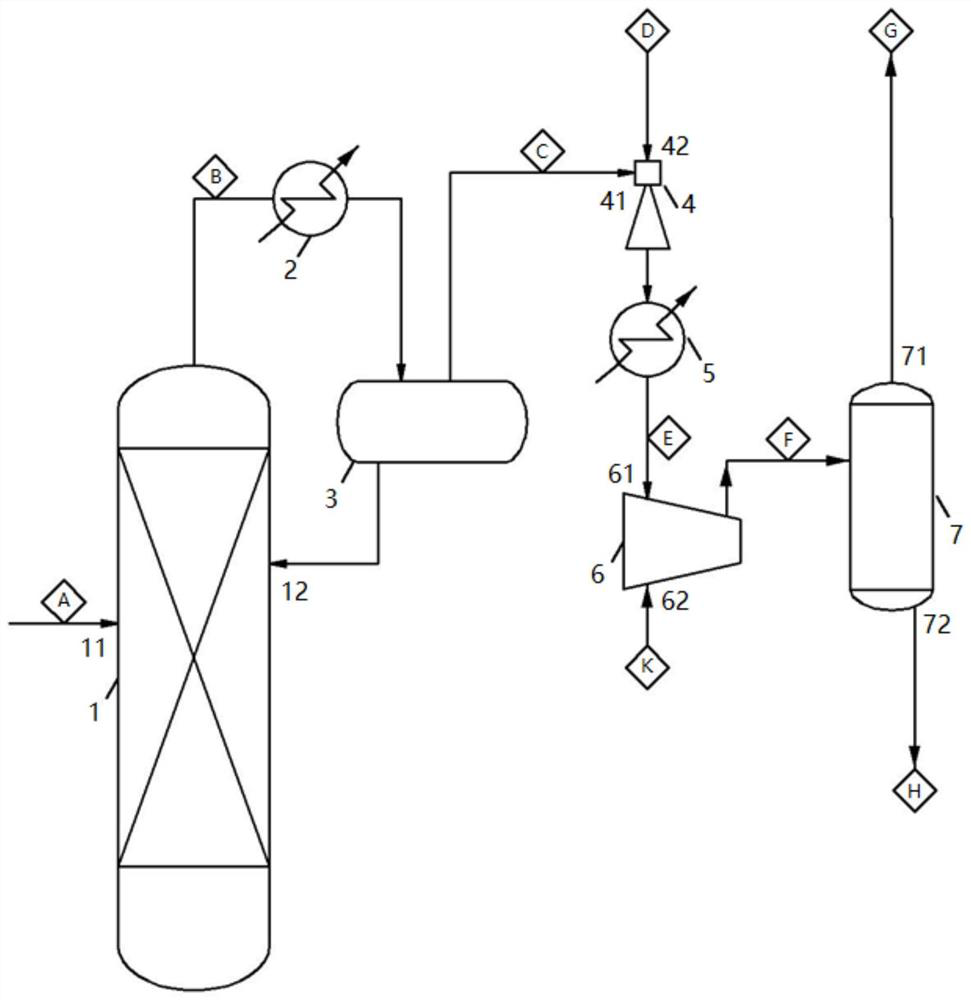

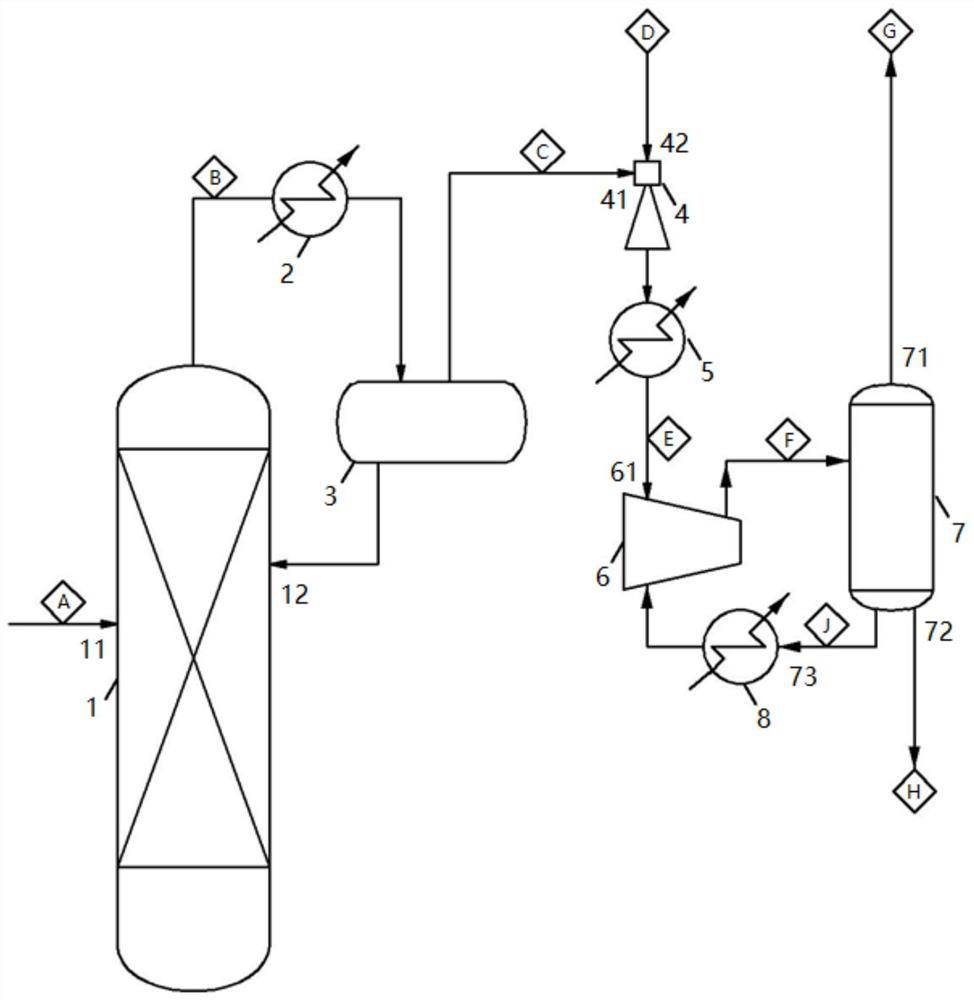

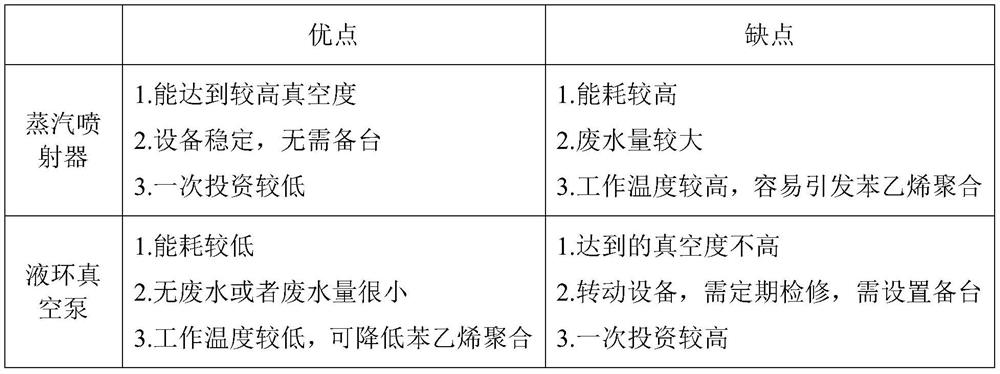

Device and method for removing light components in styrene monomer

PendingCN114573414ASufficient vacuumWill not cause accumulationChemical industryDistillation purification/separationThermodynamicsIntermediate heat exchanger

The invention belongs to the field of styrene refining, and relates to a device and a method for removing light components in a styrene monomer. The device comprises a styrene light component removal rectifying tower, a tower top condenser, a tower top reflux tank, an ejector, an intermediate heat exchanger, a liquid ring vacuum pump and a gas-liquid separation tank. According to the device and the method for removing the light components in the styrene monomer, the problems of removal and discharge of the light components can be effectively solved, and polymerization of styrene can be reduced. Compared with a single liquid ring vacuum pump system, the system has the advantages of high vacuum degree, low equipment investment, no light component enrichment and the like; compared with a multi-stage ejector system, the multi-stage ejector system has the advantages of low operation cost, low energy consumption, low wastewater amount, low working temperature and the like.

Owner:SINOPEC ENG +1

Filter system

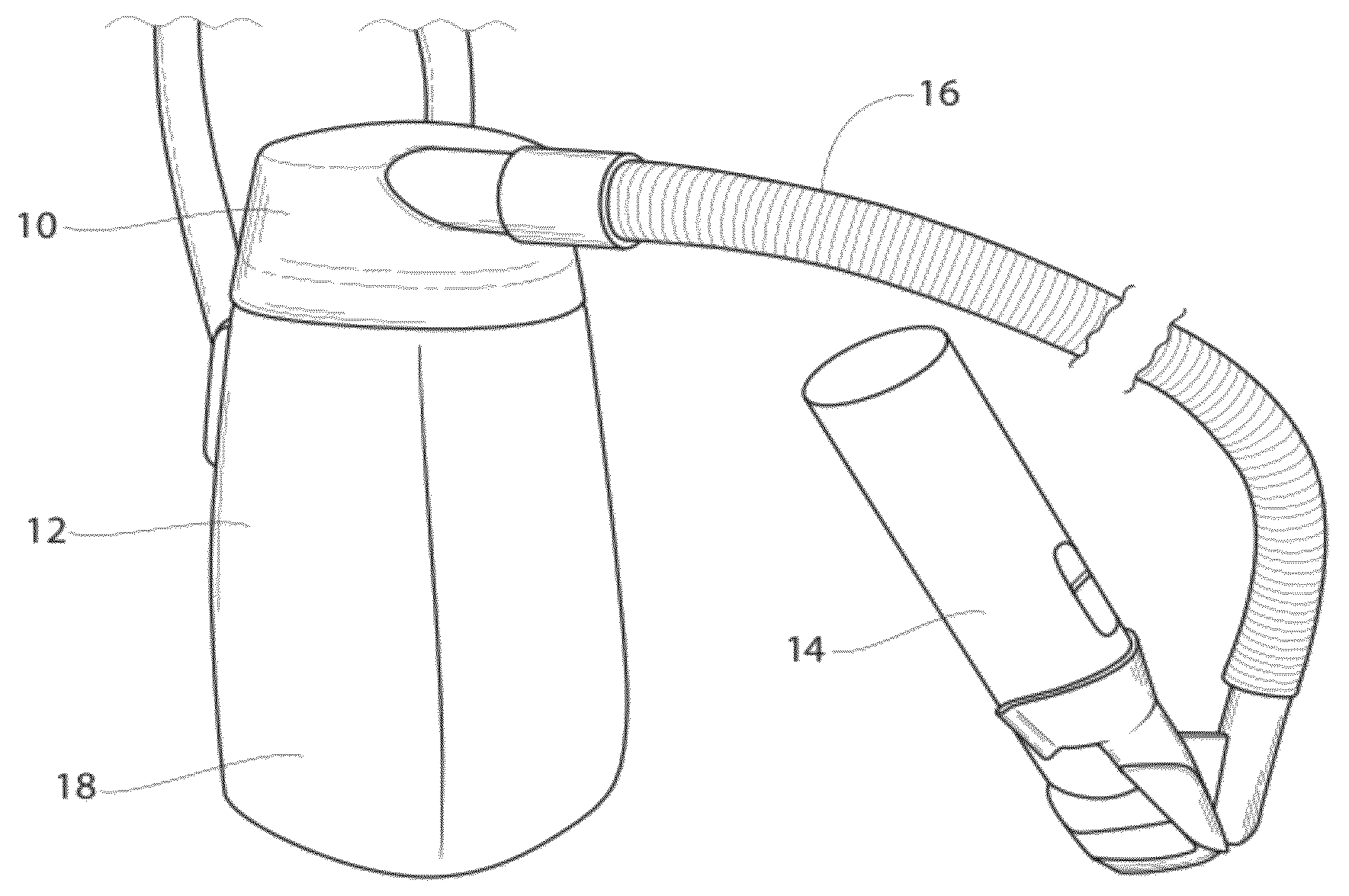

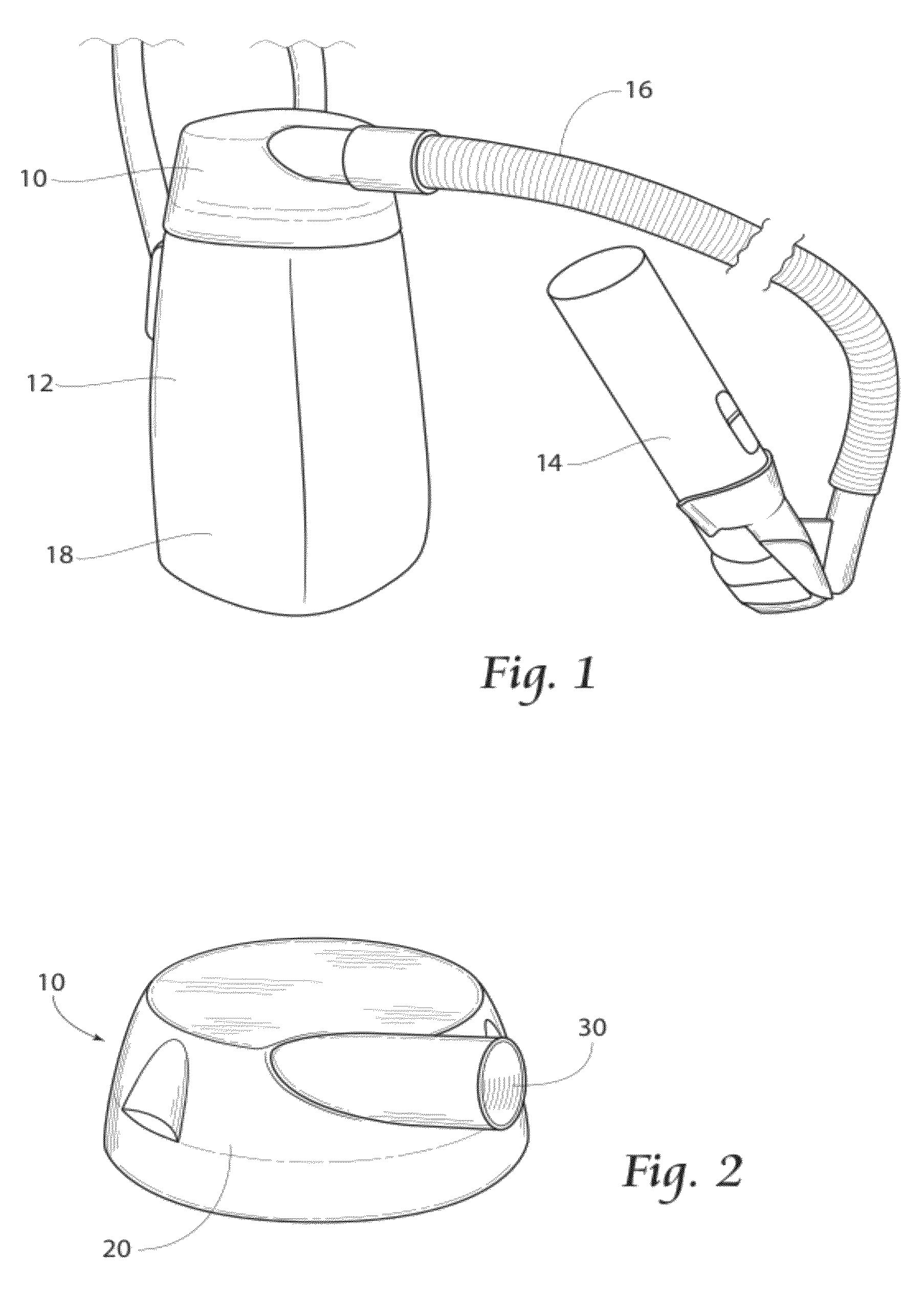

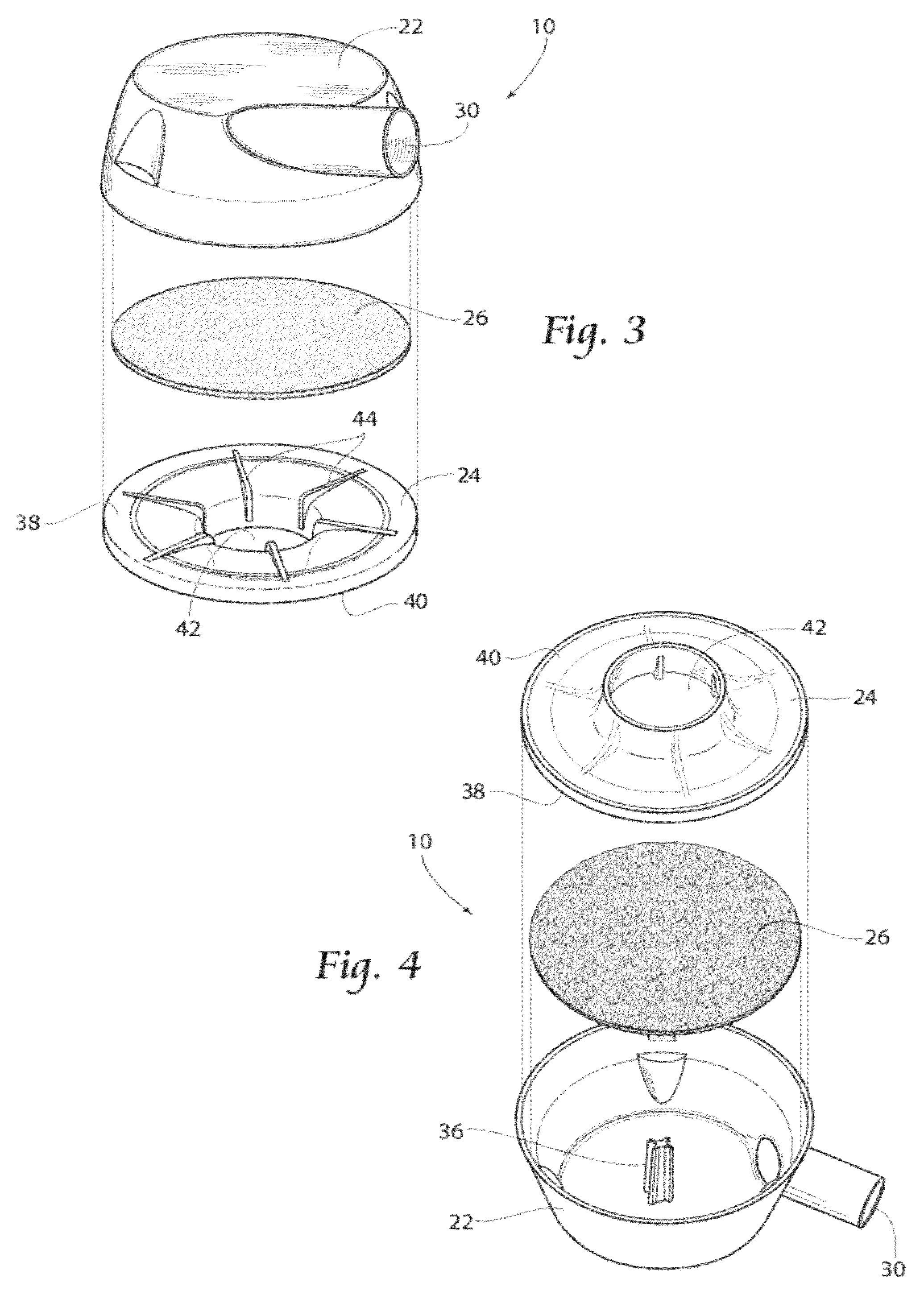

ActiveUS8876981B2Efficient and even accumulationIncreasing longevity and effectivenessDispersed particle filtrationHollow article cleaningFilter systemWaste management

A method of collecting cut hair is disclosed. The steps include providing a vacuum source and a filter assembly having a top piece, a bottom piece, and a filter member. The assembly has a generally circular perimeter. A vacuum is applied to the assembly interior, and the cut hairs are moved through the aperture and into the assembly. The cut hairs are circulated in a collecting vortex and collected on the filter member.

Owner:SURGICAL SITE SOLUTIONS

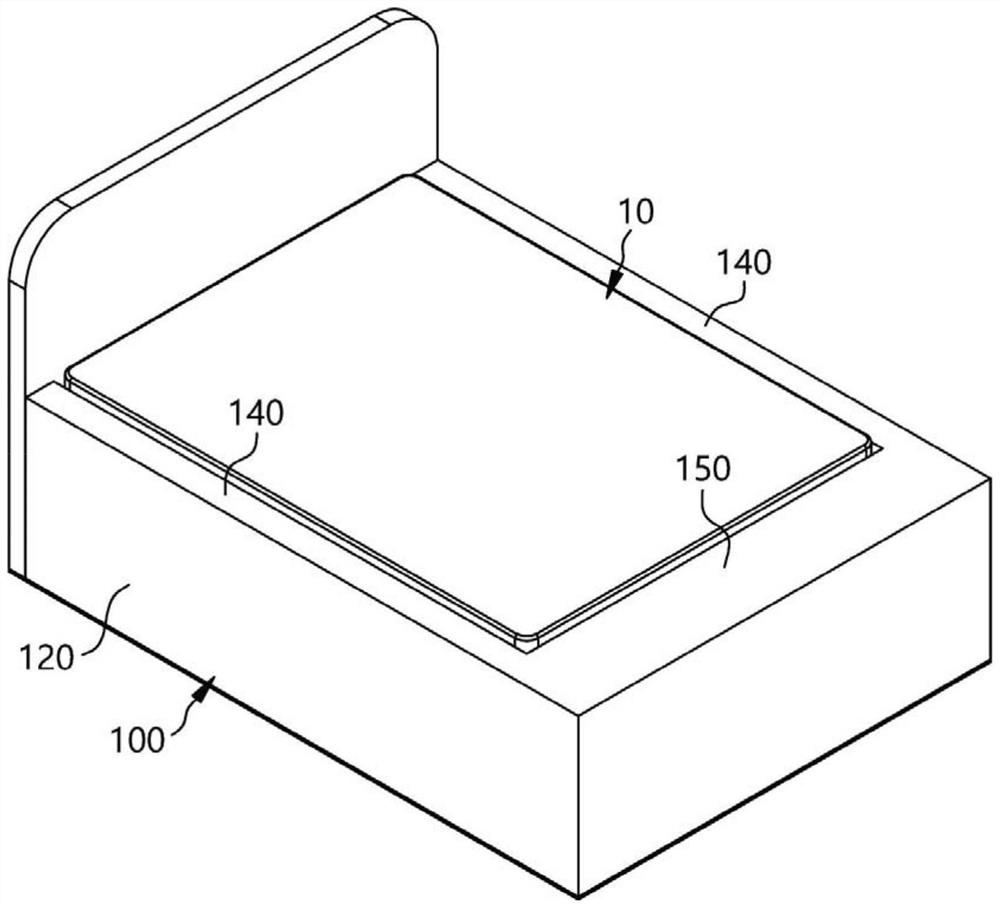

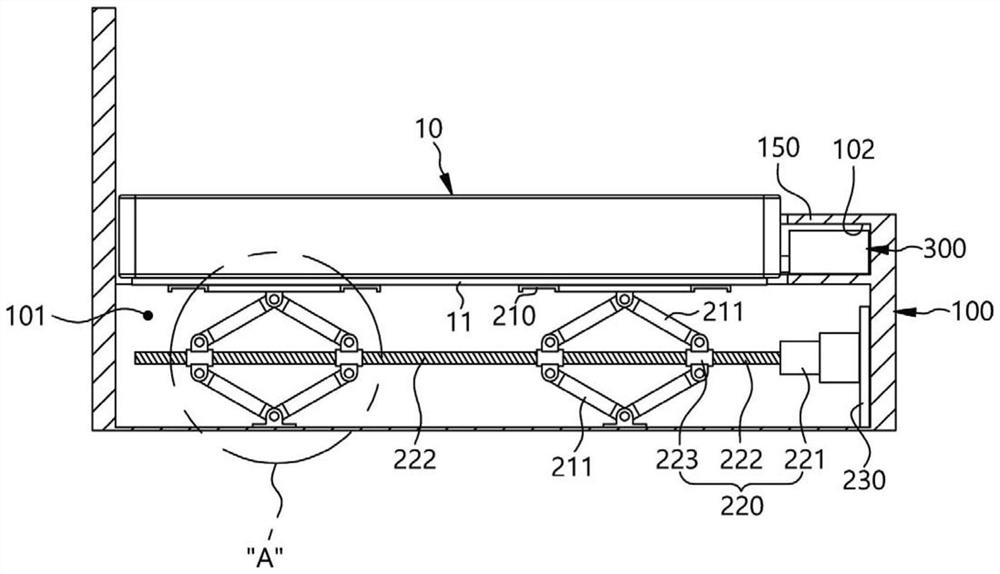

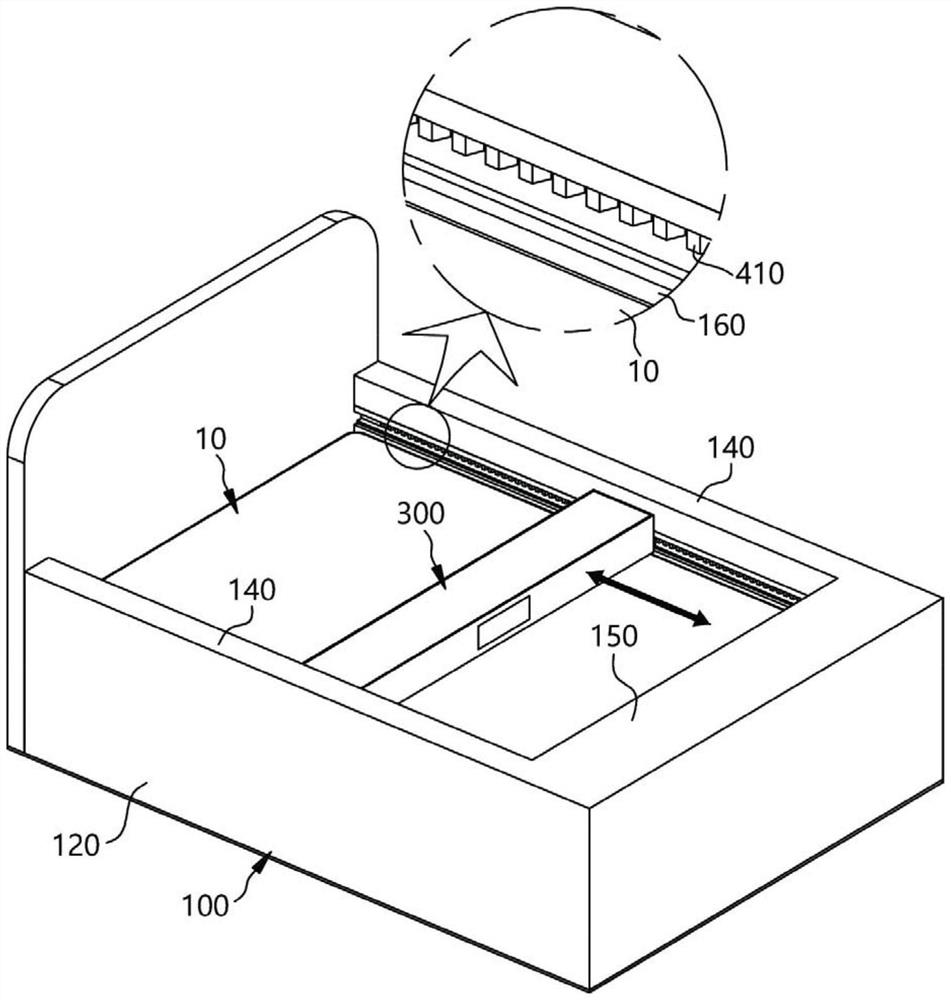

Mattress nursing device

PendingCN114762734AAvoid exposureAdjust lift heightSuction hosesMotor fan assembly mountingNursing careEngineering

The present invention provides a mattress care device which is provided so as to be capable of moving a mattress downward to a position lower than the top surface of a bed frame, and is provided with a cleaning module which performs sterilization cleaning while moving along the upper portion of the mattress when the mattress is moved downward. Therefore, under the condition that sterilization and cleaning are not carried out, the cleaning module is kept in a hidden state, and therefore the situation that a user possibly feels uncomfortable visually is avoided.

Owner:LG ELECTRONICS INC

Method and system for increasing vacuum generation by an engine

ActiveUS9322347B2Increase productionReduced MAPElectrical controlCombustion enginesAutomotive engineering

Owner:FORD GLOBAL TECH LLC

Wood floor carbonization processing method

InactiveCN101570031BEasy to operateQuality improvementWood compressionWood charring/burningCarbonizationEmbryo

Owner:周发荣

Massage device

InactiveCN112188880AImprove sealingSufficient vacuumPneumatic massageMilking pumpBreast pump (device)Physical medicine and rehabilitation

A massage device is disclosed that is made by converting an existing breast pump using a massage adapter ring that allows for the easy conversion to and from a massage device to breast pump.

Owner:FITSON SINGAPORE PTE LTD

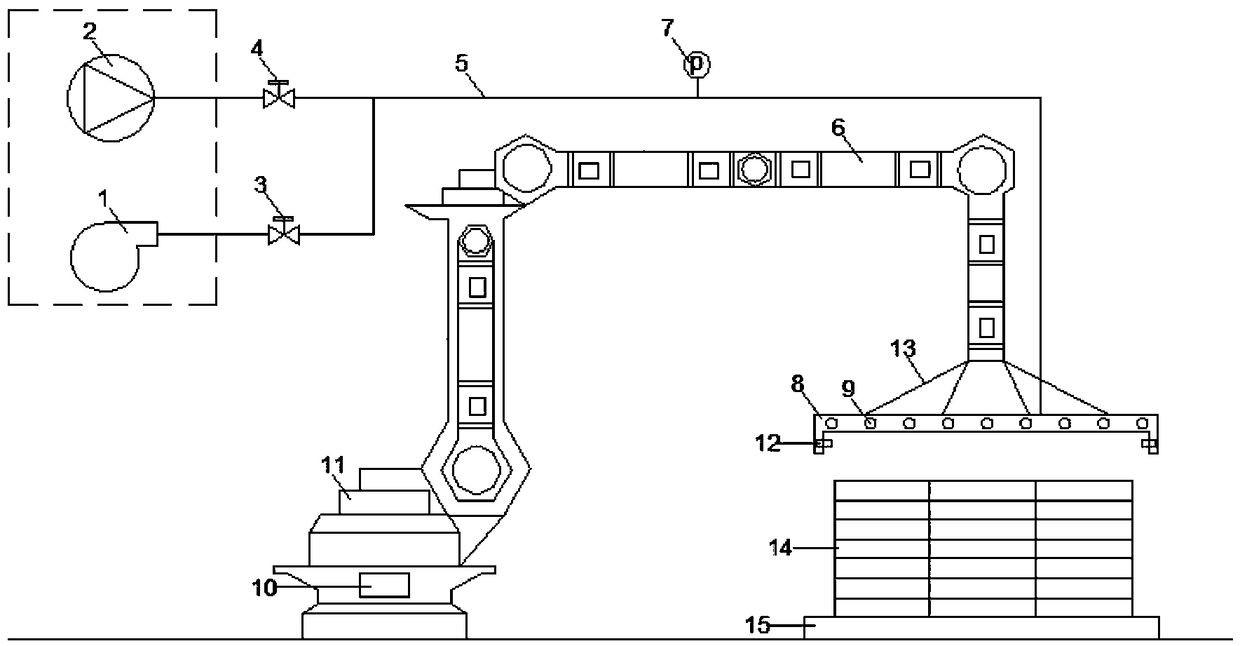

Automatic trunk loading device for bagged materials

PendingCN108438948AImprove loading efficiencyGuaranteed uptimeConveyorsLoading/unloadingEngineeringAutomation

The invention relates to an automatic trunk loading device for bagged materials. The automatic trunk loading device for bagged materials comprises an aspiring mechanism and a vacuumizing mechanism connected in parallel, wherein the aspiring mechanism and the vacuumizing mechanism connected in parallel are connected to a general gas port of an integral adsorption disc; at least one suction head isarranged on the adsorption surface of the adsorption end of the integral adsorption disc; and an optoelectronic switch is arranged on the integral adsorption disc. The automatic trunk loading device for bagged materials provided by the invention can solve the technical problem that the degree of automation of an operating mechanism stops in a relatively low level as existing travelling cranes forlarge materials for a long term in environments such as a hoisting warehouse, a plant and a stock ground are operated in driving cabs by professional operators.

Owner:HUBEI SANNING CHEM

Air extraction mechanism and air extraction device with the air extraction mechanism

ActiveCN105489924BSimple structureSimple pumping operationFinal product manufactureNon-aqueous electrolyte cellsLithiumEngineering

The invention discloses an air pumping mechanism, which includes a suction cup, a vacuum tube, a needle and a needle driving mechanism; the vacuum tube is a hollow structure and includes a cavity extending along its length, and the suction cup is used for being adsorbed on a soft-packed lithium battery The airbag bag, the rear end of the suction cup is hermetically sleeved on the front end of the vacuum tube and communicated with the through cavity of the vacuum tube, the needle driving mechanism is sealed and arranged at the rear end of the vacuum tube and It has an output shaft that protrudes into the through cavity and can slide back and forth. The needle is accommodated in the through cavity and its rear end is fixedly connected with the output shaft. A vacuum hole communicating with the through cavity is provided between them. The air extraction mechanism of the invention has simple structure and high air extraction efficiency. The invention also provides an air extraction device with the air extraction mechanism.

Owner:DONGGUAN TEC RICH ENGINEERING CO LTD

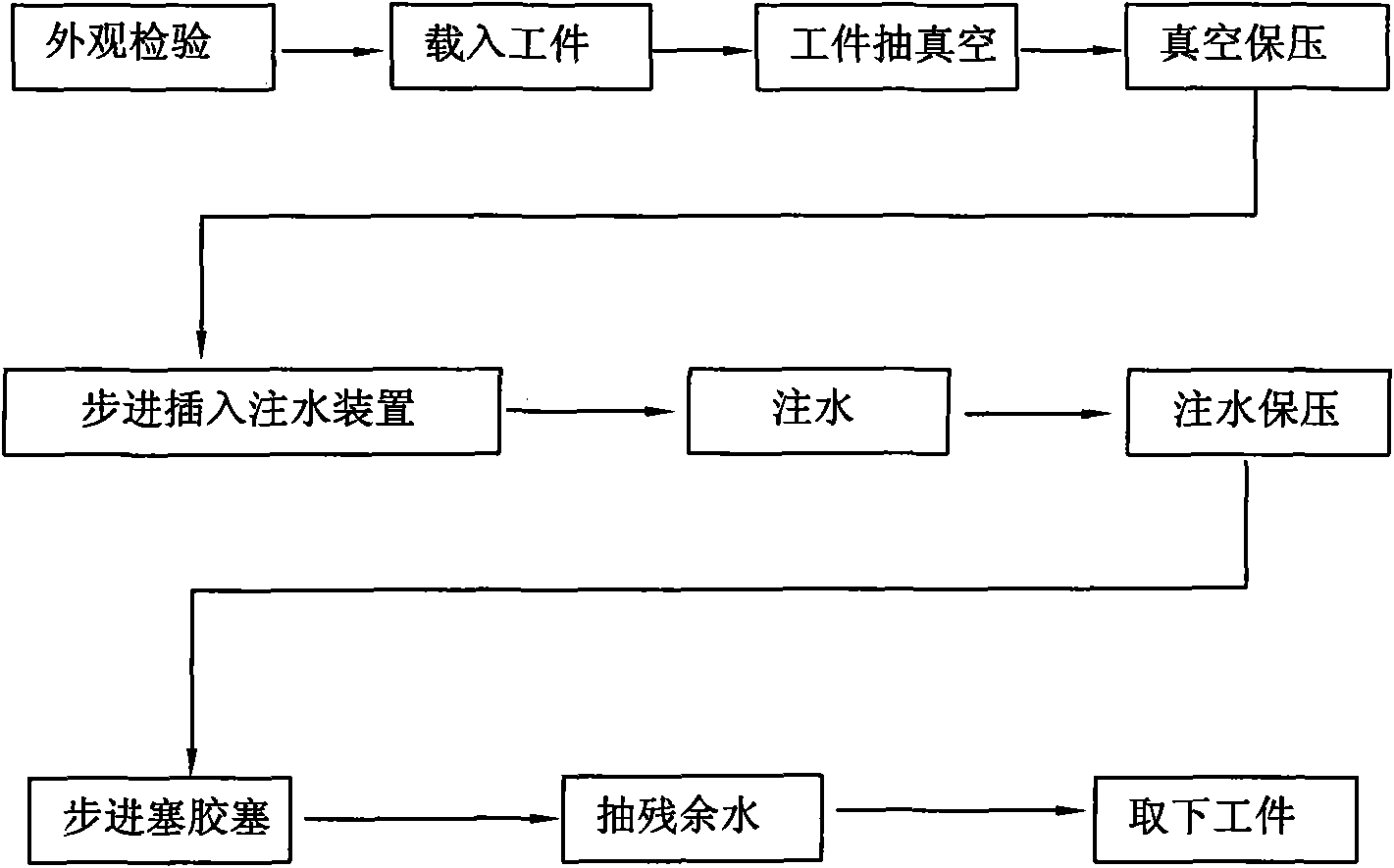

Vacuum water injection method for radiator

InactiveCN101550949ASufficient vacuumImprove cooling efficiencyPressure pumpsMachines/enginesAir contentHeat spreader

The invention relates to a water injection method for a radiator, in particular to a vacuum water injection method for the radiator. The method comprises the following two procedures: the capillary pipes of the radiator are vacuumized, and water is injected into the capillary pipes. The invention has the advantages that a negative pressure water injection way is adopted, i.e. the capillary pipes of the radiator, ;which are needed to be injected with water, are vacuumized, and enough vacuum degree which can reach up to lower than 10Pa is ensured, thereby the air content in the capillary pipes of the radiator is only about 0.25 percent, the water can be injected into the capillary pipes to the largest extend, and the radiating efficiency is increased by 30-50 percent.

Owner:祝翌

Method for controlling electric vacuum pump based on ECU (Electronic Control Unit) control

ActiveCN103072563BSufficient vacuumGet rid of dependencyBraking action transmissionLower limitEngineering

The invention provides a method for controlling an electric vacuum pump control method based on ECU (Electronic Control Unit) control. The method comprises the following steps of: detecting the vacuum degree of a vacuum booster in real time, and comparing with the upper and lower limits of a safety threshold value; and adjusting the vacuum degree of the vacuum booster according to a comparison result. Measures for adjusting the vacuum degree of the vacuum booster include starting the electric vacuum pump to assist the vacuum booster in generating a vacuum degree, and lowering an engine load to increase the vacuum degree. The control method can be implemented on the basis of an engine ECU by fully depending on the structure of the conventional vehicle model, so that the defects of excessive dependence on a mechanical structure and large modification on a vehicle existing in the conventional method are overcome, the cost is saved, and a better control effect can be achieved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

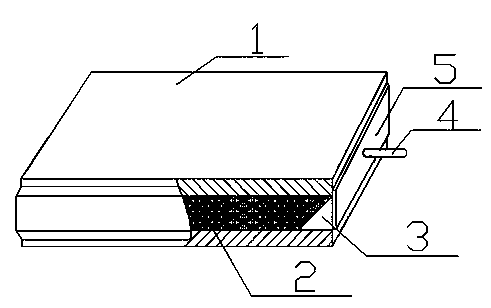

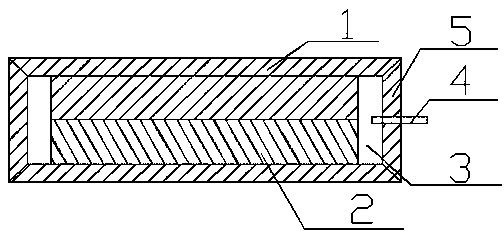

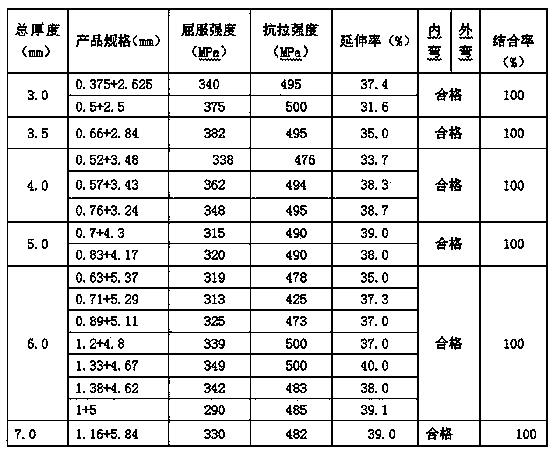

Method for vacuum assembling and non-vacuum rolling laminated metal composite material roll

The invention provides a production method of rolled laminated metal composite roll, in which laminated metal composite blank is in vacuum state before assembling and rolling and in non-vacuum state in the hot rolling process. The method is characterized in that the inner end of an aluminum hollow pipe segment enters a reserved rolling extension space in the composite blank, the other end is connected with a vacuum pump; and the composite blank is evacuated through the vacuum pump and the pipe segment. The method can ensure the high vacuum degree in the composite blank before rolling, and can keep the internal junction surface of the composite blank clean and prevent oxidation. The method can ensure that air is discharged in time, thereby radically solving the problems of the prior art caused by the difficulty in discharging air in the composite blank, such as surface damages of the composite rolls or even damages to rolling equipment. The laminated metal composite material roll prepared by the method has the advantages of high strength, good mechanical processing performance, high corrosion resistance, high surface decorativeness, high quality and low production cost.

Owner:云南昆钢新型复合材料开发有限公司

High-yield capsule filling machine

ActiveCN101829022BIncrease the total amount of fillingImprove drug filling qualityCapsule deliveryBiomedical engineering

The invention relates to a high-yield capsule filling machine which is provided with a plurality of capsule sequencing and separating mechanisms (1) and an indexing rotating disk mechanism (11), wherein an upper module (2) and a lower module (3) of the indexing rotating disk mechanism (11) are provided with a plurality of die discharging holes corresponding to the capsule sequencing and separating mechanisms; a capsule vacuum separating and balancing device (14) of each capsule sequencing and separating mechanism comprises a vacuum suction pipe (23) and a vacuum suction base (22), balance upright poses (27) are arranged under two side edges of the vacuum suction base, and springs (28) are arranged under the balance upright posts which are arranged in hollow upright posts (29) through positioning bearing (26) and sealing pressure covers (25). The invention is used for improving and updating partial mechanisms of the capsule filling machine, and increases the operation balance degree and the sealing property of part of a machine body when in high yield so as to meet the requirement for high yield; and the yield of finished drugs filled by the filling machine can reach about 7200 grains per minute.

Owner:楚天飞云制药装备(长沙)有限公司

Method for increasing vacuum production for a vehicle

ActiveUS10677196B2Sufficient vacuumSave fuelElectrical controlInternal combustion piston enginesControl theoryMechanical engineering

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com