Method for vacuum assembling and non-vacuum rolling laminated metal composite material roll

A metal material and laminated metal technology, applied in the field of steel rolling, can solve the problems of broken composite coils, damage to heating furnaces, rolling mills and other equipment, and the inability to discharge the air of composite slabs. The effect of protecting normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

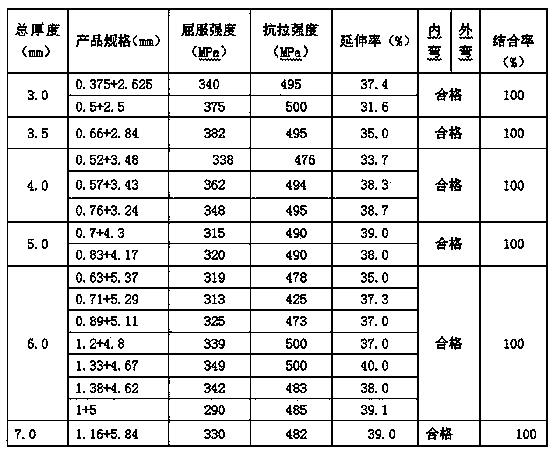

Embodiment 1

[0022] Carbon steel plate Q235B is selected as the base metal material, stainless steel plate 06Cr19Ni10 (SUS304) is used as the cladding metal material, and multiple batches of treatment are carried out respectively, and each batch is carried out according to the following method:

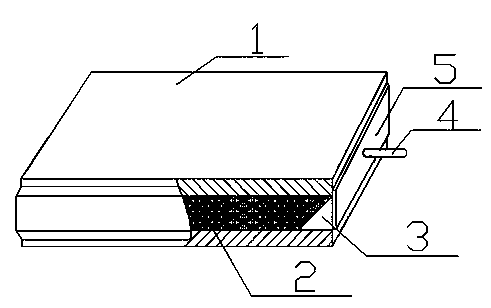

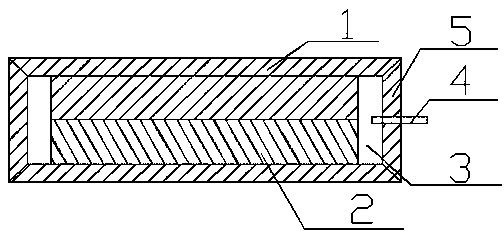

[0023] (1) Composite slab welding and sealing: the clad metal material 2 and base metal material 1 are surface treated by conventional mechanical methods until the joint interface is clean, and then the clad metal material 2 formed by stacking two pieces is placed on the Between the upper and lower base metal materials 1, and reserve a rolling extension space 3 around the clad metal material 2, use the base metal material 1 as the four side walls, and weld with the upper and lower base metal materials 1 to form a hollow body, so that the cladding metal material 2 is placed in the hollow body of the base metal material after sealing and welding to obtain a composite billet; holes are opened at inter...

Embodiment 2

[0027] Select stainless steel plate 12Cr17Mn6Ni5N (SUS201) as the base metal material, and stainless steel plate 06Cr19Ni10 (SUS304) as the cladding metal material, and carry out multiple batches of treatment, and each batch is carried out according to the following method:

[0028] (1) Composite slab welding and sealing: the clad metal material 2 and base metal material 1 are surface treated by conventional mechanical methods until the joint interface is clean, and then the clad metal material 2 formed by stacking two pieces is placed on the Between the upper and lower base metal materials 1, and reserve a rolling extension space 3 around the clad metal material 2, use the base metal material 1 as the four side walls, and weld with the upper and lower base metal materials 1 to form a hollow body , the clad metal material 2 is placed in the hollow body of the base metal material after sealing and welding to obtain a composite blank, and holes are spaced on the tail end side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com