Device and method for removing light components in styrene monomer

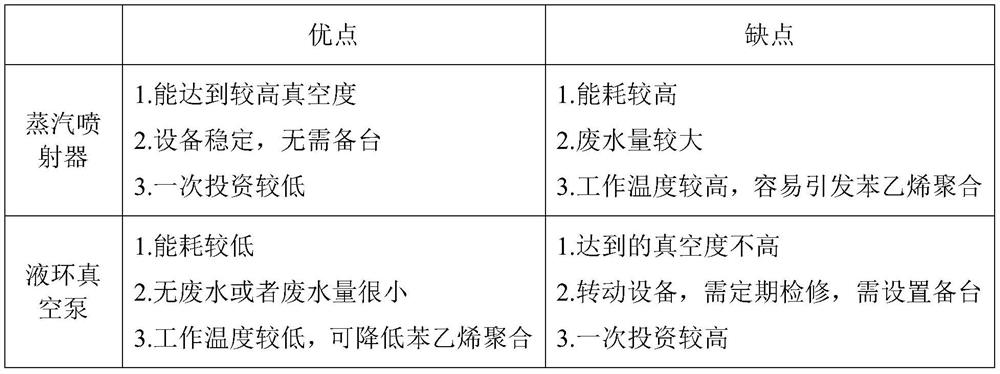

A styrene monomer, styrene technology, applied in distillation purification/separation, organic chemistry, climate sustainability, etc., can solve the problems of styrene polymerization, insufficient vacuum degree, etc. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

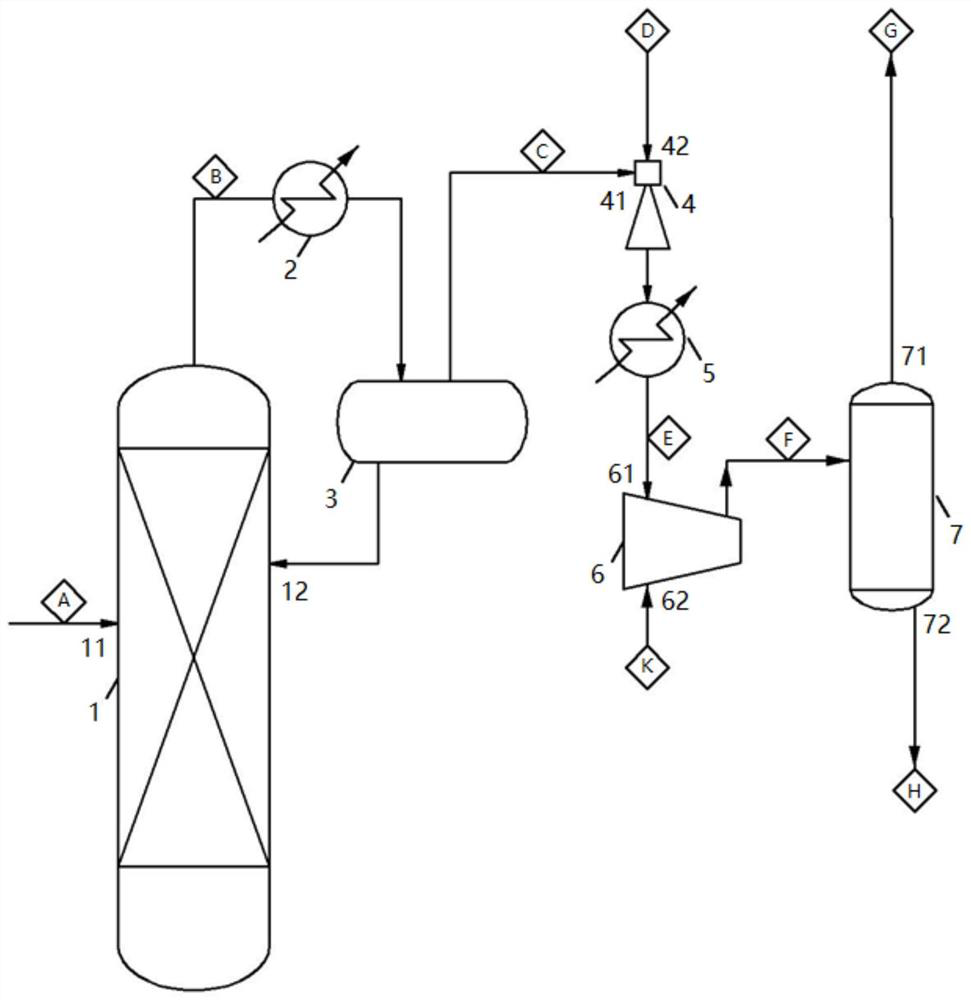

[0051] like figure 1 As shown in the figure, the present embodiment provides a device for removing light components from styrene monomer, the device includes a styrene delighting distillation column 1, a column top condenser 2, a column top reflux tank 3, and an ejector 4 , intermediate heat exchanger 5, liquid ring vacuum pump 6, gas-liquid separation tank 7; wherein,

[0052] Described styrene lightening rectifying tower 1 comprises the first inlet 11 of styrene lightening rectifying tower, the second inlet 12 of styrene lightening rectifying tower and the outlet of the styrene lightening rectifying tower located at the top, The first inlet 11 of the styrene delightening rectification column is used to transport the product of the phenylethanol dehydration reaction into the styrene delightening rectification column 1; the outlet of the styrene delightening rectification column is connected to the The inlet of the column top condenser 2 is connected;

[0053] The column top...

Embodiment 2

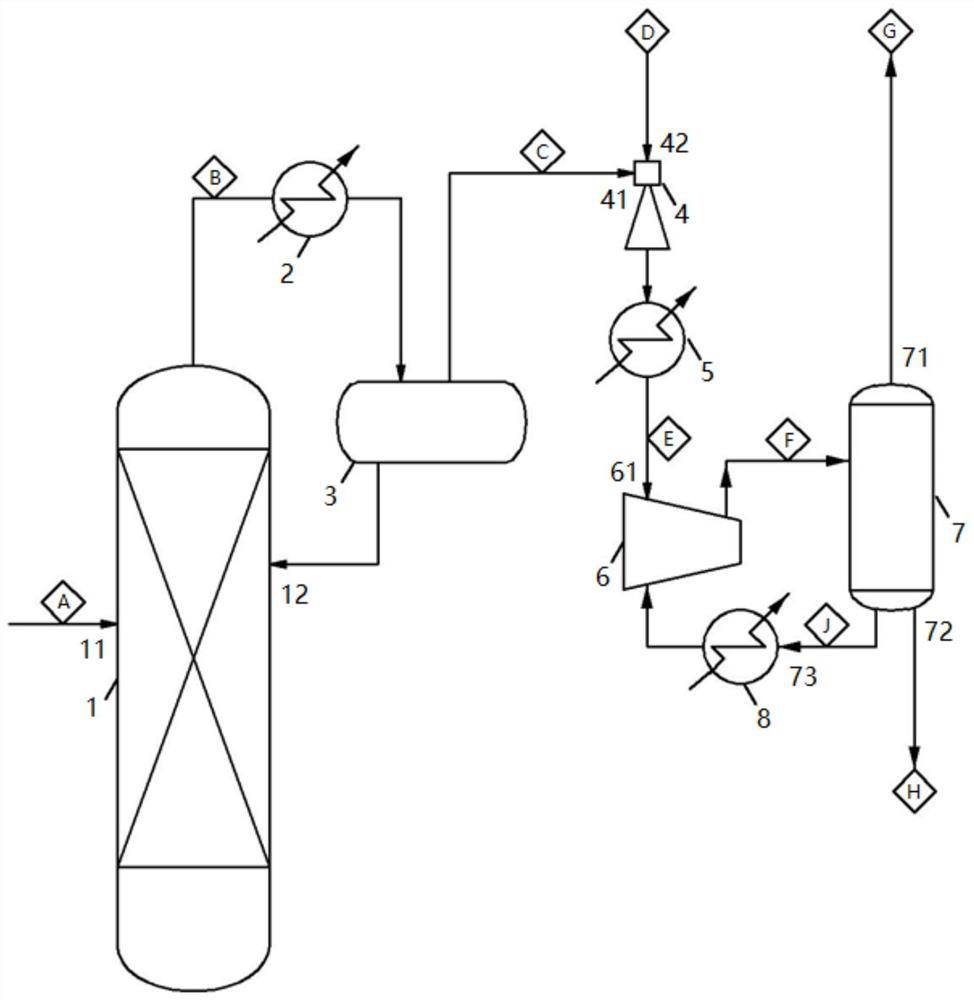

[0064] like figure 2 As shown, the difference from the device in Example 1 is that this example provides a device for removing light components in styrene monomer, a working liquid cooler is provided between the liquid ring vacuum pump 6 and the gas-liquid separation tank 7 8. The inlet of the working fluid cooler 8 is connected to the third outlet 73 of the gas-liquid separation tank, and the outlet of the working fluid cooler 8 is connected to the second inlet 62 of the liquid ring vacuum pump.

[0065] Different from the method in Example 2, a method for removing light components in styrene monomer provided in this example also includes the following steps: in the gas-liquid separation tank 7, the exhaust gas G is discharged from the gas-liquid separation tank 7. The first outlet 71 of the separation tank is discharged, part of the discharged working fluid H is discharged from the second outlet 72 of the gas-liquid separation tank, and the other part of the discharged work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com