Vacuum water injection method for radiator

A radiator and vacuum technology, applied in the direction of machine/engine, negative pressure pump, pump components, etc., can solve the problems of poor heat dissipation performance, difficult to fill the capillary tube of the radiator cavity with water, etc., and achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

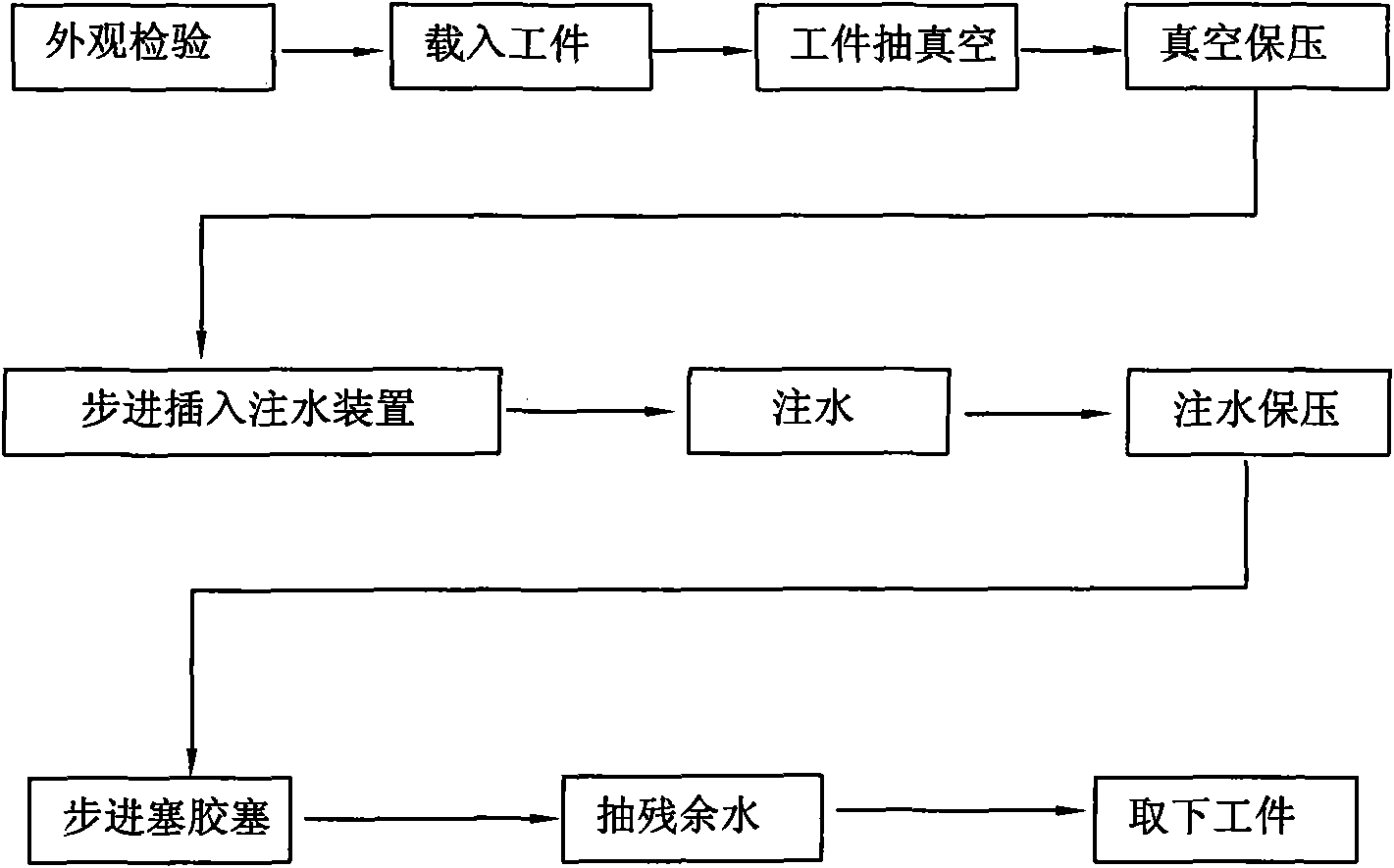

[0026] refer to figure 1 , the present invention is implemented like this:

[0027] The invention discloses a vacuum water injection method for a radiator, which comprises two processes of vacuumizing the capillary of the radiator and injecting water into the capillary. Specific methods include:

[0028] 1) Appearance inspection, conduct appearance inspection on the capillary tube of the radiator, and select the radiator with damaged appearance;

[0029] 2) Load the workpiece, and load the radiator with qualified appearance to the working position;

[0030] 3) The workpiece is vacuumed, and the capillary tube of the radiator is vacuumed by a vacuum device, so that the vacuum degree of the inner cavity reaches below 3000Pa, and the imported vacuum pump is used to vacuum the radiator, the highest vacuum degree: 1000~3600Pa. The sealing of its water injection port is especially important;

[0031] 4) Vacuum pressure maintenance. After vacuuming, carry out pressure maintenance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com