Air extraction mechanism and air extraction device with the air extraction mechanism

A technology of air extraction mechanism and air extraction device, which is applied in the direction of electrical components, structural parts, climate sustainability, etc., and can solve the problems of electrolyte and exhaust gas being easily out of control, electrolyte and exhaust gas being difficult to extract, and insufficient internal vacuum and other problems, to achieve the effect of simple structure, sufficient vacuum degree and high pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

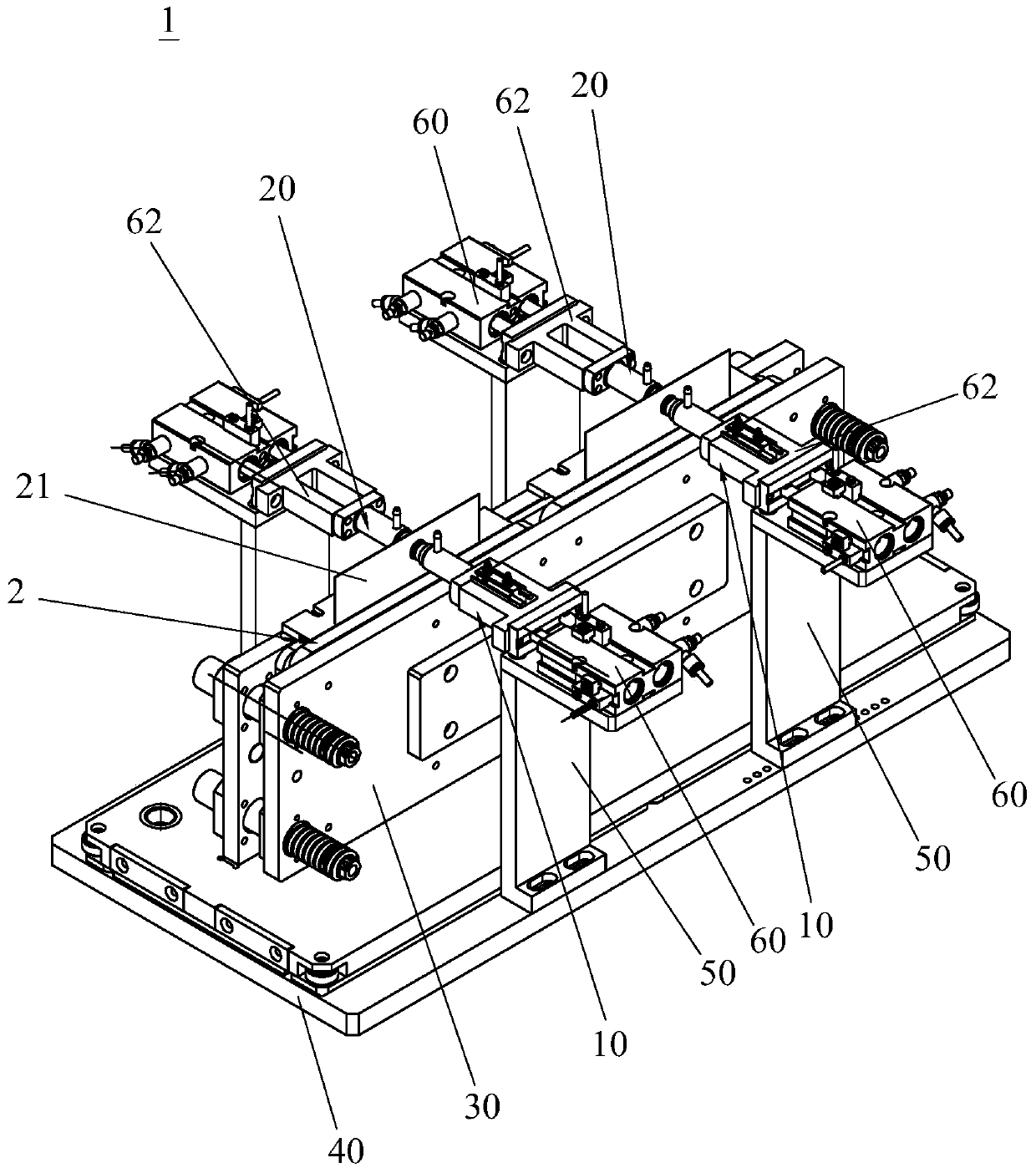

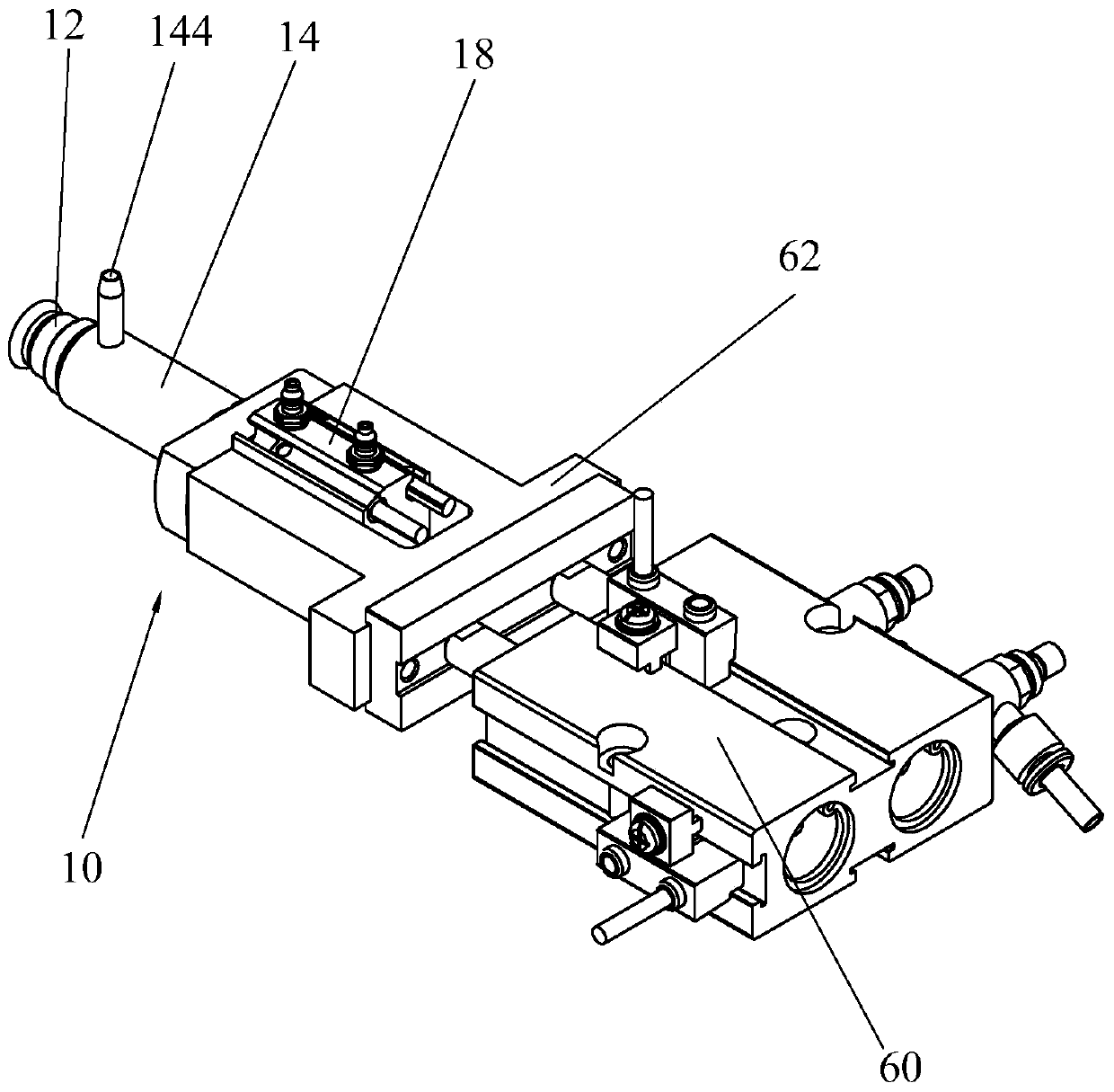

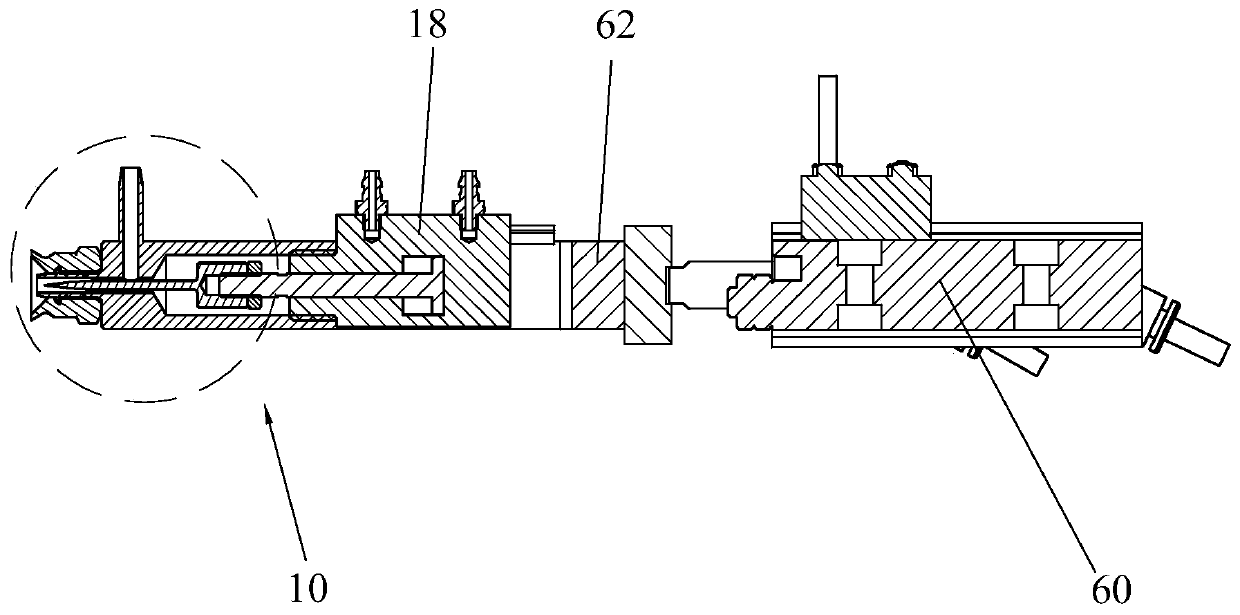

[0024] like figure 1 As shown, the soft-pack lithium battery 2 includes an air bag 21 and a battery cell (not shown) located in the air bag 21. After liquid injection, the upper opening of the soft-pack lithium battery 2 is packaged for the first time, and then packaged. The soft-pack lithium battery 2 is formed, and the waste gas and excess electrolyte produced by the formation are extracted using the air extraction device 1 provided by the present invention, and the second packaging is carried out after the extraction is completed. Specifically, the air pumping device 1 vacuumizes the inside of the airbag bag 21 after piercing the airbag bag 21 through a suction port, and the suction port is located between the first packaging line and the second packaging line.

[0025] continue to refer figure 1 The air extraction device 1 provided by the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com