Sweeping robots and floor handling units

A technology for cleaning robots and robots, applied in cleaning devices, robot cleaning machines, vacuum cleaners, etc., can solve the problems of affecting cleaning, unsealed dust suction ports, poor dust suction effect, etc., and achieve the effect of simple structure and improved cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

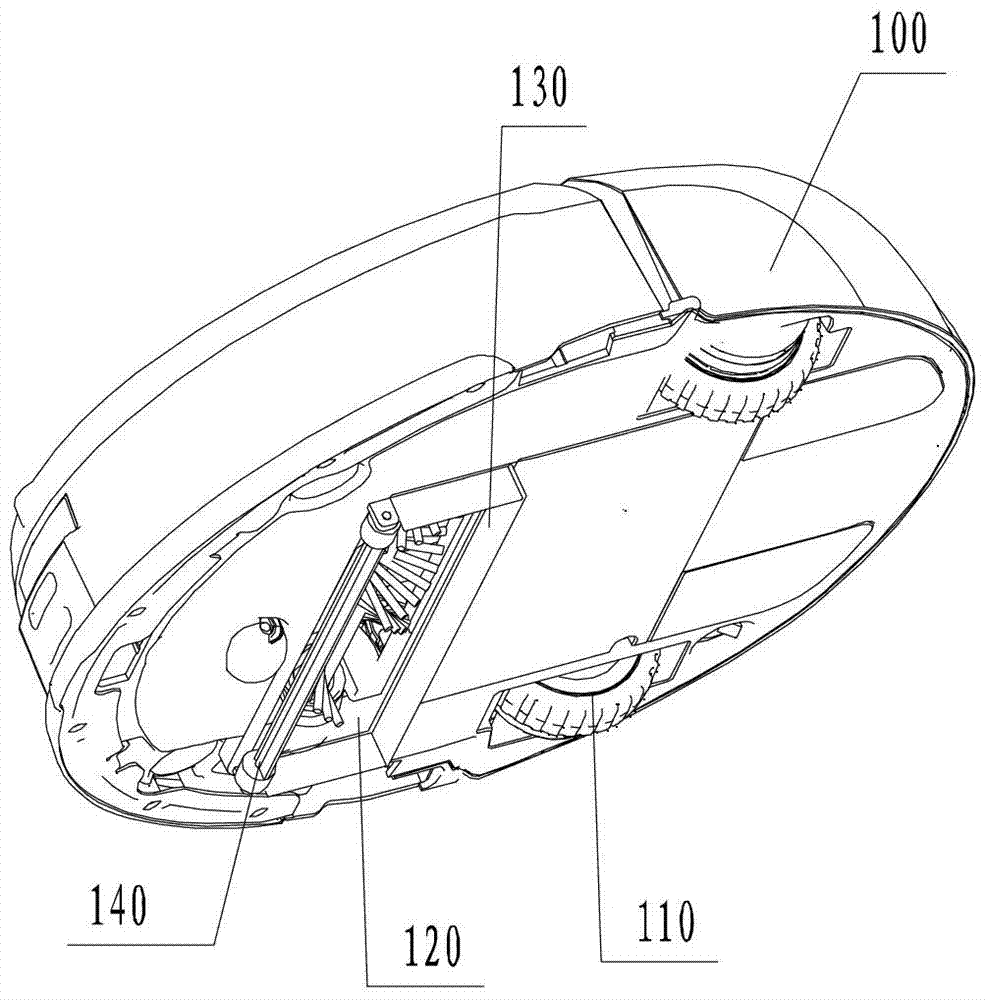

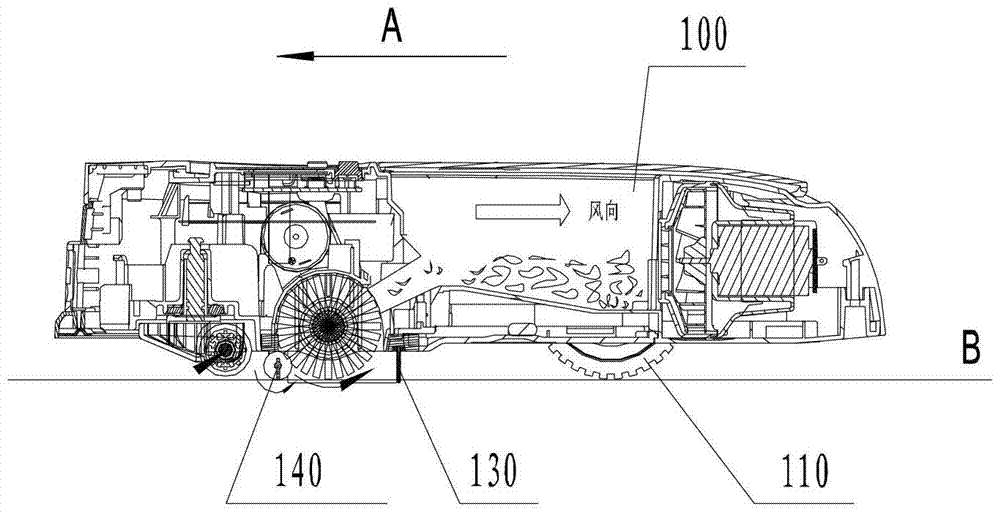

[0025] figure 1 It is a schematic structural diagram of a cleaning robot according to an embodiment of the present invention; figure 2 It is a schematic side view of a cleaning robot according to an embodiment of the present invention. Such as figure 1 and combine figure 2 As shown, the present invention provides a cleaning robot, which includes a robot body 100 with a driving wheel 110 on the body 100 and a dust suction port 120 at the bottom of the body 100 . If the walking direction A of the cleaning robot is set as the front, the rear and both sides of the dust suction port 120 are provided with a static sealing strip 130, and the lower edge of the static sealing strip 130 extends to the working surface to be cleaned; A dynamic seal 140 is also provided in front of 120 .

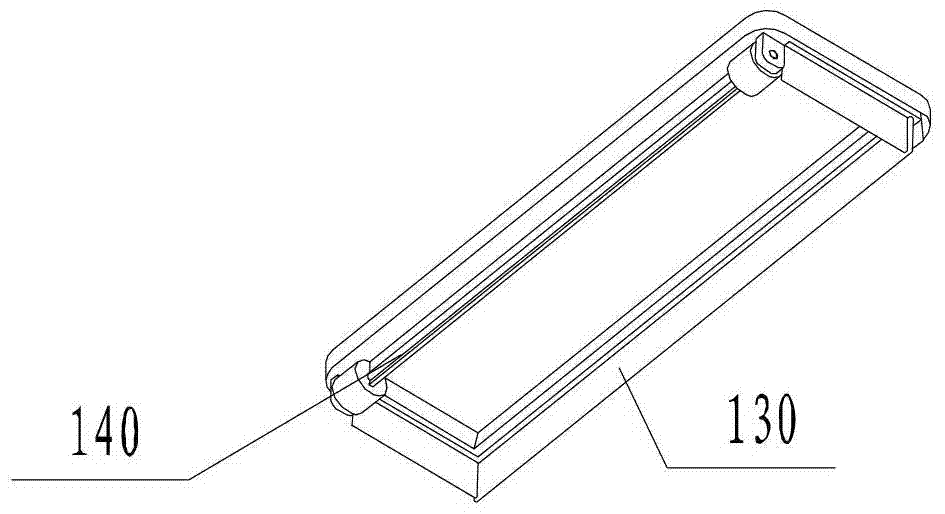

[0026] image 3 It is a schematic diagram of a local structure of the dust suction port according to the embodiment of the present invention, Figure 4 It is a schematic structural diagram of a d...

Embodiment 2

[0028] Figure 5 It is a schematic diagram of the swing angle position of the dynamic seal in Embodiment 2 of the present invention. control image 3 and combine Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that in this implementation, the dynamic sealing strip 142 is a sealing sheet, and the sealing sheet is arranged at the front of the dust suction port 120, and its top and the bottom of the body 100 can be connected to each other. Rotationally connected, the sealing sheet is driven to swing by a driving motor. Specifically, the dynamic sealing strip 142 in the dynamic sealing member 140 can also be rotatably connected to the bottom of the body 100 through a pivot 143 . The actuator includes a pivot 143 and a driving motor (not shown in the figure) connected thereto. Driven by the driving motor, the dynamic sealing strip 142 rotates or swings around the pivot 143 . When the dynamic sealing strip 142 rotates around the pivot 143 , the rot...

Embodiment 3

[0030] Figure 6 It is a structural schematic diagram of the actuator of the third embodiment of the present invention. Such as Figure 6 As shown, the actuator can also be a lifting mechanism 200, the lifting mechanism 200 includes a sprocket 201 and a chain 202, the chain 202 is connected with the sprocket 201 and the dynamic sealing strip 142 respectively, and the sprocket 201 is also connected with the dynamic sealing strip 142 A driving motor (not shown in the figure) is connected, and driven by the driving motor, the lifting mechanism 200 drives the dynamic sealing strip 142 to translate up and down. The height of the dynamic sealing strip 142 moving up and down is less than or equal to the distance from the edge of the suction port to the working surface to be cleaned.

[0031] The dynamic sealing strip 142 in this embodiment can also be the sealing sheet in the second embodiment, but the difference from the second embodiment is that the sealing sheet can be arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com