High-yield capsule filling machine

A filling machine and capsule technology, applied in the directions of capsule delivery, drug delivery, pharmaceutical formulation, etc., can solve the problems of uneven strength, collision of upper modules, affecting the quality of capsule locking, etc., so as to improve the quality of locking and increase the output. , The effect of improving the quality of drug filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

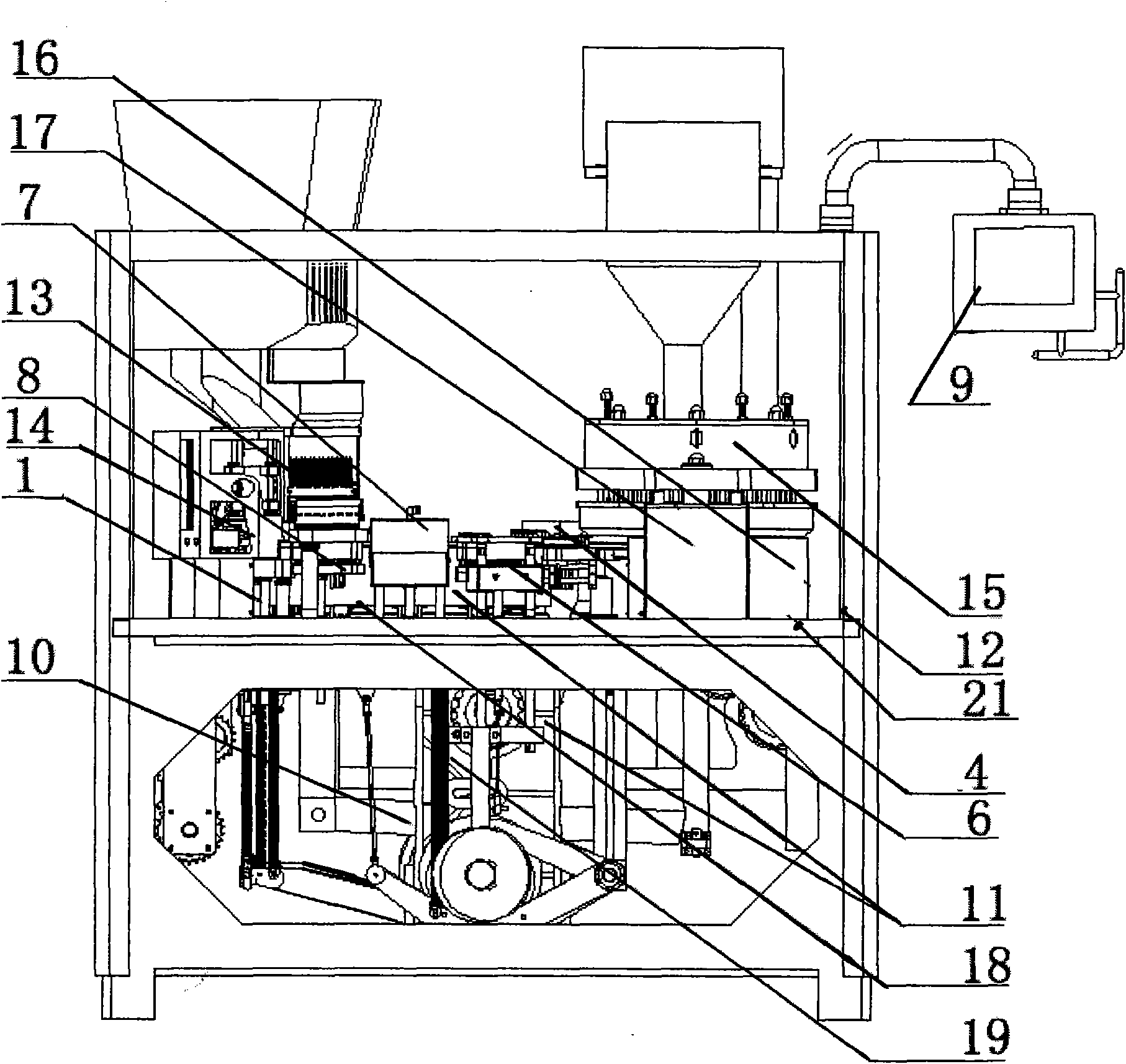

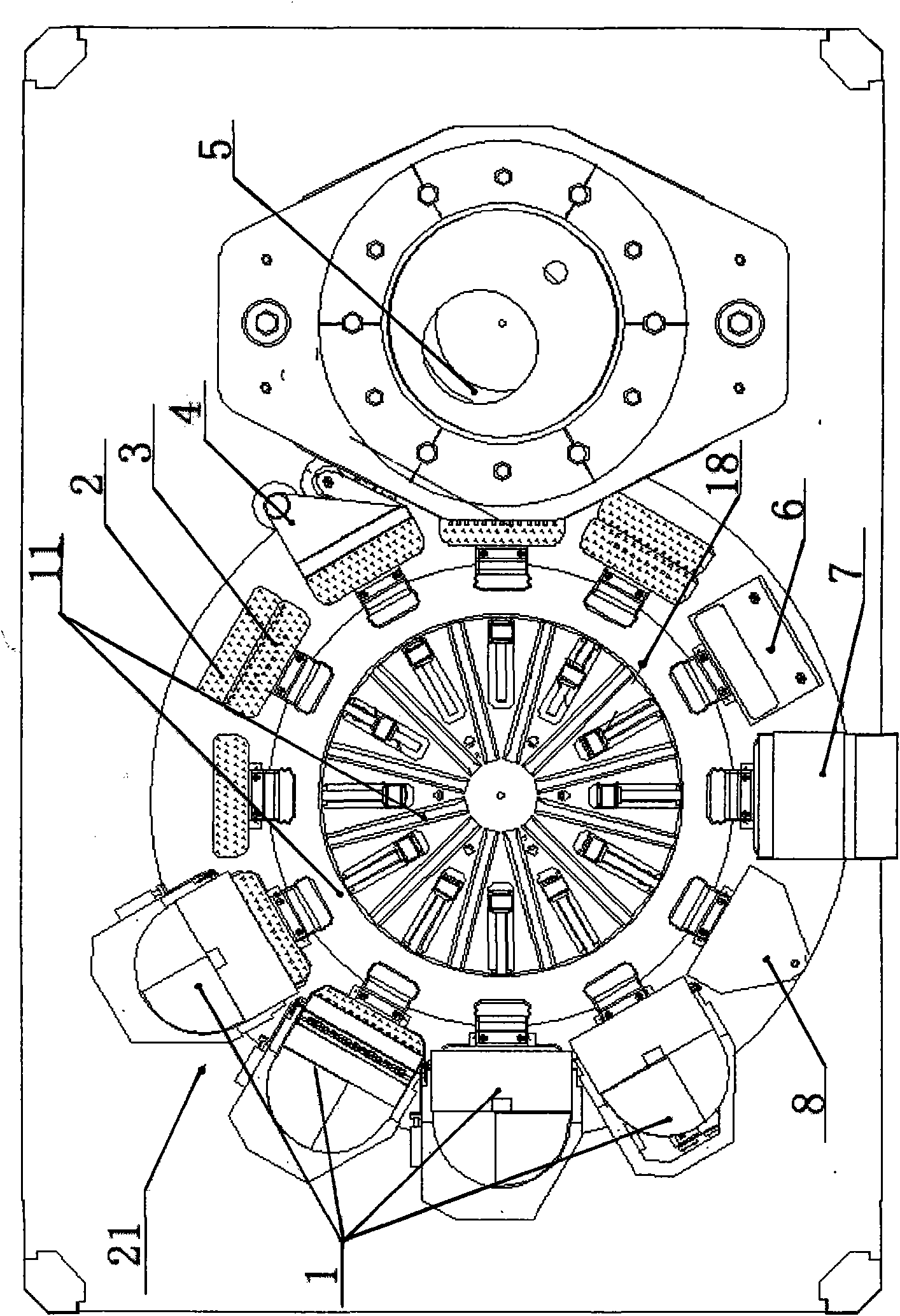

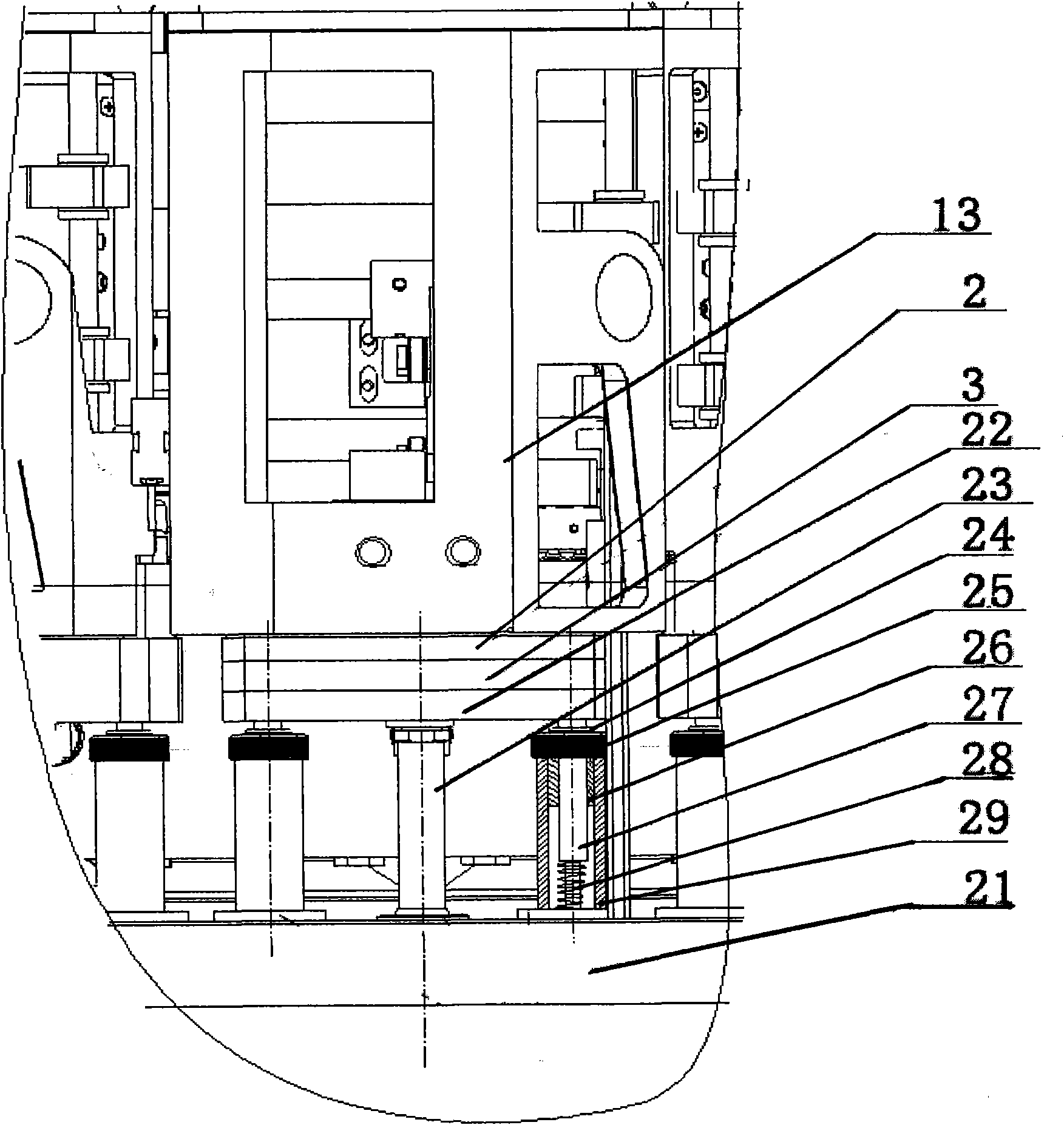

[0016] refer to Figure 1 to Figure 3 It can be seen that the high-yield capsule filling machine of the present invention includes a capsule sorting and separating mechanism 1, a waste rejecting mechanism 4, a material filling mechanism 5, a capsule locking mechanism 6, a finished product discharging mechanism 7, a mold cleaning mechanism 8, and a man-machine interface control mechanism 9. Mechanical transmission mechanism 10, indexing turntable mechanism 11, frame 12, and workbench 21, wherein capsule sorting and separation mechanism 1 (see image 3 ) includes a capsule U-turn sorting device 13 (for the prior art) and a capsule vacuum separation balance device 14, the material filling mechanism 5 includes a material chamber 15, a filling dust isolation device 16 and a filling bracket support balance device 17, and the indexing turntable mechanism 11 includes intermittent Type packing turntable 18, indexing box 19, upper module 2 (for installing capsule cap) and lower module 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com