Antibacterial bamboo charcoal fiber pillow production line

A technology of bamboo charcoal fiber and production line, applied in the field of bamboo charcoal fiber, can solve the problems of long operation time of filling machine, small total amount of bamboo charcoal fiber, small volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

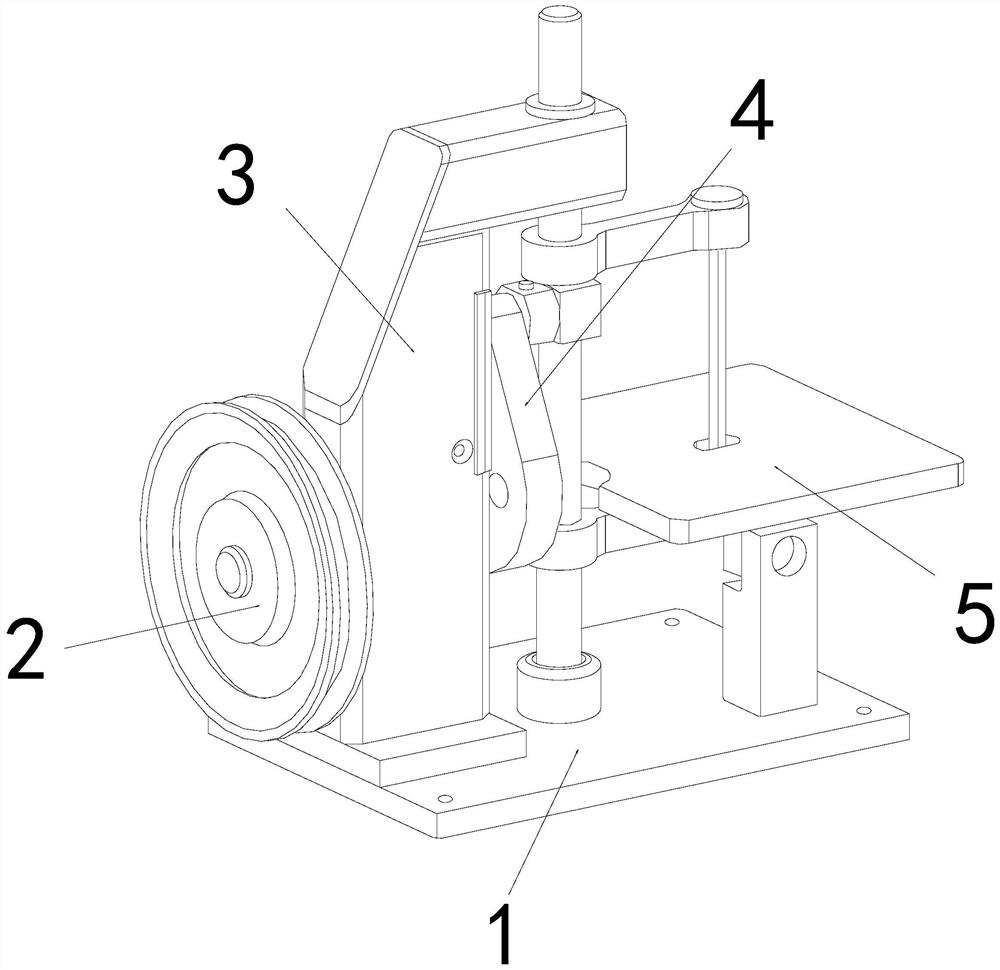

[0025] as attached figure 1 to attach Figure 4 As shown, the present invention provides a kind of antibacterial bamboo charcoal fiber pillow production line, and its structure comprises base plate 1, pulley 2, assembly platform 3, follower 4, filling structure 5, and described base plate 1 upper end is fixed on assembly platform 3 lower ends by screw , the inner wall of the pulley 2 is nested and fixed on the left outer wall of the assembly table 3, the inner wall of the follower 4 is interference fit on the right outer wall of the assembly table 3, and the left side of the upper end of the filling structure 5 is movably engaged with the assembly table 3 lower right side;

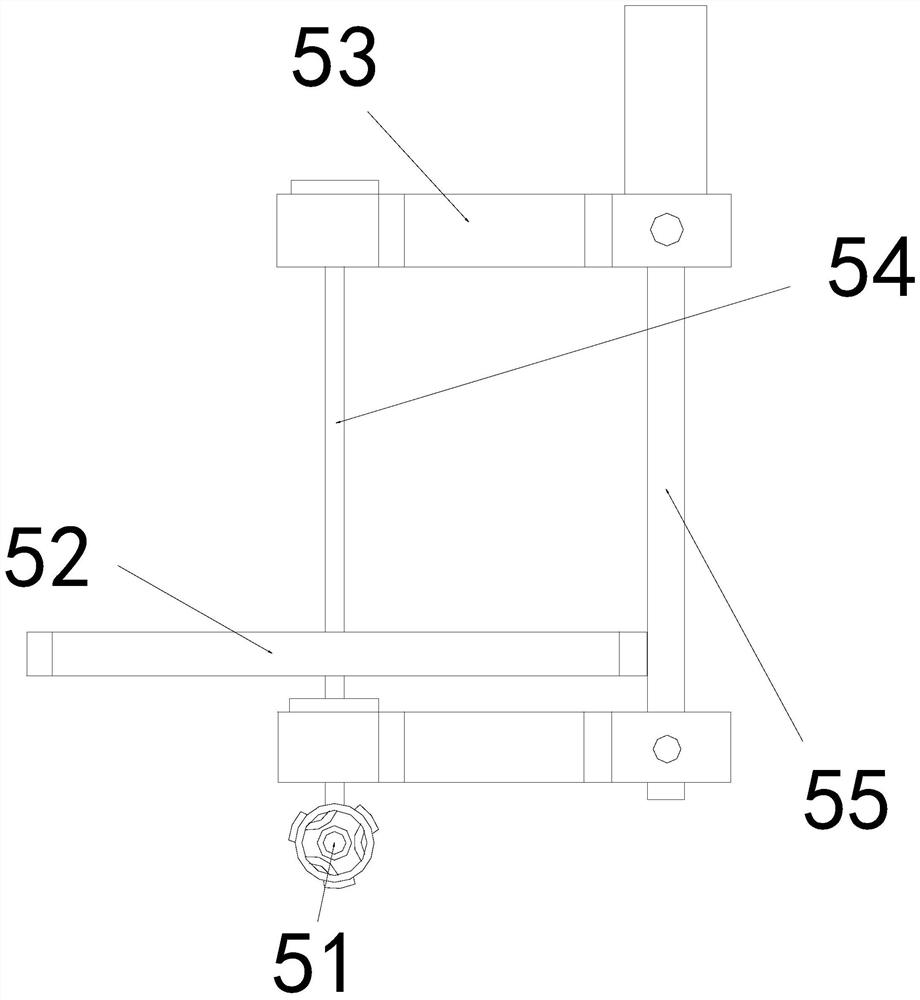

[0026] The filling structure 5 is composed of a clamper 51, a positioning plate 52, a alignment rod 53, a lifting rod 54, and a connecting shaft 55. The inner wall of the clamping device 51 is nested and fitted on the outer wall of the lower end of the lifting rod 54. The inner wall of 52 is movably matc...

Embodiment 2

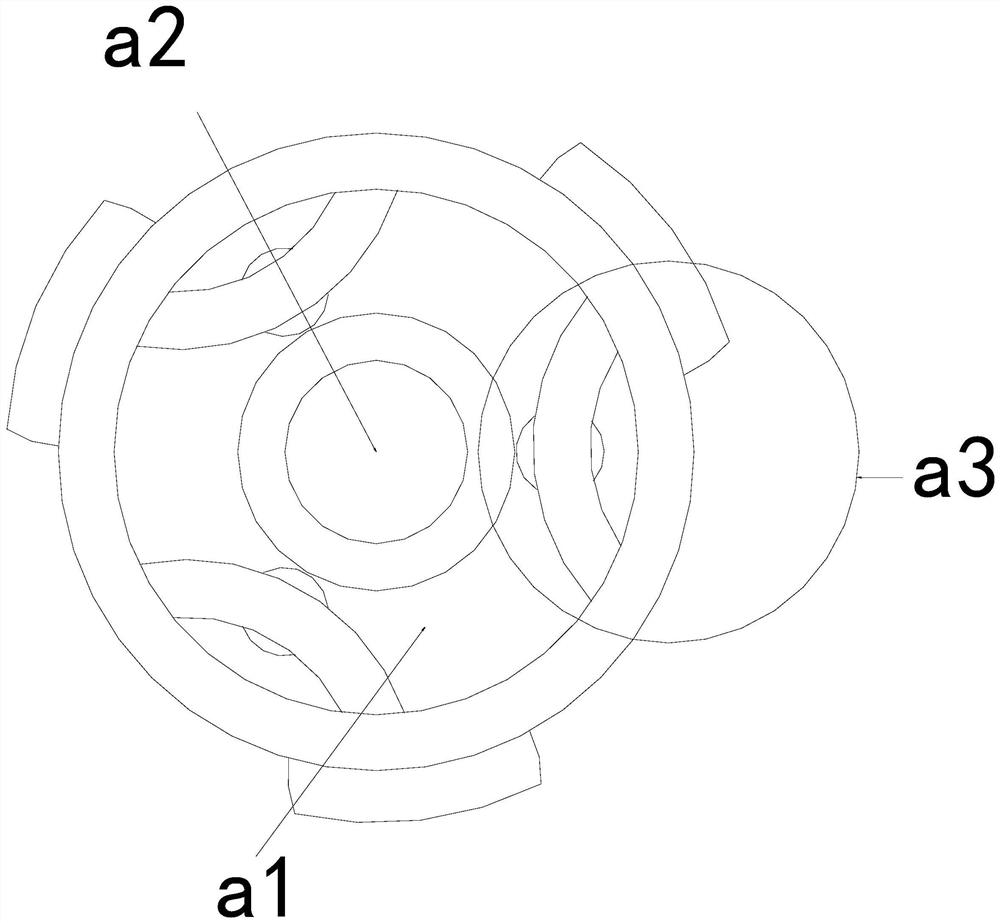

[0031] as attached Figure 5 to attach Figure 7As shown: the clamping ring a1 is composed of an expansion plate c1, a position guide plate c2, a main board c3, a connecting rod c4, and a movable seat c5. The inner wall of the expansion plate c1 is welded and fixed to the upper end of the connecting rod c4, and the position guide plate The lower end of c2 is embedded and fixed on the upper end of the main board c3. The outer edge of the upper end of the main board c3 is movably matched with the lower end of the expansion plate c1. The sleeve is engaged with the outer wall of the position guide plate c2, the structure of the position guide plate c2 is a triangle structure, the plane has an arc shape, and the height of the movable seat c5 is adjusted through the guidance of the arc surface to the movable seat c5.

[0032] Wherein, the position guide plate c2 is composed of a plate body d1, a hollow shaft d2, and a driving mechanism d3, the outer wall of the plate body d1 is emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com