Vacuum pump control system and method for double pressure sensors

A control system and differential pressure sensor technology, applied in the direction of brake safety system, brake, brake transmission, etc., can solve the problems of system paralysis, the driver can't detect, can't judge the atmospheric pressure, etc., to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

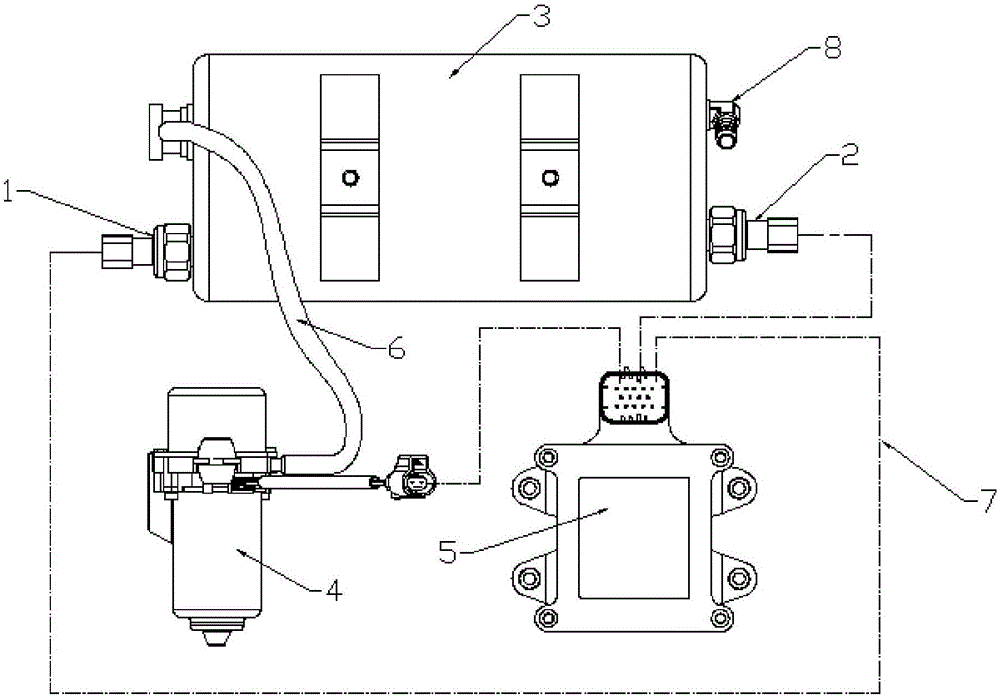

[0015] Example 1, such as figure 1 A vacuum pump control system with dual pressure sensors is shown, including a vacuum tank 3, a vacuum pump controller 5, and a vacuum pump 4 connected to the hose 6 of the vacuum tank 3. The signals of the vacuum pump 4 and the vacuum pump controller 5 are connected. An absolute pressure sensor 1, a differential pressure sensor 2 and a joint 8 for connecting with the vehicle brake booster system are also provided, and the signals of the absolute pressure sensor 1, the differential pressure sensor 2 and the vacuum pump controller 5 are connected; the absolute pressure sensor 1 is used for The absolute pressure value in the vacuum tank 3 is monitored, and the differential pressure sensor 2 is used to monitor the difference between the pressure in the vacuum tank 3 and the atmospheric pressure. The absolute pressure sensor 1 and the differential pressure sensor 2 are installed on both sides of the vacuum tank 3 respectively. The absolute pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com