Sun-screening agent spray

A technology for sunscreen agents and sunscreen ingredients, applied in skin care preparations, cosmetics, medical preparations containing active ingredients, etc., can solve the problems of sunscreen product safety, convenience and effectiveness, etc. The effect of smooth change and safe operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

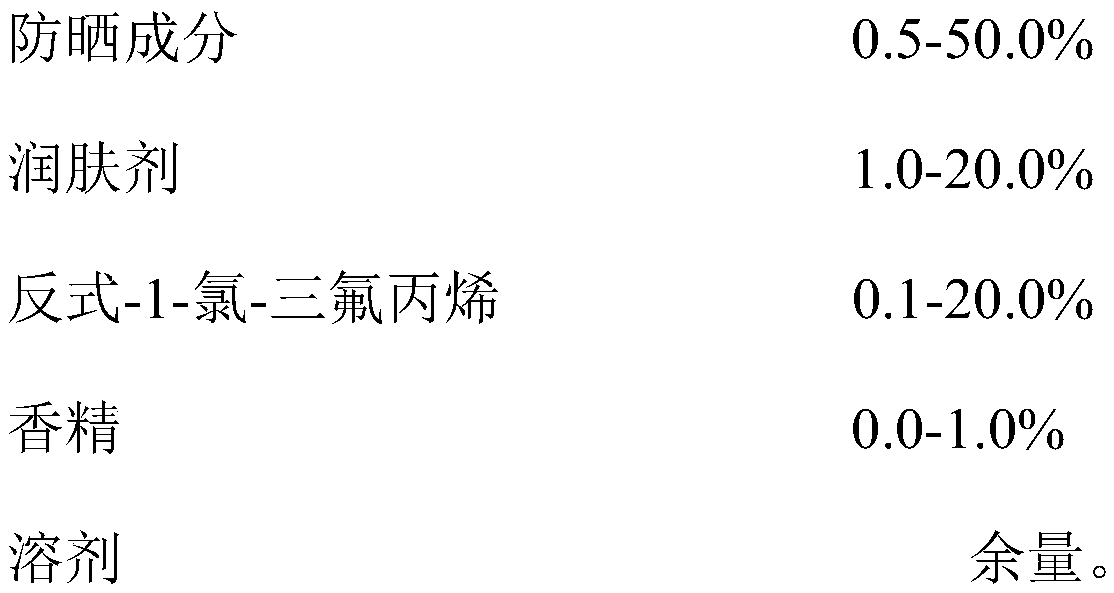

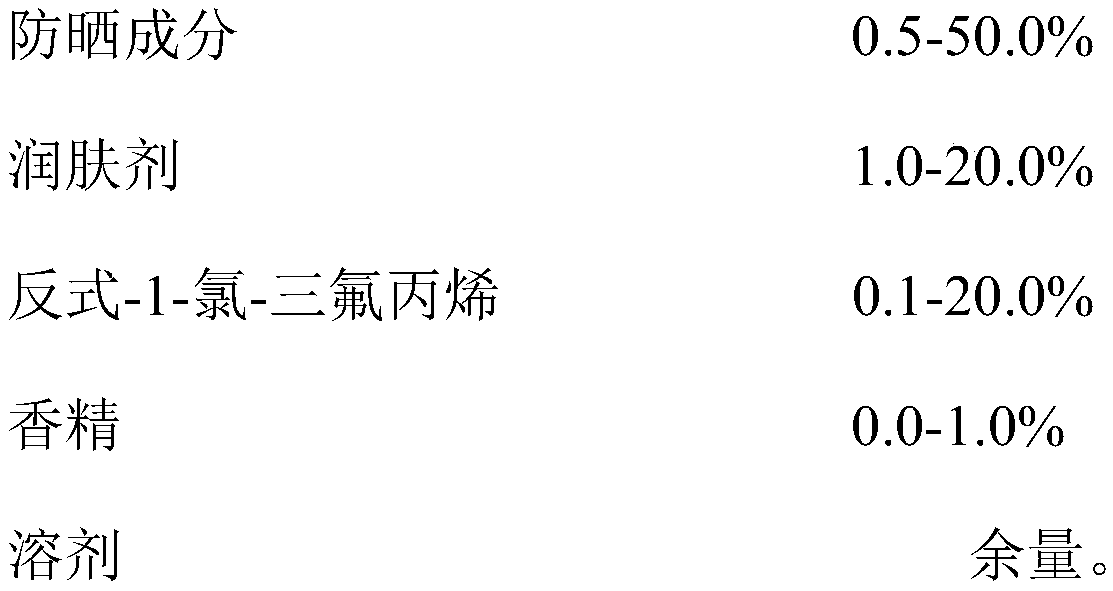

[0027] Stir and mix 10.0% sunscreen ingredients, 20.0% emollients and some solvents, heat to 80°C to dissolve evenly, cool down to 45°C or below, add 0.5% essence and the remaining solvent, stir and mix evenly, continue to cool down, add trans-1 -Chloro-trifluoropropene 0.5%, stir and mix evenly, pass the inspection and filter and let stand; put the pouch in the aerosol can, use the filling and sealing equipment to fill the propellant nitrogen into the aerosol can, seal it, and prepare the finished product The sunscreen material liquid is quantitatively filled into the pouch, and the product pressure is only 0.60MPa.

[0028] Implementation column 2:

[0029] Stir and mix 15.0% sunscreen ingredients, 30.0% emollients and some solvents, heat to 80°C to dissolve evenly, warm to 45°C or below, add the rest of the solvent, stir and mix evenly, continue to cool down, add trans-1-chloro-tri Fluoropropene 1.0%, stir and mix evenly, pass the inspection and filter and let stand; put t...

Embodiment 3

[0031] Stir and mix 50.0% of sunscreen ingredients, 15.0% of emollient and part of the solvent, heat to 80°C to dissolve evenly, warm to 45°C or below, add 0.2% of essence and the rest of the solvent, stir and mix evenly, continue to cool down, and then add trans- 1-Chloro-trifluoropropene 2.0%, stir and mix evenly, pass the inspection and filter and let stand; put the pouch in the aerosol can, fill the propellant nitrogen into the aerosol can with filling and sealing equipment, seal, and the preparation will be completed The sunscreen agent material liquid is quantitatively filled into the pouch, and the product pressure is only 0.75MPa.

Embodiment 4

[0033] Stir and mix 15.0% of sunscreen ingredients, 20.0% of emollients and some solvents evenly, add 0.5% of essence and the remaining solvent, stir and mix evenly, then add 5.0% of trans-1-chloro-trifluoropropene, stir and mix evenly, test Qualified filter and stand still; put the pouch in the aerosol can, use the filling and sealing equipment to fill the propellant nitrogen into the aerosol can, seal it, and quantitatively fill the prepared sunscreen material liquid into the pouch, the product The pressure is 0.85MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com