Doping type spinel lithium manganate electrode material and preparation method thereof

A spinel lithium manganate, electrode material technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problem of low capacity retention rate and low capacity retention rate of lithium ion batteries, and it is difficult to meet the needs of high-power lithium ion batteries. requirements and other issues, to achieve the effect of suppressing the Jahn-Teller effect, low specific surface area, and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

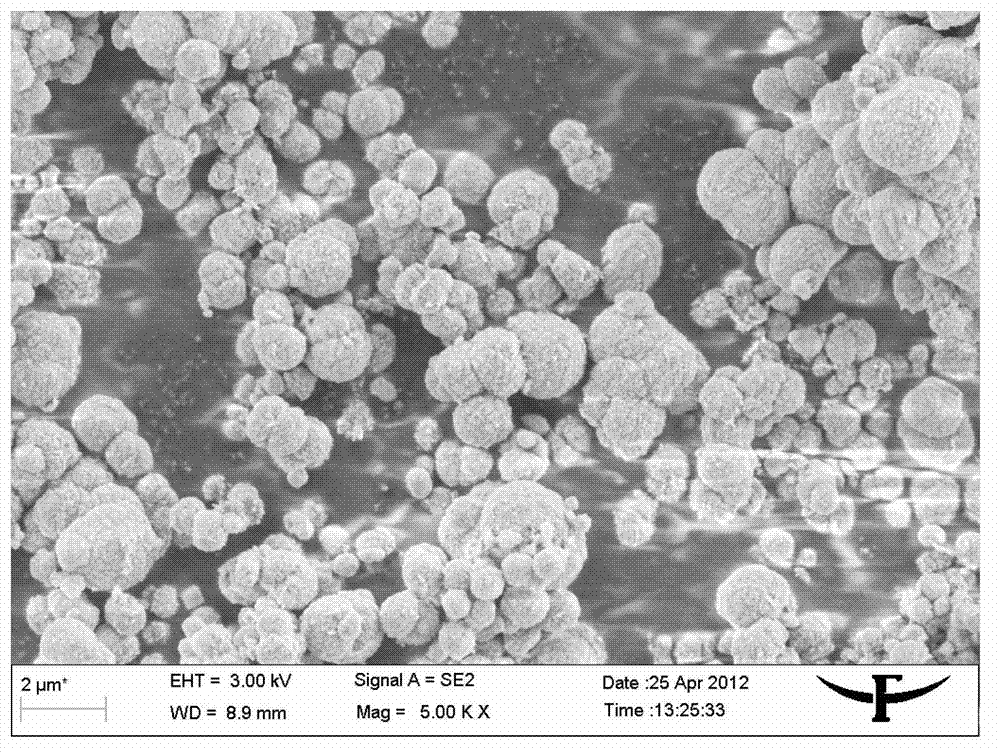

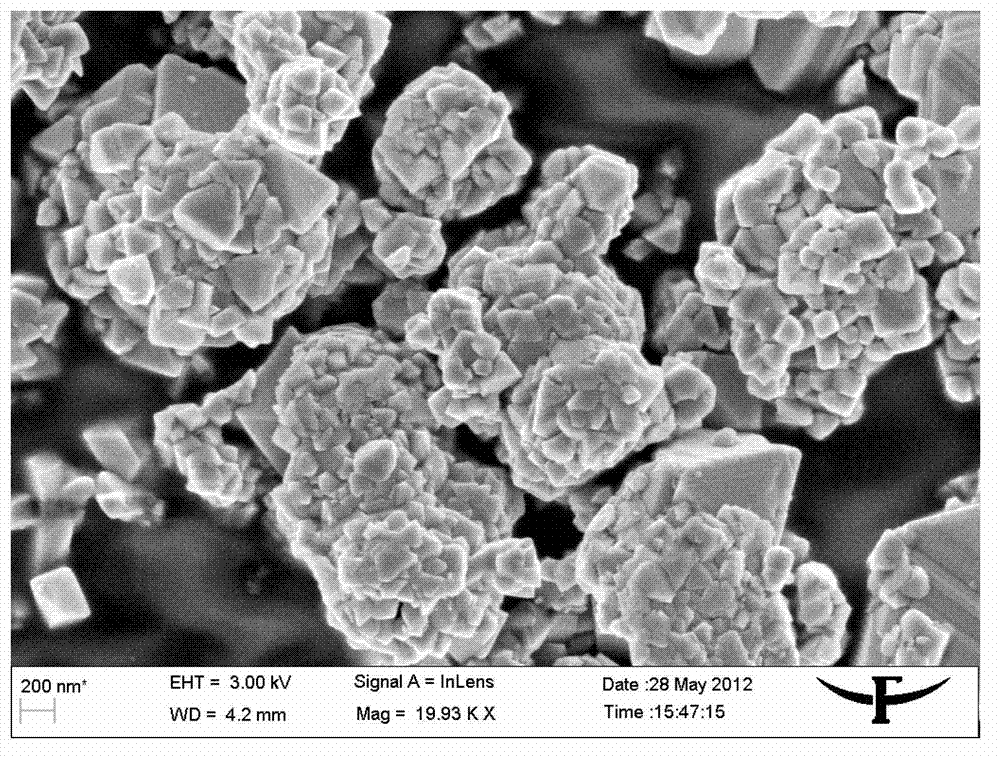

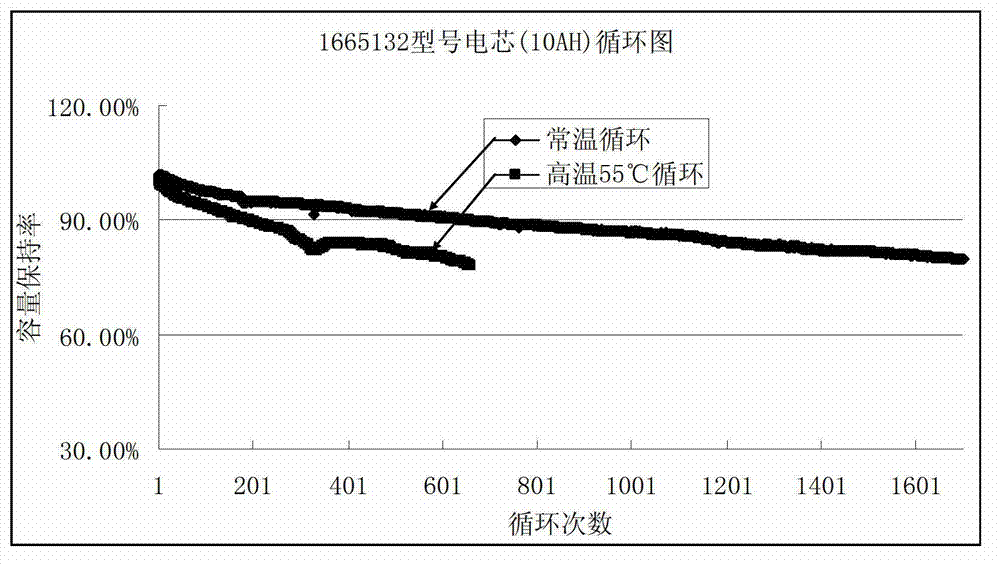

[0036] The molecular formula of the doped spinel lithium manganate electrode material of the present embodiment is LiMn 1.7 Cr 0.2 co 0.1 o 4 .

[0037] The doped spinel lithium manganese oxide electrode material of this embodiment is prepared by the following method:

[0038] 1) Solution configuration:

[0039] Solution A: Prepare manganese sulfate into a 1.0mol / L manganese sulfate aqueous solution, take chromium nitrate according to the ratio Mn:Cr=1.7:0.2 in the molecular formula and dissolve it in the manganese sulfate aqueous solution to obtain solution A;

[0040] Solution B: the buffer ammonium bicarbonate was prepared into a 1.5mol / L ammonium bicarbonate aqueous solution to obtain solution B;

[0041] 2) Pre-body preparation:

[0042] Combine solution A and solution B in step 1) into the co-precipitation tank at a flow rate of 2.0L / h, adjust the pH value of the system to 7.0, keep warm at 55°C and keep stirring for 3h, filter and dry to obtain the precursor preci...

Embodiment 2

[0052] The molecular formula of the doped spinel lithium manganate electrode material of the present embodiment is LiMn 1.5 Al 0.3 co 0.2 o 4.

[0053] The doped spinel lithium manganese oxide electrode material of this embodiment is prepared by the following method:

[0054] 1) Solution configuration:

[0055] Solution A: Manganese nitrate was prepared into a 0.6mol / L manganese nitrate aqueous solution, and aluminum sulfate was taken according to the ratio Mn:Al=1.5:0.3 in the molecular formula and dissolved in the manganese nitrate aqueous solution to obtain solution A;

[0056] Solution B: the buffer sodium carbonate was prepared into a 0.8mol / L sodium carbonate aqueous solution to obtain solution B;

[0057] 2) Pre-body preparation:

[0058] Combine solution A and solution B in step 1) into the co-precipitation tank at a flow rate of 2.0L / h, adjust the pH value of the system at 8.5, keep warm at 60°C and continue to stir for 2h, filter and dry to obtain the precursor...

Embodiment 3

[0068] The molecular formula of the doped spinel lithium manganate electrode material of the present embodiment is LiMn 1.45 Mg 0.4 co 0.15 o 4 .

[0069] The doped spinel lithium manganese oxide electrode material of this embodiment is prepared by the following method:

[0070] 1) Solution configuration:

[0071] Solution A: Prepare manganese acetate into a 0.2mol / L manganese acetate aqueous solution, take magnesium acetate according to the ratio Mn:Mg=1.45:0.4 in the molecular formula, and dissolve it in the manganese acetate aqueous solution to obtain solution A;

[0072] Solution B: the buffer potassium carbonate was prepared into a 0.2mol / L potassium carbonate aqueous solution to obtain solution B;

[0073] 2) Pre-body preparation:

[0074] Combine solution A and solution B in step 1) into the co-precipitation tank at a flow rate of 8.0 L / h, adjust the pH value of the system at 9.5, keep warm at 40°C and continue stirring for 6 hours, filter and dry to obtain the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Volumetric energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com