Front silver paste for high sheet resistance silicon-based solar cell and preparing method of front silver paste

A solar cell, high square resistance technology, applied in the field of solar cells, can solve the problems of reducing glass powder and silicon wafer sintering, low paste welding tension, poor silicon wafer corrosion, etc., to improve conversion efficiency, maintain welding tension, expand Effect of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

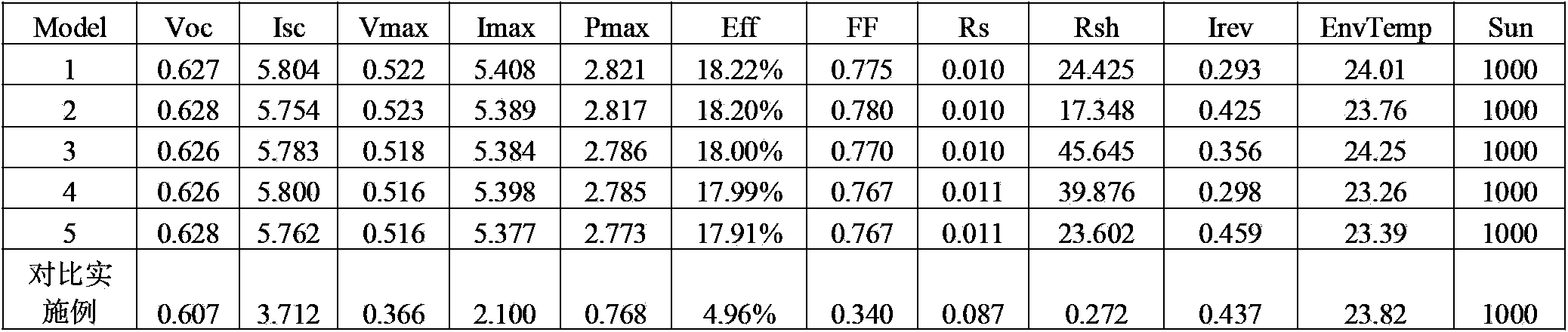

Examples

Embodiment 1

[0034] A solar cell front silver paste, comprising the following components in weight percentage: 88% silver powder, 3% glass powder, 9% organic vehicle, wherein the glass powder contains the following components in glass powder weight percentage: 30% TeO 2 , 30%PbO, 2.5%Na 2 O, 5.0%Bi 2 o 3 , 6.5%B 2 o 3 , 5.0%ZnO, 6.0%Al 2 o 3 , 10%SiO2 2 , 2.0%Sb 2 o 3 , 3.0%Li 2 O, the organic vehicle comprises the following components accounting for the weight percentage of the organic vehicle: 8% ethyl cellulose resin, 5% rosin resin, 5% phenolic resin, 82% organic solvent (50% terpineol, 22% ethylene glycol Alcohol monobutyl ether acetate, 28% propylene glycol methyl ether acetate mixture).

[0035] The preparation method of the battery front silver paste of described embodiment 1 comprises the following steps:

[0036] (1) Preparation of organic vehicle: Add 8g ethyl cellulose resin, 58g rosin resin, and 5g phenolic resin to 82ml organic solvent (50% terpineol, 22% ethylene ...

Embodiment 2

[0041] A solar cell front silver paste, comprising the following components in weight percentage: 83% silver powder, 2% glass powder, 15% organic vehicle, wherein the glass powder contains the following components in glass powder weight percentage: 40% TeO 2 , 20%PbO, 15%Na 2 O, 5.0%Bi 2 o 3 , 3%B 2 o 3 , 7.0%ZnO, 4.0%Al 2 o 3 , 4.5%SiO2 2 , 1.5%Sb 2 o 3 , the organic vehicle comprises the following components occupying the weight percentage of the organic vehicle: 9% ethyl cellulose resin, 2% rosin resin, 6% phenolic resin, 83% organic solvent (50% terpineol, 22% ethylene glycol Monobutyl ether acetate, 28% mixture of propylene glycol methyl ether acetate).

[0042] The preparation method of the battery positive silver paste of described embodiment 2 comprises the following steps:

[0043] (1) Preparation of organic vehicle: Add 9g ethyl cellulose resin, 2g rosin resin, 6g phenolic resin to 83ml organic solvent 45% terpineol, 25% ethylene glycol monobutyl ether acet...

Embodiment 3

[0048] A solar cell front silver paste, comprising the following components in weight percentage: 89% silver powder, 3% glass powder, 8% organic vehicle, wherein the glass powder contains the following components in glass powder weight percentage: 43% TeO 2 , 37%PbO, 10%Na 2 O, 5.0%Bi 2 o 3 , 2.5%ZnO, 2.5%SiO 2 , the organic vehicle comprises the following components occupying the weight percentage of the organic vehicle: 7% ethyl cellulose resin, 2% rosin resin, 6% phenolic resin, 85% organic solvent (50% terpineol, 22% ethylene glycol Monobutyl ether acetate, 28% mixture of propylene glycol methyl ether acetate).

[0049] The preparation method of the battery front silver paste of described embodiment 3 comprises the following steps:

[0050] (1) Preparation of organic vehicle: Add 7g ethyl cellulose resin, 2g rosin resin, 6g phenolic resin to 85ml organic solvent (50% terpineol, 22% ethylene glycol monobutyl ether acetate, 28% propylene glycol Methyl ether acetate mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com