Manufacturing method for diamond honing oilstone

A technology for honing oil stone and diamond, which is applied in the field of preparation of tungsten-coated diamond honing oil stone, which can solve the problems of poor cleanliness of tungsten atoms, graphitization of diamond, weak interface bonding force, etc., achieve excellent self-sharpening, increase matrix hardness, strengthen binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

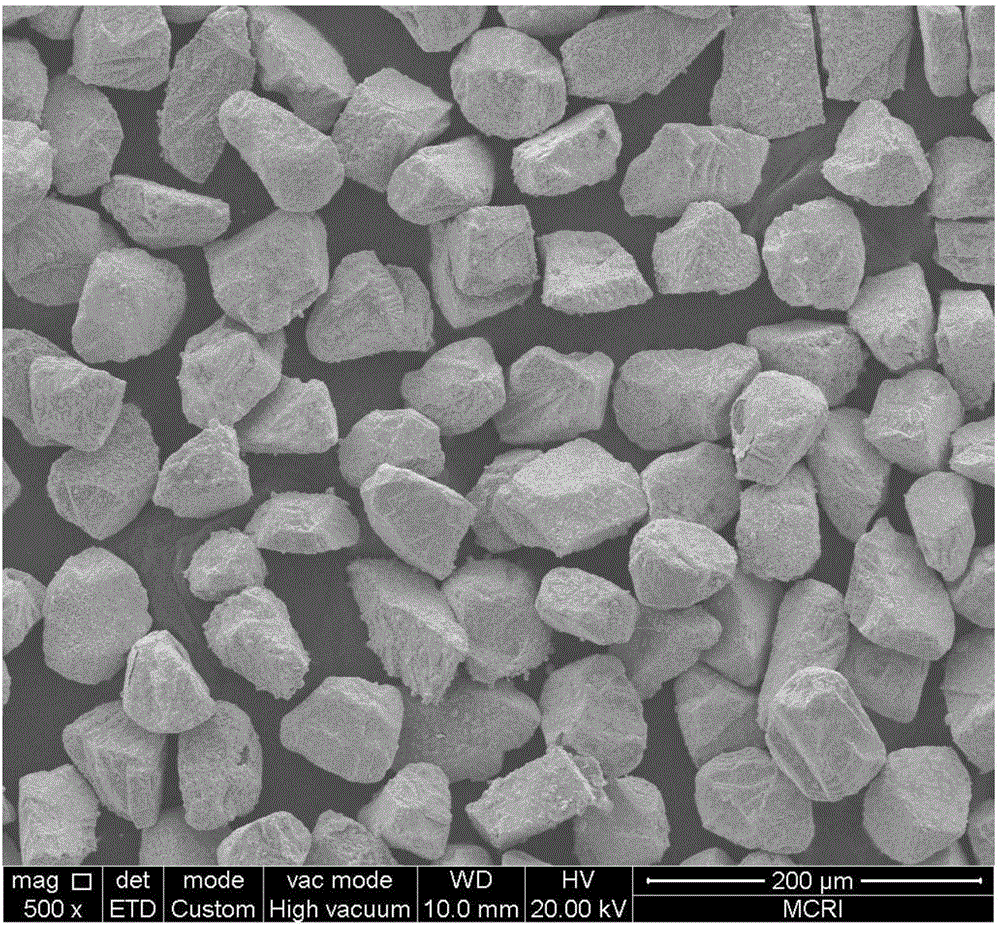

[0031] (1) Combine commercially available diamond with a particle size of about 120 μm, ammonium tungstate (calculated in moles of tungsten atoms), and salt (sodium chloride: potassium chloride = 1:1, molar ratio) at a molar ratio of 20:1:20 Mix and then put it in a ball mill jar for roller milling for 24 hours; take out the ball milled mixed powder, put it in an alumina crucible, heat it to 1000°C under vacuum, keep it warm for 120min, and subject the obtained product to multiple times of ultrasonic vibration and boiling in distilled water To remove the salt, tungsten-coated diamond is obtained.

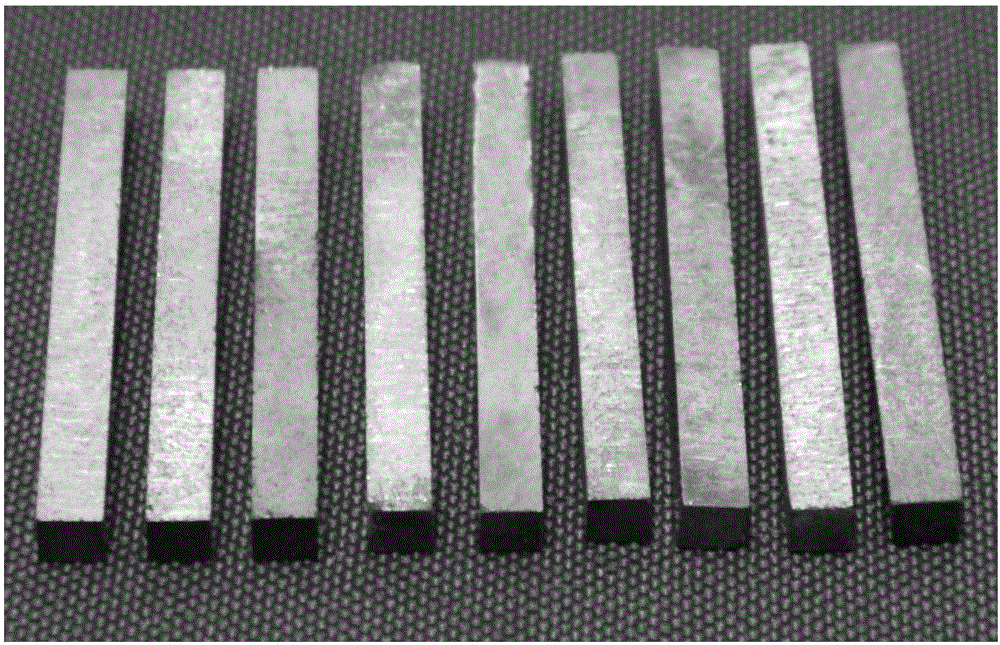

[0032] (2) the volume ratio obtained above is 8% tungsten-coated diamond and metal powder (mass composition is 50% Cu, 25% Sn, 8% Ag, 12% Co, 5% Ti, the particle size is about 40 μm) mixed ball mill, wherein the ball milling balls are agate balls, the ball milling medium is alcohol, the ball-to-material ratio is 1:1, the ball milling speed is 100r / min, the ball milling time is 24h, ...

Embodiment example 2

[0034] (1) The commercially available diamond with a particle size of about 120 μm, ammonium paratungstate (calculated in terms of moles of tungsten atoms), and salt (sodium chloride: sodium carbonate: barium chloride = 1:1:1, molar ratio) at a ratio of 15:1:15 The molar ratio is mixed, and then placed in a ball mill tank for roller milling for 48 hours; the milled mixed powder is taken out, placed in an alumina crucible, heated to 1100°C under vacuum, and kept for 60 minutes, and the obtained product is subjected to multiple ultrasonic vibrations Boil with distilled water to remove the salt, and then get tungsten-coated diamond.

[0035] (2) the volume ratio obtained above is 25% tungsten-coated diamond and metal powder (mass composition is 50% Cu, 25% Sn, 8% Ag, 12% Co, 5% Ni, the particle size is about 40 μm) mixed ball milling, wherein the ball milling balls are agate balls, the ball milling medium is alcohol, the ball-to-material ratio is 1:1, the ball milling speed is 10...

Embodiment example 3

[0037] (1) The commercially available diamond with a particle size of about 120 μm, ammonium metatungstate (calculated in terms of moles of tungsten atoms), and salt (sodium chloride: sodium carbonate: sodium sulfate = 1:1:1, molar ratio) at a ratio of 15:1 : mixed at a molar ratio of 15, and then placed in a ball mill tank for roller milling for 36 hours; the milled mixed powder was taken out, placed in an alumina crucible, heated to 1200 ° C under vacuum, kept for 30 minutes, and the resulting product was subjected to multiple Ultrasonic vibration and distilled water boiling to remove the salt, that is, tungsten-coated diamond.

[0038] (2) the volume ratio obtained above is 15% tungsten-coated diamond and metal powder (mass composition is 50% Cu, 25% Sn, 8% Ag, 12% Co, 2.5% Ti and 2.5% Fe, the particle size is about 40 μm) mixed ball mill, wherein the ball milling ball is agate ball, the ball milling medium is alcohol, the ball material ratio is 1:1, the ball milling speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com