Method for rapidly preparing high heat conduction Si3N4 ceramic with low cost

A high thermal conductivity and low cost technology, applied in the field of low cost and rapid preparation of high thermal conductivity Si3N4 ceramics, can solve the problems of long Si powder nitriding time, long holding time, high nitrogen pressure, and achieve rapid preparation, improved densification, low The effect of cost preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

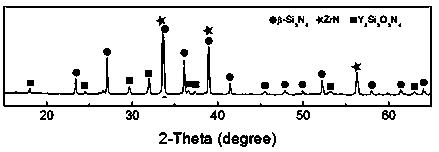

[0030] Rapid and low-cost preparation of high thermal conductivity Si 3 N 4 Ceramics, the specific method is as follows:

[0031] (1) Si powder (particle size 2 powder (particle size 2 o 3 Powder (99.9% purity) is an additive, according to Si powder mass fraction of 80%, ZrO 2 The mass fraction is 10%, MgO-Y 2 o 3 The mass fraction of powder is 10% for batching, where MgO: Y 2 o 3 The mass fraction ratio is 55%: 45%, with ethanol as solvent and Si 3 N 4 The ball is the ball milling medium, mixed on a roller ball mill for 24 hours, after mixing and drying, a uniformly mixed Si-ZrO 2 -MgO-Y 2 o 3 Mix powder.

[0032] (2) Si-ZrO 2 -MgO-Y 2 o 3 The mixed powder is put into a mold for cold isostatic pressing molding, the cold isostatic pressing molding pressure is 200MPa, and the holding time is 5min.

[0033] (3) Si-ZrO 2 -MgO-Y 2 o 3 The green body is put into a boron nitride crucible, and the temperature is raised to 1400°C at a heating rate of 20°C / min for 2 h...

Embodiment 2

[0036] According to Si powder mass fraction is 60%, ZrO 2 Powder mass fraction is 20%, MgO-Yb 2 o 3 Powder mass fraction is 20% for batching, where MgO: Yb 2 o 3 The mass fraction ratio is 60%: 40%, and Si is prepared according to the method of Example 1 3 N 4 Ceramics, wherein the temperature is first raised to 1375°C for 4 hours, and then heated to 1700°C for 2 hours. The relative density of the prepared ceramic material is 99%, the hardness of the material is 16GPa, and the fracture toughness is 6.5MPa·m 1 / 2 , the bending strength is 750Mpa, and the thermal conductivity is 50W·m -1 ·K -1 .

Embodiment 3

[0038] According to Si powder mass fraction of 70%, ZrO 2 Powder mass fraction is 20%, MgO-La 2 o 3 The powder mass fraction is 10% for batching, wherein MgO: La 2 o 3 The mass fraction ratio is 75%: 25%, and Si is prepared according to the method in Example 1 3 N 4 Ceramics, wherein the temperature is first raised to 1375°C for 4 hours, and then heated to 1800°C for 2 hours. The relative density of the prepared ceramic material is 98%, the hardness of the material is 16GPa, and the fracture toughness is 7MPa·m 1 / 2 , the bending strength is 600Mpa, and the thermal conductivity is 60W·m -1 ·K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com