High-voltage high-capacity anode material for lithium ion battery and preparation method of anode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as coating uniformity, inconsistency in roasting temperature, and product consistency, and achieve good thermal cycle performance, Solve the effect that the roasting temperature cannot be unified and has good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

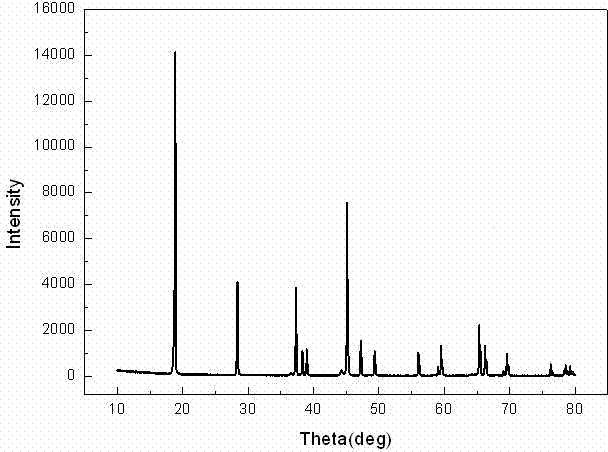

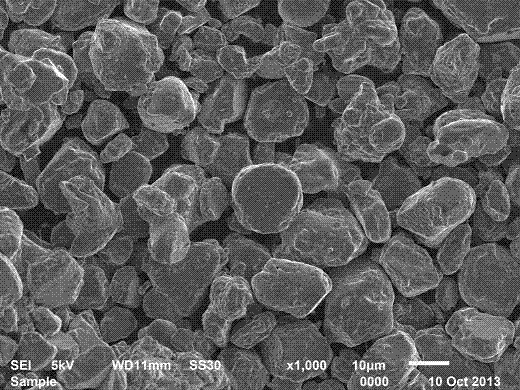

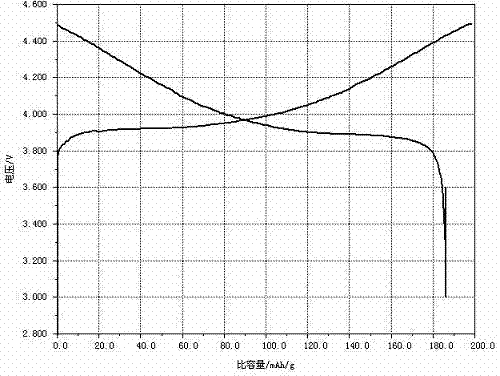

[0031] Such as figure 1 , 2 , 3 and 4.

[0032] (1) Using battery-grade cobalt oxyhydroxide (D50 of 8 μm), battery-grade lithium hydroxide, magnesium oxide, and aluminum oxide as raw materials, the molar ratio of Li:Co is 1.06, the addition of aluminum is 0.1 wt%, and the addition of magnesium The amount is 1 wt%, placed in a dry mixer and mixed evenly.

[0033] (2) Sinter the materials in step (1). The temperature in the main temperature zone of sintering is 900°C, and the sintering time is 15.5h. 3 / h, the sintered lithium cobalt oxide is processed by crushing, crushing, grading, sieving and other processes.

[0034] (3) In a wet environment, combine a mixed solution of Ni, Co, and Mn salts with a concentration of 0.5 to 3 mol / L, a NaOH solution with a concentration of 1 to 10 mol / L, and a complexing agent solution of 0.5 to 200 g / L Add it into the reaction vessel, control the appropriate temperature, pH value and stirring conditions, and then go through drying, classifi...

Embodiment 2

[0040] (1) Use battery-grade cobalt tetroxide (D50 is 11 μm), battery-grade lithium hydroxide, and zirconia as raw materials, the molar ratio of Li:Co is 0.95, and the addition of zirconium is 0.01 wt%, and they are placed in a dry mixer and mixed evenly .

[0041] (2) Sinter the materials in step (1). The temperature in the main temperature zone of sintering is 500°C, and the sintering time is 40h. The whole sintering process is carried out in an air atmosphere, and the ventilation rate in the main temperature zone is controlled at 2m 3 / h, the sintered lithium cobalt oxide is crushed, crushed, classified, sieved and other processes to obtain a semi-finished product of lithium cobalt oxide.

[0042] (3) Coat the semi-finished lithium cobalt oxide synthesized in step (2), and the coating material is LiNi 0.5 mn 0.2 co 0.3 o 2 (D50 is 5 μm), and its coating amount is 0.01 wt%. The coating method adopts dry coating. This equipment has high impact force and high shear force...

Embodiment 3

[0047] (1) Using battery-grade cobalt oxyhydroxide (D50 is 25 μm), battery-grade lithium hydroxide, titanium oxide, and zirconium oxide as raw materials, the molar ratio of Li:Co is 1.2, the addition of titanium is 5 wt%, and the addition of zirconium The amount is 5 wt%, placed in a dry mixer and mixed evenly.

[0048] (2) Sinter the materials in step (1). The temperature of the main temperature zone for sintering is 1350°C, and the sintering time is 5 hours. The whole sintering process is carried out in an air atmosphere, and the ventilation rate of the main temperature zone is controlled at 30m 3 / h, the sintered lithium cobalt oxide is crushed, crushed, classified, sieved and other processes to obtain a semi-finished product of lithium cobalt oxide.

[0049] (3) Coat the semi-finished lithium cobalt oxide synthesized in step (2), and the coating material is LiNi 0.7 mn 0.15 co 0.15 o 2 (D50 is 5 μm), and its coating amount is 20 wt%. The coating method adopts wet coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com