Cyclic baking method of enamelled wire and oven for realizing method

A baking method and enameled wire technology, applied in the direction of conductor/cable insulation, sustainable manufacturing/processing, electrical components, etc., can solve the difficulty of controlling and adjusting wind speed and wind pressure, the limitation of oven volume and product specifications, and reduce the surface of products The uniformity of film formation and other issues can be improved to achieve the effect of improving enamelling production efficiency, good product surface quality and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

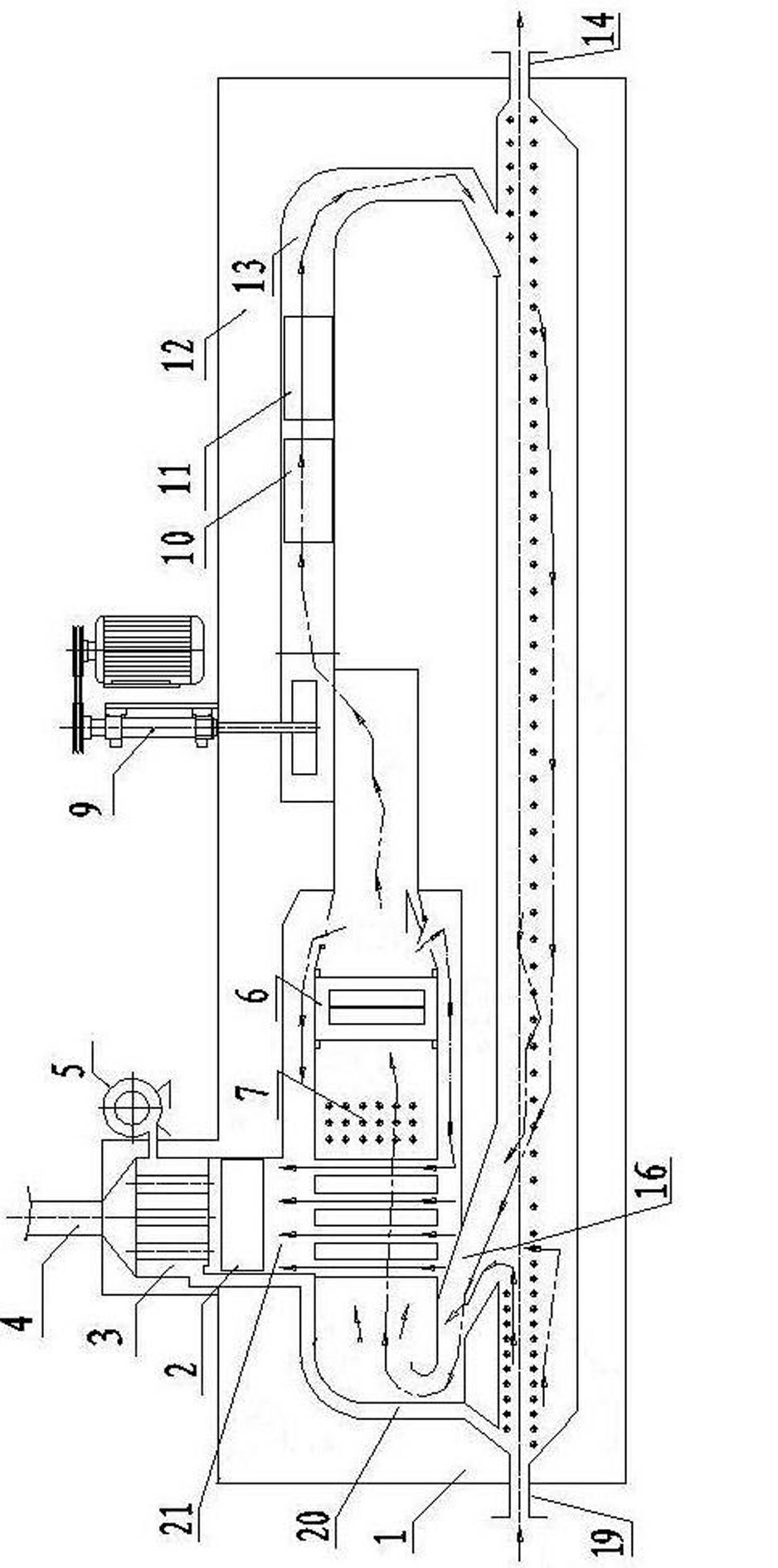

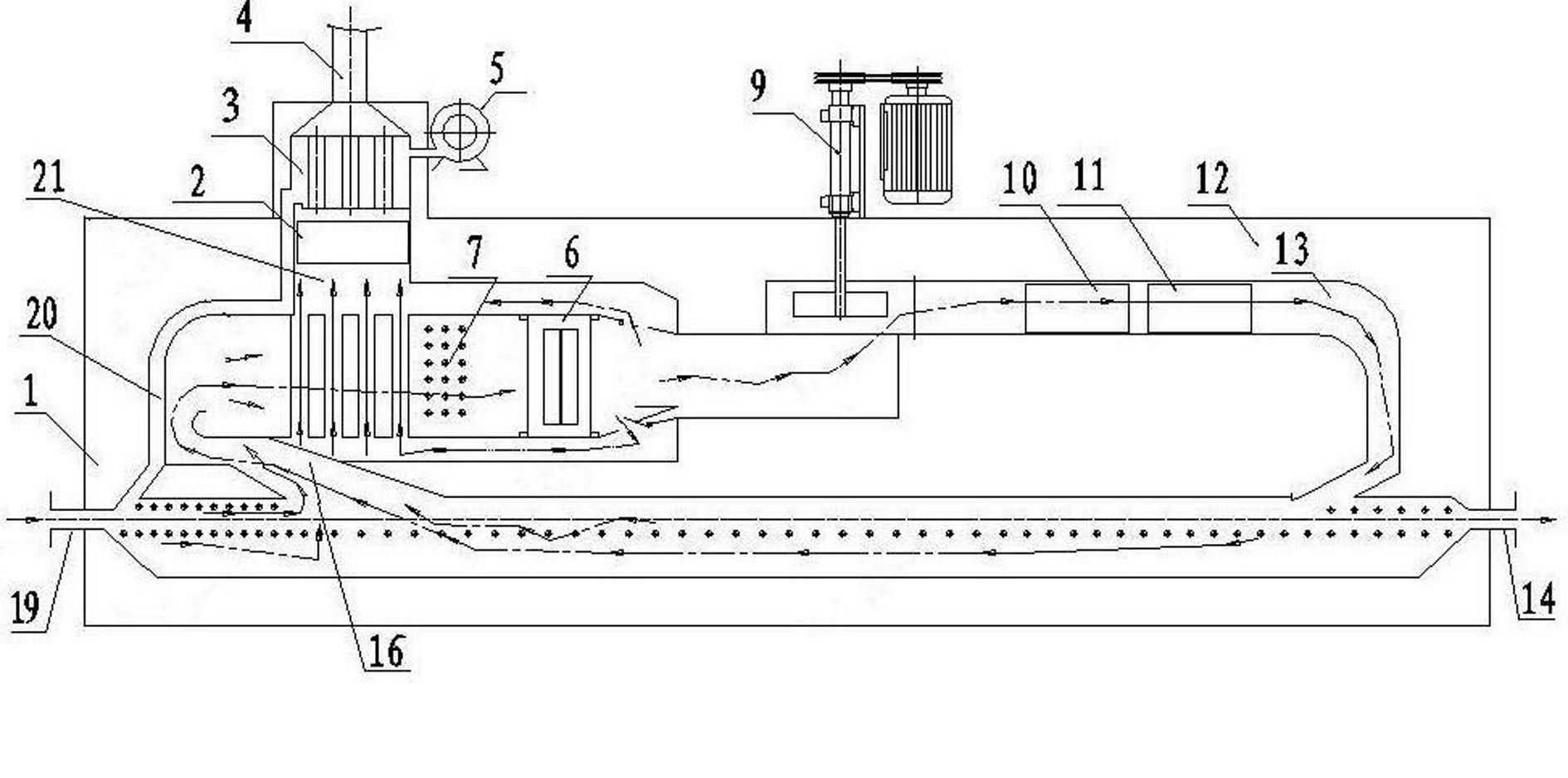

[0030] Such as figure 1 A circulating heating type enamelling machine oven as shown includes a hearth 1, the two sides of the hearth 1 are provided with an inlet 19 and an outlet 14, and a baking channel 15 is formed between the inlet 19 and the outlet 14;

[0031] The furnace 1 is provided with a primary catalytic combustion chamber 6, the entrance of the primary catalytic combustion chamber 6 communicates with the baking channel 15 through the solvent vapor channel 16, and the outlet of the primary catalytic combustion chamber 6 communicates with the baking channel 15 through the hot air flow channel 13 connected. The baking passage 15, the solvent vapor passage 16, the primary catalytic combustion chamber 6 and the hot air flow passage 13 form a circulation baking passage.

[0032] An air equalizer 10 and a voltage stabilizing device 11 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com