Gas integral heat treating method and device for large-scale pressure container

An integral heat treatment and pressure vessel technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of low heat treatment quality, limited application and improvement, unfavorable uniform heat distribution in the vessel, etc., to improve heat treatment construction efficiency, The effect of stratified combustion uniform heating and improving thermal circulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

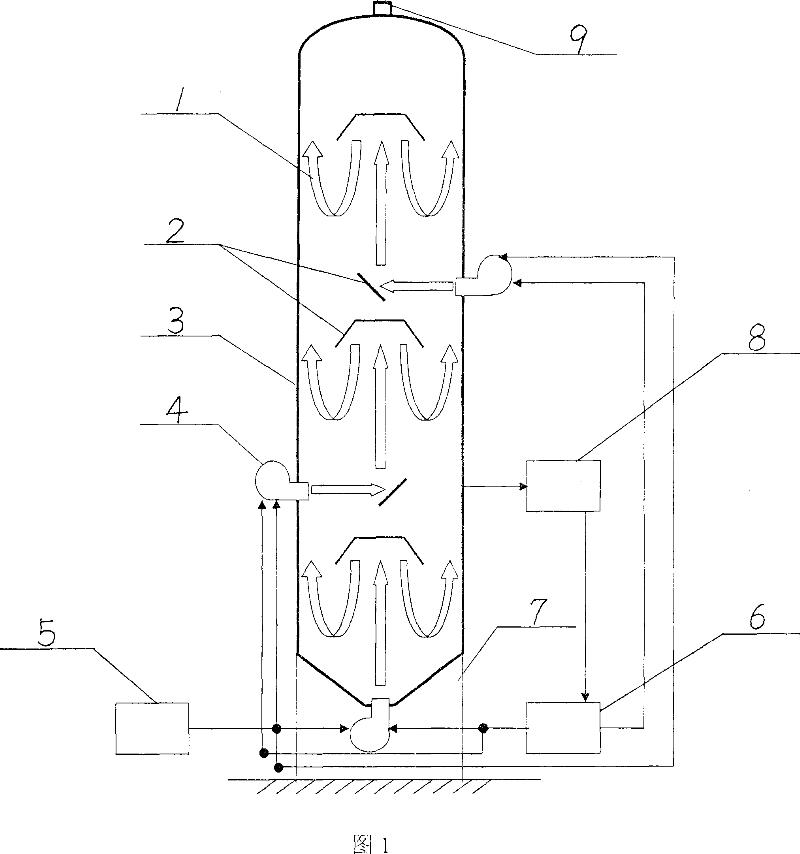

[0029] With reference to Fig. 1, the integral gas heat treatment method of the present invention comprises the following steps:

[0030] (1) At first the pressure vessel 3 is used as a sealed furnace, which is located on the skirt 7;

[0031] (2) Insulate the outside of the pressure vessel 3 using an insulating material;

[0032] (3) A plurality of gas burners 4 are respectively connected and sealed with the manholes or connecting pipes on the bottom and side walls of the pressure vessel 3, so as to supply heat in layers to the pressure vessel and provide sufficient heat sources;

[0033] (4) Installing a diversion device 2 inside the pressure vessel 3 to divert the gas hot air flow 1 to improve the internal thermal cycle effect of the pressure vessel;

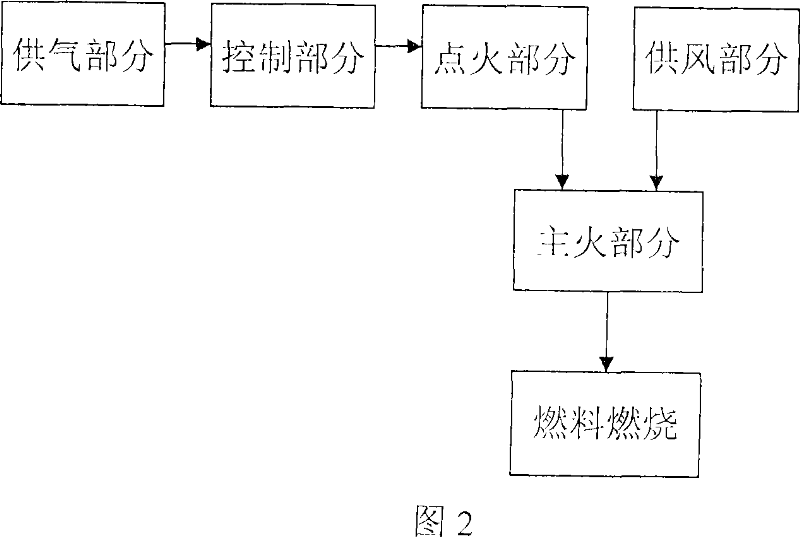

[0034] (5) The automatic control device 6 is connected with the gas burner 4 to automatically control the gas burner. The gas burner 4 ignites and heats the gas provided by the gas supply device 5. The gas can be liquefied ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com