Piston with (ti,al)n multi-layer heat-insulating and wear-resistant ultra-thick coating on the surface, its preparation method and application

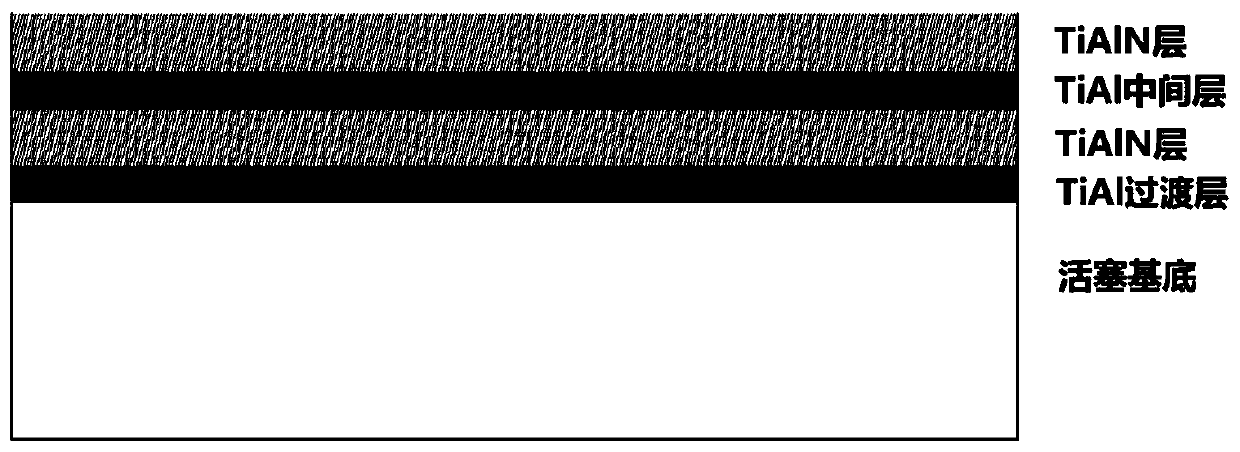

A multi-layer heat insulation and piston technology, which is applied in the direction of coating, piston, metal material coating process, etc., can solve the problems of easy ablation and damage of pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

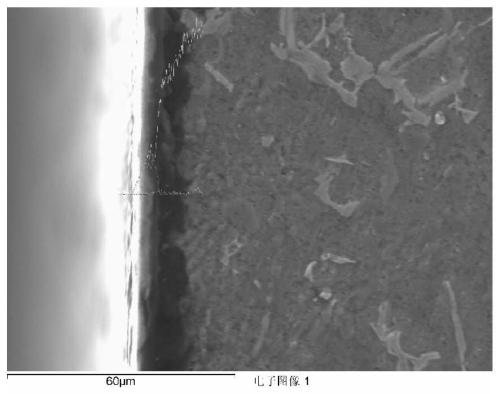

Examples

Embodiment 1

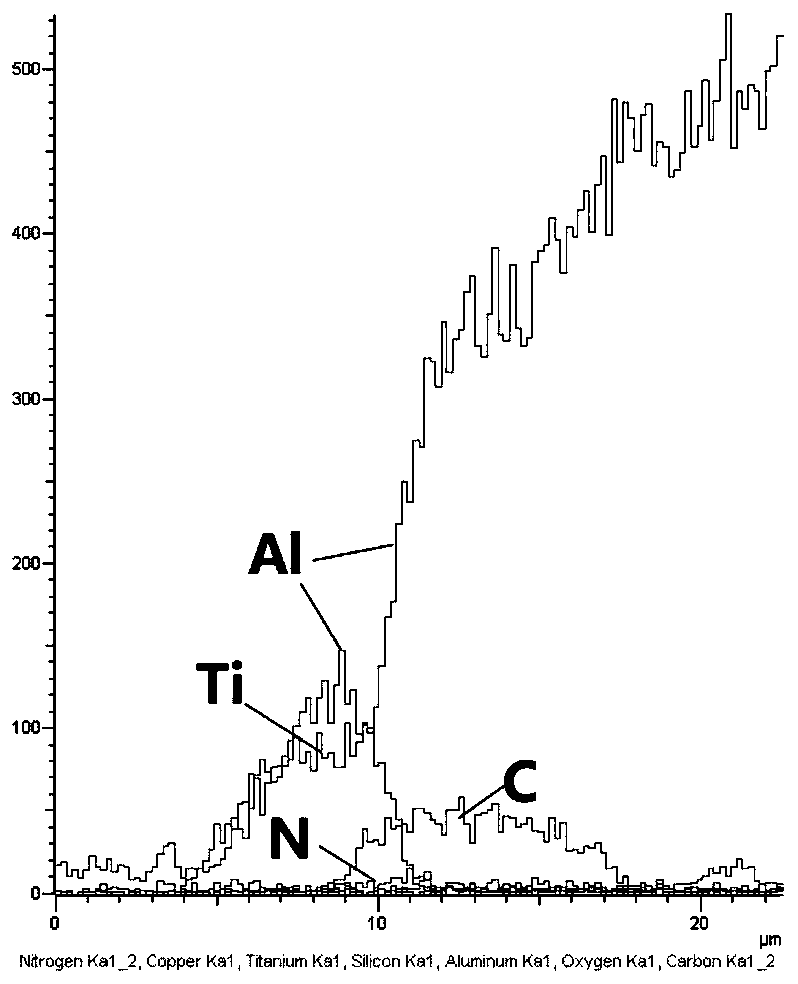

[0071] The number of processed samples is 5; in the processing of each sample, except for the different flow rate of nitrogen gas in step two, the others are completely the same.

[0072] step one:

[0073] Using titanium alloy as the arc source, preferably titanium aluminum alloy with a purity greater than or equal to 99%, adopts the magnetic filter cathode vacuum arc deposition technology. Before the magnetic filter cathode vacuum arc deposition, control the vacuum chamber in the magnetic filter cathode vacuum arc deposition equipment The pressure is 1.0~4.5×10 -3 Pa; when the magnetic filter cathode vacuum arc is deposited, control the arc starting current to 100A, the curved tube magnetic field to 1.5A, the straight tube magnetic field to 3.5A, and adjust the duty cycle to 90%; the order is -1000V, -900V, -800V, Deposit at -700V, -600V, -500V, -400V, -300V, -200V, deposit at each negative pressure point for 30s, after the deposition at -200V is completed, deposit at negat...

Embodiment 2

[0081] Step 1: Using titanium alloy as the arc source, preferably titanium-aluminum alloy with a purity greater than or equal to 99% as the arc source, using magnetic filter cathode vacuum arc deposition technology, before magnetic filter cathode vacuum arc deposition, control the magnetic filter cathode vacuum arc deposition equipment The pressure of the medium vacuum chamber is 1.0~4.5×10 -3 Pa; when the magnetic filter cathode vacuum arc is deposited, control the arc starting current to 100A, the curved tube magnetic field to 1.5A, the straight tube magnetic field to 3.5A, and adjust the duty cycle to 90%; the order is -1000V, -900V, -800V, Deposit at -700V, -600V, -500V, -400V, -300V, -200V, deposit at each negative pressure point for 30s, after the deposition at -200V is completed, deposit at negative pressure -100V for 20min; in a clean and dry piston A dense TiAl transition layer is obtained on the surface of the substrate;

[0082] Step 2: Turn on the reaction gas swi...

Embodiment 3

[0092] Step 1: Using titanium-aluminum alloy with a purity greater than or equal to 99% as the arc source, using the magnetic filter cathode vacuum arc deposition technology, before the magnetic filter cathode vacuum arc deposition, control the pressure of the vacuum chamber in the magnetic filter cathode vacuum arc deposition equipment to 1.0~ 4.5×10 -3 Pa; when the magnetic filter cathode vacuum arc is deposited, control the arc starting current to 100A, the curved tube magnetic field to 1.5A, the straight tube magnetic field to 3.5A, and adjust the duty cycle to 90%; the order is -1000V, -900V, -800V, Deposit at -700V, -600V, -500V, -400V, -300V, -200V, deposit at each negative pressure point for 30s, after the deposition at -200V is completed, at negative pressure -100V, deposit for 15min; on a clean and dry piston A dense TiAl transition layer is obtained on the surface of the substrate;

[0093] Step 2: Turn on the reaction gas switch, use titanium alloy as the arc sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com