Adapter for vacuum pumps and associated pumping device

The technology of a pumping device and an adapter is applied to the components of the pumping device for elastic fluid, the pump device, the pump, etc., which can solve the problems of difficulty in adjusting multiple control valves at the same time, increasing the unevenness of the pumping speed, etc. Achieve the effect of reducing dead zone, improving pumping uniformity and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

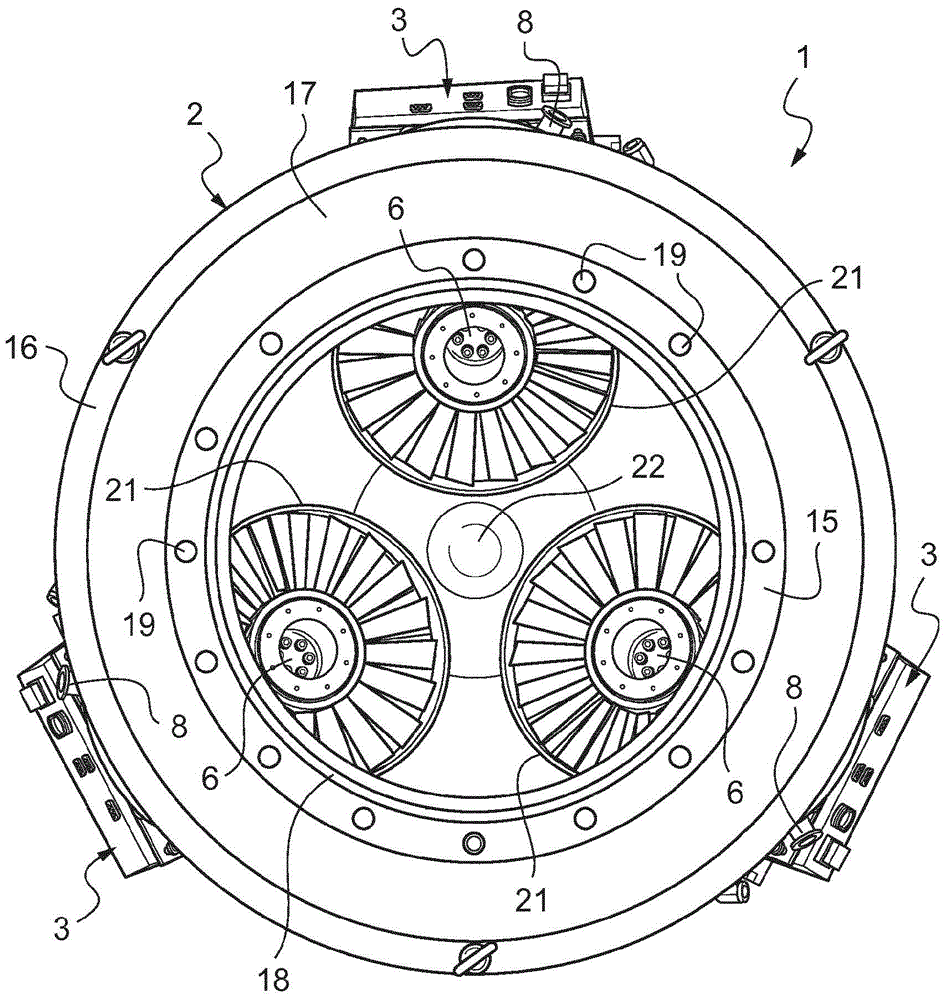

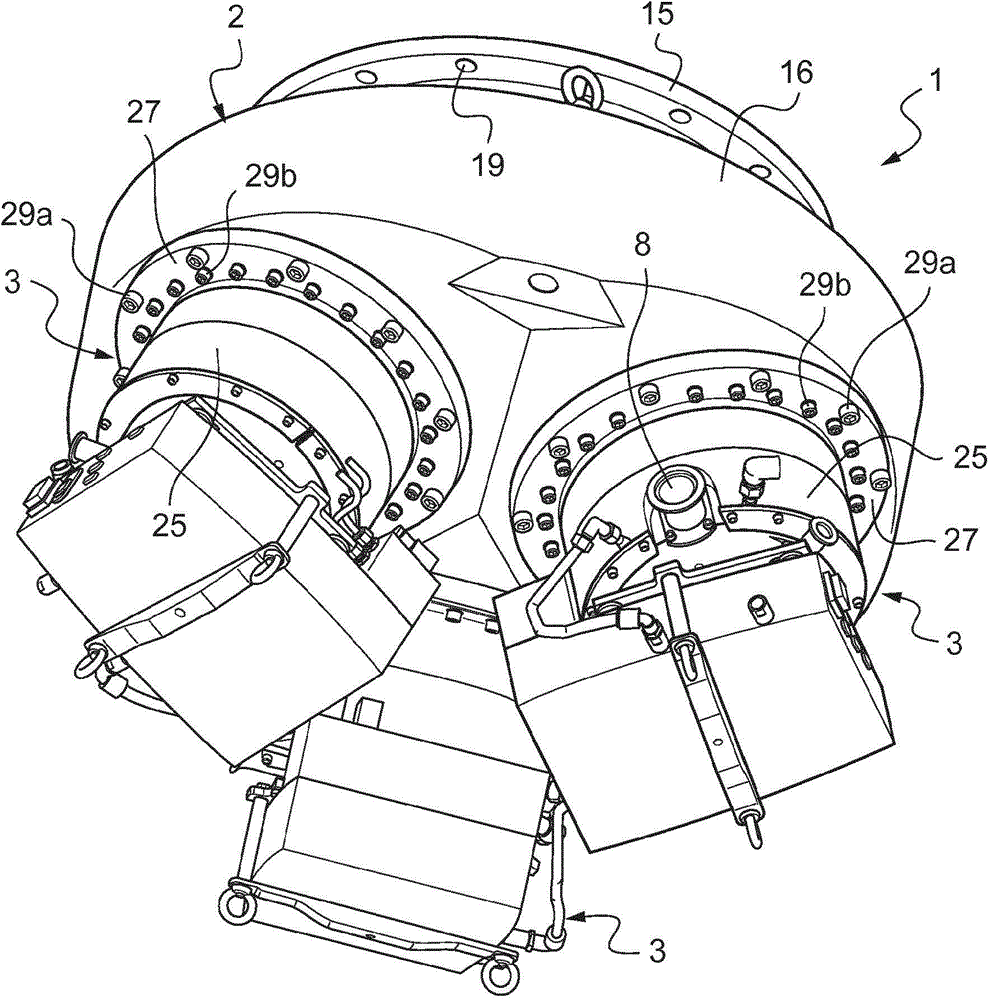

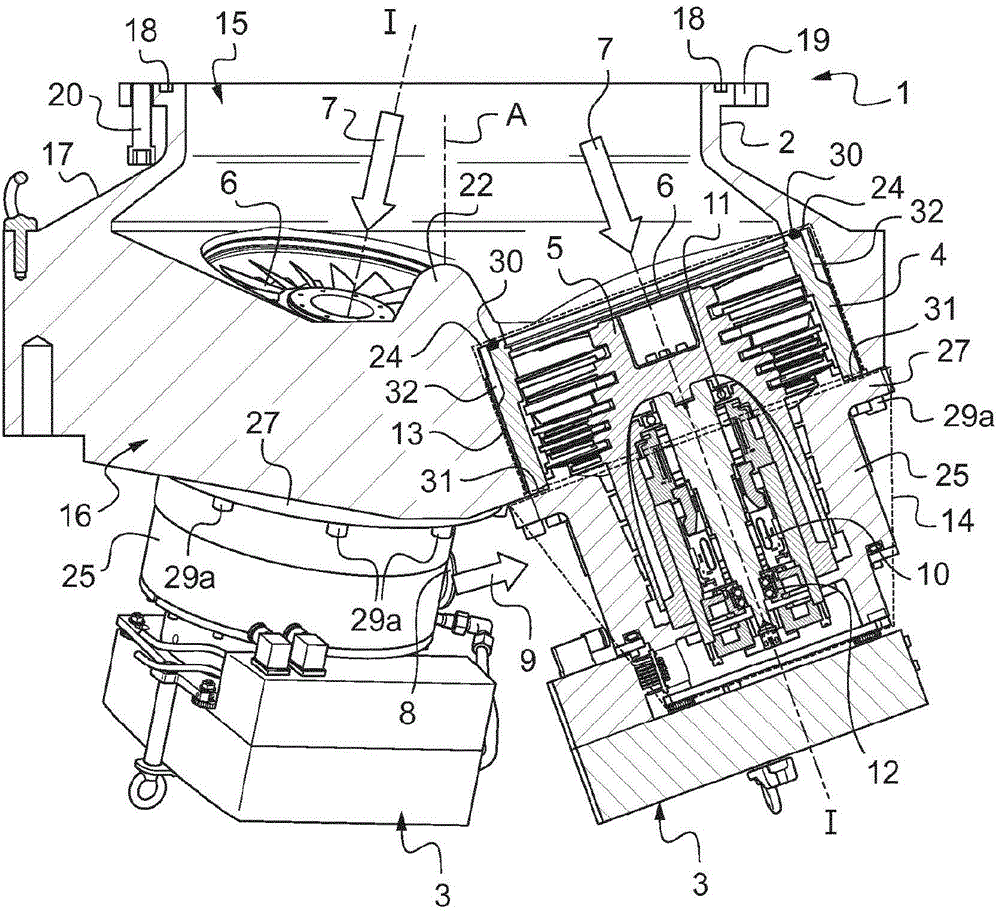

[0049] Figure 1-4 A first embodiment of the pumping device 1 is shown.

[0050] The pumping device 1 comprises an adapter for a vacuum pump 2 and at least two turbomolecular vacuum pumps 3 , the number of turbomolecular vacuum pumps 3 being three in the example shown.

[0051] The turbomolecular vacuum pumps 3 are identical and each comprise, in a manner known per se, a stationary part in which the rotor 5 moves at a relatively high speed along the axis of rotation I (see image 3 sectional view) for axial rotation.

[0052] In the illustrated example, the turbomolecular vacuum pump 3 comprises a turbomolecular stage 13 and a molecular stage 14 , respectively.

[0053] At the turbomolecular stage 13 the stationary part comprises a housing 4 comprising at a first end an inlet hole 6 coaxial with the axis of rotation through which the pumped gas 7 passes.

[0054] According to an exemplary embodiment, the rotor 5 comprises an upstream part (in the direction of the gas flow) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com