Visual broken line detection system for warp knitting machine

A technology of broken wire detection and warp knitting machine, which is applied in the field of warp knitting machine detection, can solve the problems of reduced work efficiency, potential safety hazards, and inability to detect, etc., to overcome the limitations of type and thickness, strong adaptability of machine vision, and reduce The effect of false positive rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

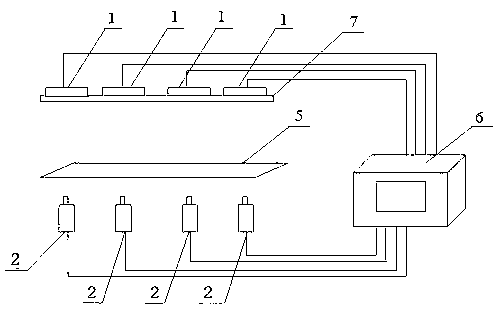

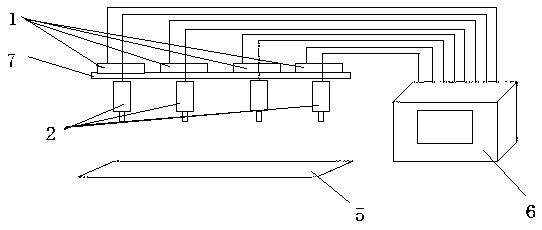

[0015] Such as figure 1 The shown warp knitting machine visual disconnection detection system includes a light source, an image acquisition module and a control module. The image acquisition module has multiple image acquisition devices. The image on the surface is transmitted to the control module, and the control module controls the warp knitting machine according to the image information collected above. The light source can also be erected by light transmission: the light source and the image collector are respectively arranged on both sides of the cloth, and the clear digital image is formed by the light transmission to detect the broken yarn. The control modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com