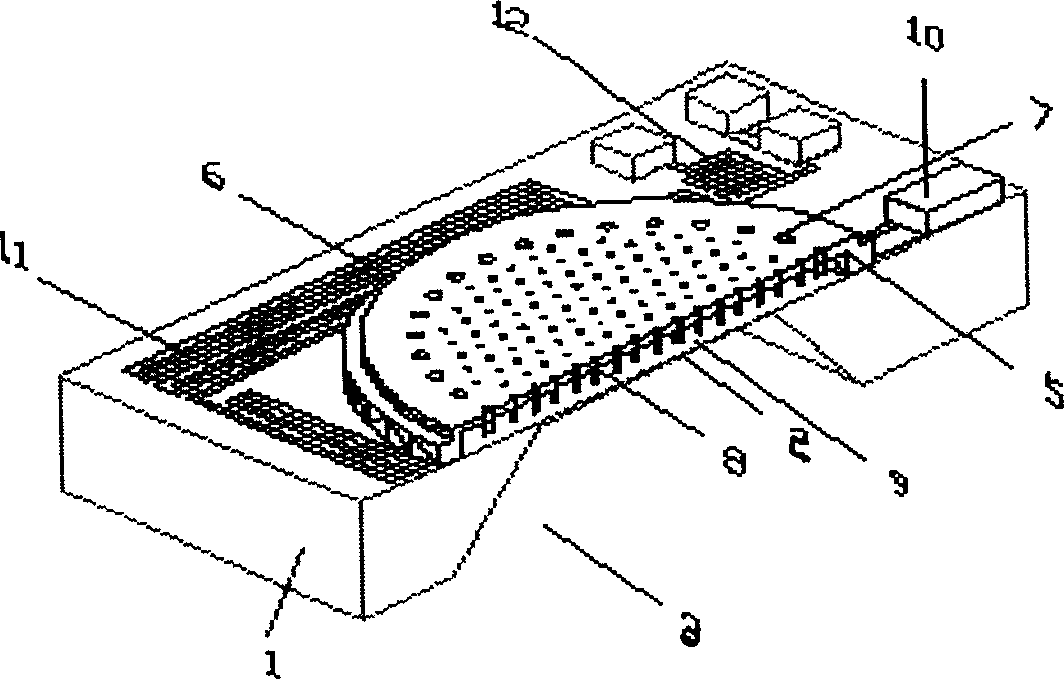

One-chip silicon-base miniature capacitor microphone and manufacturing method thereof

A micro-capacitor and microphone technology, applied in the field of electro-acoustics, can solve the problems such as the adhesion of the diaphragm and the back plate, the high production cost, the decline in the yield, etc., and achieve the effect of reducing the production accuracy of the process and the requirements of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention are given below.

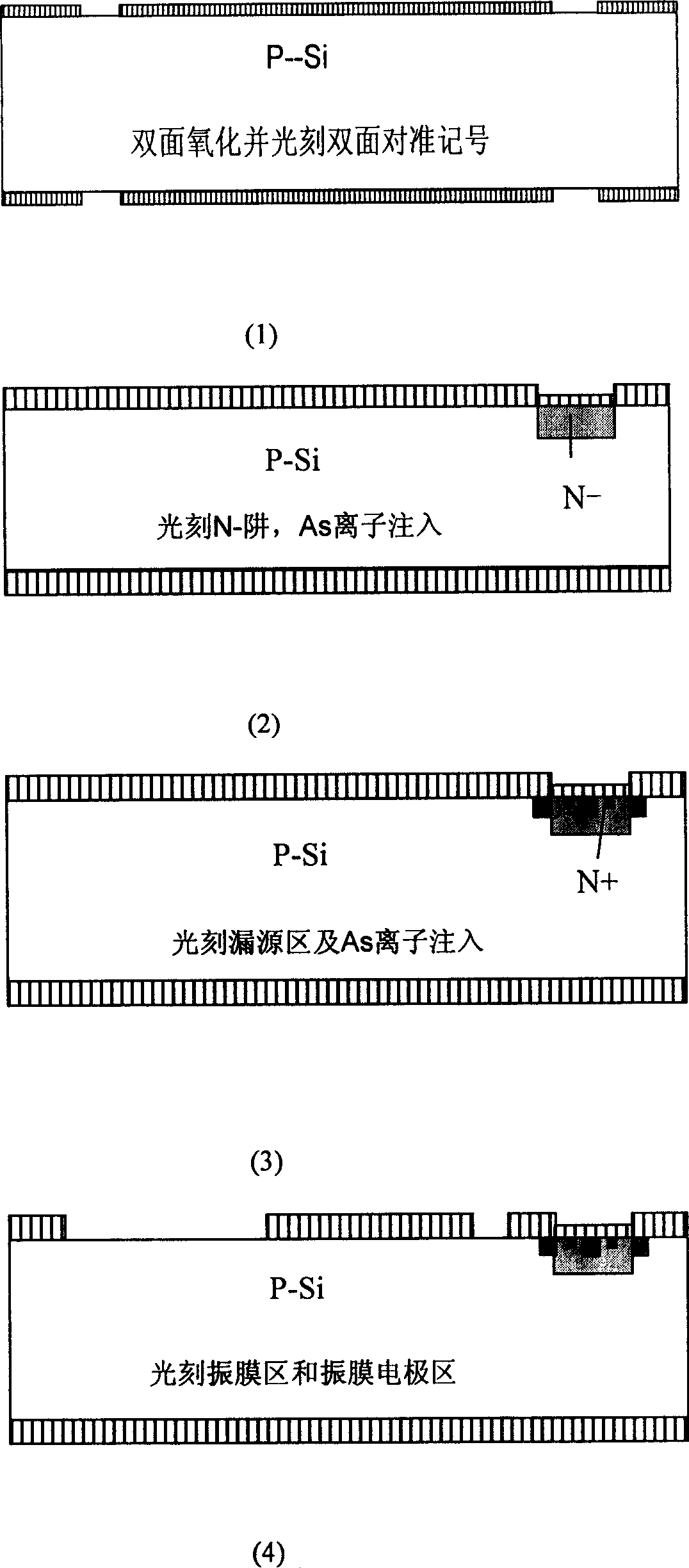

[0040] 1. Double-sided thermally grown SiO 2

[0041] 2. Double-sided photolithography to form alignment marks on the front and back sides, see image 3 (1)

[0042] 3. Double-sided thermally grown SiO 2

[0043] 4. Photolithographic JFET N - well and resistive regions of N - trap, see image 3 (2)

[0044] 5. As ion implantation, high temperature chemical treatment, push the surface implanted As ions to the designed well depth

[0045] 6. Photolithography of the gate region and boron diffusion resistance region of the JFET field effect transistor

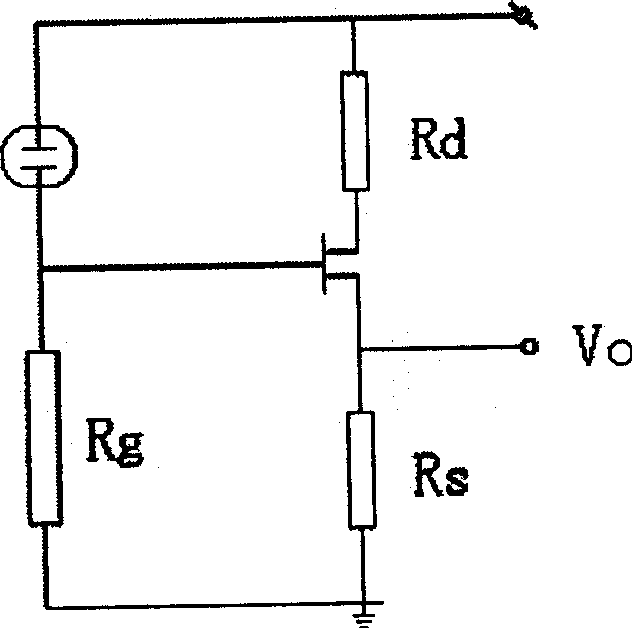

[0046] 7. Boron diffusion, forming the gate area of the JFET field effect transistor and the boron diffusion resistance R D and R S

[0047] 8. Photolithography of the drain-source region of the JFET field effect transistor

[0048] 9. As ion implantation, high temperature chemical treatment, forming N of the drain and source + contact hole, see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com